MPS M.C. Rexx QD2000 Series Guide

Uncontrolled Copy - Publication # : INST1144 Rev. 4

Use Care and Service Parts Manual

Bed Model:QD2000_series

QD2250_series

www.mchealthcare.com

beds@mchealthcare.com

M. C. Rexx - Low Bed

Instruction manual

Visit our Web site:

Email us:

WARNING!

To avoid injury, you must read this

manual before using bed.

Table of Contents

Important Safety Precautions .................... 2

Product Specifications ................................. 6

Unpacking and Assembly ............................ 8

Operating Instructions................................... 13

Maintenance..................................................... 18

Troubleshooting Tips ...................................................... 20

Warranty Claims ............................................ 22

Parts Order Form .........................................

Replacement Parts ..................................................

23

24

Warranty .............................................................................. 54

M.C. HEALTHCARE PRODUCTS

a division of Span Medical Products

Canada Inc.

4658 Ontario St.

Beamsville, Ontario

Canada L0R 1B4

Tel: 1 800 268 8671

Fax: 1 905 563 8680

800.779.2660

2

IMPORTANT SAFETY PRECAUTIONS -

Read all instructions before using Bed.

T

he International Electrotechnical Commission (IEC) requires use of icons to improve

readability and increase understanding of the content. The text uses uppercase signal

words "CAUTION", "WARNING" or "DANGER". Iconic symbols are used to permit easier

comprehension.

Classifications and Icons

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

Icons and Symbols used on the

M. C. Rexx - series

Bed

WARNING! Symbol is used to identify situations or actions that may cause severe

injury or death to you or to other persons.

TYPE B APPLIED PART

ALTERNATING CURRENT

FUNCTION LOCK

IP54 ENCLOSURE PROTECTION TYPE - Limited protection against dust and splashed water.

IPX4 ENCLOSURE PROTECTION TYPE - Protection against water sprayed from all directions.

FUNCTION UNLOCKED

SAFE WORKING LOAD

(Note: include the weight of Resident, Head and Foot Panels, Mattress siderails and accessories.)

BED ELEVATION

HEAD DECK ELEVATION

KNEE DECK ELEVATION

UP

DOWN

CSA listing mark with "C" and "US" indicating that the product to which the mark is attached

is certified to the applicable U.S. and Canadian standards.

CAUTION!

Care must be made to ensure that the resident does not fall-on or slide-over the

mattress side stops which may cause injury.

WARNING!

For your safety, the information in this manual must be followed to

minimize the risk of electric shock, fire, or to prevent property damage, personal injury, or

loss of life.

WARNING!

Make sure the bed is in the lowest position when the patient is left

unattended. This can reduce the severity of any injuries resulting from patient falls.

WARNING!

Except for when the bed is being moved, the brakes should always be set

(locked). After applying the brakes test the motion of the bed to ensure that the brakes are

properly engaged. Patients use the bed for support when getting in or out of bed, and could

be injured if the bed unexpectedly moves.

WARNING! POSSIBLE INJURY OR DEATH.

This bed is intended for use as an

adjustable mattress deck surface. Use of this product in any way other than the intended use,

could result in injury or death.

WARNING!

Patients with diminished mental awareness should not be allowed access to

the pendant, as they may become entangled in the cable. Failure to do so may result in injury

or death.

WARNING!

The Safe Working Load of this bed is 450 lbs (200 Kg) evenly distributed,

which includes the weight of the patient, mattress and any accessories and visitor. Also

jumping, falling or standing on the bed will concentrate the load and may result in property

damage, personal injury or death.

WARNING!

Ensure that no arms, hands, legs or feet are under the mattress decks when

lowering them.

WARNING! POSSIBLE INJURY OR DEATH

Use only the proper size mattress

that will minimize the gap between the side of the mattress and the side rails. The gap must

be small enough to prevent the patient from getting his/her neck caught in this zone (read

the FDA Entrapment Guidelines for further information).

WARNING!

When lowering the bed, ensure that no person, limbs, bedding or any

foreign objects are between the bed frame and the floor. Ensure that Over-bed tables and

patient lifts are safely removed.

WARNING!

POSSIBLE INJURY OR DEATH . The Mattress Stops help control the

Entrapment Zone gaps between the Mattress, Side rails, the Head and Foot Boards. Improper installa-

tion or absence of Mattress Stops could result in entrapment injury or death. Ensure the Mattress fills

the entire width and length of the sleeping deck with the corners of the Mattress snuggly fitted within

the Mattress Stops.

3

IMPORTANT SAFETY PRECAUTIONS - continued

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

4

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

WARNING!

Use of replacement parts or accessories from other manufacturer's will

invalidate the warranty and could damage the bed.

WARNING!

Possible fire hazard when used with Oxygen Administrating Equipment

of other than the Nasal, Mask or 1/2 bed length Tent type. Oxygen Tent should not extend

below the mattress support level. Remove or lock-out hand control when using oxygen

administrating equipment.

WARNING!

The Electric Motors must remain dry. Care must be taken during cleaning

and use to ensure that electrical components remain dry.

WARNING!

Ensure that no damage is made to power cords by rolling the bed over them.

Ensure cords are not frayed or damaged.

WARNING!

Fluid spills on the bed electronics can result in a hazard. In the event of a

spill, immediately:

•

Unplug the bed from the power source and remove it from service.

• Remove the patient from the bed and clean the spill

• Remove the bed from service until the bed is tested and determined to be safe.

Failure to do so may result in personal injury or property damage.

WARNING!

The siderails should always be in the up position when the patient is left

unattended. Test the siderails to ensure that they are properly latched before leaving the

patient.

WARNING!

Only authorized / certified personnel should perform preventative

maintenance. Maintenance by unauthorized personnel could result in property damage or injury.

WARNING!

Follow Manufacturer instructions when installing accessories especially

the Patient Helper Bar, this bar could fall and result in injury or death.

IMPORTANT SAFETY PRECAUTIONS - continued

WARNING!

Improper connection of the equipment grounding conductor can result in

the risk of electrocution. DO NOT modify the plug. The plug must be plugged into a 3-prong

receptacle marked "

Hospital Grade" or "Hospital Only"

. Check with a certified electrician.

WARNING!

Plug the bed directly into a 110-120 VAC 60 Hz properly grounded Hospital

Grade outlet. Avoid use of extension cords at all times.

WARNING!

Listen for unusual sounds and watch out for uneven running. Stop the motor

immediately if anything unusual is observed.

5

IMPORTANT SAFETY PRECAUTIONS - continued

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

The entrapment zones are a resultant of the

dimensional interaction between the bed and

components that are often assembled by the

Healthcare Facility and not the Manufacturer.

The Healthcare Facility is responsible for

compliance with the Entrapment Guidelines by

matching the right components and accessories

to the right bed.

To learn more about the entrapment zones,

assessment methods and guidelines for

compliance with the entrapment regulation visit

the FDA website.

