Mountain MTN5520 User manual

MTN5520 1 rev. 02/04/03

Model 1006A

6 TON

CAPACITY

RATCHETING

JACK STAND

Model 1006A

6 TON

CAPACITY

RATCHETING

JACK STAND

FOR YOUR SAFETY & TO PREVENT INJURY:

USE ONLY ON HARD LEVEL SURFACES.

DO NOT GET UNDER A VEHICLE THAT IS ONLY SUPPORTED BY A

TROLLEY/SERVICE JACK–USE VEHICLE SUPPORT STANDS.

THIS IS A LIFTING DEVICE ONLY. DO NOT MOVE OR DOLLY THE

VEHICLE WHILE ON THE JACK. IMMEDIATELY AFTER LIFTING,

SUPPORT THE VEHICLE WITH APPROPRIATE MEANS.

DO NOT OVERLOAD. OVERLOADING CAN CAUSE DAMAGE TO OR

FAILURE OF THE JACK.

LIFT ONLY ON AREAS OF THE VEHICLE AS SPECIFIED BY THE

VEHICLE MANUFACTURER.

CENTER LOAD ON SADDLE PRIOR TO LIFTING. OFF-CENTER LOADS

MAY CAUSE DAMAGE TO JACK, LOSS OF LOAD, PROPERTY

DAMAGE, PERSONAL OR FATAL INJURY.

NO ALTERATIONS TO THE JACK SHALL BE MADE.

READ, STUDY AND UNDERSTAND THE OPERATING MANUAL

PACKED WITH THIS JACK BEFORE OPERATING.

FAILURE TO HEED THESE WARNINGS MAY RESULT IN LOSS OF

LOAD, DAMAGE TO JACK, AND/OR FAILURE RESULTING IN

PROPERTY DAMAGE, PERSONAL OR FATAL INJURY.

THIS OPERATING MANUAL CONTAINS

IMPORTANT SAFETY INFORMATION.

READ CAREFULLY AND UNDERSTAND

ALL INFORMATION BEFORE

OPERATING TOOL. SAVE THIS

MANUAL FOR FUTURE USE.

Features:

• Chrome Plated Lift Ram

• Self-Retracting Ram Springs for Fast Ram Retraction

• Push Valve Lever for Fast Air Control

• 3 Position Lock Lever

• Safety Overload Valve

• Large Diameter Wheels for Ease of Operation

Owner/User Responsibility:

The owner and/or user must have a thorough understanding of the

manufacturer’s operating instructions and warnings before using

the service jack. Personnel involved in the use and operation of

equipment shall be careful, competent, trained, and qualified in the

safe operation of the equipment and its proper use when servicing

motor vehicles and their components. Warning information should

be emphasized and understood. If the operator is not fluent in

English, the manufacturer’s instructions and warnings shall be read

to and discussed with the operator in the operator’s native language

by the purchaser/owner, making sure that the operator

comprehends its contents.

Owner and/or user must study and maintain for future reference

the manufacturer’s instructions and pertinent warning information.

Owner and/or user is responsible for keeping all warning labels

and instruction manuals legible and intact. Replacement labels and

literature are available from the manufacturer.

MTN5520

22 Ton Air/Hydraulic Jack

ALWAYS

Support Vehicle with

Appropriately Rated

Support Stands!

Use Service Jack

for Lifting Purposes

ONLY!

