MPFiltri FZH Series Manual

ATEX 2014/34/UE

& U.K. Regulation S.I. 2016 No. 1107 (as amended)

FZH series

Installation, service and maintenance manual

and safety instructions

intended for use in potentially explosive atmospheres

Manuale di installazione, uso, manutenzione

ed istruzioni di sicurezza

& U.K. Regulation S.I. 2016 No. 1107 (as amended)

destinati all'impiego in zone a rischio di esplosione

ENGLISH

INDEX

Please scan the QR codes to get updated

electronic version of the related document.

FZH040FZH012

2

2

2

3

4

5

5

6

6

7

7

8

10

12

12

13

14

14

14

15

16

17

17

18

18

19

19

20

22

24

24

25

26

26

29

31

31

31

31

30

Page

Page

1. Description

2. General warnings

3. Tools

4. Handling

5. Dimensional drawings

6. Installation

7. Commissioning

8. Standard maintenance

8.1 Filter element replacement

9. Special maintenance

9.1 Clogging indicator (or plug) replacement

9.2 Seals replacement

10. Spare parts list

11. Ordering code

11.1 Filter / Housing / Bowl

11.2 Filter element

12. Instructions for use in explosive atmospheres

12.1 Marking

12.2 Safety instructions for installation in a hazardous area

13. Regulations

14. Troubleshooting

14.1 Misuse of the product

14.2 Clogging indicator alarm

14.3 Leaks of working uid

Stainless steel high pressure lters

1

EN

1. Description

The hydraulic lters are components intended for use in potentially explosive atmospheres to remove the

contaminants from the hydraulic uids used in the hydraulic systems. FZH lters are made of stainless steel to meet

extreme conditions and corrosive environments, with maximum pressure up to700 bar, ow rate up to50 l/min.

2. General warnings

- Before the installation, use or maintenance of the lter carefully read the manual

- The system and the lter are pressurised! Be sure the system is at ambient pressure before starting any activity

- The uid temperature inside the system and the lter can cause injuries to personnel or create a hazardous

environment

- Any activity must be carried out by trained and certied specialists, they must use the correct protective equipment

- Any activity must be carried out using the correct tool

- Any activity must be carried out in accordance with the laws in force in the country where the system is in

operation

- The data shown onto the nameplate must be complete and legible during the whole lter working life

- Connect the lter with an anti-loosening system and regularly check the condition of the connection

- The declared performances and the safety of the product are only guaranteed when MP Filtri original spare parts

are used

- Warranty is only effective if MP Filtri original spare parts are used.

