Refrigerating Specialties Division 4

Principles of Operation A2BO, A2BOE

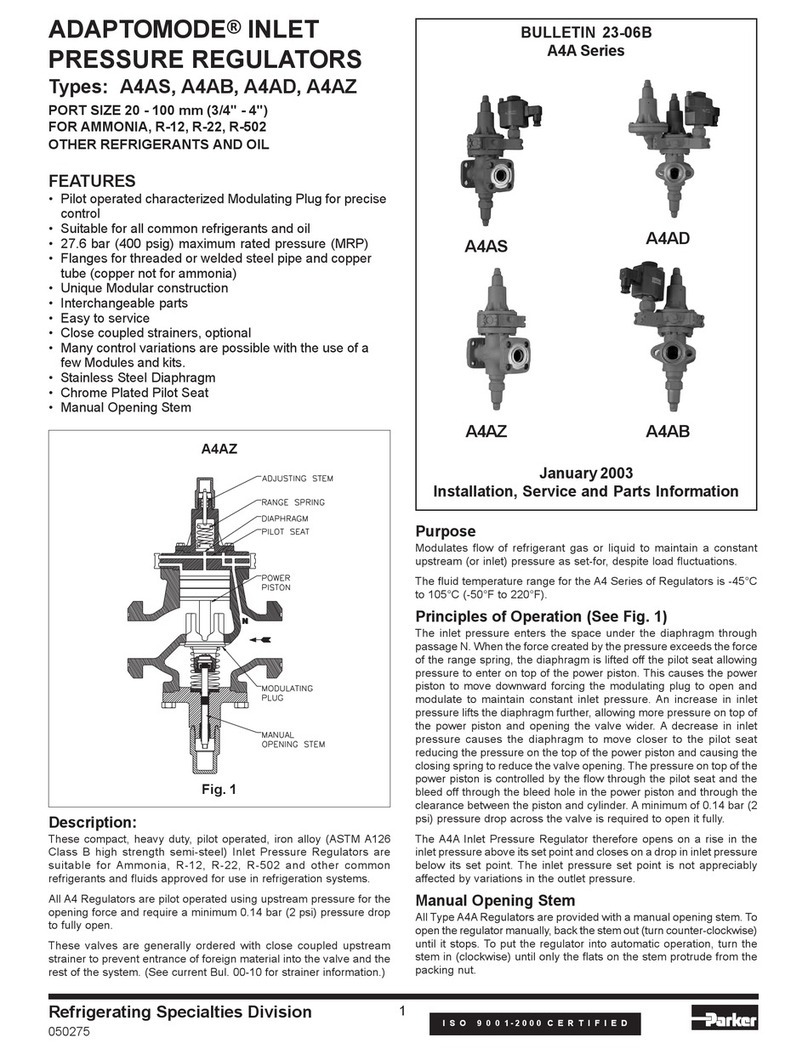

In the A2BO the outlet pressure is sensed under the diaphragm. As the

outlet pressure decreases below the set point, the range spring pushes

the diaphragm against the valve plug, moving the plug off the seat and

allowing flow through the regulator (Fig. 3).As the outlet pressure increases

it moves the diaphragm against the force of the range spring and allows

the valve plug to move towards its seat, thus reducing the flow through

the valve. When the outlet pressure exceeds the regulator set point, the

regulator is closed.

TheA2BOE externally equalized pressure regulator operates like the A2BO

except the sensing pressure under the diaphragm is from a point

downstream of the valve (Fig. 4).

Adjustment A2BO, A2BOE

Anaccuratepressuregaugeshouldbeinstalledattheoutletoftheregulator

(or at the pressure sensing point for A2BOE). In case of a compensated

pressure regulator, pressure gauges should be installed at the outlet of

the regulator and also at the compensating pressure to the bonnet.

Carefully remove the seal cap and turn the adjusting stem in (clockwise)

to raise the set point, tending to open the seat; or out (counterclockwise)

to lower the set point, tending to close the seat. Table 2 shows the set

point pressure ranges for the regulators. Do not attempt to exceed the

rated maximum pressure setting adjustment because this could damage

the regulator or make it inoperative. Severe over adjusting could also apply

enough force to damage the diaphragm, or put the spring in solid position.

So, if the maximum tightening adjustment has been reached, stop and

back out the adjusting stem (counterclockwise) at least one half turn so

the range spring can move.

