MPFiltri DEH Series Manual

Operators Guide DEH Series

Differential Clogging Indicator

Hazardous Area

Operators Guide

Operators Guide

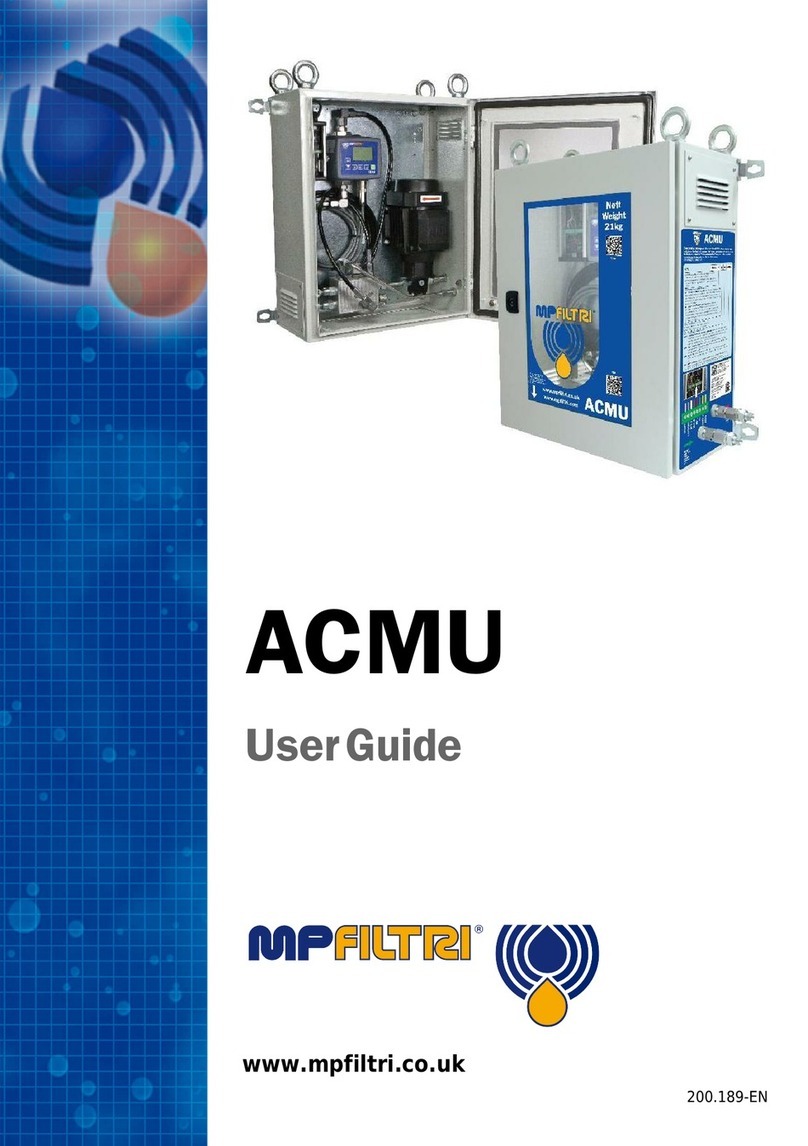

PRODUCT OVERVIEW

• Construction from AISI 316 Stainless steel

• 420 bar (6,091 PSI) maximum working pressure

• Approved for use in hazardous environments

• ATEX, IECEX, UL, CSA, and TRCU EAC certication

• Compact and reliable design

• Fully tested to one million cycles at maximum working pressure

Designed to thrive in hazardous work environments, the indicators provide critical early warnings for operators, alerting them that lter

elements need to be cleaned or changed.

Suitable for a wide variety of applications from oil, sea and gas to industrial production plants, the indicators have been designed to

prevent machinery failures, reduce unplanned downtime, and improve safety.

New DEH series of ATEX clogging indicators

Features & Benets

The new DEH series features three different models each with a distinct connection type.

1

Operators Guide

2

Operators Guide

PRODUCT OVERVIEW

Product Presentation

Filter elements are efcient only if their dirt holding capacity is fully exploited. This is achieved by using lter housings equipped

with DEH Series clogging indicators.

These devices trip when the lter elements become blocked which causes an increase in the pressure drop across the lter.