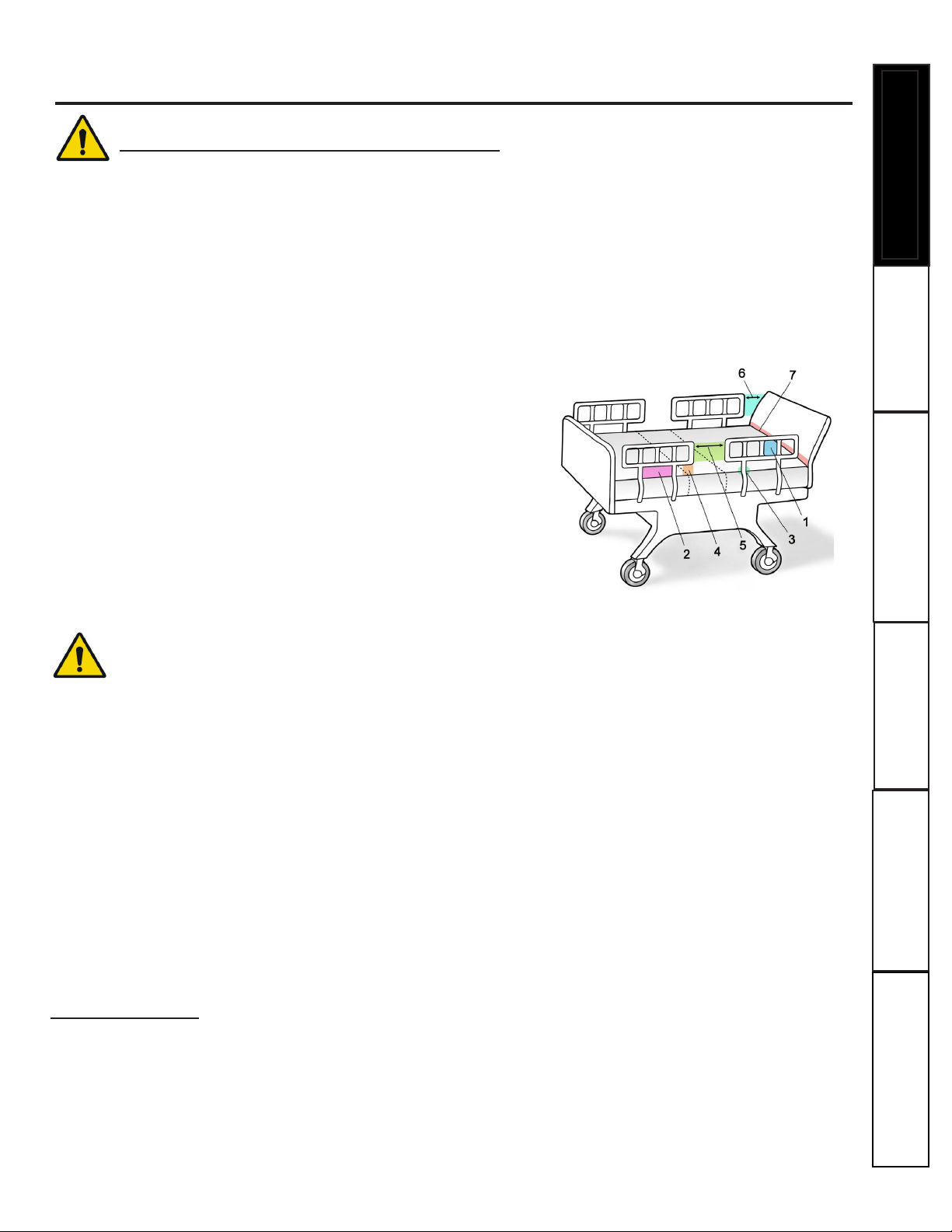

DANGER - RISK OF ENTRAPMENT

The U.S. Food and Drug Administration (FDA) has recently warned against the potential danger of

entrapment and published safety guidelines for hospital beds. The FDA has identified seven zones

in the hospital bed system where there is a potential for patient entrapment. Entrapment may occur

in flat or articulated bed positions, with the rails fully raised or in intermediate positions. The seven

entrapment zones are identified in the drawing below.

ENTRAPMENT ZONES:

Zone 1: Within the Rail

Zone 2: Between the Top of the Compressed Mattress and the

Bottom of the Rail, Between the Rail Supports

Zone 3: Between the Rail and the Mattress

Zone 4: Between the Top of the Compressed Mattress and the

bottom of the Rail, at the End of the Rail

Zone 5: Between the Split Bed Rails

Zone 6: Between the End of the Rail and the Side Edge of the Head

or Foot Board

Zone 7: Between the Head or Foot Board and the Mattress End

MC Healthcare is a member of the FDA's Hospital Bed Safety Workgroup. All beds purchased from MC

Healthcare with mattress, side rails and accessories as a complete system meet the federal entrapment

guidelines at the time of shipping. MC Healthcare is available to work with customers to minimize the

risk of patient entrapment.

COMPLIANCE - Entrapment Safety

DISCLAIMER

The M. C. Rexx - series low beds are intended to be used for resting and sleeping in a long

term care environment. The beds are not to be used as a tool for diagnosis (determining cause of

an illness), treatment (action(s) taken to change the course of an illness) or monitoring (reading

and/or recording physiological parameters).

6

PRODUCT FEATURES AND SPECIFICATIONS

The M. C. Rexx series bed is designed for a safe working load of 450 pounds (226kg). Body weight

should be evenly distributed over the surface of the bed. Do Not lay, sit or lean in such a way that the entire

body weight is placed only on a raised head or foot section of the bed.

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

M. C. Rexx Bed Specification

Height Floor to Mattress Support 7 7/8 – 26" Travel range and 7 7/8 – 28" on Fast bed.

Deck Angles 1. Head elevation 0 - 70 degrees with horizontal.

2. Knee elevation 0 - 20 degrees with horizontal.

Adult Bed Length 1. Overall length 85 1/4" inches with Boards (add 3 1/4" for wall bumpers).

2. Sleep surface 80 inches.

Youth Bed Length 1. Overall length 81 1/4" inches with Boards (add 3 1/4" for wall bumper).

2. Sleep surface 76 inches.

Bed Width Overall width (with side rails) 40 1/2" inches.

Mattress Deck 1. Width 35 inches.

2. Length 76 or 80 inches.

Mattress Support Deck Construction Welded steel angle frame and rod.

Mattress Stops Steel Corner and Side Stops.

Bed End Panels Permanent or removable mounting.

Electrical Safety Certification Certified to:

CAN/CSA STD C22.22 No. 601.1-M90

UL Std No. 60601-1 (2003)

Mechanical Safety Certification Conforms to:

IEC 60601-2-38 Clause 28.4(2)

Classification Class I, Type B.

Voltage/Hertz/Phase

Maximum Input Current Rating

120/60/1.

3.5 Amp (120V).

Cord Type / Length 2 .5 Meters minimum, 3 prong hospital grade plug.

Electric Motors Three (3) DC self lubricating Linear Actuators.

Operation 10% Maximum Duty Cycle (2 minutes on/18 minutes off)

Emergency Power back-up battery Pack. 24 V DC Wall Mounted Battery with Charger.

Protection against splashing water IPX4.

Mass of bed 170 lbs without any accessories.

Safe Working Load

200 Kg = 450 Lbs (includes the Patient, Head/foot Panels,

Mattress Side Rails and accessories).

Mobility At any height (7 7/8 - 26") or (7 7/8 - 28").

Swivel Casters Heavy duty 3”– total locking casters.

7

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

PRODUCT FEATURES AND SPECIFICATIONS- continued

Environment conditions

OPERATING Temperature

Relative Humidity

Atmospheric Pressure

STORAGE Temperature

Relative Humidity

Atmospheric Pressure

10 º C to 40 º C

30 % to 75 %

700 to 1060 hPa

-10 º C to +50 º C

20 % to 90 % @ 30 º C - not condensing

700 to 1060 hPa

Motor Function Controls Six (6) function pendant.

1. Hi/Low Elevation Up and Down keys.

2. Head Deck Up and Down keys.

3. Knee Deck Up and Down keys.

Foot End (Staff) Controller

1. Hi/Low Elevation

2. Head Deck

3. Knee Deck

Optional - Factory or Field Installed.

Individual Lock and Unlock control over all functions. FEC

remembers setting before power outage or removal of

foot-board.

Vascular Foot Deck Ratchets Manual elevation to help aid for cases of edema.

Head End Wall Stand-Off Bumpers. Impact absorption bumpers.

