2

99289GB - GOOUT - REV. 00

IMPORTANT WARNING

The security characteristics of this product are essential for guaranteeing the safety of individuals and for conformity to EN 179 and EN

1125. DO NOT modify this product in any way, except as described in these instructions.

The anti-panic device has been certied for use on single leaf doors no larger than 2520 x 1320 mm (H x W) with weight over 200 kg.

As required by the standard, it is recommended that the owner of the business and/or their authorized representative perform the fol-

lowing routine maintenance checks at intervals of no more than one month:

- inspect and activate the anti-panic device to verify that all components are in a satisfactory working condition;

- verify that the holes on the striker plate are not obstructed;

- verify that no locks or other locking devices have been added on the door in addition to the initial device;

- verify the rules governing the installation and maintenance established by the Ministerial Decree of 11/03/2004;

- with a dynamometer, periodically check the working force needed to open the exit device. Make sure the working force has not changed

signicantly from the force measured at the time of installation.

The lock operating device should be lubricated, using Mottura lubricant (for locks), once a year or whenever a stiening of the mechanisms

is detected. Do not use oil or other lubricants: the use of such substances promotes the deposit of dust and fragments that may aect the

correct operation of the lock.

Warning

Mottura Serrature di Sicurezza S.p.A., thanks you for your condence in choosing this product and recommends:

· to read the instructions carefully before proceeding with the installation;

· to hand over all the instructions to the user by the installer;

· to keep the instructions for future reference and attach the receipt to validate the warranty;

· to contact the dealer only if a problem occurs.

The characteristics of the products described in these instructions may be subject to change by Mottura Serrature di Sicurezza S.p.A. at any time

without prior notice.

WARRANTY conditions

This product tested by Mottura Serrature di Sicurezza S.p.A. is guaranteed against all manufacturing defects for the duration of the period stipu-

lated by applicable Italian legislation from the date of purchase demonstrated in a scal receipt.

Guarantee claims may only be accepted upon presentation of the scal sales receipt, containing the details identifying the product, to technical

support personnel. The guarantee covers the replacement or repair of parts found to have manufacturing defects. The guarantee does not cover

transport costs to and from the technical support centre, which remain at the sole expense of the customer. In the event of a recurring fault of

the same cause, or of an unrepairable fault, Mottura Serrature di Sicurezza S.p.A., at its sole discretion, may decide to replace the entire product.

The guarantee will continue to cover the replacement product until the expiry of the original contract.

If a home call-out should be necessary, the customer is required to pay - if asked to- a call-out fee for the travel expenses of the authorized

service personnel. The customer is solely responsible for any transport damage in the event of direct shipment, or the sole responsibility of the

authorised technician where the product is collected and transported by the technician.

Limited responsibility

Not covered under warranty are damages resulting from the improper installation not in accordance with the instructions attached to the pro-

duct, negligence, carelessness or inappropriate operation, maintenance by unauthorized personnel, transport without due care and attention

and in any case by circumstances that cannot result from manufacturing defects.

Mottura serrature di sicurezza S.p.A. declines any liability for possible damages caused to persons or property resulting from the failure to obser-

ve the indicated precautions for use.

GOOUT locks are certied by the ICIM Institute, based on reference standards, with regard to each complete component (speci-

cally: lock, switchlocks, bars). Any modication of the product assembly or installation not conforming to this instruction manual

will automatically void such certication. In these cases, the party that makes such modication/replacements will be responsible

for conformity to the reference standards.