The indicator is set to alarm before the element becomes fully clogged. This indicator will reduce the frequency of replacing lter

elements as well as maximising the performance of each lter.

• Constructed from AISI 316 stainless steel 420 bar (6,091 PSI)

• 420 bar (6,091 PSI) maximum working pressure

• Approved for use in hazardous environments

• ATEX, IECEX, UL, CSA and TRCU, EAC certied

• Temperature class T4 (135 °C) and T6 (85 °C)

• Protection grade IP66 or IP67 when used with suitable cable gland

• Indication range from 5 bar to 7 bar

• Suitable for use with all MP Filtri stainless steel pressure lters and cast iron pressure lters

Benets

• Prevents machinery failures

• Cuts unplanned downtime

• Critical early warning system

• Saves time and costs

• Improves safety

Disclaimer

As part of our policy of continual improvement, MP Filtri reserves the right to alter the specication without prior notication.

Area of Application

Hazardous Area Indicators can only be used in the appropriate zone classication.

Ex d indicators should only be used in zones 1 and 2 - zones in which potentially explosive atmospheres created by

gases, vapours or mists are unlikely to occur in normal operation. In the event of an occurence, the situation will persist

for only a short period.

Ex ia indicators can be used in zones 0, 1 and 2. These are suitable in an area where explosive atmospheres are

continually present. For more information please see section 6 - Certication.

• Marine

• Mining

• Petrochemical

• Offshore oil and gas

• Saw mills

• Paper mills

• Car plants

• Industrial plants

• Storage silos

• Hazardous environments

The full range of applications the DEH series is designed for includes:

3

Operators Guide

4

Operators Guide

DECLARATION OF CONFORMITY

EC Declaration of Conformity

The products included in this Declaration are all variants of the following:

• Standard (2.5 bar) or High Pressure (4.5 bar)

• Compatible with mineral oil/ synthetic uids, offshore uids, phosphate esters (inc. aerospace versions)

• Glass or Acrylic Chamber

• All power supply options

For part codes see the Designation & Ordering Code (section 3.3 on page 16).

Product Manufacturer:

MP Filtri UK

Bourton Industrial Estate

Bourton on the Water

Cheltenham

Gloucestershire

GL54 2HQ

01451 822522

sales@mpltri.co.uk

The products described are in conformity with the following directives:

2014/34/EU

Certication Testing that has been carried out is in accordance with:

• BS EN 10272

• EN/IEC 60079-0:2012 + A 11:2013

• EN/IEC 60079-11:2012

• EN/IEC 60079-31: 2014

• IEC 60079 - 11 2012

• UL 1203

• CAN/USA C22.2 No. 25-1966

• CAN/USA C22.2 No. 30-M1986 + 2:1988-11

• ISO 10771-1

Date: July 2020

Signed

Phil Keep (Managing Director) on behalf of MP Filtri UK Ltd

5

Operators Guide

Product overview 1

EC Declaration of Conformity 5

1 General warnings and information for the Operator 8

1.1 General safety warnings 8

1.2 Operator informations and Warnings 10

2 Warranty, Limitations and Disclaimers 12

3 Technical Specication 14

3.1 General Specication 14

3.2 Dimensions 16

3.3 Designation & Ordering code 16

3.4 Wiring Instructions 17

3.5 Temperature Range 17

4 Product Installation and Maintenance 18

4.1 Special Conditions of Safe Use 18

4.2 Installation Instructions 18

4.3 Wiring Instructions 19

4.4 Suitable Operating Fluids 20

4.5 Commissioning 20

4.6 Specic Conditions for Safe Use 20

4.7 System Requirements 21

5 Technical Specication 21

5.1 Spare Parts 21

6. Certication 22

6.1 ATEX 22

6.2 IECEX 22

6.3 UL/CSA 23

6.4 TR/CU 23

6.5 Fatigue Declaration 23

Page

6

Operators Guide

TABLE OF CONTENTS

7 Servicing 24

7.1 General Information 24

7.2 Torque Values 24

7.3 Service Measures 24

7.4 Service Intervals 24

7.5 Seal Replacement 24

7.6 Removing the Clogging Indicators 58

7.7 Installing the Clogging Indicators 58

Page

7

Operators Guide

It means that failure to comply with the relevant safety regulations may result in mild injury or property damage.

