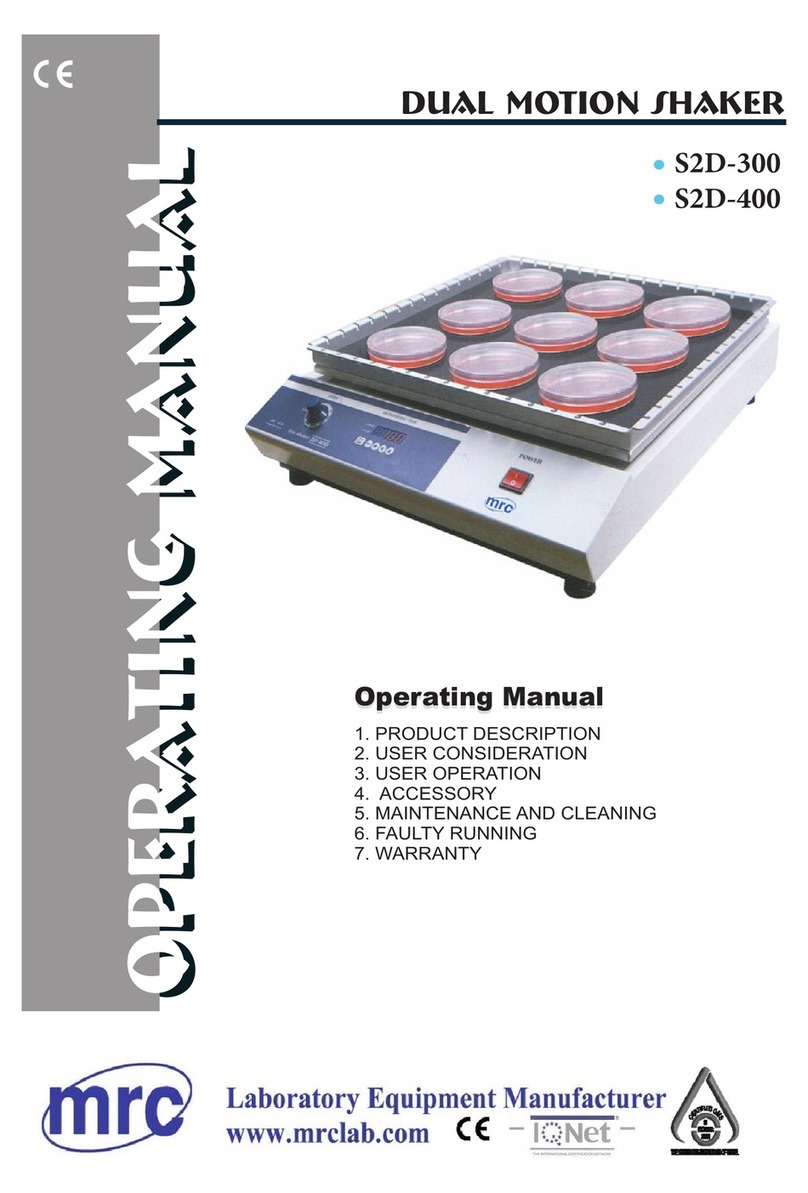

0BUEQUIPMENT DESCRIPTION

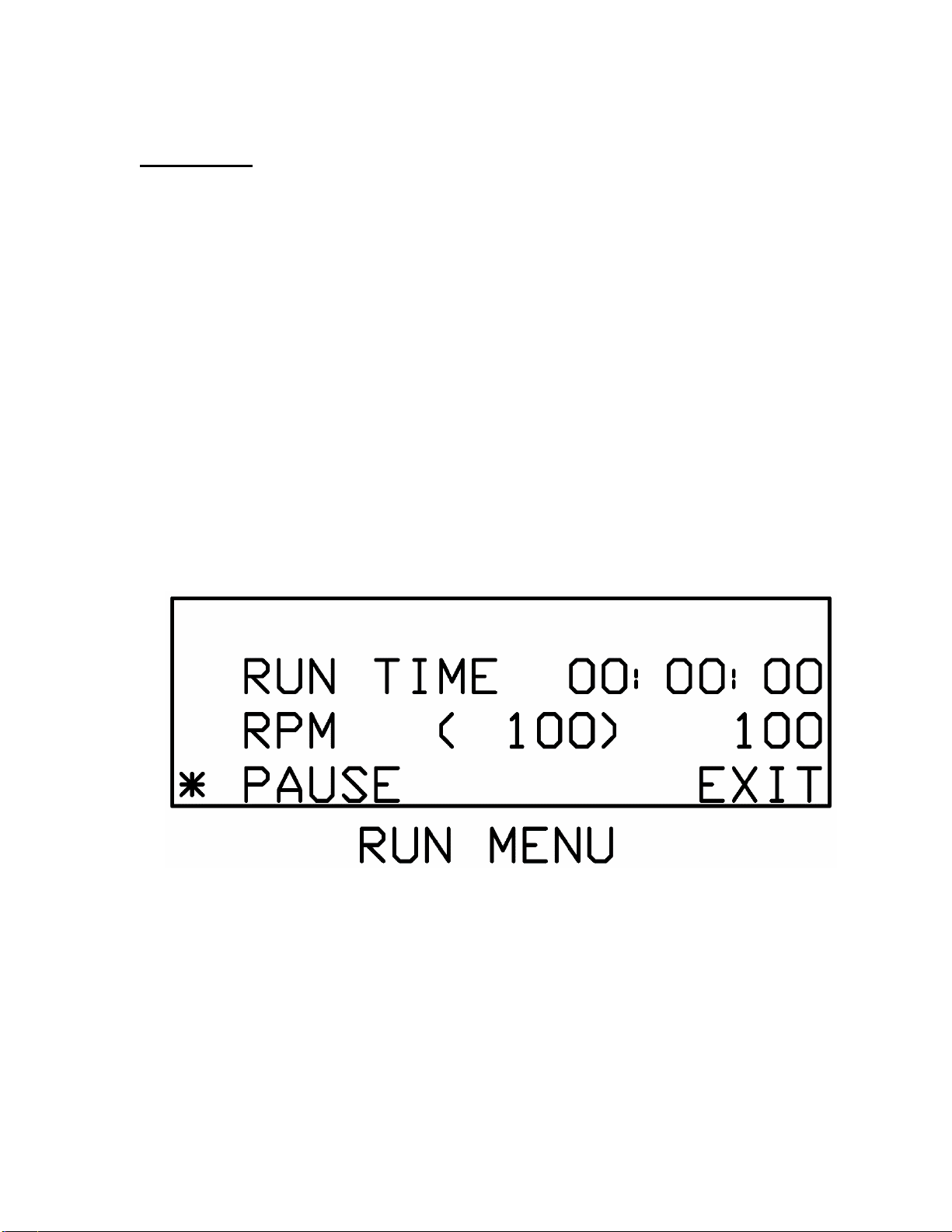

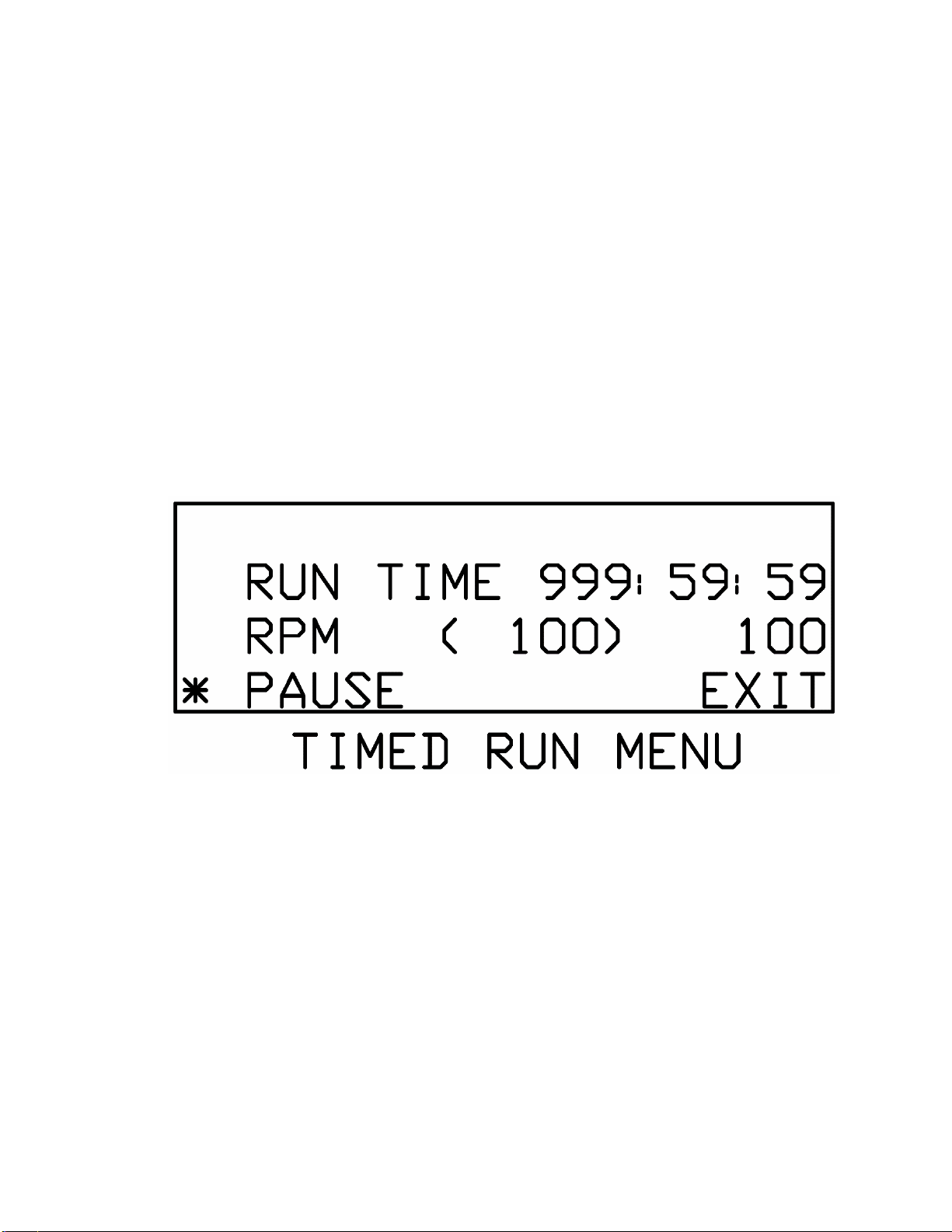