General information

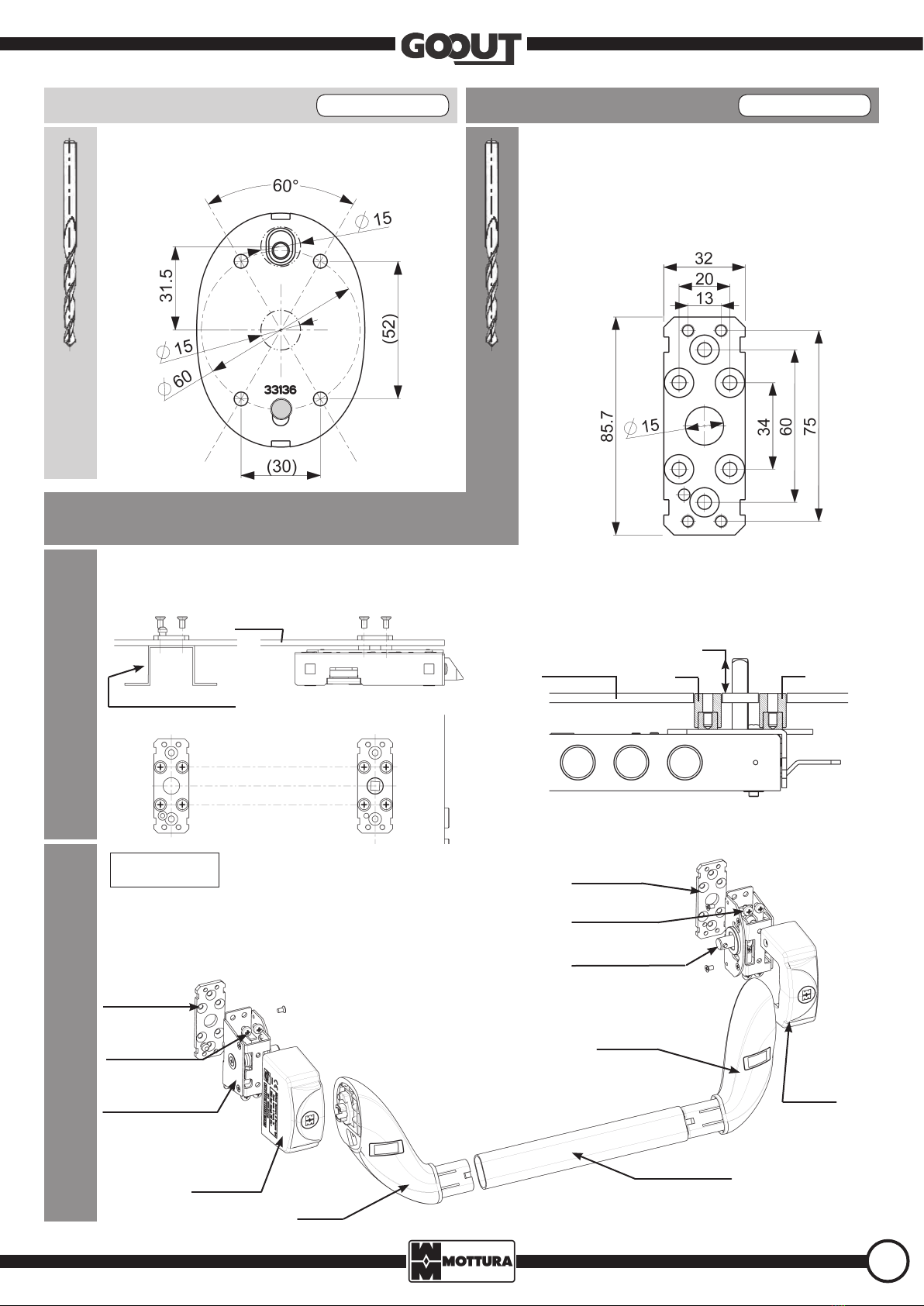

To ensure good operation of the lock and panic exit device, check that the door is in good condition (planarity, solidity, rigidity). The door and

frame must be built of suciently rigid material, such as welded steel or aluminum proles, to ensure that any distortion during use does not

exceed 5 mm at any position of the lock attachment points. Also check that the device and the door open and close without any obstruction.

If the panic exit device is to be installed on a glass door, the glass MUST be tempered and laminated. Panic exit devices are not intended to be

used on doors that open in both directions (entrance and exit) unless specically designed by the manufacturer.

If you have to use a door closer or a closing switch to return the door to closed position, be careful not to make the door dicult to use by

children, the elderly, and invalids.

Before assembling a panic exit device on a smoke/re door, check the re resistance certication for the door on which the exit device was tted

during tests to ensure it is suitable for use on the re door. It is extremely important NOT to use an exit device on a re door whose re resistance

time exceeds the time for which the device was approved.