It relates to important information concerning the product, its use or part of this documentation

to which special attention must be paid

It means that failure to comply with the relevant safety regulations may result in death, serious injury

or serious property damage.

CAUTION

NOTE

DANGER

!

!

!

1 General warnings and information for the Operator

1.1 General Safety Warnings

Do not operate, maintain or carry out any procedure before reading this manual. Any individual operating the unit shall wear the

following Personal Protective Equipment:

- Protective eyewear

- Safety shoes

- Gloves

- Overalls (or other suitable protective clothing)

Before carrying out any machine installation procedures and/or before use, one should scrupulously follow the in- structions listed

in this manual. Moreover, it is necessary to comply with the current regulations related to occupational accident prevention and

safety in the workplace.

Notices aimed at the prevention of health hazards for personnel operating the machine are highlighted in this document with signs

having the following meaning:

Failure to comply with the relevant safety regulations may result in death, serious injury or serious property damage.

8

Operators Guide

GENERAL WARNINGS

To allow rapid identication of the employees who must read this manual, denitions have been used with the following meaning:

This is any individual whose task is to use the machine for production purposes. The operator is

aware of all the measures taken by the machine manufacturer in order to eliminate any source

of injury risk in the workplace and takes into account the operational constraints.

This is any individual whose task is to carry out maintenance activities on the machine. The

maintenance technician is aware of the possible danger situations that may arise and takes the

appropriate precautions in order to eliminate the risks of accidents in the workplace.

This is any individual whose task is to carry out maintenance activities on the electrical wiring of

the machine. The electrician is aware of the possible danger situations that may arise and takes

the appropriate precautions in order to eliminate the risks of accidents in the workplace.

This is any individual whose task is to handle the machine or parts of it. Personnel involved in

slinging and hoisting operations are aware of the issues regarding the safe transfer of machinery

or parts of it and, therefore, uses appropriate lifting equipment, following the instructions provi-

ded by the product manufacturer.

This is any individual whose task is to set up the machine for its operation. The machine setter is

aware of the measures taken to eliminate all sources of injury risks in the workplace and takes

into account the operational constraints. The machine setter takes all the appropriate precau-

tions in order to operate in utmost safety conditions.

OPERATOR

MAINTENANCE

TECHNICIAN

ELECTRICIAN

PERSONNEL INVOLVED

IN SLINGING AND

HOISTING OPERATIONS

MACHINE SETTER

9

Operators Guide

CAUTION

NOTE

DANGER

!

!

!

1.2

Operator Information and Warnings

• This pressure unit must only be operated in conjunction with the appropriate machine or system.

• The pressure unit must only be used in strict accordance with the requirements of the operating instructions

of the machine or system.

• This pressure unit must only be operated using hydraulic or lubricating uid.

• The user must, by appropriate action (e.g. venting), prevent the formation of air pockets.

• Repair, maintenance work, and commissioning must be carried out by trained personnel only. Personnel must ensure the

pressure unit has cooled down before handling. Operating instructions for the machine or system must be strictly followed.

• Statutory accident prevention regulations, safety regulations and safety data sheets for uids must be observed.

• When working on, or in the vicinity of, the hydraulic system, naked ames, spark generation and smoking are strictly

forbidden.

• Hydraulic oils and water polluting uids must not be allowed to enter the soil, watercourses or sewerage systems.

Operators must ensure safe and environmentally-friendly disposal of hydraulic oils. The relevant regulations in the country

concerned with regard to ground water pollution, used oil and waste must be followed.

• When work is carried out on the lter, operators must be prepared for the escape of hot oil. This can cause injury or scalding

due to high pressure or high temperature.

• The Filter housing must be earthed when hydraulic hoses are used to connect the lter to the system.

• Before any work is carried out on the pressure unit, operators must ensure the pressure chamber concerned (lter housing)

is depressurised.

• No alterations, such as welding, drilling, or opening by force, are to be carried out on the pressure unit.

• When using electrical clogging indicators, the electrical power supply to the system must be switched off

before removing the clogging indicator connector.