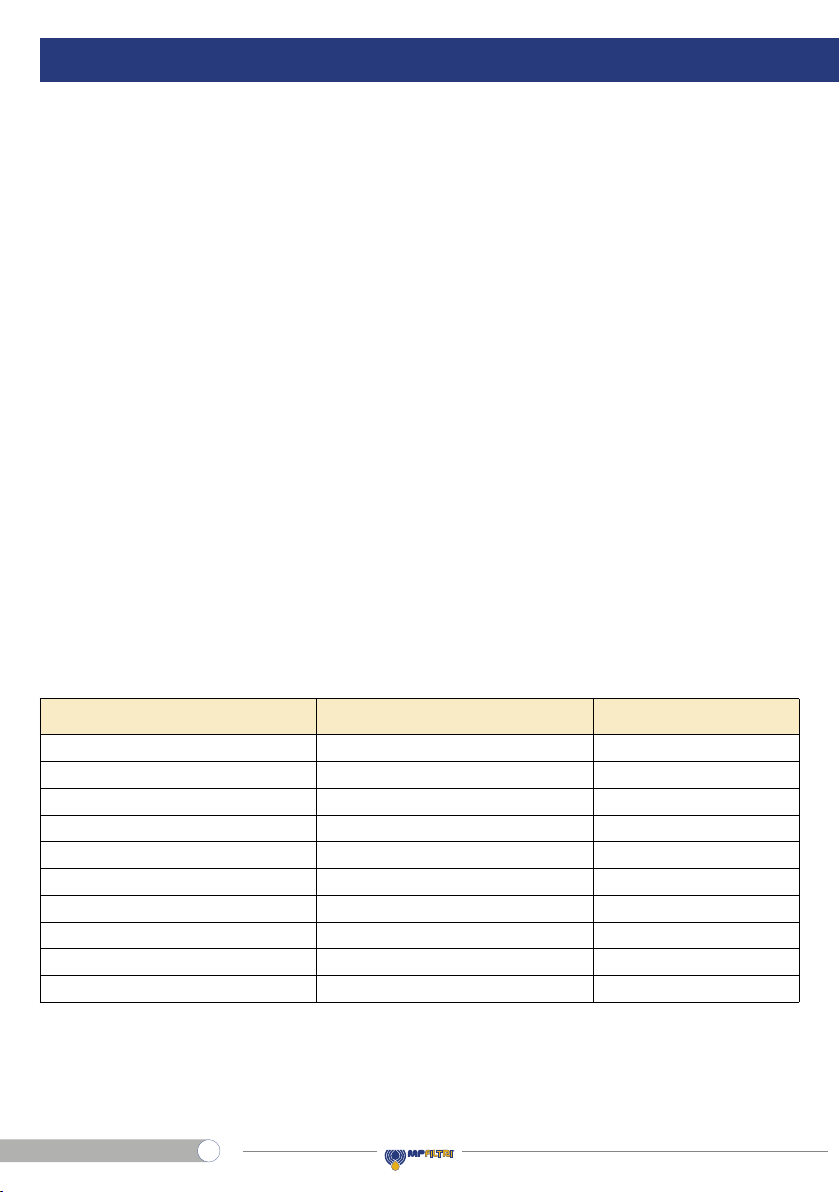

3. Tools

FZH012 TOOL TIGHTENING TORQUE

Differential indicator Wrench A/F 30 110 N∙m

Bowl Wrench A/F 50 45 N∙m

Connection G 1/4 Wrench A/F 19 Max 35 N∙m

Connection 1/4-18 NPT Wrench A/F 14 Max 28 N∙m

Connection 1/2-20 (SAE 5) Wrench A/F 17 Max 28 N∙m

Connection G 3/8 Wrench A/F 22 Max 45 N∙m

Connection 3/8-18 NPT Wrench A/F 19 Max 34 N∙m

Connection 9/16-18 (SAE 6) Wrench A/F 17 Max 34 N∙m

Fastening screws M6 Socket wrench A/F 10 11 N∙m

Fastening screws 1/4-20 UNC Socket wrench A/F 7/16" (11) 12 N∙m

Stainless steel high pressure lters

2

EN

ENGLISH

FZH012

4. Handling

- The unit is shipped in a cardboard box with dimensions depending on the order

- The handling must be carried out in accordance with the laws in force in the country of use of the product

- Handle the product with care, avoid impacts

- Store in a dry and frost-free room

- The unit should be stored in a suitable location away from the production area when not in use.

The unit should be stored with the caps provided on the ports and the bowl’s protective net, if present.

This location should not impede any other production or personnel.

Please refer to the following Weight table:

2.1 3.32.2 2.7

1Length 42 3

FZH012

WEIGHTS [kg]