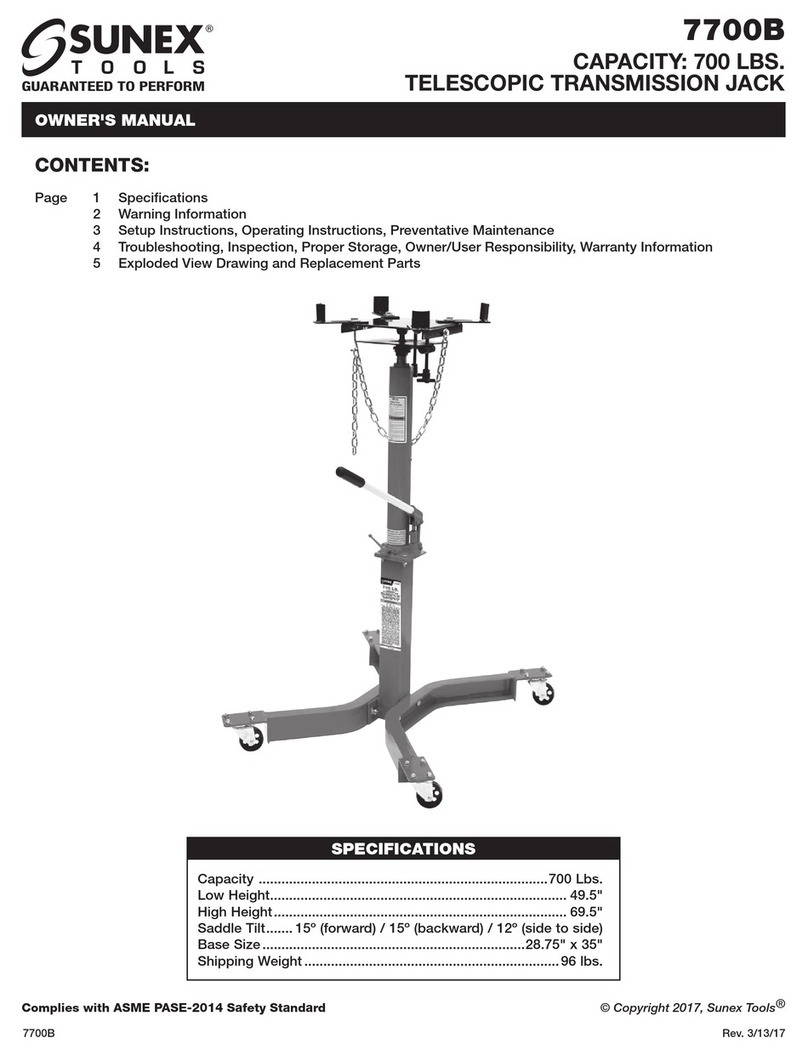

SPECIFICATIONS:

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . 22 Tons

Min. Saddle Height . . . . . . . . . . . . . . . . . . . . . . . 9"

Max. Saddle Height . . . . . . . . . . . . . . . . . . . . . .17"

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3/4"

Handle Length . . . . . . . . . . . . . . . . . . . . . . . . . 49"

Wheel Diameter . . . . . . . . . . . . . . . . . . . . . . . . . .8"

Dimensions . . . . . . . . . . . . . . .21"L x 13"W x 56"H

Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . . .90 psi

MTN5520 2 rev. 02/11/03

Assembly Instructions:

This jack comes pre-assembled, except for the handle. The handle is

a two piece handle. Align the thru hole of the upper and lower

piece, and insert (2) M6 allen bolts. Align through hole on the three

position lock lever and insert Phillip screw.

Inspection:

Visual inspection should be made before each use of the service

jack, checking for leaking hydraulic fluid and damaged, loose or

missing parts. Each jack must be inspected by a manufacturer’s

repair facility immediately, if accidentally subjected to an abnormal

load or shock. Any jack which appears to be damaged in any way,

found to be badly worn, or operates abnormally MUST BE

REMOVED FROM SERVICE until necessary repairs are made

by a manufacturer’s authorized repair facility. It is recommended

that an annual inspection of the jack be made by a manufacturer’s

authorized repair facility and that any defective parts, decals or

warning labels be replaced with manufacturer’s specified parts.

A list of authorized repair facilities is available from the

manufacturer.

Maintenance:

To Add Oil: With saddle fully lowered and ram depressed, set jack

in an upright position and remove oil filler plug. Fill until oil is level

with filler plug hole.

To Change Oil: For best performance and longest life, replace the

complete oil supply at least once a year. To drain the oil, remove the

filler plug. Lay the jack on its side and allow the oil to run out into

suitable drain pan. The oil will run slowly because air must enter as

oil drains out. Be careful to prevent dirt or foreign matter from

entering the system. Replace with proper oil.

IMPORTANT! Use only a good grade hydraulic fluid. Avoid

mixing types of oil. Do not use brake fluid, alcohol, glycerin,

transmission fluid, or dirty oil. Improper fluid can cause serious

internal damage to the jack, rendering it inoperative.

Operating Instructions:

IMPORTANT: Before attempting to raise a vehicle, check vehicle

service manual for recommended lifting surfaces.

1. To raise load: Close release valve tightly (by turning handle

clockwise).

DO NOT OVERTIGHTEN.