10

Operators Guide

GENERAL WARNINGS

11

Operators Guide

2 Warranty, Limitations and Disclaimers

MP Filtri warrants that the products that it manufactures and sells will be free from defects in material, workmanship & performance

for a period of 12 months from the date of shipment.

Hardware/Firmware

Should the hardware prove defective during the warranty period, MP Filtri, at its discretion, will either repair the defective product

or replace it with an equivalent product in exchange for the defective unit without charge for parts, labour, carriage and insurance.

Eligibility

This warranty extends to the original purchaser only or to the end-user client of a MP Filtri authorised afliate.

How to obtain service?

To obtain service under the terms of this warranty, the customer is required to notify MP Filtri before the expiration of the warranty

period and to return the item in accordance with MP Filtri product return policy. Any product returned for warranty repair must be

accompanied by a full fault report specifying the symptoms and the conditions under which the fault occurs. Should MP Filtri incur

additional cost as a result of a failure to complete the appropriate paperwork, an administrative charge may be levied.

Exclusions

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate care. MP Filtri

shall not be obligated to provide service under this warranty if:

a) Damage has been caused by a failure to make a full and proper inspection of the product (as described by the

documentation enclosed with the product at the time of shipment) on initial receipt of the product following shipment;

b) Damage has been caused by the attempts of individuals, other than MP Filtri staff to repair or service the product;

c) Damage has been caused by the improper use or a connection with incompatible equipment or product including software

applications.

12

Operators Guide

WARRANTY

Charges

Under cover of this warranty, MP Filtri will pay the carriage and insurance charges for the shipment of defective product back to

site of manufacture and for its return to the client’s original site of despatch except when:

a) MP Filtri product return policy has not been followed.

b) Product failure is caused by any of the exclusions described above, when the customer will be liable for the full cost of the repair

(parts and labour) plus all carriage and insurance costs to and from MP Filtri premises.

c) The product is damaged in transit and a contributory cause is inadequate packaging. It is the customer’s responsibility to ensure

that the packaging used to return equipment to MP Filtri is the same, or has equivalent protective qualities, to that used to ship

the product to the customer in the rst instance. Any damage resulting from the use of inadequate packaging will nullify MP Filtri

obligations under this warranty. Should the customer’s product be damaged in transit following a repair at MP Filtri site, a full

photographic record of the damage must be obtained (packaging and the product) to support any claim for recompense. Failure to

present this evidence may limit MP Filtri obligations under this warranty.

THIS WARRANTY IS GIVEN BY MP FILTRI IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO ANY IMPLIED WARRANTY OF MERCHANTABILITY, NON INFRINGEMENT OR FITNESS FOR A PARTICULAR PURPOSE. MP FILTRI LTD

SHALL NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES OR LOSSES ( INCLUDING LOSS

OF DATA), WE SPECIFICALLY DISCLAIM ANY AND ALL WARRANTIES TO CUSTOMERS OF THE CUSTOMER. THE CUSTOMER’S SOLE

REMEDY FOR ANY BREACH OF WARRANTY IS THE REPAIR OR REPLACEMENT, AT MP FILTRI DISCRETION, OF THE FAILED PRODUCT.

MP Filtri Ltd maintains a policy of product improvement and reserves the right to modify the specications without prior notice.

13

Operators Guide

DEH SERIES - 5 METER CABLE INDICATOR Ex ia M20

PROPERTIES

Housing material 316 Stainless steel

Body shape Cylindrical

Connection type M20 x 1.5 - 3 core polyrad cable supplied with 5 metres

Temperature range -60 °C to +125 °C

Contact type SPCO/SPDT (Hermetically sealed - volt free contacts)

Contact material Rhodium (tungsten optional)

Dimensions 114 x 28mm

Ingress Protection IP 66/67/68

3.Technical Specication

3.1 General specication

Type of indicator Electrical Switch

Weight 5m Cable model: 750g (approx)

M12 Short model: 270g (approx)

Seal material Various

Temperature range See Section 3.5 -20 °C to + 100 °C (T4)