After adjusting the regulator, it is advisable to observe the maintained

pressure while the system is operating normally, and to make any minor

adjustments desired at that time. Replace the seal cap after the desired

set point is reached.

TABLE 2. A2BO OUTLET PRESSURE SETTING RANGES

SET POINT RANGES APPROX. CHANGE PER TURN

OF ADJUSTING SCREW

V: 500 mm hg to 8 bar

(20 in. hg to 120 psig) 1.8 bar (25 psi)

D: 5 to 19 bar (75 to 280 psig) 3.6 bar (53 psi)

Installation All A2 Regulators

Do not remove the protective coverings from the inlet and outlet of the

regulator until the regulator is ready to be installed. Protect the inside of

the regulator from moisture, dirt and chips before and during Installation.

When welded or brazed flange connections are used, all slag, scale, and

loose particles should be removed from the flange interior before the

regulator is installed between the flanges.

Tighten flange bolts and nuts evenly to provide proper seating of the flange

gasket and to avoid damage to gasket or flanges. A close coupled

companion strainer is available for installation at the inlet of the regulator

to help to protect it from any foreign material in the system.

The regulator must be installed with the arrow on the valve body pointing

in the direction of the flow for the regulator to function properly. Backwards

flow through the regulator is uncontrolled and will vary with the valve model,

itssettingandthereversepressuredropencountered.The regulator should

be installed in a location where it is easily accessible for adjustment and

maintenance. The location should be such that the regulator can not be

easily damaged by material handling equipment. When it is necessary to

insulate the regulator (and companion strainer), the insulation should be

installed to provide access to the regulator (and companion strainer) for

adjustment and maintenance. Proper indicating pressure gauges should

be installed to be easily visible to the operator adjusting the regulator.

Warranty

All Refrigerating Specialties Products are warranted against defect in

workmanship and materials for a period of one year from date of shipment

from factory. This warranty is in force only when products are properly

installed, maintained and operated in use and service as specifically stated

in Refrigerating Specialties Catalogs or Bulletins for normal refrigeration

applications, unless otherwise approved in writing by Refrigerating

Specialties Division. Defective products, or parts thereof, returned to the

factory with transportation charges prepaid and found to be defective by

factory inspection will be replaced or repaired at Refrigerating Specialties’

option, free of charge, F.O.B. factory. Warranty does not cover products

which have been altered or repaired in the field; damaged in transit, or

have suffered accidents, misuse, or abuse. Products disabled by dirt, or

other foreign substances will not be considered defective.

THE EXPRESS WARRANTY SET FORTH ABOVE CONSTITUTES THE

ONLY WARRANTY APPLICABLE TO REFRIGERATING SPECIALTIES

PRODUCTS, AND IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, WRITTEN OR ORAL, INCLUDING ANY

WARRANTY OR MERCHANTABILITY, OR FITNESS FORAPARTICULAR

PURPOSE. No employee, agent, dealer or other person is authorized to

give any warranties on behalf of Refrigerating Specialties, nor to assume,

for Refrigerating Specialties, any other liability in connection with any of

its products.

Safe Operation

(see also Bulletin RSBCV)

People doing any work on a refrigeration system must be qualified and

completely familiar with the system and the Refrigerating Specialties

Division valves involved, or all other precautions will be meaningless. This

includes reading and understanding pertinent Refrigerating Specialties

Division product Bulletins, and Safety Bulletin RSB prior to installation or

servicing work.

Where cold refrigerant liquid lines are used, it is necessary that certain

precautions be taken to avoid damage which could result from liquid

expansion. Temperature increase in a piping section full of solid liquid will

cause high pressure due to the expanding liquid which can possibly rupture

a gasket, pipe or valve. All hand valves isolating such sections should be

marked, warning against accidental closing, and must not be closed until

the liquid is removed. Check valves must never be installed upstream of

solenoid valves, or regulators with electric shutoff, nor should hand valves

upstream of solenoid valves or downstream of check valves be closed

until the liquid has been removed. It is advisable to properly install relief

devices in any section where liquid expansion could take place.

Avoid all piping or control arrangements which might produce thermal

or pressure shock.

For the protection of people and products, all refrigerant must be

removed from the section to be worked on before a valve, strainer, or

other device is opened or removed.

Flanges with ODS connections are not suitable for ammonia service.

Parker Hannifin Corporation • Refrigerating Specialties Division

2445 South 25th Avenue • Broadview, IL 60155-3891

Telephone (708) 681-6300 • Fax (708) 681-6306