3/4 Length Collapsible Side Rail Model #

RR501

Optional - Field Installed.

Fits 76" and 80" Sleeping Surface Decks.

Head End Assist Rail Model # RAD306 Optional - Fits 76" and 80" Sleeping Surface Decks.

Three Position Assist Rail Model # RM930 Optional - Fits 76" and 80" Sleeping Surface Decks.

Frame Mounted Assist Rail # RM950 Optional - Fits 76" and 80" Sleeping Surface Decks.

I.V. Ports Optional.

Trapeze- patient helper bracket and a

patient helper bar.

Optional.

Bed Extender, Board Extender and Rail

Extenders.

Optional - 6" Foot or Head End.

Mattress Proper sized mattress with special firm borders to

prevent patients from being trapped between the

mattress and rail. Contact your M.C. Healthcare Products

Representative for mattress sizing recommendations.

MANUFACTURER DISCLAIMER Specifications are subject to change without notice, MC Healthcare reserves the right to

continuously improve its products. Illustrations are intended to represent the product and may vary from actual production

models.

200 Kg = 450 lbs.

=

8

Your M. C. Rexx Bed is equipped with three motors to operate each of three functions:

Bed up/down Adjusts the height of the bed from 7-7/8” to 26” or 28".

Head up/down Adjusts the angle of the head deck from 0° to 70°.

Knee up/down Adjusts the angle of the knee deck from 0° to 20°.

This instruction manual covers options and accessories which may not be included on your bed.

Before operating your M. C. Rexx Bed, be sure that you have completely read and understood the

instructions and warnings contained in this manual and included with the accessories.

Unpacking Instructions - (PLEASE RECYCLE)

Your M. C. Rexx bed is shipped in a vertical position with the Head-End on the ground. If it has not been

lowered flat, then two people are required to lower it gently to the ground.

Cut the "shipping ties" securing the deck to the frame. There are also ties securing wiring in place, care must be

taken so that only the "shipping ties" are removed. The "shipping ties" can be identified by the fact that they

have not been trimmed.

Remove one package attached to the frame containing the Mattress Stops, the Roller Bumpers and the Board

Mounting Brackets. Make sure that all parts are included prior to disposing of the packaging material and

immediately report any missing parts to MC Healthcare Customer Service.

Mattress

The M. C. Rexx bed has been designed to minimize the risk of patient entrapment while

maintaining as much patient comfort and protection as possible. All mattresses supplied by M.C.

Healthcare Products work together with the siderails to meet the FDA guidelines at the time of

purchase. If other mattresses are used, it is up to the end user to determine whether their mattress is

suitable for minimizing entrapment risks.

In any case only hospital grade mattresses with firm borders, a minimum of 6" thick by 35" wide by

80" long (76" for a 76" deck) should be used. It is also up to the end user to periodically check the

mattresses to ensure that they maintain their dimensions over time.

Contact your local M.C. Healthcare Products Representative for mattress recommendations.

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

ASSEMBLY INSTRUCTIONS

1

2

3

www.mchealthcare.com

Introduction

WARNING! POSSIBLE INJURY OR DEATH

improper routing of the power cord

could result in injury or death. Ensure that you do not remove any Cable ties that are intended to

keep the power cord away from moving parts.

Power Supply Cord

To keep the power supply cord off the floor when

moving or storing the bed, you need to secure the

cord using the VelcroRStrap as shown.

Secu

re

Cor

d with

the

Ve

lc

ro

Str

ap

9

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

ASSEMBLY INSTRUCTIONS - continued

The optional patient helper consists of a bracket mounted to the frame, and an

arm with an adjustable handle. The arm can be located in three positions by use

of a locking spring pin. There is a side position for assistance entering and exiting

the bed (A), an in-bed position for assistance with repositioning (B), and a storage

position (C). The chain is attached using a “quick link” that allows the height and

position of the handle to be easily adjusted. You must follow the instructions

provided with the Helper.

WARNING!

Ensure that the spring loaded Pull Pin is properly engaged to prevent the Patient

Helper Pole from rotating. Failure to do so could result in serious injury.

Patient Helper - optional

A

PULL PIN

B

C

Bed Extender - optional

The bed extender is designed to be attached at the foot or at the head end of

the bed. The extender attaches directly to the foot or the head deck. If a foot

or head board is to be used with the extender, then a set of board extender

brackets are required to offset the foot or head board, and allow clearance for

the extender. The mattress pad extends the actual sleep surface.

To meet FDA Entrapment Guidelines a Side Rail Extender must be used on

beds equipped with 1/2 Length Side-Rails.

WARNING! POSSIBLE INJURY OR DEATH

Use only the proper size mattress and

extension pads in order to minimize the Entrapment Zone gaps. The gaps must be small enough to

prevent the patient from getting his/her neck caught in this location (you must read and follow the

FDA Entrapment Guidelines).

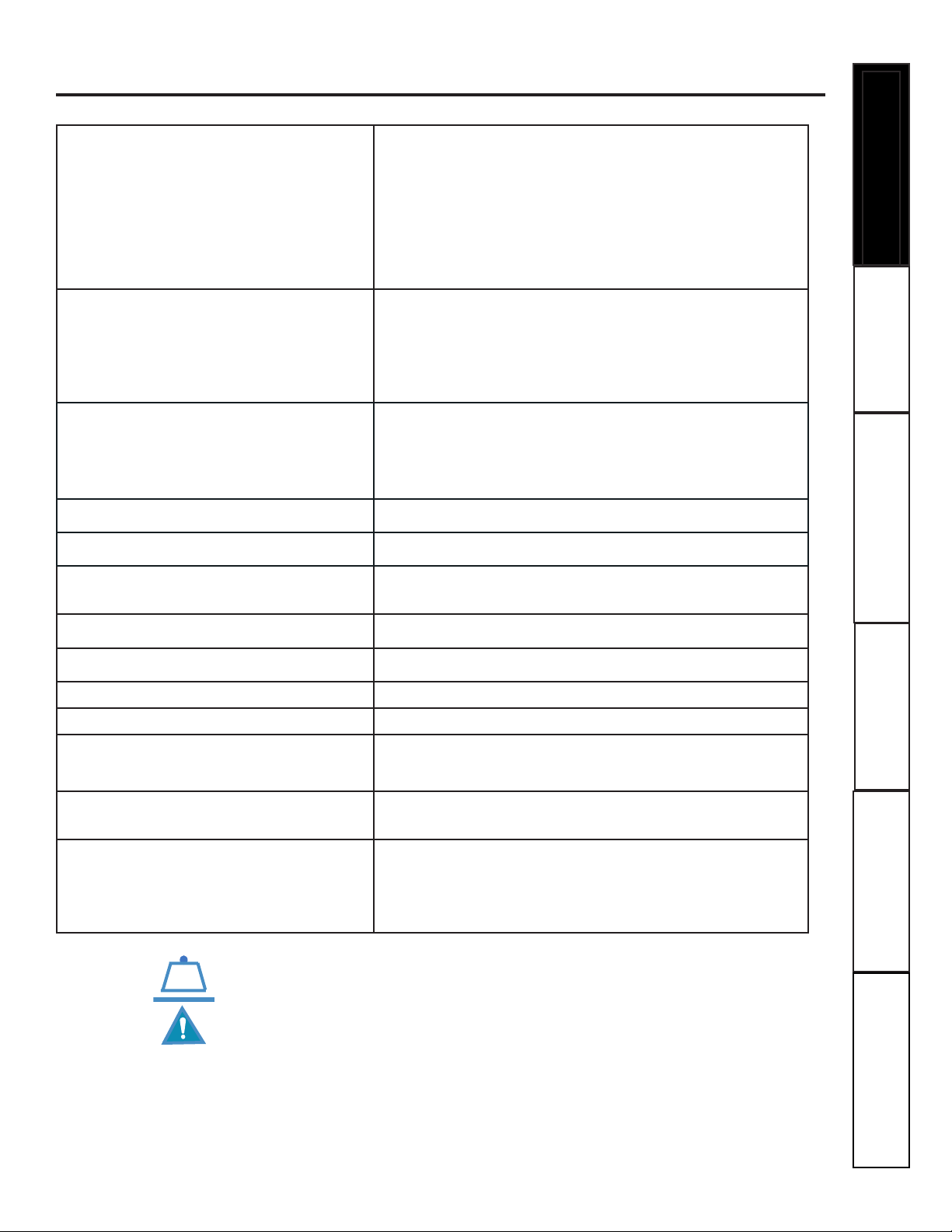

Mattress Stops Installation

Tools Required: 5/16 and 3/8” wrenches.