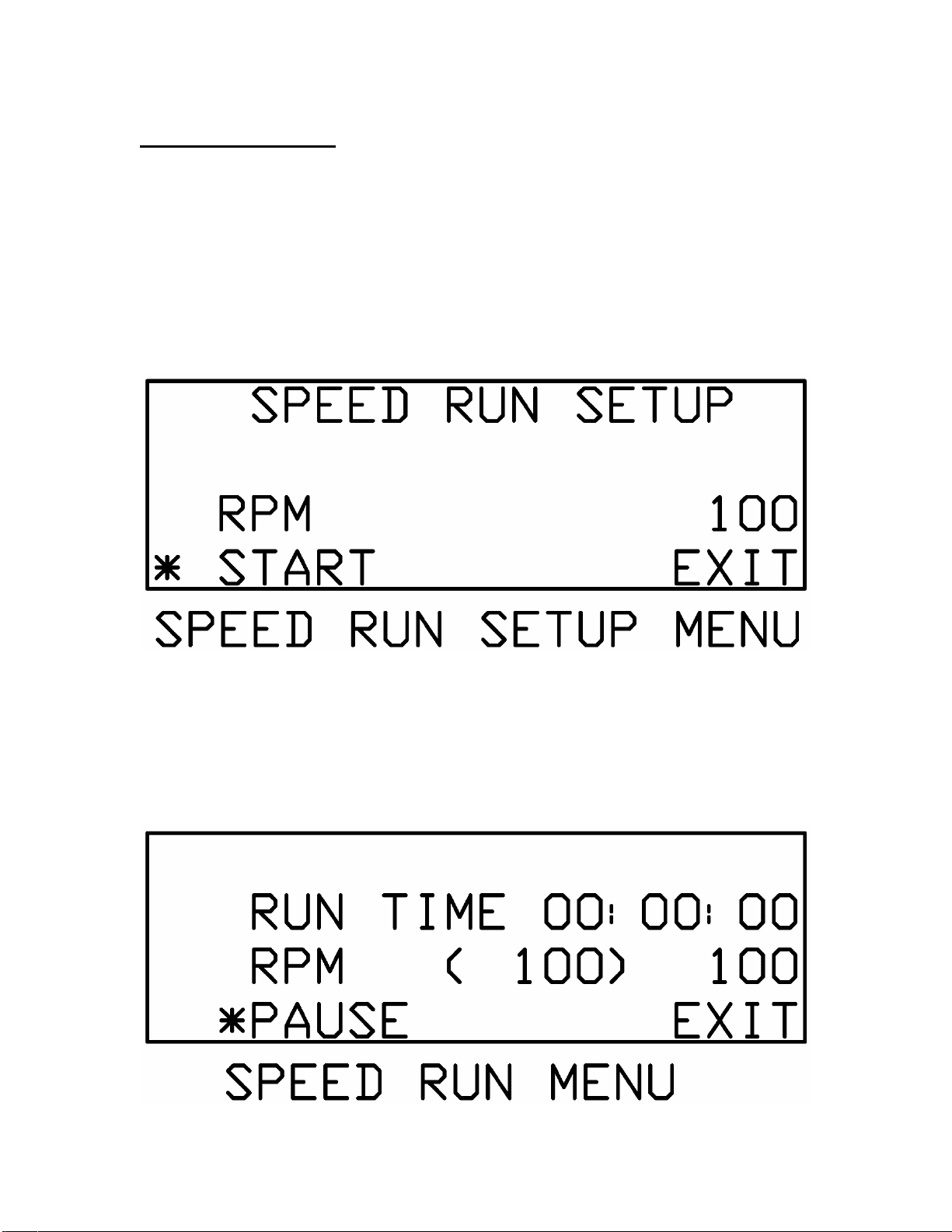

Hand Motion Shaker: Electronic regulation between 100 and 960 oscillations

per minute. Oscillation amplitude is 9mm. Easily, detachable arms equipped

with 8 clamps for attaching and processing up to 8 samples at one time.

