Assembly manual „Manuela_HR“ Nixie-clock

Page 4 from 9

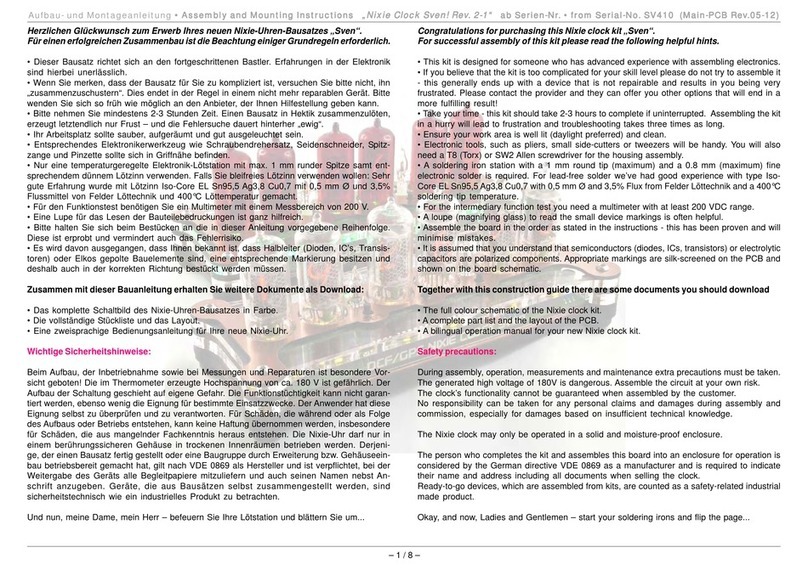

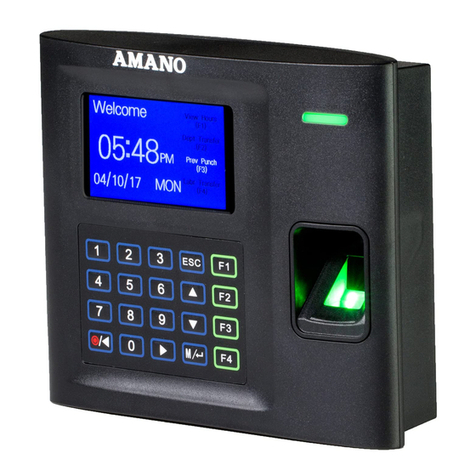

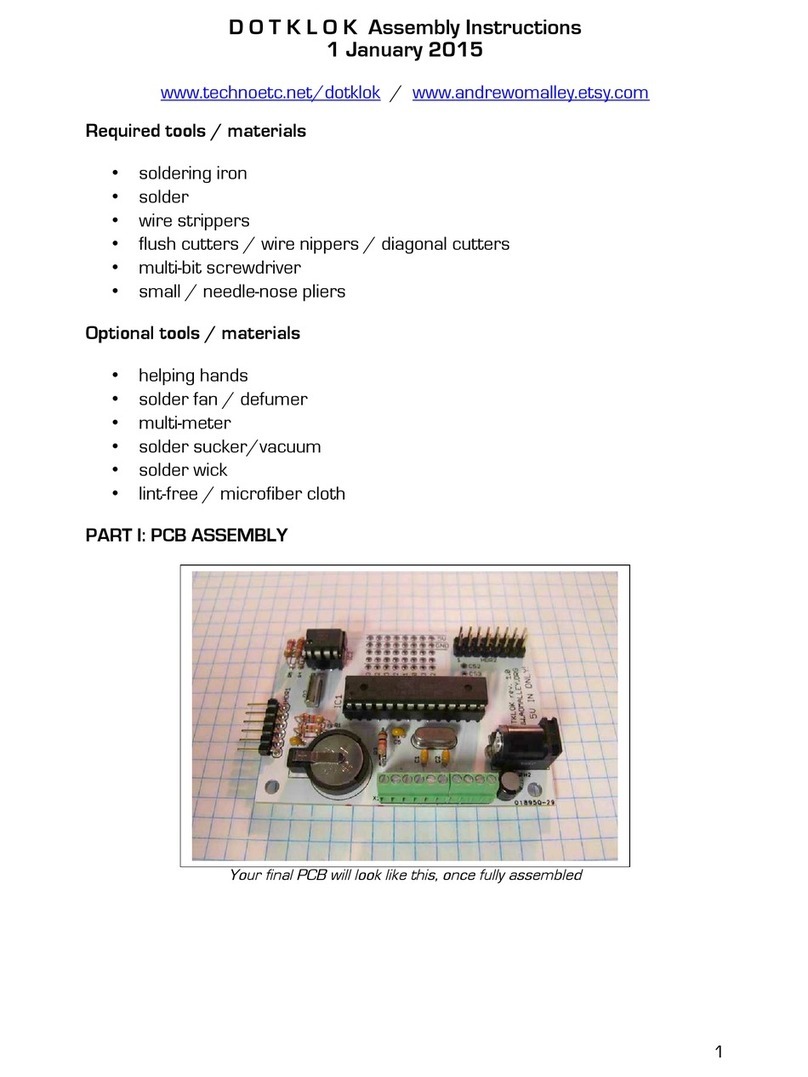

Set your multimeter to voltage measurement and a range of around 20 VDC.