Parts Included:

Item # Qty Part Number Description

1 4 QS3484 CORNER MATTRESS STOP

2 8 QP2501 MACHINE SCREW #10-32 X 5/8” HEX HEAD ZP

3 8 QP2502 NUT 10-32 HEX NYLOCK ZP

1- Raise the bed to make the installation easier.

2- Place one Mattress Stop (1) in one corner overlapping the pre-punched holes; as illustrated.

3- Place one Screw (2) through one of the holes and thread a Nut (3) onto the screw behind the deck frame.

Tighten Nut finger tight . Repeat for the other hole.

4- Tighten the screws with a 5/16" Wrench while using a 3/8”Wrench to prevent the nut from spinning.

5- Repeat for the other 3 corners of the bed.

6- Tighten all screws.

Procedure:

2

3

1

10

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

ASSEMBLY INSTRUCTIONS - continued

www.mchealthcare.com

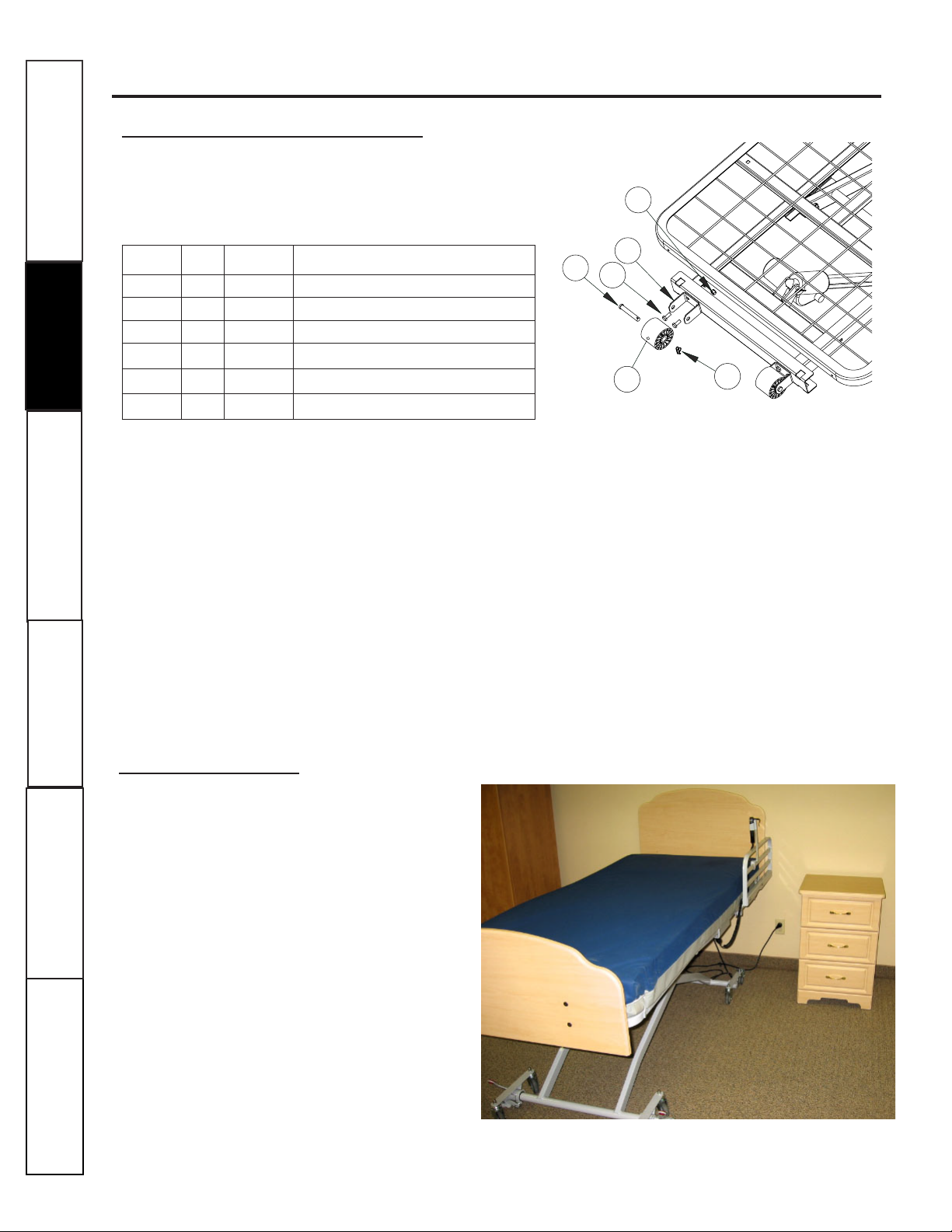

Bed Installation

The M. C. Rexx bed is approved for

operation in a dry environment. To operate

the bed, plug the Power Cord running from

the patient left hand side of the frame into

a three prong 110 V hospital grade wall

receptacle. The Hand Pendant is already

plugged into the controller and the bed

should now be operational.

Roller Bumper Installation

Tools Required:

Ratchet wrench with ½” socket- ½” wrench

Parts (included):

Item # Qty Part # Description

1 4 1850 BOLT HEX 5/16-18 X 3/4"

2 2 QP-1550 CLEVIS PIN 7/16 X 2-3/4"

3 2 QP-2041 URETHANE ROLLER

4 2 QS-3560 ROLLER BUMPER BRACKET

5 2 QP-1748 COTTER RING RUE 1/2"

6 4 1854 LOCKNUT 5/16 - 18

Procedure:

Step 1 - Mount Roller bracket (4) on the head end of the bed frame as shown, using two hex head

bolts (1) and lock nuts (6). Repeat for other side.

Step 2 - Hold roller (3) inside the opening of the bracket, and insert clevis pin (2) through both of

the holes in the bracket and the center of the roller to hold it in place.

Step 3 - Insert the cotter ring (5) in the small hole in the end of the clevis pin.

Step 4 - Repeat for the opposite side.

4

2

35

1

6

11

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

Head and Foot Board Mounting Bracket Installation

Tools Required: two 5/32" Hex-Allen-Keys.

Parts (included):

Item # Qty Part # Description

1 4 QP-2432 Board Mounting Bracket

2 8 QP-2431 NUT JCN 1/4-20- 17mm Long

3 8 QP-2433 Screw 1/4-20 x 5/8 Flat Head Hex Drive Zn

Procedure:

HEAD BOARD

Install two Board Mounting Brackets (1) with four Screws

(3) and four Nuts (2) as illustrated. Do not tighten until after

inserting the mounting brackets in the bed frame posts- (see

next page).

FOOT BOARD

Install two Board Mounting Brackets (1) with four Screws (3) and

four Nuts (2) as illustrated. Do not tighten until after inserting the

mounting brackets in the bed frame posts - (see next page).