SERIES

AND SIZE

Stainless steel high pressure lters

3

EN

OUTIN

Recommended

clearance space

for maintenance

Connection for

differential indicator

X3 plug not included

R - depth 12 mm

Nr. 3 holes

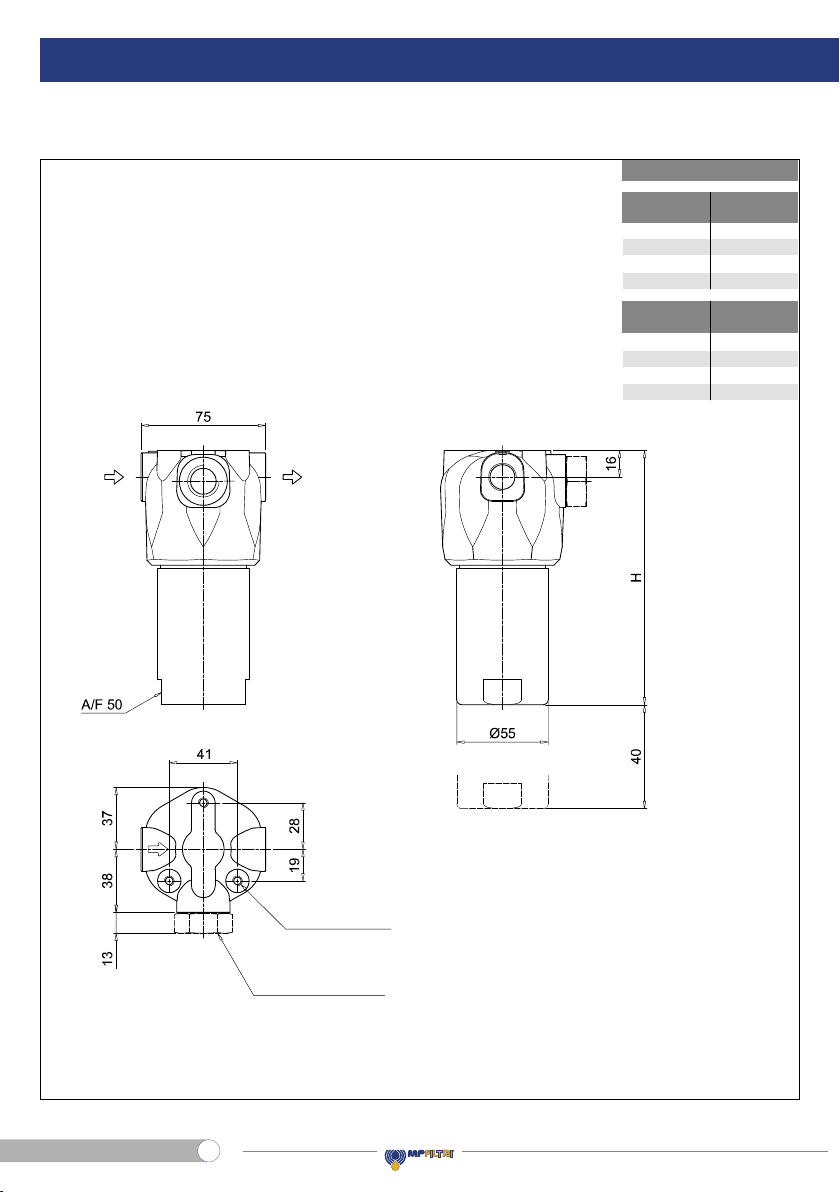

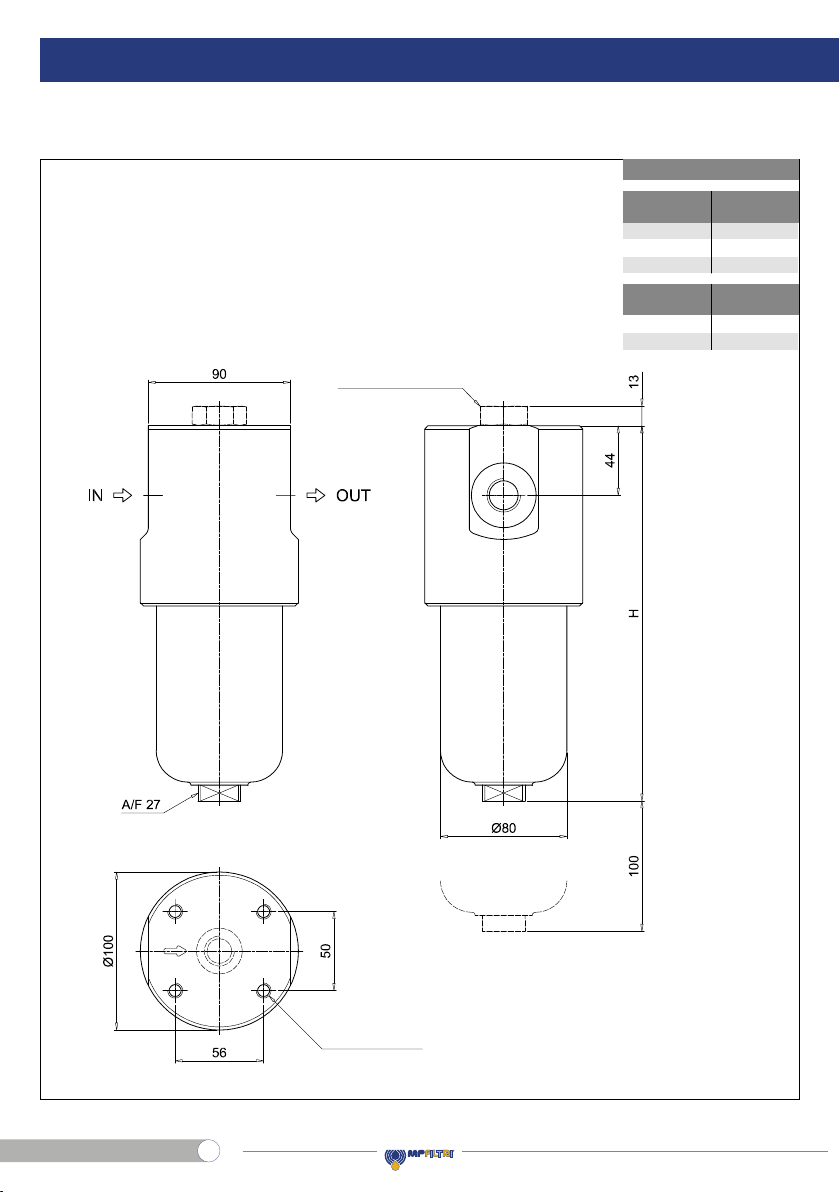

5. Dimensional drawings

FZH012

H

[mm]

1

2

3

4

93

104

154

204

R

A

B - C

D

E - F

M6

1/4” UNC

M6

1/4” UNC

Connections

Filter

length

Stainless steel high pressure lters

4

EN

ENGLISH

FZH012

6. Installation

- Check that the system working pressure does not exceed the maximum working pressure of the lter.

The maximum working pressure of the lter is shown on the laser marking on the head

- Check that the lter is compatible with the uid used in the system

- Remove the plastic plugs from the inlet, the outlet and the indicator connection

- Check that the correct lter elements are tted into the lter

- Check the ow direction (the ow is indicated byan arrowon the on the head)

- Install the clogging indicator, if required.

In the case of using an electrical clogging indicator, follow the electrical diagram for correct installation

- Fasten the lter to the bracket with the correct bolts. Be sure to t the lter without any tension stress

- Check that there is appropriate clearance for maintenance and the lter elements replacement.

Correct operation is only guaranteed if the lter is installed in a vertical orientation with the lter housing at the top

- Check for a good view of the clogging indicator

- Connect the lter to the hydraulic system, using the appropriate hydraulic ttings.

7. Commissioning

- Switch on the hydraulic system

- Check the lter is free of leaks

- Check the lter for leaks at the maximum working conditions. (Pressure, temperature …)

- Check the lter does not cause excessive pressure drop checking that the indicator does not show the alarm signal.