1BUTECHNICAL FEATURES

Voltage supply 115V/230V, 50/60 Hz

Height 10in

Length 13 in

Width 11.375 in

Maximum Capacity 4 kg (8.8 lbs)

Oscillations per minute 100-960

Power Consumption 0.7 Amps

2BUINSTALLATION

1) Place the apparatus on a flat, horizontal, level surface with sufficient

stability to resist its own vibrations.

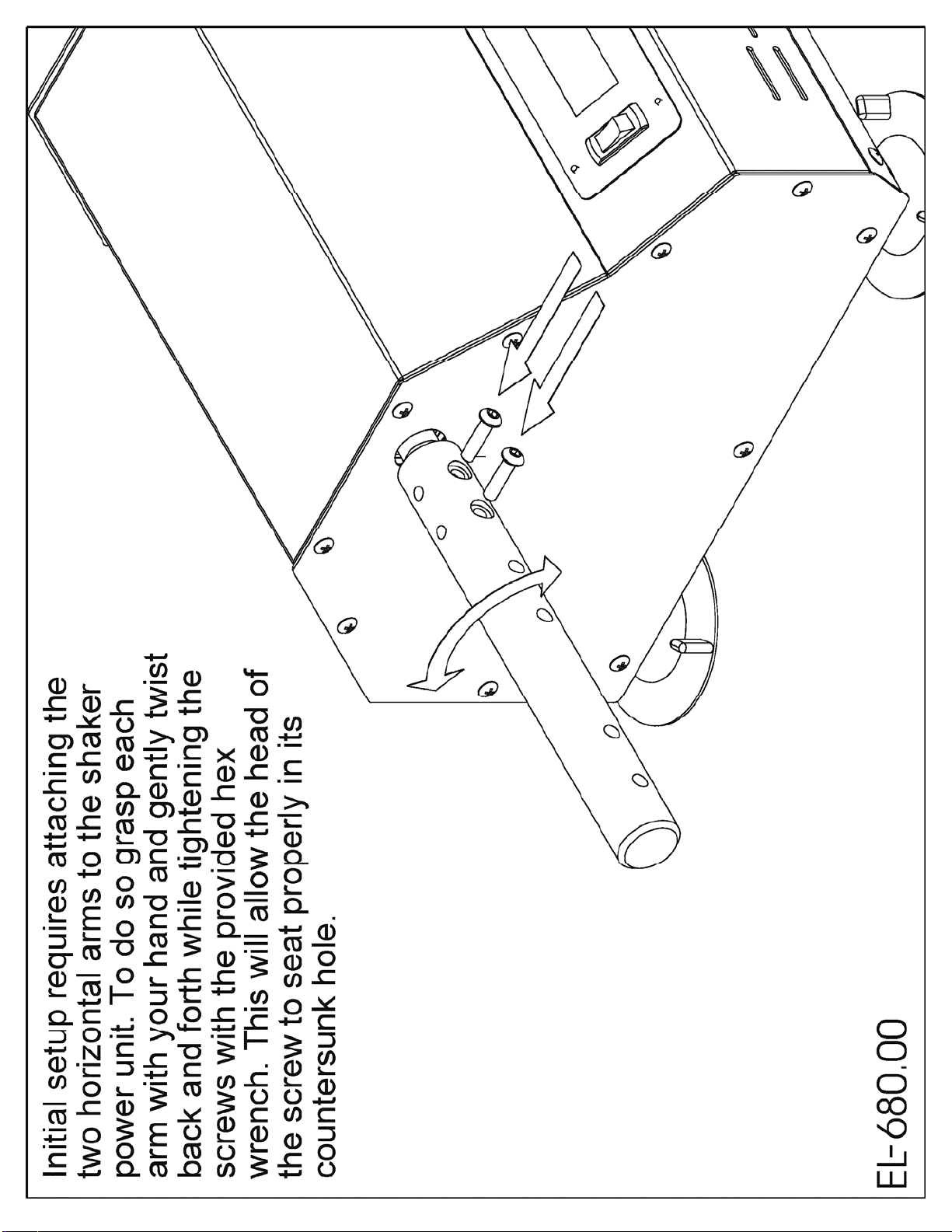

2) Fit the arms with clamps to the shaker side shaft so that the screws

tighten against the flat surface of the shaft.

3BUCAUTION!!! IMPORTANT FOR YOUR SAFTEY

Be sure that the voltage supply is the same as the one indicated on the serial

tag. Operating range is 115V/230V +/- 10%

Do not shake products capable of making an explosive mixture.

Do not use the apparatus if it is not grounded properly.