MPFiltri BS110 Manual

Operators Guide

BS110 - BS500

Bottle Samplers

PRODUCT OVERVIEW

• Vacuum feature for de-aeration of uids

• Compatible with all portable MP Filtri Contamination Monitoring Products

• Strong Laboratory aesthetic

• Transparent outer for visual indication

• Full accessories kit included

• Includes carry case (BS110 only)

• Contact MP Filtri for use with uids other than those stated

The 110 ml and 500 ml bottle samplers are suitable for off-line and laboratory applications where uid sampling at point of use is

inaccessible or impractical. A uid de-aeration facility comes as standard.

BS110 - 110 ml Bottle Sampler & BS500 - 500 ml Bottle Sampler

Features & Benets

Operators Guide

1

Product Presentation

The Bottle Sampler is an off-line unit designed to be used with the LPA2, LPA3 and CML2 for accurate contamination monitoring

and suitable for laboratory applications.

The product is compatible with various hydraulic uid types depending on the version being used (please refer to section 5 for

further details). The product is also compatible with a wide range of uid viscosities.

High Viscosity uids

The high-pressure version of the BS500 is suitable for uids with a viscosity grade of ISOVG 68 (68 cSt @40C).

This feature is used to decrease the de-aeration and ush times of such uids.

Benets

• Easy to use

• De-aeration Facility

• Large sample volume sampling up to 500 ml bottles

Operators Guide

2

Scope of Supply BS110

- 1 x 110 ml Bottle Sampling unit

- 1 x Pressure cap

- 1 x Vacuum cap

- 1 x M16x2 microbore pressure hose, 600 mm long

- 1 x 1 L waste receptacle

- 1 x 12V, 2A power adapter c/w UK/EU/US/AUS/CN heads

- 1 x pack of disposable dip tubes

- 1 x hand pump

- 3 x plastic bottles

- 3 m hand pump hose

- Fluid condition handbook

- Support case

- Digital copy of user guide/software/drivers

Scope of Supply BS500

- 1 x 500 ml Bottle Sampling base unit (*)

- 1 x Top cap, pressure/vacuum chamber (*)

- 1 x M16x2 microbore pressure hose, 600 mm long

- 1 x Power adapter

- 1 x UK/EU/US/AUS/CN power lead*

- 3 x 210 ml clear glass bottles

- 2 x 500 ml clear glass bottles

- 1 x Digital copy of user guides/software/drivers

(*) Specic model will be as per ordered item

PRODUCT OVERVIEW

IMPORTANT:

Do not use the contamination monitoring product power supply with the 500 ml bottle sampling unit, as it has an inadequate power

rating.

Operators Guide

3

Operators Guide

4

DECLARATION OF CONFORMITY

EC Declaration of Conformity

The products included in this Declaration are all variants of the following:

• Standard (2.5 bar) or High Pressure (4.5 bar)

• Compatible with mineral oil/ synthetic uids, offshore uids, phosphate esters (inc. aerospace versions)

• Glass or Acrylic Chamber

• All power supply options

For part codes see the Designation & Ordering Code (section 4.7 on pages 18-19)

Product Manufacturer:

MP Filtri UK

Bourton Industrial Estate

Bourton on the Water

Cheltenham

Gloucestershire

GL54 2HQ

01451 822522

sales@mpltri.co.uk

The products described are in conformity with the following directives:

2014/30/EU Electromagnetic Conformity

Certication Testing that has been carried out is in accordance with:

• DEF STAN 00-35 Part 3 issue 4 Environmental Test Methods

• BS EN 60068 range of standards covering environmental conditions

• BS EN 60529: 1992 + A2:2013 Degrees of Protection provided by enclosures (IP Code)

• BS EN 62262:2002 Degrees of Protection Provided for Electrical Equipment against External Mechanical Impacts (IK Code)

• BS EN 60721-3-4: 1995 Part 3: Classication of Groups of Environmental Parameters and their severities, Section 3.4