1

23

HEAD BOARD

23

1

FOOT BOARD

ASSEMBLY INSTRUCTIONS - continued

Bed Components

EMERGENCY BATTERY

EXTENSION CORD SOCKET

BACK-UP PORT

24V BATTERY

HEAD MOTOR

TOTAL FLOOR

LOCK

FOOT MOTOR

CONTROL BOX

END

OF BED

HEAD

POWER CORD

FOOT END CONTROLLER

(FEC) PLUGS

STRAIN RELIEF

POWER CORD

HAND PENDANT

Hi-Lo MOTOR

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

12

Assembly

ASSEMBLY INSTRUCTIONS - continued

Insert the Head and Foot Boards as illustrated with the proper

Mounting Bracket orientation.

After the Boards are in place, tighten the eight Screws and JCN

Nuts that were left untightened from the previous step.

Attach a # 6 Screw and Nut through each hole in the bottom of

the Foot Board Mounting Brackets to prevent the Foot Board

from being removed accidentally.

Secure the Head Board to the bed frame by installing a Lynch

Pin through the hole in the bottom of each Head Board

Mounting Bracket to prevent the Head Board from being

accidentally removed.

1

2

Head and Foot Board Installation

www.mchealthcare.com

WARNING!

Entrapment Safety:

Use only the proper

size boards and mattress to minimize the Entrapment

Zone gaps. The gaps must be small enough to prevent the

patient from getting his/her neck caught in this location

(you must read the FDA Entrapment Guidelines ).

The entrapment zones are a resultant of the dimensional

interaction between the bed and components that are

often assembled by the Healthcare Facility and not the

Manufacturer.

The Healthcare Facility is responsible for compliance

with the Entrapment Guidelines by matching the right

components and accessories to the right bed.

3

WARNING!

To prevent fingers from getting caught

between the sleeping surface and the foot and head ends of

the bed, the Head and Foot Boards should remain attached

to the bed frame at all times.

4

HEAD BOARD

FOOT BOARD

FOOT BOARD

Maintenance

Operating Instructions

Safety Instructions

Assembly

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

OPERATING INSTRUCTIONS

WARNING!

The siderails should always be in the up position when the patient is left

unattended. Test the siderails to ensure that they are properly latched before leaving the patient.

WARNING!

Always evaluate patients for and guard against patient risk of side rail entrapment

in accordance with medical protocols. Failure to do so could result in injury and/or death.

WARNING!

The siderail pads must be removed prior to operating siderails. Failure to do so

could result in injury.

Customer

Support

Siderails -

All Siderails are optional.

¾ Length Siderails

Lifting the siderail up completely will latch it into the upright position.

To lower the rail, you must pull the large knob which is located at the

foot end of the siderail before lowering. The ¾ rail swings towards the

head of the bed.

Three Position Pivoting Assist Rail

The optional Pivot Assist will latch in three upright

positions. To rotate the Pivot Assist you must press

the release button located at the base of the rail

- you must follow the instructions included with

the rail.

WARNING!

Test the Assist Rail to ensure that it is properly latched before leaving the patient.

WARNING!

To prevent fingers from getting caught

between the rails:

Fixed Assist Rail

The optional Assist Rail fits on the left or the right

hand of bed - you must follow the instructions

included with the rail.

Pull the large knob to lower the side rail to its first position.

Keeping fingers clear from between the rails, pull the small knob to

take the rail to its lowest position. Failure to do so could result in injury.

1.

2.

Safe Hand Position

LARGE KNOB

13

1

2

3

Three Position

Assist Rail

Assist Rail

14

OPERATING INSTRUCTIONS

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

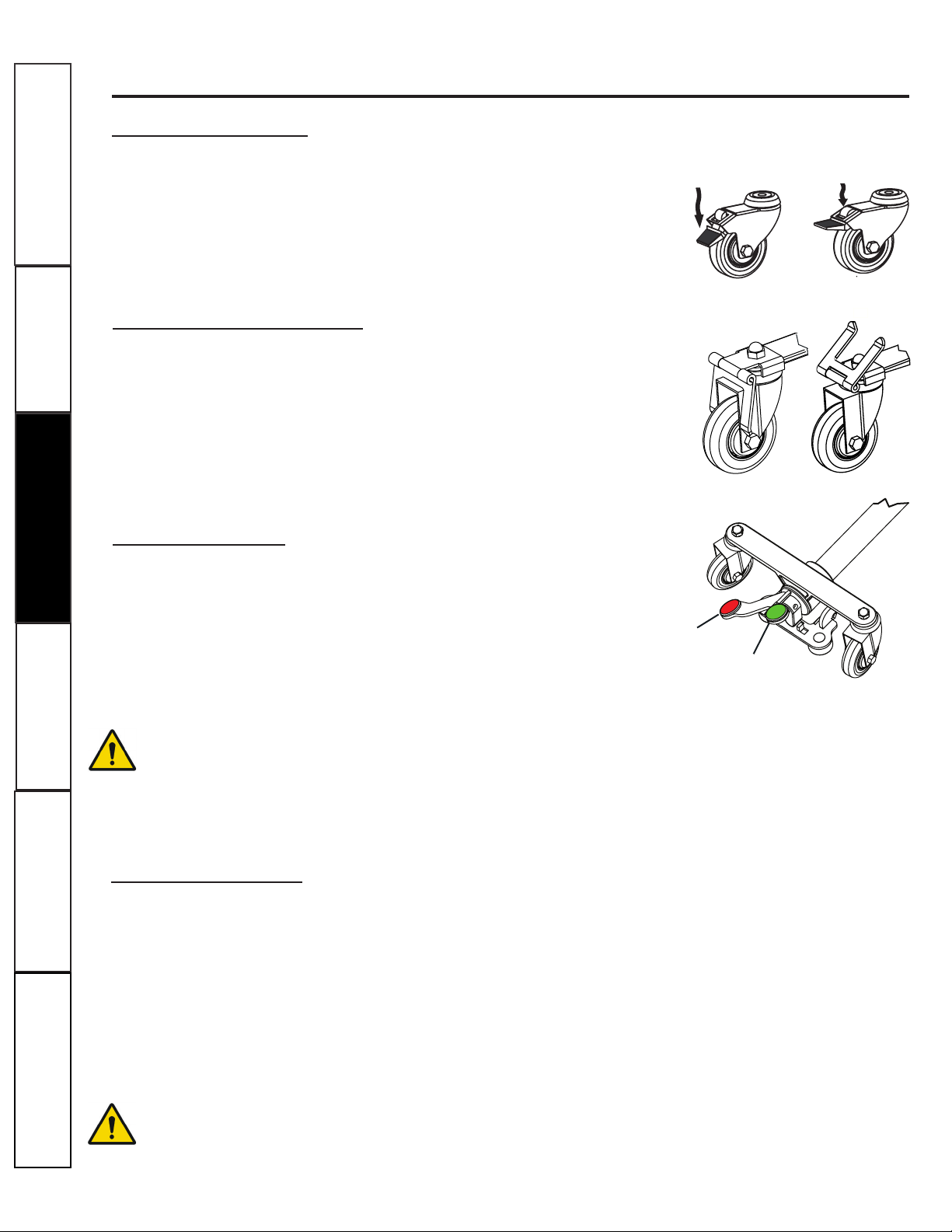

To engage the total lock casters, simply press down on the locking tab with

your toe on all four casters. This will prevent any movement of the caster

(rolling or swiveling). The rubber wheel gives good traction on most floor

surfaces.

To release the casters and allow mobility of the bed, press down on the

release lever to unlock each caster.

Total Lock Casters

LOCKED CASTER UNLOCKED CASTER

WARNING!

When the bed is not being moved, the casters should always be locked. After

applying the brakes test the motion of the bed to ensure that the brakes are properly engaged.

