MPFiltri BS500 User manual

BS500

500ml Bottle Sampling Unit

User Guide

201.010-EN

www.mpfiltri.co.uk

SAFETY WARNING

Contents

1 Introduction 5

2 Scope of Supply 6

3 Specification 7

4 Preliminary operations 8

Precautions

5 Fluid/Assembly Preparation and Analysis 11

Flushing and Flushing Fluids Procedure De-aeration Operating

with contamination monitoring . . .

6 Information 17

Warranty Spare Product / Part Numbers

7 Fault Finding 18

Introduction 5

1 Introduction

Benefits

•

•

•

Check that...

•

•

•

6 Scope of Supply

2 Scope of Supply

•

•

•

•

•

•

Impor-

tant: do not use the contamination monitoring product power

supply with the 500ml bottle sampling unit, as it has an inad-

equate power rating

Specification 7

3 Specification

Power supply

Indicator

Fluid compatibility

Hoses

Viscosity

Ambient temperature

Working temperature

Dimensions

Weight

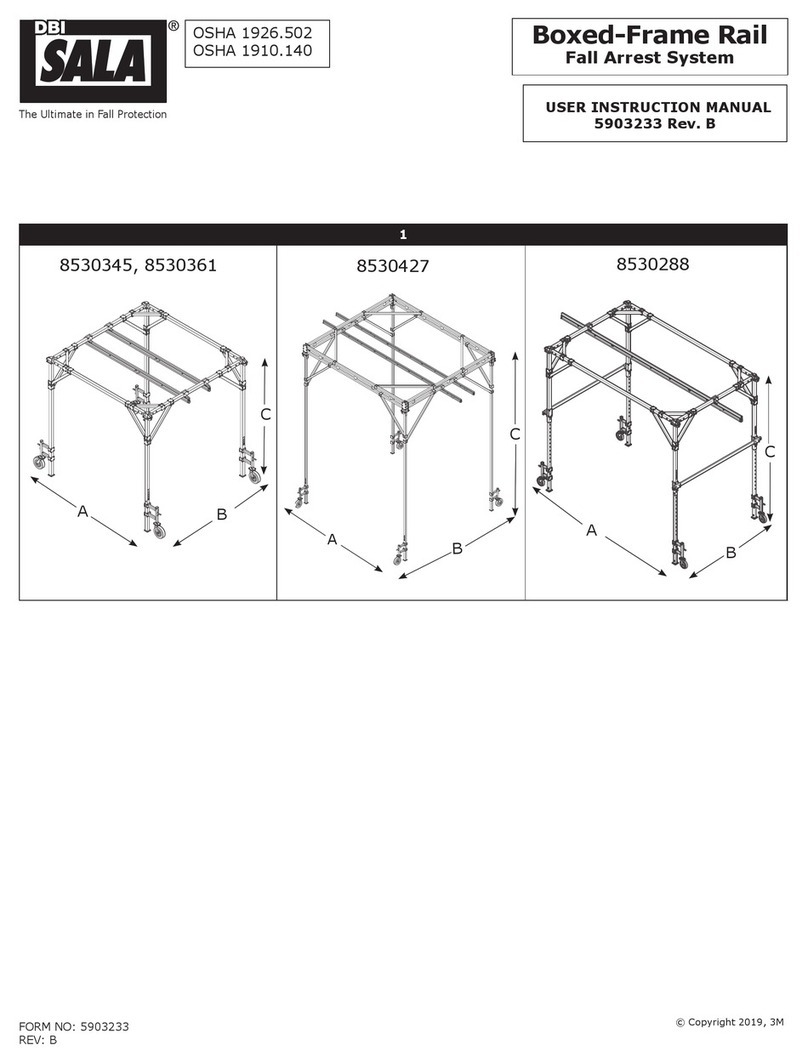

Figure 3.1

8 Preliminary operations

4 Preliminary operations

4.1 Precautions

4.1.1 Internal Cleaning

4.1.2 Pressurisation and Opening

4.1.3 Bottle Cleanliness and Verification

Preliminary operations 9

How to clean and re-use your own bottles

This allows any trace amounts of Petroleum Ether to evaporate

from the bottle, and reduces the risk of any air-borne particles entering the

container.)