Date: 13 July 2018

Signed

Phil Keep (Managing Director) on behalf of MP Filtri UK Ltd

Operators Guide

5

Operators Guide

6

TABLE OF CONTENTS

Product overview 1

EC Declaration of Conformity 5

Table of Contents 6

What this guide is for 8

1 General warnings and information for the Operator 10

1.1 General safety warnings 10

1.2 Operator position and dangerous areas 12

1.3 Dangers and Hazards that cannot be eliminated 12

1.4 Personal Protective Equipment 12

2 Transportation and Storage 13

2.1 Transportation and Handling Conditions 13

2.2 Storage 13

3 Warranty, Limitations and Disclaimers 14

4 Technical Specication 16

4.1 Performance 16

4.2 Electrical Interface 16

4.3 Physical Attributes 16

4.4 Fluid Characteristics 16

4.5 Environment 16

4.6 Connection to use with Particle Analyser 17

4.7 Dimensions and ordering code 18

5 Product Installation and General Operation 21

5.1 Preliminary Operations 21

5.1.1 Internal Cleaning 21

5.1.2 Pressurization and Opening 21

5.1.3 Bottle Cleanliness and Verication 21

5.1.4 Fluid Sampling/ Hand Pump 22

5.2 General Operation 22

5.2.1 Physical Checks 22

5.2.2 Flushing and Flushing Fluids 22

5.2.3 De-aeration 25

5.2.4 Operating with Contamination Monitoring Product 26

5.3 Disposal 27

6 Related Products 28

7 Troubleshooting / FAQ 31

7.1 Misuse of Product 31

7.2 Fault Finding 31

Page

Operators Guide

7

What this guide is for

This guide will take you through the installation and instructions for making the most out of your Bottle sampling units.

It contains detailed information to enable you to master the full functionality of the device, as well as key information on safety,

waranty, maintenance and accessories.

At MP Filtri we are commited to customer service and hope this manual will help you to fully master the Bottle sampling units.

Disclaimer

As a policy of continual improvement, MP Filtri reserves the right to alter the specication without prior notice.

Operators Guide

8

OPERATOR’S GUIDE

Operators Guide

9

This means that failure to comply with the relevant safety regulations may result in slight injury

or damage to equipment.

If important information concerning the product affects the use of the product or a part of this

documentation, all of it must be particularly taken into account.

This means that failure to comply with the relevant safety regulations can result in death, serious injury

or considerable damage to equipment.

CAUTION

NOTE

DANGER

!

!

!

1 General warnings and information for the Operator

1.1 General Safety Warnings

The mobile ltration units of the UFM series have been designed and manufactured in compliance with the machinery directive and

the low voltage directive with regards to electric motors. The EC Declaration of Conformity is included in this manual.

The warranty has a duration of twelve months starting from the date shown on the delivery note.

To consulte “General Warranty Conditions” section of this Use and Maintenance Manual.

Read this manual carefully before commissioning, maintenance or other activities on or with the unit. Each operator involved in the

operation of the mobile ltration unit must wear the following personal protective equipment:

Before carrying out any installation or work on and/or with the machine it is necessary to strictly follow the instructions listed in

this manual. It is also necessary to comply with the provisions in force concerning accident prevention and safety in the workplace.

The warnings to prevent dangers to the health of the personnel assigned to the machine, are highlighted in this documentation

with signal words to notications:

Safety glasses Safety shoes Gloves

Operators Guide

10

GENERAL WARNINGS

To allow rapid identication of the employees who must read this manual, denitions have been used with the following meaning:

The person in charge of using the machine for productive purposes. The operator is aware of the

measures taken by the machine manufacturer to eliminate the sources of risk of accidents at

work and complies with the operational constraints.

The person in charge of performing maintenance operations on the machine. The maintenance

technician is aware of the possible dangerous situations that may arise during his work and

takes the necessary precautions to avoid risks of accidents at work.

The person in charge of carrying out maintenance operations on the machine's electrical system.

The electrician is aware of the possible dangerous situations that may arise during his work and

takes appropriate precautions to avoid risks of accidents at work.

The person in charge of handling the machine or parts thereof. The slinger is aware of the

problems concerning the transport of machines or parts thereof in safe conditions; for this

purpose, they use lifting equipment suitable for the purpose following the instructions provided

by the machine manufacturer.