Clogging indicator

connection

A

A

A

DescriptionItem

Parts identificationParts identification

FZH012

Clogging indicator connection

Stainless steel high pressure lters

5

EN

8. Standard maintenance

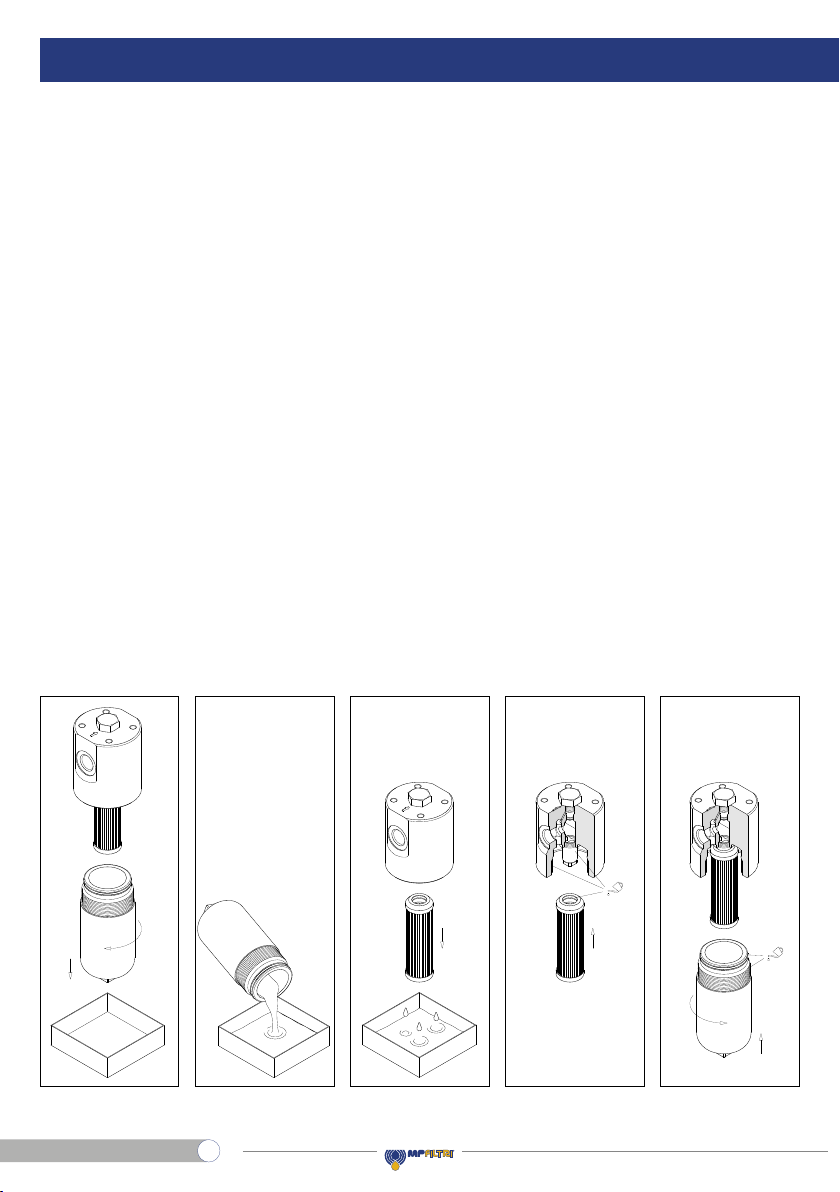

8.1 FILTER ELEMENT REPLACEMENT

The clogging indicator monitors the conditions of the lter element in the working section of the lter. The alarm signal

shown by the differential indicator during the normal working conditions (Pressure, temperatures …) means that the

lter element needs to be replaced.

- Checktherightsparelterelementisavailable,comparethesparelterelementpartnumberwiththepartnumbershown

on the lter name plate or in the spare parts list

- Switch off the system

- For the disassembly and the assembly of the parts, please refer to the tools table in paragraph 3

- (Fig. 1) Unscrew the lter bowl after placing a vessel to collect the operating uid

- (Fig. 2) Empty the operating uid from the bowl into the collection vessel

- (Fig. 3) Pull the lter element out

- Clean the cavity in the housing, the tap and the bowl. Check them for damage

- Check the condition of the bowl seals and, if necessary, replace them referring to the “Special maintenance”

paragraph

- (Fig.4) Lubricate with the operating uid the lter element O-ring,the housing tap and cavity, then t the lter element

on the tap. Pay attention not to damage the O-ring seal

- (Fig.5) Lubricate the thread and the O-ring of the bowl,then screw the bowl in referring to the tightening torque table

in paragraph 3

- Switch on the system and check the lter for leaks at the maximum working conditions (pressure, temperature…)

- Dispose of the replaced parts and the collected uid in accordance with the laws in force in the country of use of

the product.

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

g. 1 g. 3 g. 4 g. 5g. 2

Stainless steel high pressure lters

6

EN

ENGLISH

FZH012

9. Special maintenance

9.1 CLOGGING INDICATOR (OR PLUG) REPLACEMENT

- Check the right spare lter element is available, compare the spare lter element part number with the spare parts list

- Switch off the system

- For the disassembly and the assembly of the parts, please refer to the tools table in paragraph 3

- (Fig. 6) Unscrew the indicator body

- (Fig. 7) Lubricate with the operating uid the thread and the O-ring of the indicator body, then screw the indicator body

in referring to the tightening torque table in paragraph 3

- Switch on the system and check the lter for leaks at the maximum working conditions (pressure, temperature…)

- Dispose of the replaced parts and the collected uid in accordance with the laws in force in the country of use of the

product.

g. 6 g. 7

Smontaggio

indicatore

Montaggio

indicatore

Sost. guarnizioni

indicatore

Smontaggio

indicatore

Montaggio

indicatore

Sost. guarnizioni

indicatore

Stainless steel high pressure lters

7

EN

9.2 SEALS REPLACEMENT

- Check the right spare lter element is available, compare the spare lter element part number with the spare parts list

- Switch off the system

- For the disassembly and the assembly of the parts, please refer to the tools table in paragraph 3

- (Fig. 8) Unscrew the lter bowl after placing a vessel to collect the operating uid

- (Fig. 9) Empty the operating uid from the bowl into the collection vessel

- (Fig. 10) Pull the lter element out

- Remove all the seal from the bowl and the lter element, and prepare the spare parts referring to the list in

paragraph 12.