5. Once complete, the uid sample should be disposed of correctly and respon-

sibly in line with local and international regulations.

10 Preliminary operations

This reduces the risk of any air-borne particles entering the

container.)

5. Once complete, the uid sample should be disposed of correctly and respon-

sibly in line with local and international regulations.

4.1.4 Fluid Sampling / Hand Pump

Fluid/Assembly Preparation and Analysis 11

5 Fluid/Assembly Preparation and

Analysis

5.1 Flushing and Flushing Fluids

Important! Do NOT use acetone

12 Fluid/Assembly Preparation and Analysis

5.2 Procedure

Fluid/Assembly Preparation and Analysis 13

Note: Please ensure that the pump and hose are cleaned with an appropriate

ltered solvent (i.e. Iso-propyl alcohol) prior to the sample being taken.

Sample bottles and associated products are to be cleaned in accordance with

the instructions on .

5.3 De-aeration

14 Fluid/Assembly Preparation and Analysis

Note: Do NOT pour uid sample directly into the chamber.

Note: It may be necessary

Fluid/Assembly Preparation and Analysis 15

to vent the chamber on occasion, to stop spill over due to foaming.

5.4 Operating with contamination monitoring product

Note: The top valve must not be opened BEFORE the operating mode selector

has been changed to the position P. To do so, could allow uid to reverse ow

back into the sample bottle and contaminate the sample.

16 Fluid/Assembly Preparation and Analysis

Ensure

that the visiwink indicator is green before removing the top chamber.

Note: Do not allow uid to drip from the dip tube onto the pressure/vacuum

port. The pressure/vacuum port is the small vertical hole that can be seen in

the base unit after the top chamber has been removed.

Information 17

6 Information

6.1 Warranty

6.2 Spare Product / Part Numbers

18 Fault Finding

7 Fault Finding

FAULT CHECK

Unexpected results

obtained from sample

Bottle sampler not

reaching required

pressure.

Produced by MP Filtri UK

Table of contents

Other MPFiltri Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs LS68 DA-F2 Series manual