The person in charge of preparing the machine for normal operation. The machine setter is

aware of the measures taken by the machine manufacturer to eliminate the sources of risk of

accidents at work and complies with the operational constraints. The machine setter takes the

necessary precautions to intervene in conditions of maximum safety.

OPERATOR

MAINTENANCE

TECHNICIAN

ELECTRICIAN

PERSONNEL INVOLVED

IN SLINGING AND

HOISTING OPERATIONS

MACHINE SETTER

Operators Guide

11

1.2 Operator Position and Dangerous Areas

The bottle sampling units create an internal pressure of either 2.5 or 4.5 bar, as such precautions should be taken and operates

should be aware of the surroundings when using this equipment.

1.3 Dangers and Hazards that cannot be eliminated

- Electric shock risk on the electric motor; in case of motor malfunction

- Burn risk because of high temperatures

- Accidental oil leaks with consequent risk of slipping

- Hose breakage and resulting lubricant loss

- With oil temperatures exceeding 40/45 °C, it is vital to be extremely careful when connecting to the portable particle counters

and when moving the unit.

ALL EQUIPMENT SHOULD BE ALLOWED TO COOL PRIOR TO HANDLING, AFTER IT HAS BEEN IN USE

1.4 Personal Protective Equipment

When operating the unit, personnel must be wearing safety shoes, gloves and goggles. In general, the PPEs to be used according

to the activities on the machinery are listed in the following table:

ACTIVITY

Ordinary operation

Planned maintenance

Shoes, gloves, goggles, overall

Shoes, gloves, goggles, overall

PPE

The unit shall be taken out of service and/or dismantled in accordance with the current regulations in force

in the country where the machinery is installed

The machinery is not suitable for outdoor use and all the electrical devices have a protection class

starting from IP 55 upwards.

NOTE

!

CAUTION

!

Operators Guide

12

TRANSPORT / STORAGE

2 Transportation and Storage

2.1 Transportation and handling Conditions

The unit is shipped in a cardboard box, encased in polyurethane foam.

The packed weight of the BS110 unit and accessories is 10 kg.

The packed weight of the BS500 unit and accessories is 13 kg.

The packaging dimensions are 60 x 50 x 40 cm

2.2 Storage

The unit should be stored in a suitable location away from the production area when not in use. The unit should be stored with

the caps provided on the ports. This location should not impede any other production or personnel.

Operators Guide

13

3 Warranty, Limitations and Disclaimers

MP Filtri warrants that the products that it manufactures and sells will be free from defects in material, workmanship & performance

for a period of 12 months from the date of shipment.

Hardware/Firmware

Should the hardware prove defective during the warranty period, MP Filtri, at its discretion, will either repair the defective product

or replace it with an equivalent product in exchange for the defective unit without charge for parts, labour, carriage and insurance.

Software

MP Filtri warrants that software will operate substantially in accordance with its functional specication for 12 months from date

of shipment provided that the integrity of the operating environment has not been compromised through misuse, inappropriate

handling, abnormal operating conditions, neglect or damage (unintentional or otherwise) or the introduction of third party product

(software or hardware) that in any way conicts with the MP Filtri product.

Eligibility

This warranty extends to the original purchaser only or to the end-user client of a MP Filtri authorised afliate.

How to obtain service?

To obtain service under the terms of this warranty, the customer is required to notify MP Filtri before the expiration of the warranty

period and to return the item in accordance with MP Filtri product return policy. Any product returned for warranty repair must be

accompanied by a full fault report specifying the symptoms and the conditions under which the fault occurs. Should MP Filtri incur

additional cost as a result of a failure to complete the appropriate paperwork, an administrative charge may be levied.

Exclusions

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate care. MP Filtri

shall not be obligated to provide service under this warranty if:

a) Damage has been caused by a failure to make a full and proper inspection of the product (as described by the

documentation enclosed with the product at the time of shipment) on initial receipt of the product following shipment;

b) Damage has been caused by the attempts of individuals, other than MP Filtri staff to repair or service the product;

c) Damage has been caused by the improper use or a connection with incompatible equipment or product including software

applications.