Position jack under load so

that saddle will contact load firmly and load is centered so it cannot

slip. Operate the air valve until saddle approaches the load. Once

again check to see that saddle is correctly positioned. Raise load to

desired height. Place jack stands of appropriate capacity under the

vehicle. DO NOT CRAWL UNDER VEHICLE WHILE LIFTING

VEHICLE OR PLACING OR REMOVING JACK STANDS!

Place jack stands at vehicle manufacturer’s recommended lift areas

that provide stable support for the raised vehicle.

2. To lower load: Open release valve VERY SLOWLY (by turning

handle counterclockwise). When release valve is opened, saddle

and load will be lowered. Lower the vehicle slowly so as not to shock

load the jack stands. Once repairs are completed, raise vehicle

enough to remove jack stands. Lower vehicle very slowly.

CAUTION: Keep hands or feet away from the hinge mechanism of

the jack.

MTN5520 3 rev. 02/04/03

Troubleshooting:

SOLUTION

The release valve is not closed.

✔Turn the valve clockwise tightly.

Low on hydraulic fluid.

✔✔ Refill the jack to the correct level of

hydraulic fluid.

Pump seals and back-up ring are defective.

✔Clean hydraulic fluid passages, replace seals

and renew hydraulic fluid.

(Must be serviced by qualified service center)

The hydraulic system is filled with air. Open

✔✔the release valve, pump handle rapidly (4)

full strokes to purge air, close release valve.

Return spring is broken or linkages binding.

✔Replace spring if broken. Grease pivot shaft,

oil all lift arm linkages.

Discharge ball is not sealing hydraulic system

and oil may be dirty. Manually flush

hydraulic system by raising and lowering lift

✔arm by hand. Open the release valve, as

required to raise and lower the lift arm.

Manually raise and lower lift arm.