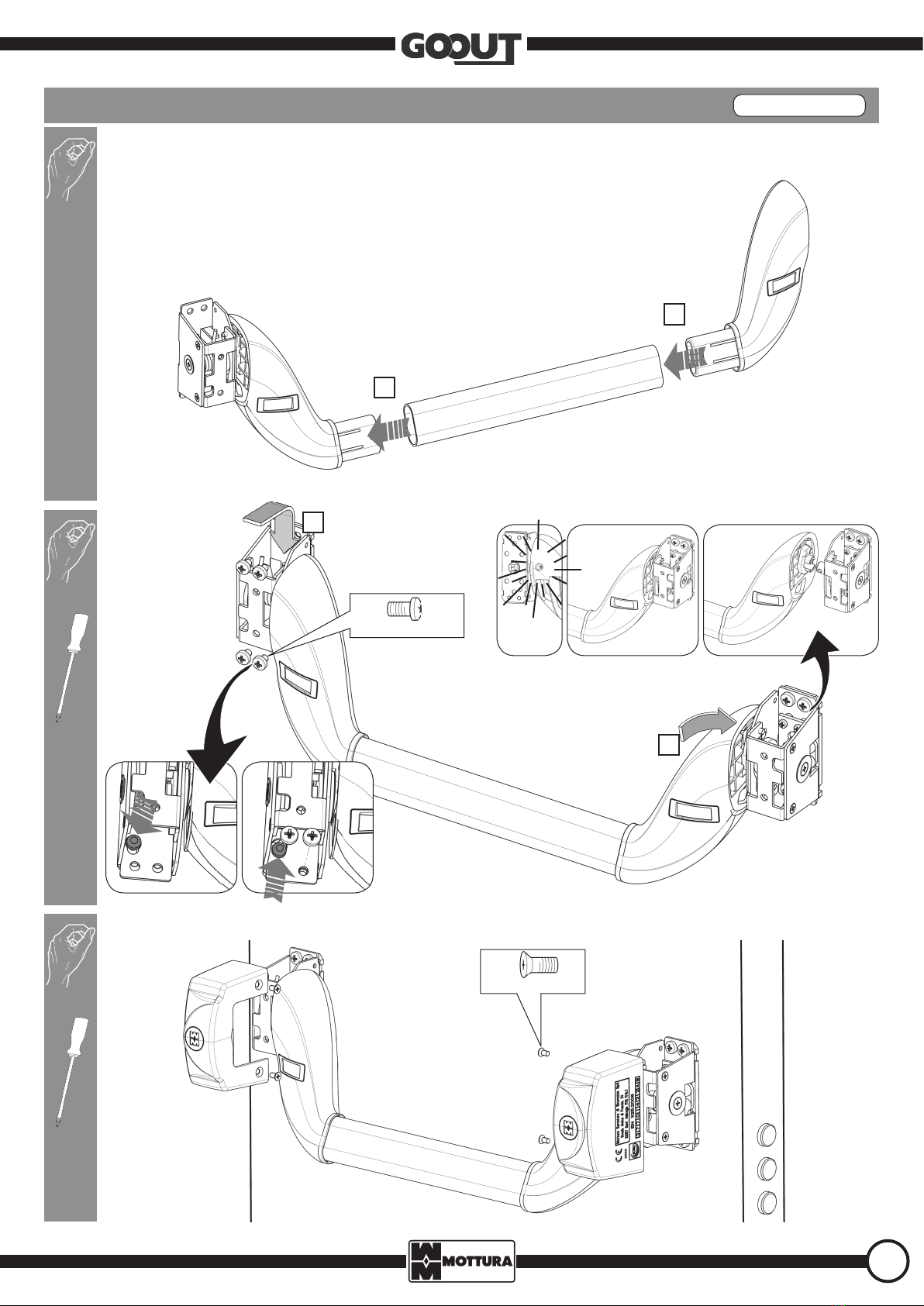

A sign stating“Push bar to open”or a pictogram (photo to the right) must be placed on the inside of the door imme-

diately above the horizontal bar or on the bar itself if the bar has a at surface area sucient for the required letter

size. The pictogram must have an area not smaller than 8,000 mm2, with white letters on a green background. The

pictogram must be positioned so that the arrow points to the exit device, when installed (EN 7546 – Italian Decree

Law 493 of 14/08/1996).