Operators Guide

14

WARRANTY

Charges

Under cover of this warranty, MP Filtri will pay the carriage and insurance charges for the shipment of defective product back to

site of manufacture and for its return to the client’s original site of despatch except when:

a) MP Filtri product return policy has not been followed.

b) Product failure is caused by any of the exclusions described above, when the customer will be liable for the full cost of the repair

(parts and labour) plus all carriage and insurance costs to and from MP Filtri premises.

c) The product is damaged in transit and a contributory cause is inadequate packaging. It is the customer’s responsibility to ensure

that the packaging used to return equipment to MP Filtri is the same, or has equivalent protective qualities, to that used to ship

the product to the customer in the rst instance. Any damage resulting from the use of inadequate packaging will nullify MP Filtri

obligations under this warranty. Should the customer’s product be damaged in transit following a repair at MP Filtri site, a full

photographic record of the damage must be obtained (packaging and the product) to support any claim for recompense. Failure to

present this evidence may limit MP Filtri obligations under this warranty.

THIS WARRANTY IS GIVEN BY MP FILTRI IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY, NON INFRINGEMENT OR FITNESS FOR A PARTICULAR PURPOSE. MP FILTRI LTD

SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES ( INCLUDING LOSS

OF DATA), WE SPECIFICALLY DISCLAIM ANY AND ALL WARRANTIES TO CUSTOMERS OF THE CUSTOMER. THE CUSTOMER’S SOLE

REMEDY FOR ANY BREACH OF WARRANTY IS THE REPAIR OR REPLACEMENT, AT MP FILTRI DISCRETION, OF THE FAILED PRODUCT.

MP Filtri Ltd maintains a policy of product improvement and reserves the right to modify the specications without prior notice.

Operators Guide

15

4. Technical specication

4.1 Performance

Indicator Visiwink pressure indicator (only for BS500 version)

Pressure Output Standard Version 2.5 bar

High Pressure Version 4.5 bar (only for BS500 version)

Vacuum Output (gauge) 18 inHg

4.2 Electrical Interface

Supply Voltage 12V DC

Supply Current BS110

BS500

2.5 bar version: 2.0A maximum current

2.5 bar version: 5.0A maximum current

4.5 bar version: 8.5A maximum current

4.3 Physical Attributes

Dimensions BS110

BS500

212 mm (H) x 130 mm (W) x 163 mm (D)

340 mm (H) x 264 mm (W) x 350 mm (D)

Weight BS110

BS500

1.8 kg - for packed weight see section 2.1

7 kg - for packed weight see section 2.1

Connections M16x2 hydraulic connection

Hoses 600 mm M16x2 hydraulic pressure hose

Seal Material M/N Version

Viton®(contact MP Filtri for any uids that are incompatible with Viton®seals

S Version - Perouroelastomer (only for BS500 version)

E Version - EPDM (only for BS500 version)

4.4 Fluid Characteristics

Fluid compatibility V version - mineral oils, synthetic uids and diesels

E version – Aerospace phosphate esters, Skydrols

®

S version – Aerospace phosphate esters, Skydrols

®

and V version uids.