Check the voltage on testpoint “5V” (right picture). It must be in the range of 5.1…5.5VDC.

Now unplug the power supply and turn the pcb over. Remove the provisional wire from the slide switch

and the capacitor pin. Now solder both solder jumpers labelled “5V” together just below the test points.

Turn around the pcb again and fit all remaining transistors and the six 330µF capacitors C1…C6.

When complete, take some time to carefully inspect your work for any solder bridges or component

placement errors.

Now plug in the MC34063A (IC4) voltage converter.

Decoder IC2 and processor IC1 are not fitted at this time!

Set the slide-switch „LED“ to „off“ and connect the DC power supply to the DC jack again.

Caution: Now the step up converter should work and produces around

190 VDC. At this stage be very carefully during handling the circuity!

Check again if the polyfuse R17 does not run hot. Now the LEDs do not light

up anymore. This is not a fault – so don’t panic.

Put your red probe on the measuring point shown on the right picture, it is the

cathode leg of D16. Check the generated high voltage. It should be in the

range of 180...190 VDC.

Check now all voltages on every pin from both multipole integrated circuit

sockets (the decoder IC1 and the processor IC2). The maximum allowed voltage is 5.5V.

If this test is also finished successfully unplug the clock’s circuit from the power supply and fit now the

both remaining integrated circuits IC1 and IC2.

8.: Fitting the tube sockets.

First take a shallow bowl or a similar pot and put into it all sockets from the bag 10.

First pick up the tube. Now slide on all tube pins the socket pins out of your pot.

Tip: First press gently the socket pins on its upper end with your fingers for a good electrical

contact with the tube pins.

Put the tube aside on a safe place when fitted with all the pins.

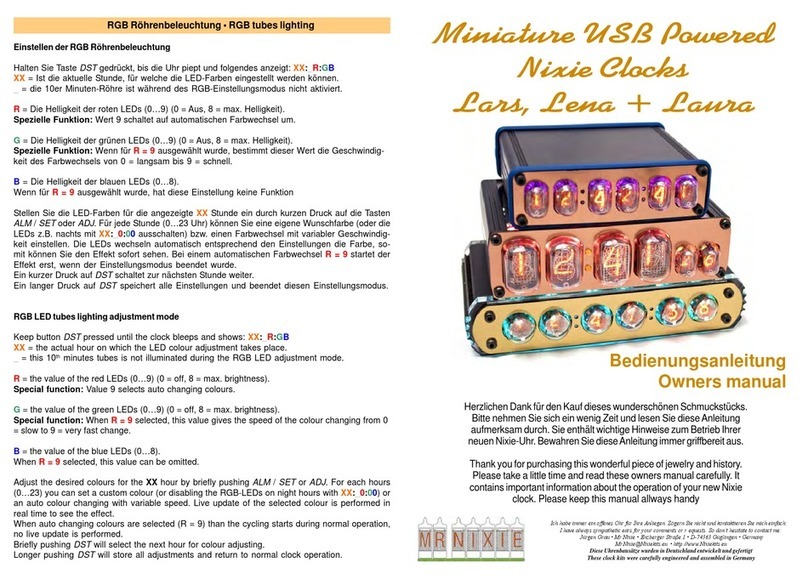

Note: With the IN12 tubes only 11 socket pins (and connections) are used.

The pin to the left of the anode pin is not used on the IN12 types (this is the

non-used decimal point).

Please note also that the PCB has also no pad for this Pin (The anode pin has

a white sleeve internally marked.)

Have a look at the right picture.

On the ZM tubes this 12th pin does not exist and therefore this position is left

blank.

Now fit both tubes on the PCB.

Please pay attention of the direction of the tube. The marked anode pin on the

IN-12 tubes must be orientated to the ring marked solder pad on the PCB.

The tall end of all socket pins will easily slide to the pads’ drill holes on the PCB but for the thicker

part of the socket you need a little sense. Depending on the tube sockets tolerances, one or two

socket pins may need a bit of help by tweezers to fit correct in its drill hole.

Please don’t force the tube together with its sockets into the PCB. You’ll need to have a little patience

for this step. Before soldering adjust the tube correctly.

During soldering use as less solder as possible. The socket pins are hollow. If you use too much

solder, the excess solder might flow into the socket pin which will result in soldering the tube to the

socket pin and the PCB.

9. Fitting of the decimal point LEDs

After soldering the two tubes take the decimal point LED’s and the three

spacers* out from its bag. Thread the LED’s through the spacer* and fit this

“combination” into the PCB. Beware of LED orientation again. Do not solder

these LED’s yet. Only bend the LED leads, also do not cut them at this

stage.

Attention: LED7 is not fitted in the Office enclosure version.