- (Fig. 11) Fit 1°: the anti-extrusion ring and #2: the O-ring in the bowl groove, insert the O-ring in the lter element cap

- Clean the cavity in the housing, the tap and the bowl. Check them for damage

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

g. 8 g. 10 g. 11g. 9

Stainless steel high pressure lters

8

EN

ENGLISH

FZH012

- (Fig. 12) Lubricate with the operating uid the lter element O-ring, the housing tap and cavity, then t the lter

element on the tap. Pay attention not to damage the O-ring seal

- (Fig. 13) Lubricate the thread and the O-ring of the bowl, then screw the bowl in referring to the tightening torque table

in paragraph 3

- (Fig. 14) Replace the O-rings of the indicator body

- For the mounting/dismounting of the indicator, please refer to the paragraph “Clogging indicator replacement”

above (Fig. 6÷7)

- Switch on the system and check the lter for leaks at the maximum working conditions (pressure, temperature…)

- Dispose of the replaced parts and the collected uid in accordance with the laws in force in the country of use of the

product.

g. 12 g. 13 g. 14

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Sost. guarnizioni

elemento+contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Smontaggio

indicatore

Montaggio

indicatore

Sost. guarnizioni

indicatore

Stainless steel high pressure lters

9

EN

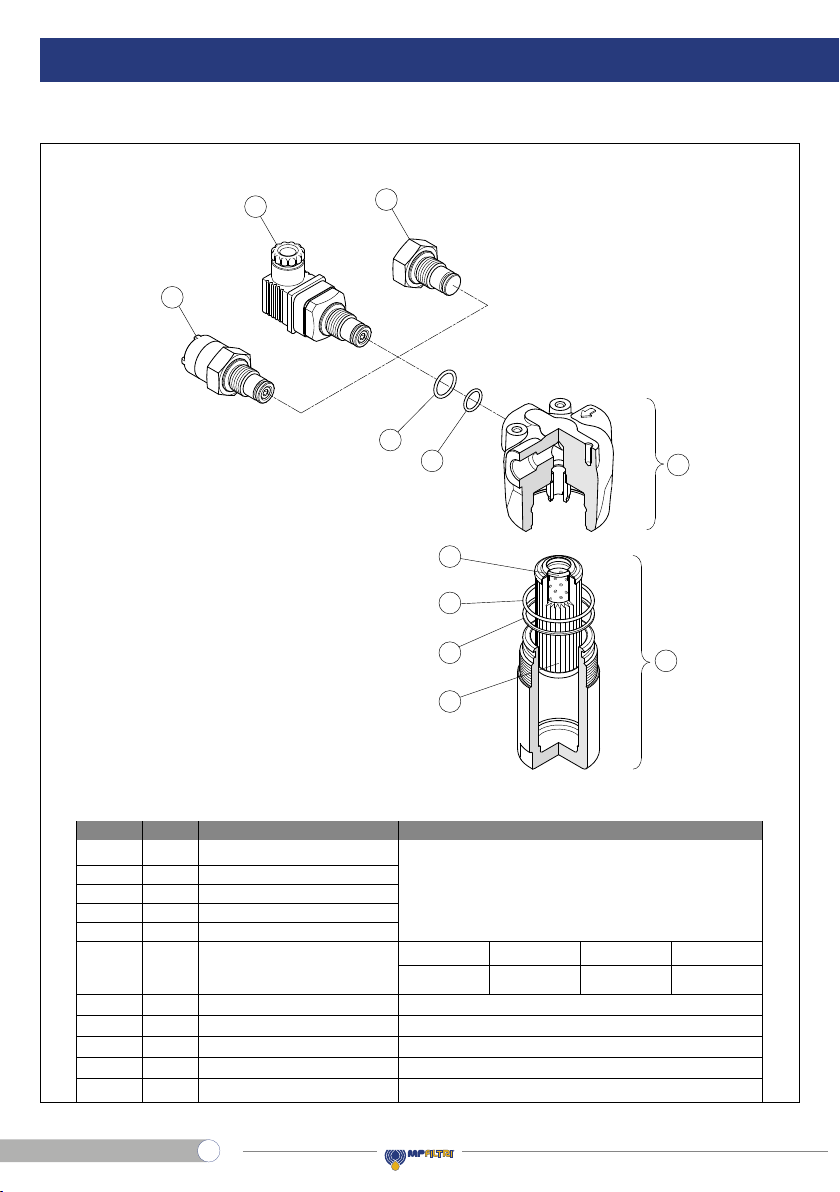

10. Spare parts list

Seals kit

7

Clogging indicator

5 Filter element

4Bowl

3Housing

Complete filter

1

DescriptionItem Designation / ordering codeQ.ty

6

Filter element seal

Bowl seal

Indicator seal

NBR FPM

7b

7a

7c

7d

O-Ring 121 - di = 15,88 - d2= 2,62

Indicator seal

See ordering table

O-Ring 3168 - di = 42,52 - d2= 2,62

O-Ring 2050 - di = 12,42 - d2= 1,78

O-Ring BS908 (01636-221) - di = 16,36 - d2= 2,21 - 90 °Sh A

1

1

1

1

1

1

1

1

1

1

See ordering table

See ordering table

See ordering table

See ordering table

Bowl anti-extrusion ring SR131

1

7e

02050856 02050857

EPDM

02050858

MFQ

02050859

Spare parts list

FZH012

6a

3

4

6b

6c

7a

7d

7e

7b

7c

5

Item Quantity Description Designation / Ordering code

Complete lter

Housing

Bowl assembly

Filter element

Clogging indicator

Filter element seal

Bowl seal

Bowl anti-extrusion ring

Indicator seal

Indicator seal

Seals kit

NBR EPDMFPM MFQ

See “Ordering Code” table

0205085902050856 02050857 02050858

1

1

1

1

1

1

1

1

1

1

1

1

3

4

5

6

7

7a

7b

7c

7d

7e

O-Ring 121 - di = 15.88 - d2= 2.62

O-Ring 3168 - di = 42.52 - d2= 2.62

SR131

O-Ring BS908 (01636-221) - di = 16.36 - d2= 2.21 - 90 °Sh A

O-Ring 2050 - di = 12.42 - d2= 1.78

Stainless steel high pressure lters

10

EN

ENGLISH

FZH012

Stainless steel high pressure lters

11

EN

11. Ordering code

11.1 FILTER / HOUSING / BOWL

FILTER / HOUSING / BOWL

Valves

ZVBS

•

•

•

•

•

•

•-

-

-

-

•

Element ∆p

N

H

U

20 bar

210 bar