Banner

Banner EZ-SCREEN instruction manual

Conductix-Wampfler

Conductix-Wampfler MultiLine 0835 Mounting instruction

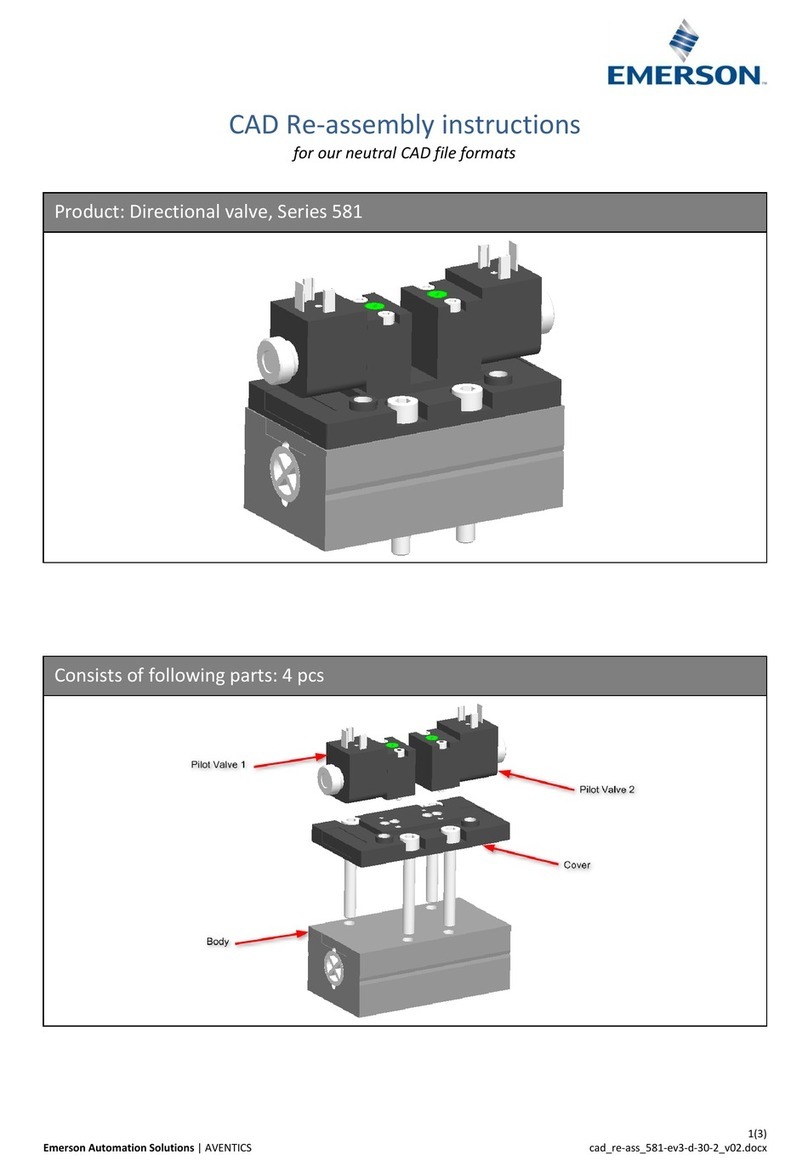

Emerson

Emerson 581 Series RE-ASSEMBLY INSTRUCTIONS

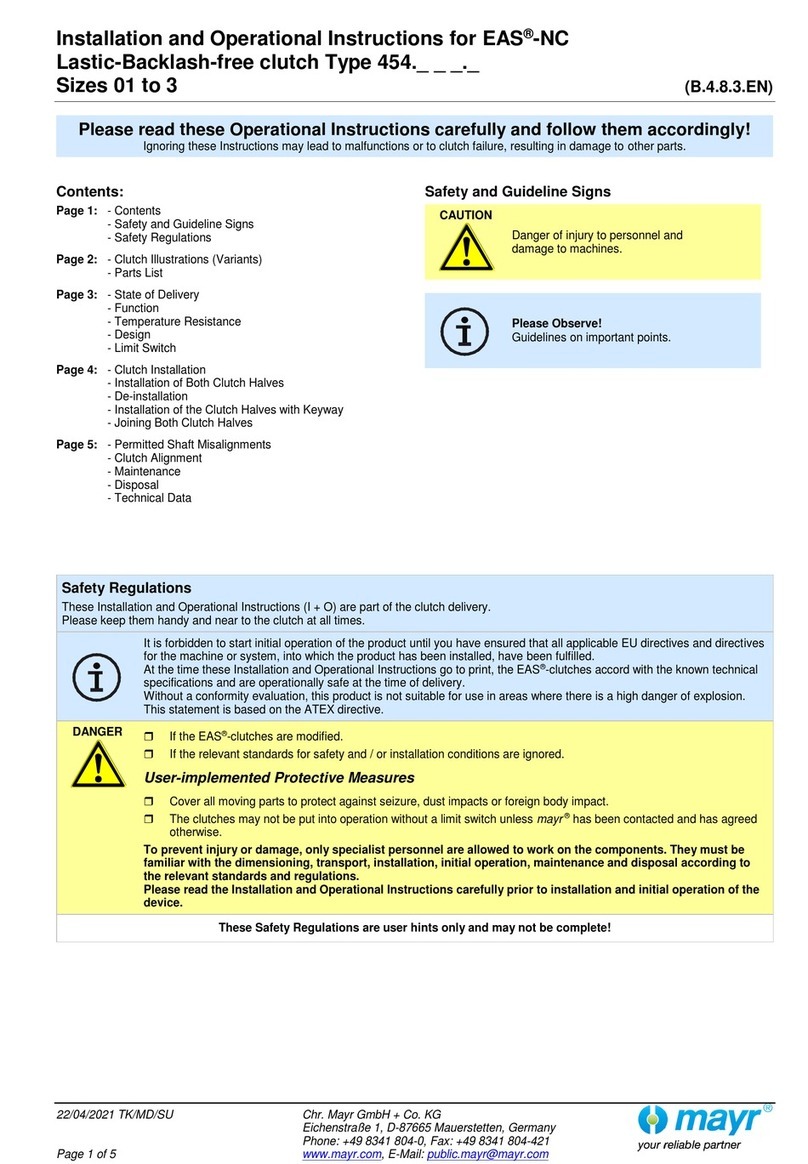

Mayr

Mayr EAS-NC Lastic-Backlash-free Installation and operational instructions

LYSON

LYSON W20210S manual