Pressure setting 5 bar and 7 bar

ELECTRICAL RATINGS

Ui 30V

Li 250mA

Pi 1.3W

14

Operators Guide

TECHNICAL SPECIFICATION

DEH SERIES - 5 METER CABLE INDICATOR Ex d 1/2” NPT / UL Class I Div 1

PROPERTIES

Housing material 316 Stainless steel

Body shape Cylindrical

Connection type 1/2” NPT - 3 core polyrad cable supplied with 5 metres

Temperature range -60 °C to +120 °C - ATEC, IECEx, TRCU, INMETRO

-60 °C to +105 °C - UL/CSA

Contact type SPCO/SPDT (Hermetically sealed - volt free contacts)

Contact material Rhodium (tungsten optional)

Dimensions 114 x 28mm

Ingress Protection IP 66/67/68

DEH SERIES - M12 INDICATOR Ex ia RESIN SWITCH

PROPERTIES

Housing material 316 Stainless steel with internal engineered resin switch

Body shape Cylindrical

Connection type 4 pole male M12 connector - plastic

Temperature range -20 °C to +80 °C

Contact type SPCO/SPDT (Hermetically sealed - volt free contacts)

Contact material Rhodium

Dimensions 90 x 28mm

Ingress Protection IP 66/67

ELECTRICAL RATINGS

Supply Voltage 24 VDC - 110 VAC

Maximum switching current 830mA - 180mA

Maximum voltage 150V AC/DC

Power Watts 20W VA

ELECTRICAL RATINGS

Ui 30V

Li 250mA

Pi 650mW

15

Operators Guide

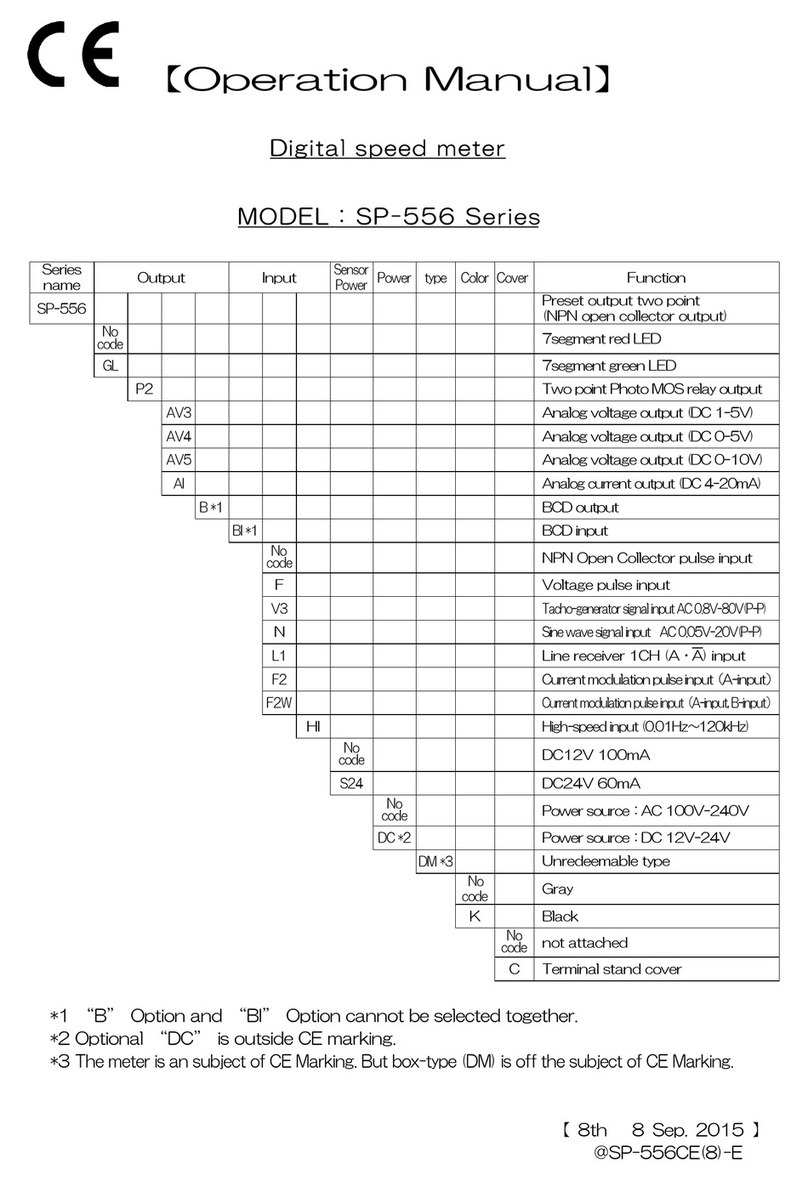

DIFFERENTIAL CLOGGING INDICATOR - DEH

Series

DE

Fluid Compatibility (*)