Viscosity 400 cSt

Working temperature 0 °C to +40 °C

4.5 Environment

Ambient working temperature -10 °C to 80 °C

Operators Guide

16

TECHNICAL SPECIFICATION

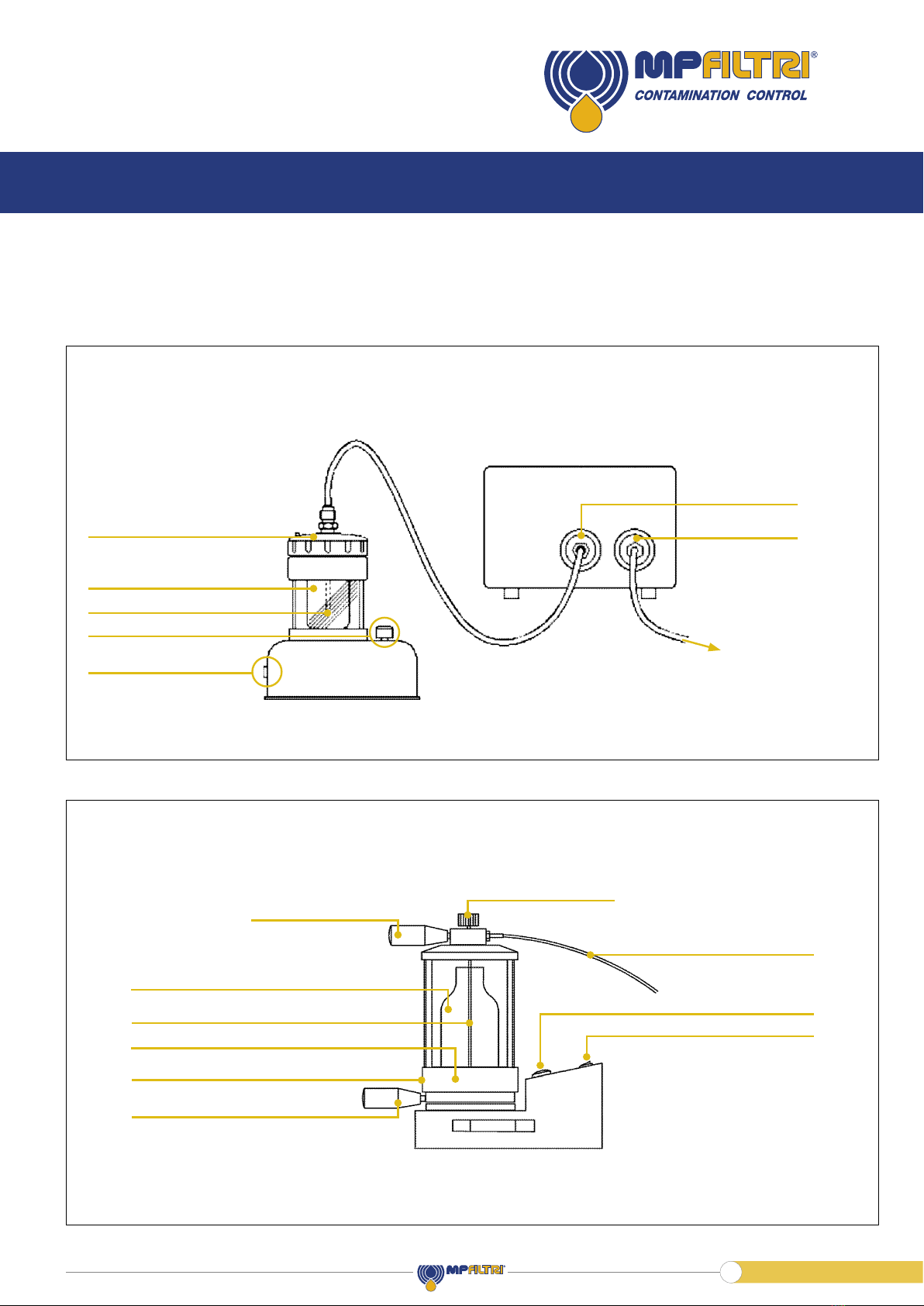

4.6 Connection to use with Particle Analyser

Waste connector

HP connector

Vacuum cap (not illustrated)

Pressure cap (as illustrated)