Patients tend to use the bed for support when getting in or out of bed, and could be injured if the

bed unexpectedly moves sideways.

www.mchealthcare.com

Transporting Bed

The M. C. Rexx bed is designed for mobility at any height. Use the Foot Board to move the bed. Never use

Side Rails, Assist Rails or other accessories to move the bed.

To prevent any damage or injury, it is recommended that two Personnel be present when moving a bed.

1 The Power Cord is unplugged and the cord is safely stored off the floor .

2 All the head and foot brakes are released.

3 All accessories used on the bed are secured or removed.

Before moving the bed you should check all around the perimeter of the bed to ensure that no accessories will fall or

get damaged and that:

WARNING!

Do not roll the bed over high thresholds with the patient in the bed.

Directional Lock Hinge

Patients tend to use the bed for support when getting in or out of bed.

Patients could be injured if the bed moves sideways, to guard against

this risk you must engage the "Directional Lock Hinges". Simply flip the

U-shaped tab down with your toe over both casters. This will prevent

any lateral movement (swiveling) of the caster. To release the casters and

allow full mobility of the bed, gently flip the U-shaped tab over the square

leg tube for each caster.

The Total Floor Lock is engaged by simply stepping with the ball of your

foot on the Red end of the Pedal located on the Foot and/or Head ends

of bed - as illustrated. This will immobilize the Foot and/or Head ends of

the bed.

To make the bed mobile again, unlock the Total Floor Lock by stepping

on the green end of the Pedal.

Total Floor Lock

LOCKED

UNLOCKED

RED

LOCKED POSITION

GREEN

15

Customer

Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

OPERATING INSTRUCTIONS

Bed Controls

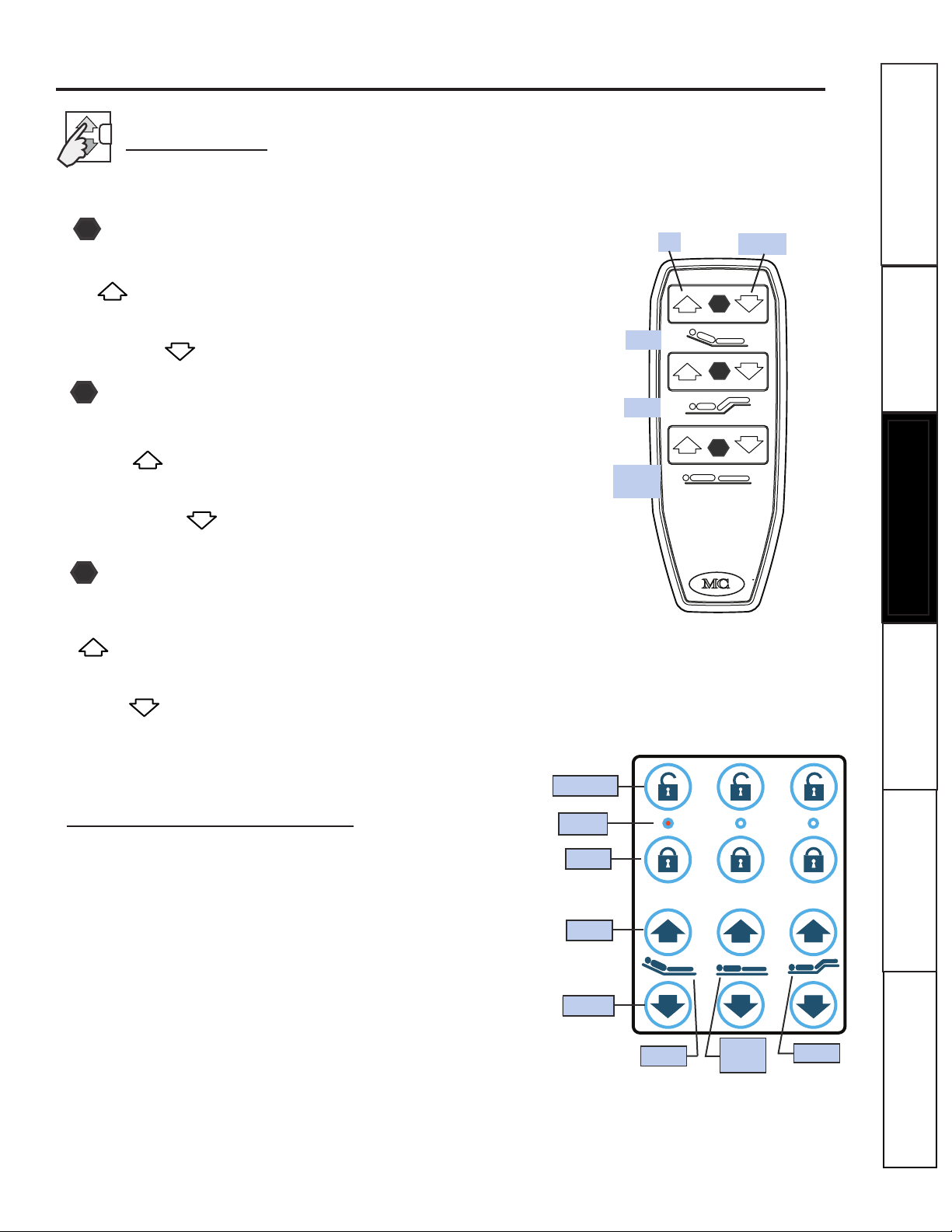

The M. C. Rexx Bed is electrically operated using Hand Pendant Controls as follows:

To gently raise the patient's Head, press and hold the top Head

UP button on the pendant.

To gently lower the patients Head, press and hold the top

Head DOWN button on the pendant.

Head Deck Operation

1

Knee Deck Operation

2

To gently raise the patient's Knees and Feet, press and hold the

Foot UP button on the pendant.

To gently lower the patient's Knees and Feet, press and hold

the Foot DOWN button on the pendant.

Bed Deck Hi/Lo Elevation

3

To gently raise the Bed, press and hold the bottom Bed UP

button on the pendant.

To gently lower the Bed, press and hold the bottom Bed

DOWN button on the pendant.

1

UP

DOWN

HEAD

2

KNEE

BED

Hi/Lo

3

The FEC (Staff) Controller mounts flush on the Foot-Board

and allows the caregiver to operate the bed or to lockout the

bed functions so that they cannot be operated with the hand

pendant. The FEC remembers the last setting before the foot-

board is removed or before an electrical power outage.

Foot End (Staff) Controller

- The LED light turns ON to indicate a LOCKED function.

- The LED Light flickers when a bed function is being operated.