PROBLEM

Jack will not lift load

Jack will not hold load

or handle rises

Jack will not lift to

its full height

Jack will not lower

completely

Jack will not lift smoothly

or jack feels spongy

MTN5520 4 rev. 02/11/03

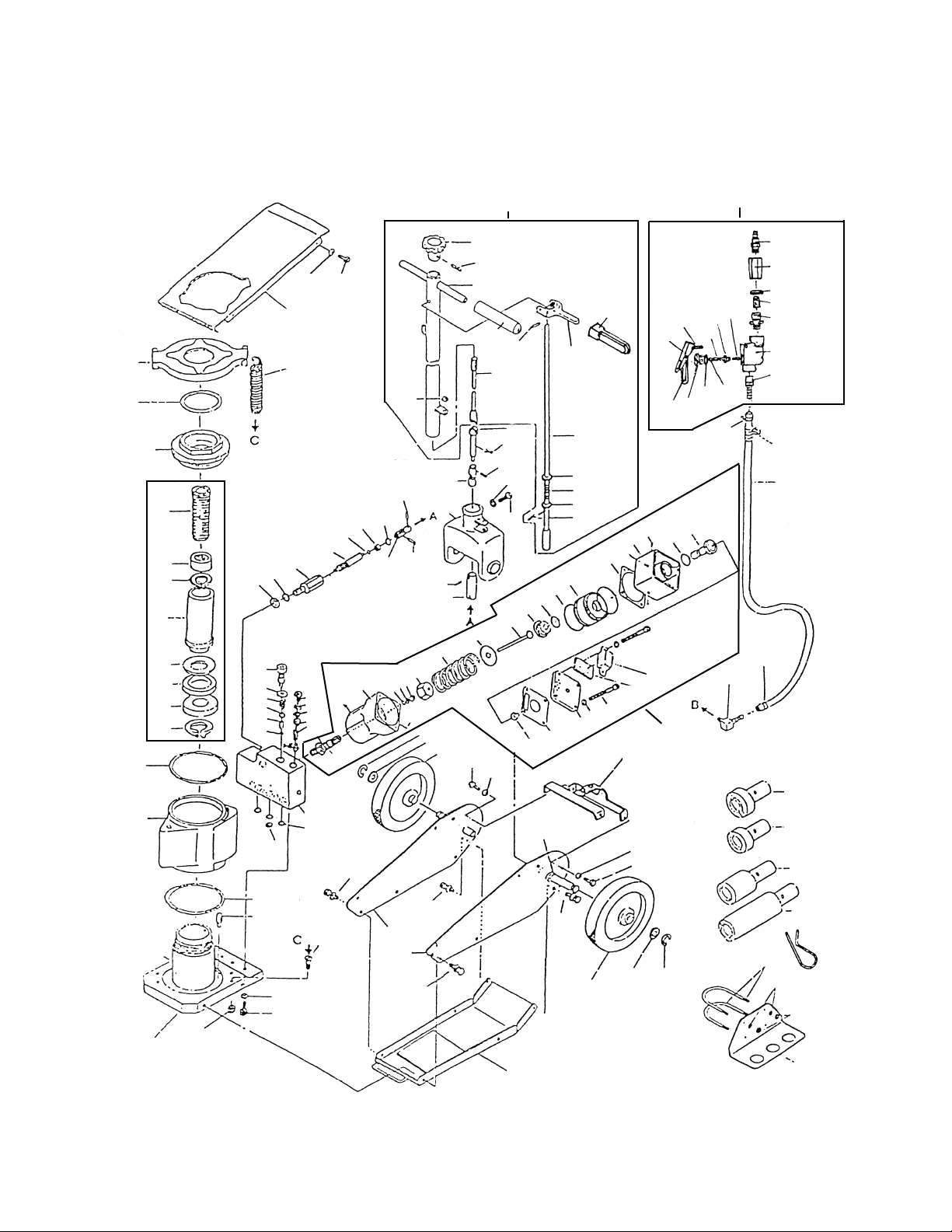

10-26

10-25

10-24

10-22

10-23

10-7

10-5

10-6

10-9

10-8

10-10

10-16

10-14

10-15

10-16

10-12

12-1

12-2

12-3

12-4

12-9

12-7

12-5

12-8

12-6

1-4

1-2

1-3

1-1

6-3

6-14

6-12

6-15

6-9

6-1

6-1

6-9

6-14

6-12

1-3

1-2 7-5 7-6

7-7 7-8

7-11

7-4

7-3

7-13

7-2

7-12

7-1

8-13

5-9

5-5

5-6

5-22

5-2

5-4

5-1

5-9

5-21

5-7

5-3

5-14

5-20

5-18

5-13