To waste bottle

Disposable dip tube

BOTTLE SAMPLING

UNIT

PARTICLE ANALYSER

Sample bottle

BS500

BS110

Sample bottle

Hose connection to Analyser

Operating mode selector

Top handle

Top valve

Visiwink

On/Off switch

DC Power IN

On/Off

BASE

UNIT

Dip tube

Removable top unit

Bayonet locking mechanism

Operators Guide

17

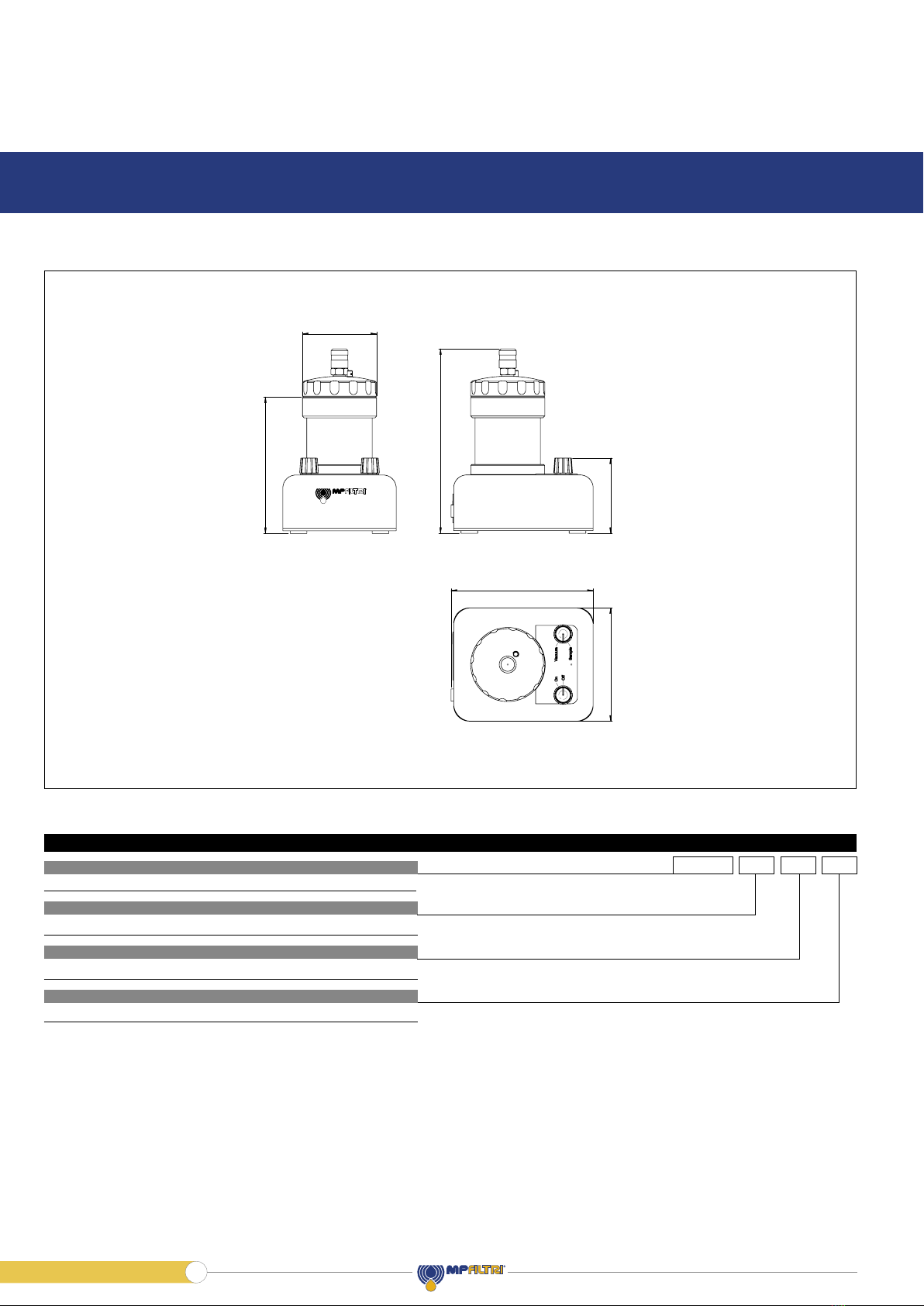

4.7 Dimensions and ordering code

BOTTLE SAMPLER BS110

Series

BS110

Fluid compatibility

Pressure rating

Pressure cylinder option

0

0

M

2 bar

Acrylic cylinder assembly

Mineral oil and synthetic uids

Conguration example: BS110 OM O

Designation & Ordering code

110 ml uid volume

BOTTLE SAMPLING UNIT

BS110

157

212

87130

163

Ø85

Operators Guide

18

Other manuals for BS110

1

This manual suits for next models

1

Table of contents

Other MPFiltri Industrial Equipment manuals