NOTES:

BED

Hi/Lo

HEAD KNEE

LED

LOCK

UNLOCK

UP

DOWN

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

16

OPERATING INSTRUCTIONS

www.mchealthcare.com

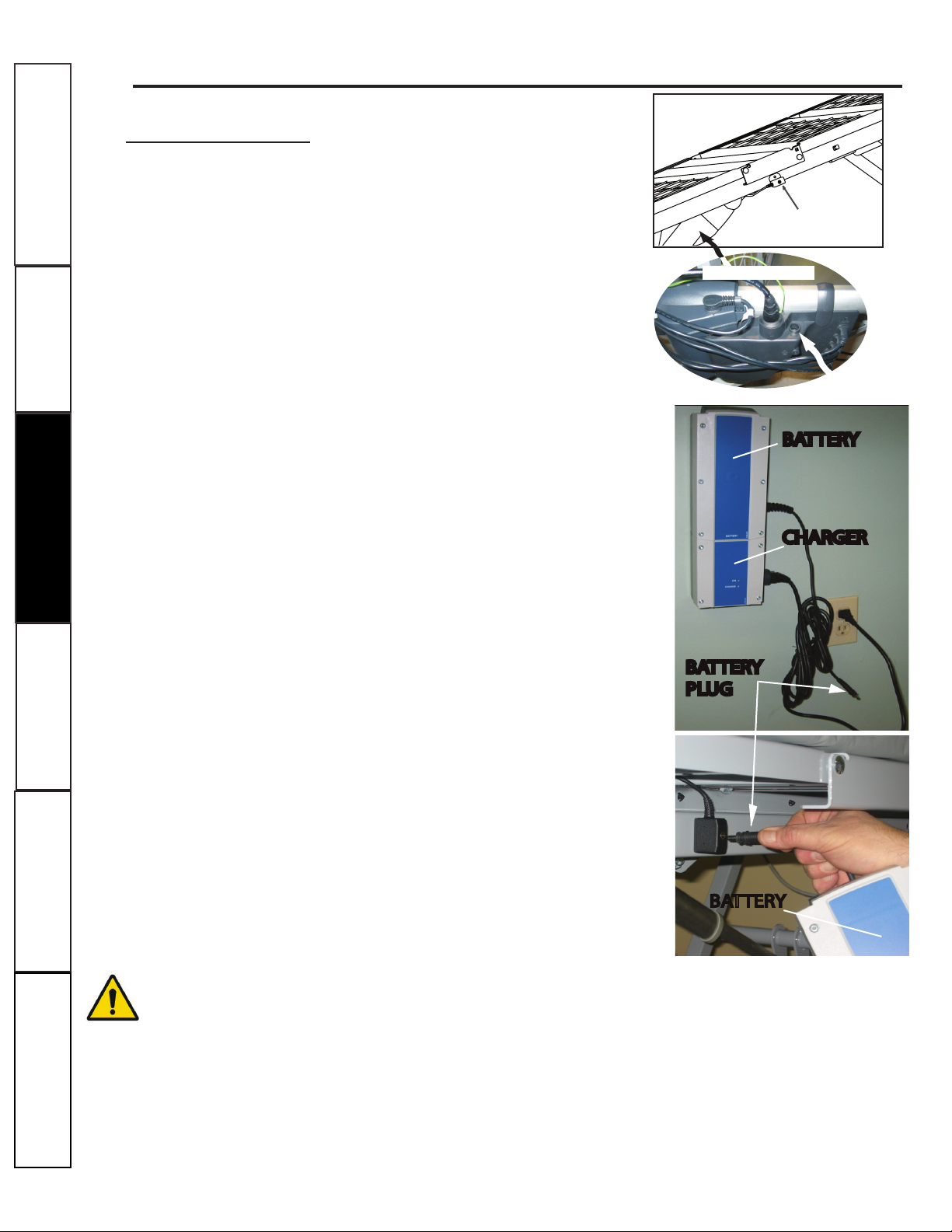

The Back-up Battery Model # Q6598L is for use when there is a

power outage, or the bed needs to be operated where there is no

power source nearby.

A fully charged battery may operate up to 30 beds on one charge.

An optional Back-up Battery Extension Cord is available that allows

easy access to the battery port on the Controller. The Extension

Cord Socket is mounted under the seat deck on the side of the bed.

Plug the Charger into a 110 V socket and insert the Battery in

the Charger - keep the battery charger plugged in when not in

use to maintain a full charge.

Back-up Battery Usage

*To use the Back-Up Battery, remove the battery from the char-

ger, and take it to the bed(s).

*If there is a Battery Extension Cord on the side of the bed, plug

the battery plug into the Socket, and operate the bed nor-

mally.

*If there is no Extension Cord, connect the battery plug into the

Back-up Battery Port on the side of the Controller box, and use

the bed normally.

*When complete, return the Back-up Battery to it’s original

location, and insert it back in the charger.

IMPORTANT!

Depending on the location of the beds within the Healthcare Facility, it is

recommended that at least one Battery-Pack is needed for 1-5 beds with an additional Battery-Pack

for each additional 5 beds. Depending on the layout of the Healthcare Facility more or less Battery-

Packs might be needed. The Healthcare Facility is responsible for matching the number of Batteries

to the number of beds in compliance with Medical Protocols, Agency and Regulatory guidelines.

Back-up Battery

CHARGER

BATTERY

BATTERY

PLUG

BATTERY

Battery Extension Cord

Socket under Seat Deck

24V DC BACK-UP

BATTERY PORT

CONTROL BOX

17

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

MAINTENANCE

WARNING!

The Actuator must be used and maintained

correctly and not exposed to violent treatment or tampered

with. If any irregularities are observed, the Actuator must be

replaced immediately.

Cleaning

The M.C. Rexx bed can be cleaned with warm water and a mild detergent or diluted disinfectant.

Use a damp cloth or a sponge to clean all exposed surfaces of the bed. Take care not to use excessive

water around the control panels and the control box.

WARNING!

The M.C. Rexx bed was not designed to be cleaned using a high

pressure wash tunnel. Never spray directly on to the actuator with a high pressure cleaner.

Preventative Maintenance

There are a number of maintenance items that should be reviewed every 6 months to ensure proper functioning

of the bed.

LUBRICATION

– All pivot and rotating joints should be lightly oiled with a penetrating lubricant containing

an extreme pressure additive (e.g. Castle Iron Man). A lithium based grease is not a suitable alternative for this

application. No lubrication is required on the motor itself, but the clevis pins may be lubricated if required.

Remove any excess oil/grease after application with a cloth.

MOTOR OPERATION– The motors should run smoothly and quietly throughout their range.

Normal operation over full range - The bed should move evenly through its full range of motion from low to high

position and from flat to contoured with no jerking or twisting.

GRINDING, POPPING, OTHER NOISES – The bed should be fairly silent. Some motor/gear noise is

normal and some settling noises are expected, but nothing loud and no squeaking. Look for abnormal wear,

lubricate any joints exhibiting noise.

ACTUATOR SYSTEM - The Actuator must be maintained correctly and not tampered with.

1- The Actuator must be cleaned at regular intervals to remove dust and dirt and inspected for

mechanical damages or wear.

2- Inspect all attachment points, wires, piston rod, cabinet, and plug as well as check that the

actuator functions correctly.

3- The actuator is a closed unit and requires no internal maintenance.

4- To ensure that the pregreased inner tube remains lubricated the actuator must only be washed

down when the piston rod is fully retracted.