5-16

5-11

5-12

4.4 4.6

5-17

4-5

4-11

4-9

4-2

4-1

4-3

4-8

4-10

3-4

2-31

2-19

2-20 3-2

3-12

3-10

2-19

2-25

2-23

3-14

3-13

2-24

2-8

2-7

2-2

2-32

2-1

2-5

2-4

2-3

2-17

2-18

2-22 2-21

6-7

6-6

6-8

2-12

2-13

2-29

2-14

3-8

3-5

3-6

3-9

3-7

5-15

7-0

Air Pump Ass’y

4-0

Release Valve Ass’y

2-0

Piston

Rod

Ass’y

5-0

Handle Ass’y

10-30

Air Valve Ass’y

5-8

5-9

5-19

8-12

8-11

8-10

8-9

8-8

8-7

8-6

8-5

8-4

8-3

8-2

8-14 7-10

7-9

1-4

6-13

6-13

10-4

10-3

10-2

10-1

10-13

2-15

8-1

2-16

MTN5520 5 rev. 02/04/03

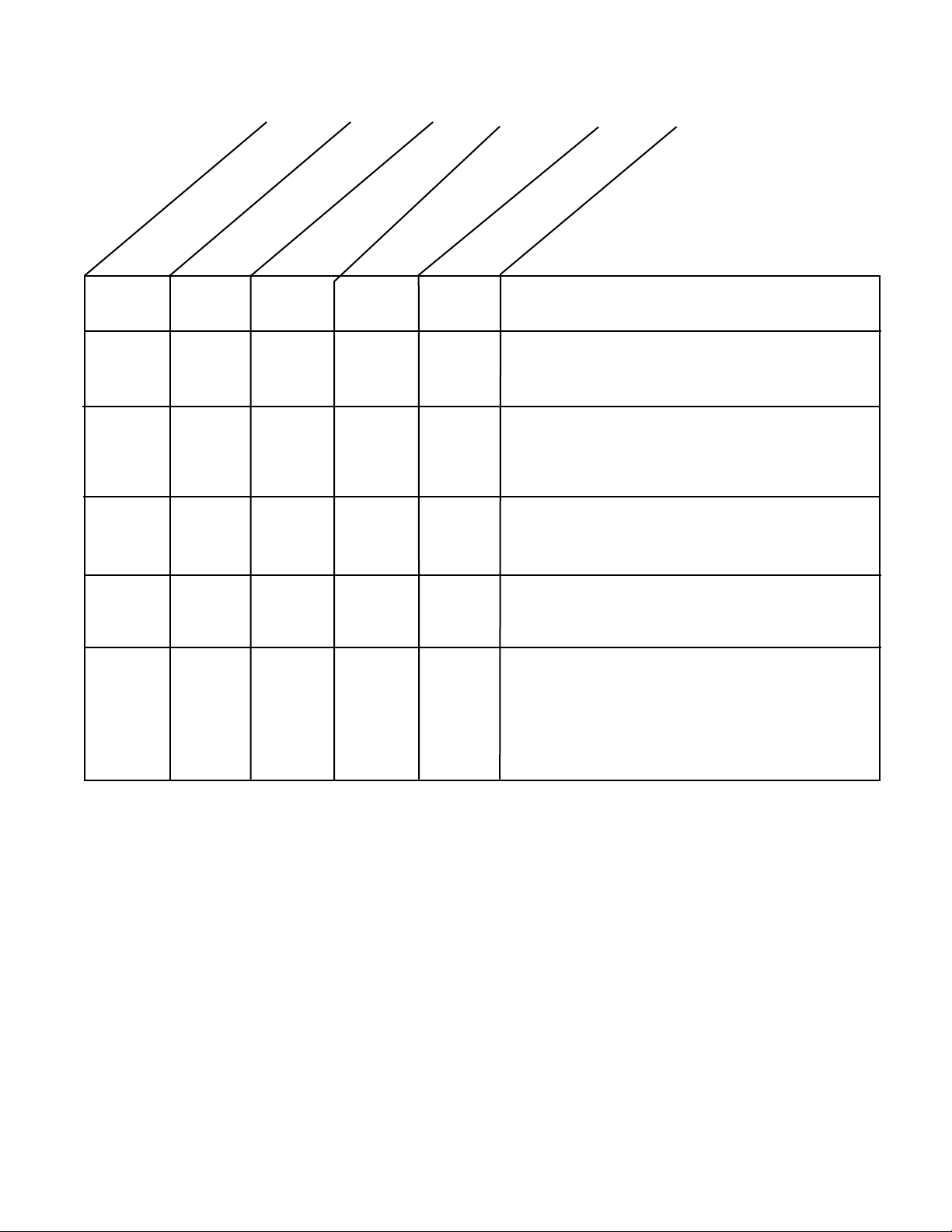

Item Part

No. No. Description Qty.