210 bar, stainless steel lter element

Filtration rating (lter media)

A03

A10

A06

A16

A25

Inorganic microber 3 µm

Inorganic microber 10 µm

Inorganic microber 6 µm

Inorganic microber 16 µm

Inorganic microber 25 µm

Filter Series and size FZH012 F2 U2B B A03

Filter length

1 2 3 4

S

FZH012

B

HZH011

Without bypass

With bypass 6 bar

V

Z

With reverse ow, without bypass

With reverse ow, with bypass 6 bar

Valves

Seals

ANBR

VFPM

E

F

EPDM

MFQ

Connections

A

D

C

F

B

E

G 1/4”

G 3/8”

SAE 5 - 1/2” - 20 UNF

SAE 6 - 9/16” - 18 UNF

1/4” NPT

3/8” NPT

Connection for differential indicator

1

2

Without connection

With connection

FZH012 F 2B B

HZH011 F2 UA03

Filter:

Filter / housing

Bowl assembly

Housing:

Bowl:

Z01 EX

Z01 EX

Z01

Certications

EX Atex certications

Execution

Z01

Zxx

MP Filtri standard

Customized

Stainless steel high pressure lters

12

EN

ENGLISH

FZH012

11.2 FILTER ELEMENT

Example:

HP011 F2 UA03

Element length

Element series and size

HP011

FILTER ELEMENT

Element ∆p

N

H

U

20 bar

210 bar

210 bar, stainless steel lter element

Filtration rating (lter media)

A03

A10

A06

A16

A25

Inorganic microber 3 µm

Inorganic microber 10 µm

Inorganic microber 6 µm

Inorganic microber 16 µm

Inorganic microber 25 µm

1234

Seals

ANBR

VFPM

E

F

EPDM

MFQ

INDICATORS

ADDITIONAL FEATURES

DEZ

DVZ

Electrical differential indicator

Visual differential indicator

X3 Plug

Z01

Execution

Z01

Zxx

MP Filtri standard

Customized

Stainless steel high pressure lters

13

EN

1. Description

The hydraulic lters are components intended for use in potentially explosive atmospheres to remove the contaminants

from the hydraulic uids used in the hydraulic systems. FZH lters are made of stainless steel to meet extreme

conditions and corrosive environments, with maximum pressure up to700 bar, ow rate up to50 l/min.

2. General warnings

- Before the installation, use or maintenance of the lter carefully read the manual

- The system and the lter are pressurised! Be sure the system is at ambient pressure before starting any activity

- The uid temperature inside the system and the lter can cause injuries to personnel or create a hazardous

environment

- Any activity must be carried out by trained and certied specialists, they must use the correct protective equipment

- Any activity must be carried out using the correct tool

- Any activity must be carried out in accordance with the laws in force in the country where the system is in

operation

- The data shown onto the nameplate must be complete and legible during the whole lter working life

- Connect the lter with an anti-loosening system and regularly check the condition of the connection

- The declared performances and the safety of the product are only guaranteed when MP Filtri original spare parts

are used

- Warranty is only effective if MP Filtri original spare parts are used.