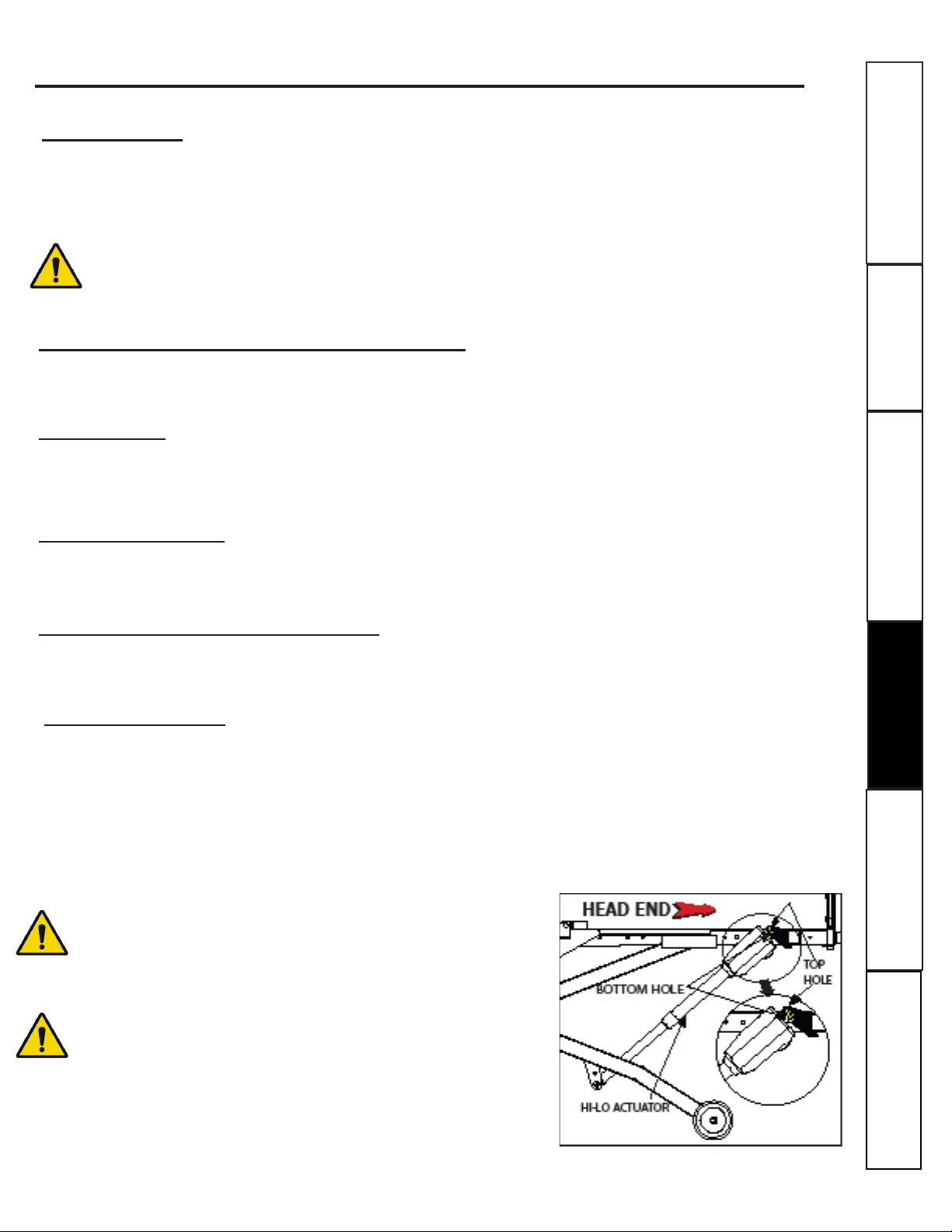

IMPORTANT! PROPER INSTALLATION OF

ACTUATOR

When replacing the Hi-Lo Actuator on this bed

you must ensure that the Actuator orientation is correct and

that the actuator is installed using the bottom hole for QD2250

or top hole for QD2000 on the clevis plates located on the head

end of bed frame. Failure to do so might result in property

damage or injury.

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

18

Assembly

MAINTENANCE

www.mchealthcare.com

FASTENERS – Ensure that all fasteners are tightened and seated completely. Do not over-tighten the

fasteners at the pivot points of the Decks.

CABLING Inspect the cabling on the bed to ensure that it is all still in place with no drooping or loose

wires, and that it is not interfering with any moving parts. Check for any cut, nicked or crushed wiring.

Reattach any loose wires, and repair or replace any damaged wires.

POWER CORD – Inspect the power cord for nicks or crushed insulation. Replace if damaged with original

manufacturer parts only.

CASTER LOCKING – Check to ensure that the casters swivel and roll freely when unlocked, and do not

swivel or roll when the lock is engaged. Tighten, repair or replace if damaged, loose or not working properly.

Note: a torque of 25-30 lb-ft (300-360 in-lb) should be applied on the 3/8" Caster.

SIDERAILS – Check the action of the siderails. The rails should move freely through their range, latch fully

when raised, and not be excessively “wobbly” when raised.

HEAD & FOOTBOARD PANELS – Inspect the wood panels for nicks, scratches and missing edging. Seal any

damage that penetrates through to the wood to prevent possible water damage.

PAINT FINISH – Check the bed for any loose, missing, peeled, scraped off or flaked paint. Touch up as

required.

OVERALL APPEARANCE – Inspect the bed generally. Visually inspect welds on the bed and accessories

and look at any bent or cracked components. Document any concern and remove the bed from service

immediately until the affected parts are replaced or the corrective action is taken.

WARNING!

Damage to the cotter pins may occur when the bed is in its lowest position

and removing patients using a patient lift and/or cleaning areas under the bed.

NOTE: The low end of the Hi-Lo Actuator must have an "Extended Prong Style Cotter Pin". The "Rue"

type pin is used on all other Clevis Pins.

RETAINING RINGS – All clevis pins must have retaining rings present. Replace any missing rings. All

"Rue" type pins should be manually locked and visually inspected on a regular basis, as illustrated below.

19

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

MAINTENANCE

Preventative Maintenance Inspection Chart

The bed must be inspected at least once a year by qualified technicians.

This chart is included to document these inspections and will help support any future warranty

claims if required.

Parts that are found to be worn or defective should be replaced with new parts from MC

Healthcare. To identify replacement and spare parts please refer to the exploded parts diagrams in

the Service Manual of the bed.

DATE

POWER CORD- NO

FRAYING OR CUTS

BUSHINGS

ACTUATOR

MOTOR OPERATION

NORMAL OPERATION

OVER FULL RANGE

GRINDING POPPING

AND OTHER NOISES

BENT PARTS

CLEVIS PINS AND

FASTENERS

RETAINING RINGS

CABLING NO VISIBLE

WEAR

CASTER LOCKING

SIDE RAIL & LATCHES

HEAD AND FOOT

BOARD PANELS

INSPECT

ALL AROUND

CLEAN DIRT AND

IMPURITIES

PAINT FINISH

INSPECTOR'S

INITIALS

COMMENTS

20

If you are having a problem with your M. C. Rexx bed, please go through this troubleshooting section

to see if your problem can be resolved easily. If you are still having problems, then please call our Parts

and Service Department for assistance at 1-800-268-8671. Do not ship any parts back to M.C. Healthcare

Products without an RMA (Return Material Authorization) number, they will not be accepted, and no credit

will be given.

Customer Support

Maintenance

Operating Instructions

Troubleshooting

Safety Instructions

Assembly

When some, but not all functions work on a bed, it typically indicates that there is a problem with the hand

pendant or one of the motors, but not the Controller.

TROUBLESHOOTING TIPS

PORTS

1 – Foot Motor (Yellow) 2 – Head Motor (Blue)

3 – Hi/Lo Motor (Red) 4 – Spare not used (Red)

H –Hand Pendant (Green)

1

If a nurse lock-out box or Foot End

(Staff) Controller is present, ensure that

it is unlocked. If it is not, then turn the

function switch to the unlock position,

and the function should now work. If this

is not the case, continue with the next

step.

2

Ensure that all of the connectors are firmly

seated, and then check to see if this corrects

the problem.

5

4

3

Try using a different handset, either from

another bed, or a spare. If this resolves the

problem then a replacement handset is

needed.

If the problem persists, try switching the

motor ports. Select a motor that is working,

and plug it into the port that is not working.

If the function works (it may work in

reverse) then the problem is with the motor.

Plug the motor that was not working into a

working port and try it. If the motor works

in this port, then the problem is with the

controller.

Before you call for Service (Always record the Serial Number of the bed)

www.mchealthcare.com

PRoBleM: one MotoR function not woRking

HI-LO MOTOR

24V DCBACKUP

CONTROLLER

120V AC POWER

1

H432

FOOTDECK

MOTOR

BATTERY

HAND PENDANT

GREEN LED

LOCK-OUT BOX OR

FEC CONTROLLER

FEC CABLES

HEADDECK

MOTOR

SPARE

This manual suits for next models

1

Table of contents

Other MPS Medical Equipment manuals