Keypad / Display

Execution

Connection

A

P01

48

No Thermostat

MP Filtri Standard

M20 Ex ia

(*) Other options available on request

Certication included as standard

Pressure Setting (*)

50

49

F

70

70

V

5 bar

1/2” NPT Ex d

MFQ - Fluorosilicone

7 bar

M12 Ex ia

FPM - Viton®

Conguration example:

DE A50H F P0170

Pressure Rating

H420 bar (6,091 PSI)

DEH SERIES - 5 METER

CABLE INDICATOR

Ex ia M20

DEH SERIES - 5 METER

CABLE INDICATOR

Ex d 1/2” NPT

DEH SERIES - 5 METER

CABLE M12 INDICATOR

Ex ia RESIN SWITCH

M20 x 1.5

A/F 25 mm

Max tightening

torque: 50 N∙m

28

114

87.5

1/2” NPT

A/F 25 mm

Max tightening

torque: 50 N∙m

28

114

87.5

A/F 25 mm

Max tightening

torque: 50 N∙m

28 mm O.D.

M12

90

26.5 42.5

3.2 Dimensions

3.3 Designation & Ordering code

16

Operators Guide

TECHNICAL SPECIFICATION

3.4 Wiring diagrams

Wiring instructions are available in section 4.3

3.5 Temperature Range

The maximum permissible operating temperature of the indicator is: T6 = 70°C for Exd. 80°C for Exia.

T4 = 120°C for Exd, 125°C for Exia, 100°C for UL. If MFQ seals are used on the indicator, the lower temperature threshold

can be dropped to -40ºC. Surface temperature and/or general heat rise will mainly be generated by the uid temperature

or ambient temperature, as the indicator itself produces minimal heat. Due to this the uid temperature must not be

allowed to exceed these temperature ranges. T6 = 70°C for Exd, 80°C for Exia

T4 = 120°C for Exd, 125°C for Exia

100°C for UL

17

Operators Guide

4. Product Installation and Maintenance Instructions

USER INSTRUCTIONS FOR DEH ELECTRICAL INDICATORS

4.1 Correct Usage

The electrical indicator is specically designed for use with MP Filtri hydraulic pressure and in line lters, the indicator

monitors differential pressure across the lter element. The indicators are made up of a certicated switch assembly in

a type approved enclosure with a pressure connection that acts on a piston and spring assembly to operate a switch, the

movement of this piston is governed by the deferential pressure across the element. The indicators should only ever be

used with in the parameters detailed in this manual, the indicator should match or be greater than the system operating

pressure.

4.2 Installation Instructions

Warning - Prior to installation the lter must be depressurised.

1. Identify the pressure rating that is etched on to the body of the indicator.

2. Ensure that the maximum system working pressure does not exceed that of the indicator operating pressure.

3. Static build up may cause sparks between the components therefore it is crucial that the connections (pipes/hoses) are

earthed separately and connected to the lter housing using electrostatic dissipative components only.

4. Before removing the indicator, to prevent a potentially hazardous situation, the depressurised system and lter must not

be subject to potentially volatile atmospheres in the form of gases vapors or mist present.

5. Ensure that the seals and connecting threads are free from debris / contamination and that they are in a good working

condition. Clean or replace seals that are defective or contaminated.

6. Inspect the lter housing and indicator thread for any signs of damage or contamination prior to installation, any signs

of damage should be rectied prior to assembly.

7. Wetting the seals of the indicator with the system uid will not only help the installation of the indicator into the cavity

but it will also help reduce the risk of seal damage during the assembly process.

8. To prevent damage to the lter body or indicator housing threads ensure that the indicator screws freely into the housing

by hand, Only once the indicator is seated should a spanner be used to achieve the nal installation torque.

Indicator Pressure Rating Torque Rating

420 bar 100 N∙m+10 N∙m

18

Operators Guide

Table of contents

Other MPFiltri Measuring Instrument manuals