3. Tools

FZH040 TOOL TIGHTENING TORQUE

Differential indicator Wrench A/F 30 110 N∙m

Bowl Wrench A/F 50 45 N∙m

Connection G 1/4 Wrench A/F 19 Max 35 N∙m

Connection 1/4-18 NPT Wrench A/F 14 Max 28 N∙m

Connection 1/2-20 (SAE 5) Wrench A/F 17 Max 28 N∙m

Connection G 3/8 Wrench A/F 22 Max 45 N∙m

Connection 3/8-18 NPT Wrench A/F 19 Max 34 N∙m

Connection 9/16-18 (SAE 6) Wrench A/F 17 Max 34 N∙m

Fastening screws M6 Socket wrench A/F 10 11 N∙m

Fastening screws 1/4-20 UNC Socket wrench A/F 7/16" (11) 12 N∙m

Stainless steel high pressure lters

14

EN

ENGLISH

FZH040

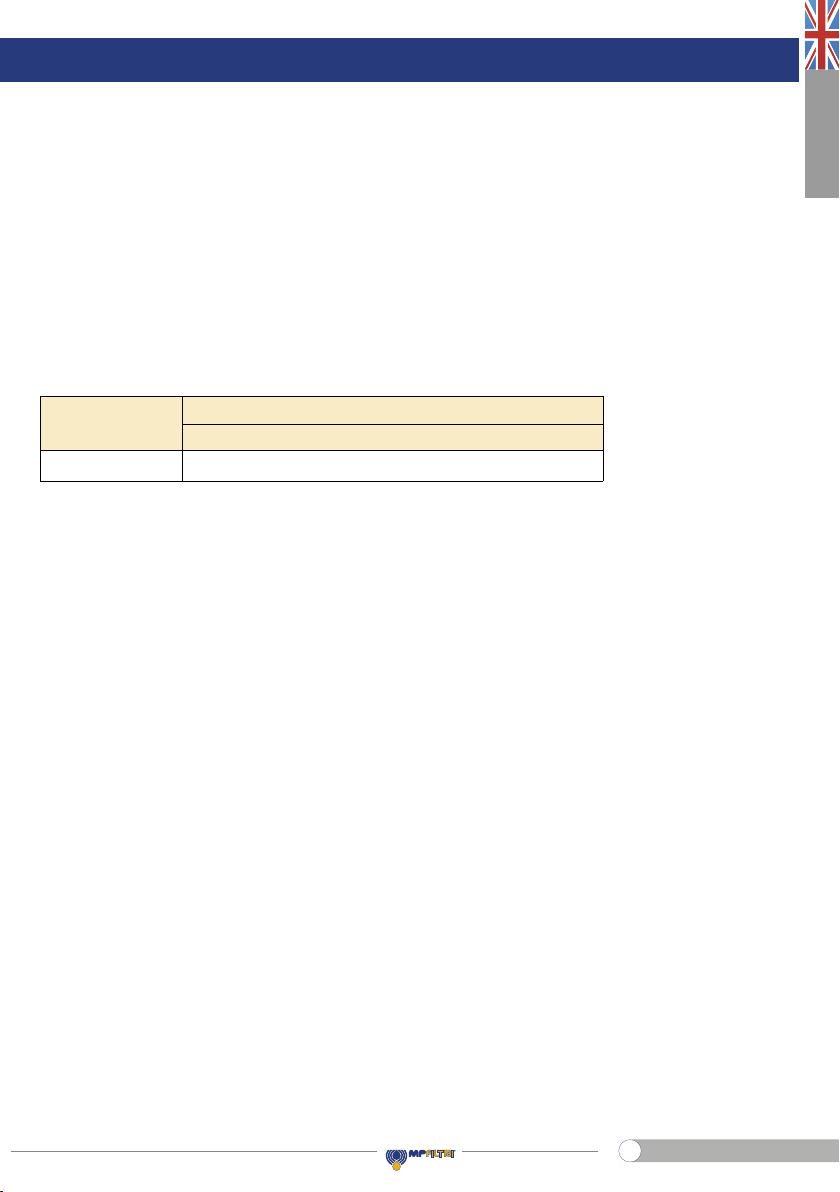

Length

5.64.5 5.1

42 3

FZH040

WEIGHTS [kg]

4. Handling

- The unit is shipped in a cardboard box with dimensions depending on the order

- The handling must be carried out in accordance with the laws in force in the country of use of the product

- Handle the product with care, avoid impacts

- Store in a dry and frost-free room

- Theunit shouldbestoredinasuitablelocationawayfromtheproductionareawhennotinuse.Theunitshouldbestored

with the caps provided on the ports and the bowl’s protective net,if present.This location should not impede any other

production or personnel.

Please refer to the following Weight table:

SERIES

AND SIZE

Stainless steel high pressure lters

15

EN

5. Dimensional drawings

FZH040

Filter

length

H

[mm]

2

3

4

204

247

291

Connections R

A

B - C

M10

3/8” UNC

Recommended

clearance space

for maintenance

Connection for

differential indicator

X3 plug not included

R - depth 12 mm

Nr. 4 holes

Stainless steel high pressure lters

16

EN

ENGLISH

FZH040

6. Installation

- Check that the system working pressure does not exceed the maximum working pressure of the lter.

The maximum working pressure of the lter is shown on the laser marking on the head

- Check that the lter is compatible with the uid used in the system

- Remove the plastic plugs from the inlet, the outlet and the indicator connection

- Check that the correct lter elements are tted into the lter

- Check the ow direction (the ow is indicated byan arrowon the on the head).

- Install the clogging indicator, if required.

In the case of using an electrical clogging indicator, follow the electrical diagram for correct installation

- Fasten the lter to the bracket with the correct bolts. Be sure to t the lter without any tension stress

- Check that there is appropriate clearance for maintenance and the lter elements replacement.

Correct operation is only guaranteed if the lter is installed in a vertical orientation with the lter housing at the top

- Check for a good view of the clogging indicator

- Connect the lter to the hydraulic system, using the appropriate hydraulic ttings.

7. Commissioning

- Switch on the hydraulic system

- Check the lter is free of leaks

- Check the lter for leaks at the maximum working conditions. (Pressure, temperature …)

- Check the lter does not cause excessive pressure drop checking that the indicator does not show the alarm

signal.

Clogging indicator

connection

A

A

DescriptionItem

Parts identificationParts identification

FZH040

Clogging indicator connection

A

Stainless steel high pressure lters

17

EN

8. Standard maintenance

8.1 FILTER ELEMENT REPLACEMENT

The clogging indicator monitors the conditions of the lter element in the working section of the lter. The alarm signal

shown by the differential indicator during the normal working conditions (Pressure, temperatures …) means that the

lter element needs to be replaced.