1-1 Wheel Shaft 2

1-2 RS66221-2 Washer 2

1-3 RS66221-3 Wheel 2

1-4 RS66221-4 Snap Ring 2

2-0 RS66222-0 Piston Rod Ass’y 1

2-1 Piston Rod 1

2-2 Packing 1

2-3 Screw 1

2-4 Bush 1

2-5 Snap Ring 1

2-7 Packing Retainer 1

2-8 RS66222-8 Cylinder 1

2-12 Bolt 2

2-13 Packing 2

2-14 Spring Retainer 1

2-15 Safety Valve 1

2-16 Spring 1

2-17 Nut 1

2-18 Oil Seal 1

2-19 O Ring 2

2-20 Oil Tank 1

2-21 RS66222-21 Spring 4

2-22 RS66222-22 Spring Hanger 1

2-23 Machine Screw 4

2-24 Nut 4

2-25 Oil Strainer 1

2-29 Packing 1

2-31 Snap Ring 1

2-32 Back-up Ring 1

3-2 Oil Box 1

3-4 Bolt 1

3-5 Spring 1

3-6 Steel Ball 1

3-7 Steel Ball 1

3-8 Copper Packing 1

3-9 Separator 1

3-10 Back-up Ring 1

3-12 O Ring 3

3-13 Bolt 3

3-14 Spring Washer 3

4-0 RS66224-0 Release Valve Ass’y 1

4-1 Valve 1

4-2 O Ring 1

4-3 Guide 1

4-4 Universal Joint 1

4-5 Spring Pin 1

4-6 Spring Pin 1

4-8 O Ring 1

4-9 Washer 1

4-10 Packing 1

4-11 Snap Ring 1

5-0 RS66225-0A Handle Ass’y - 2 piece 1

5-1 Handle 1

5-2 RS66225-2 Knob 1

5-3 Connecting Rod 1

5-4 Spring Pin 1

5-5 RS66225-5 Stopper (incl. 5-8, 5-9, 5-19) 1

5-6 Lock Lever 1

5-7 Spring Pin 1

5-8 Spring 1

5-9 Washer 3

5-11 RS66225-11 Handle Fork 1

5-12 Bolt 1

5-13 Spring Washer 1

5-14 Connecting Rod 1

5-15 Connecting Rod 1

5-16 Universal Joint 1

5-17 Spring Pin 1

5-18 Spring Pin 1

5-19 Spring Pin 1

5-20 Cotter Pin 1

Item Part

No. No. Description Qty.

5-21 Handle Cap 2

5-22 Handle Cap 1

6-1 Handle Fork Bracket 2

6-3 Frame 1

6-6 RS66226-6 Upper Cover 1

6-7 Machine Screw 4

6-8 Lock Washer 4

6-9 Bolt 4

6-12 Bolt 4

6-13 Bolt 4

6-14 Spring Washer 4

6-15 Lower Cover 1

7-0 RS66227-0 Air Pump Ass’y 1

7-1 Packing Washer 1

7-2 Muffler Cover 1

7-3 O Ring 23.6 x 3.55 1

7-4 Valve Rod 1

7-5 Rubber Pad 1

7-6 Packing Washer 1

7-7 Cover 1

7-8 Spring Washer 1

7-9 Hex Socket Screw M8 x 70 4

7-10 Filter Element 1

7-11 Filter Cover 1

7-12 ø2.5 Steel Ball 1

7-13 ø6 Steel Ball 2

8-1 RS66228-1 Plunger Cover 1

8-2 Air Pump Body 1

8-3 NL Retainer 1

8-4 O Ring 11.2 x 2.65 1

8-5 Packing Guide 1

8-6 Nut 1

8-7 Spring 1

8-8 Washer 1

8-9 Plunger 1

8-10 Retainer 1

8-11 O Ring 25 x 3.55 1

8-12 O Ring 56 x 5.30 2

8-13 Piston 1

8-14 ø3 Steel Ball 2

10-30 RS662210-30 Air Valve Ass’y 1

10-1 Valve Body 1

10-2 Nut 1

10-3 O Ring 1

10-4 O Ring 1

10-5 Packing 1

10-6 Throttle 1

10-7 Spring 1

10-8 Lever 1

10-9 Lever Pin 1

10-10 Lock Lever 1

10-12 Pump Elbow 1

10-13 Hose Connector 1

10-14 Spring 1

10-15 RS662210-15 Air Hose 1

10-16 Hose Band 2

10-22 Air Filter 1

10-23 Connector 1

10-24 O Ring 1

10-25 Connecting Nut 1

10-26 Connector 1

12-1 RS662212-1 Adaptor-A 70 x 20 1

12-2 RS662212-2 Adaptor-B 50 x 20 1

12-3 RS662212-3 Adaptor C 50 x 50 1

12-4 RS662212-4 Adaptor D 50 x 100 1

12-5 RS662212-5 Holder Adaptor 1

12-6 U-Bolt 2

12-7 Nut 4

12-8 Spring Washer 4

12-9 RS662212-9 Hitch Pin 4

Note: only items identified by part number are available

individually.

* Available only in the seal kit, part # RS6622-SK

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Table of contents

Other Mountain Jack manuals

Popular Jack manuals by other brands

Craftsman

Craftsman 48112 Operator's manual

Meec tools

Meec tools 012149 operating instructions

Meganex

Meganex MEG11 instruction manual

Blitz

Blitz XLift 2,6 user guide

Harbor Freight Tools

Harbor Freight Tools BADLAND 58395 Owner's manual & safety instructions

AME

AME 14400 Instruction manual & parts breakdown

OEM Tools

OEM Tools 24793 Operating instructions and parts manual

OEM Tools

OEM Tools 24856 Operating instructions and parts manual

Titan

Titan EZM-1500 Installation, operation & maintenance manual

Draper

Draper 53089 user manual

kincrome

kincrome K12150 Owner's assembly and operating manual

Performance Tool

Performance Tool W1627 owner's manual