- Checktherightsparelterelementisavailable,comparethesparelterelementpartnumberwiththepartnumbershown

on the lter name plate or in the spare parts list

- Switch off the system

- For the disassembly and the assembly of the parts, please refer to the tools table in paragraph 3

- (Fig. 1) Unscrew the lter bowl after placing a vessel to collect the operating uid

- (Fig. 2) Empty the operating uid from the bowl into the collection vessel

- (Fig. 3) Pull the lter element out

- Clean the cavity in the housing, the tap and the bowl. Check them for damage

- Check the condition of the bowl seals and, if necessary, replace them referring to the “Special maintenance”

paragraph

- (Fig.4) Lubricate with the operating uid the lter element O-ring,the housing tap and cavity, then t the lter element

on the tap. Pay attention not to damage the O-ring seal

- (Fig.5) Lubricate the thread and the O-ring of the bowl,then screw the bowl in referring to the tightening torque table

in paragraph 3

- Switch on the system and check the lter for leaks at the maximum working conditions (pressure, temperature…)

- Dispose of the replaced parts and the collected uid in accordance with the laws in force in the country of use of

the product.

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Sost. guarnizioni

elemento+contenitore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Sost. guarnizioni

elemento+contenitore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Sost. guarnizioni

elemento+contenitore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Sost. guarnizioni

elemento+contenitore

Filtro

completo

Smontaggio

contenitore

Svuotamento

contenitore

Smontaggio

elemento

Montaggio

elemento

Montaggio

contenitore

Smontaggio

connettore

Smontaggio

corpo indicatore

Montaggio

corpo indicatore

Montaggio

connettore

Sost. guarnizioni

indicatore

Sost. guarnizioni

elemento+contenitore

g. 1 g. 3 g. 4 g. 5g. 2

Stainless steel high pressure lters

18

EN

This manual suits for next models

2

Table of contents

Languages:

Other MPFiltri Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB Tmax PR232 Getting started

SKF

SKF MonoFlex OI-AL-SR Component Lifecycle Manual

Siemens

Siemens SIMOVERT MASTERDRIVES 6SE70 C.87-2DA0 Series operating instructions

Tescom

Tescom 44-3200 Instructions for use

Dorner

Dorner 3200 Series Installation, maintenance & parts manual

Festo

Festo CPE PRS Series operating instructions

Mayr

Mayr EAS-NC Lastic-Backlash-free Installation and operational instructions

dymax

dymax SD-100 user guide

deconta

deconta smart dec S 50 Original instruction manual

MK Diamond Products

MK Diamond Products MK-Manta III manual

Stahl

Stahl 8162 Series operating instructions

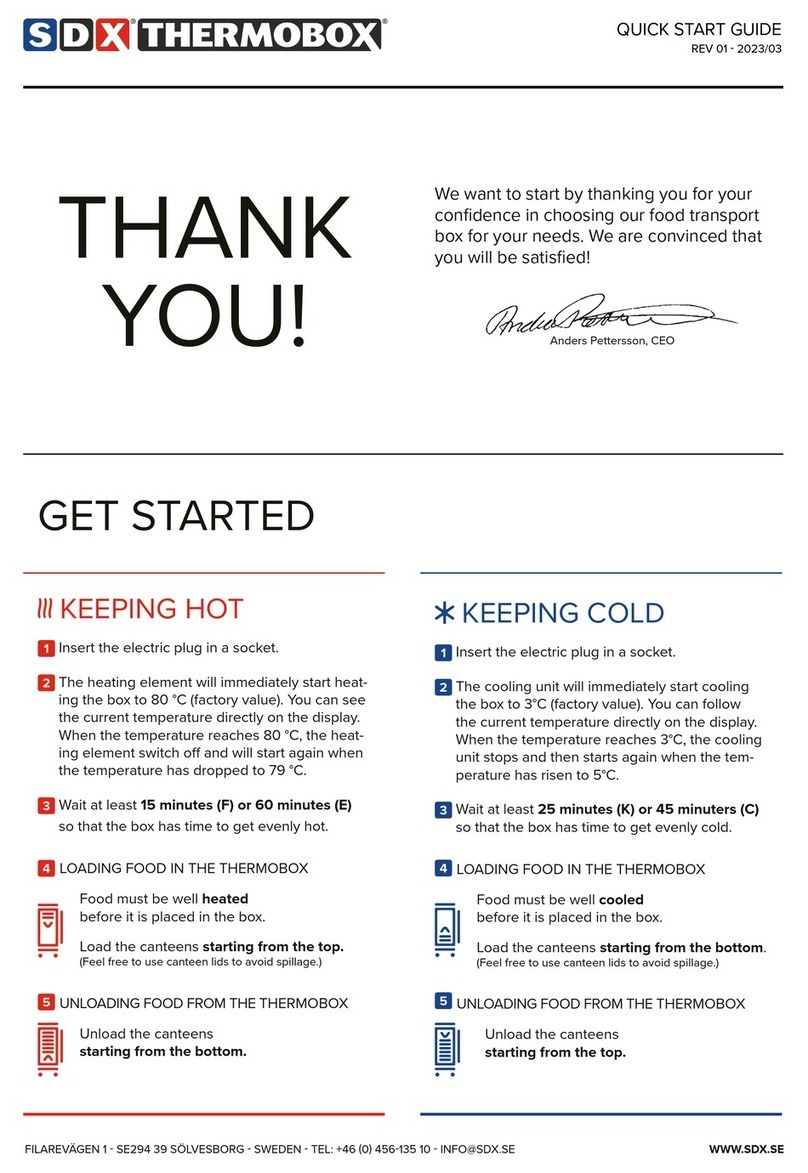

SDX Audio

SDX Audio THERMOBOX quick start guide