3

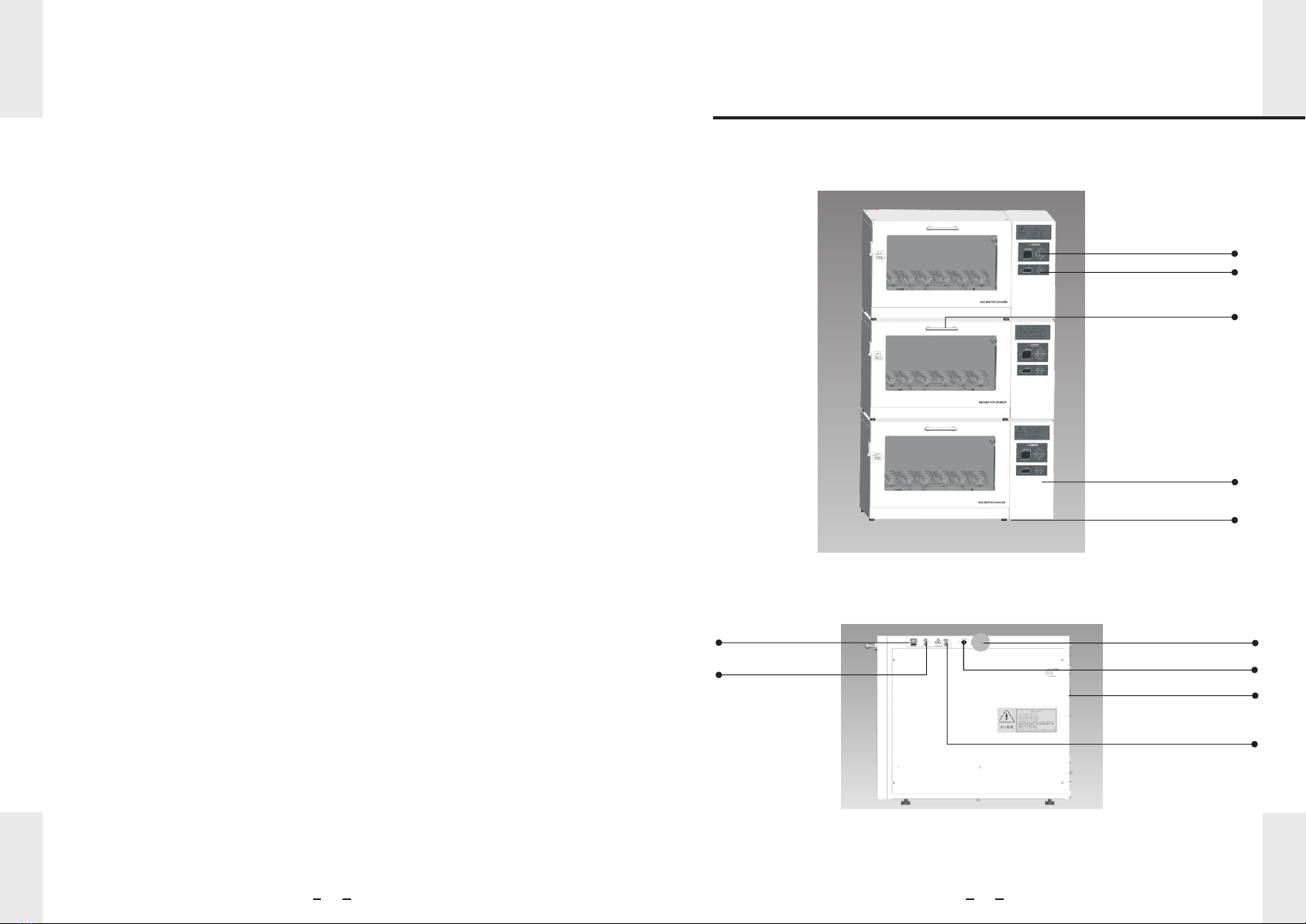

2.1 Description

LOM-7450 are a stackable incubator shaker models with cooling function. The instrument

can be used individually or stacked on top of each other to save floor space. Flip-down

door style allows independent operations of stacked instruments, which makes batch

treatment of samples easy. The triple-eccentric counterbalanced drive, with a

circumferential oscillation diameter of 2.6 centimeters, provides dependable and durable

operation of the instrument. Speed terminal feedback system guarantees high precision

oscillation within the speed range of 30 to 300 rpm. Innovatively combined PID and fuzzy

control technique makes into reality less than 0.1 °C temperature fluctuation within 4 °C to

60 °C range. LOM-7450-CO2 are a stackable incubator shaker model equipped with a

CO2 incubator. It is configured with accurate CO2 and humidity monitoring system that

ensures stable pH level for high-efficiency cell culture.

LOM-7450-L are a stackable incubator shaker model that provides 9 levels of lighting

which meets most needs of plant, seed, microbial, and viral cell culture.

The instrument can be operated under continuous or 0 to 999 hours timed mode. Up to 6

segments of parameters' programming automates environmental condition moderations

and treatment time change for the same sample.

Sliding rail structure of the shaking platform makes sample operations convenient. Large

chamber size accepts flasks up to 5 liters.

2. Overview 2. Overview

2.2 Features

● Large view window

● LCD dot-matrix display

● User-friendly interface

● Multi-segment programming

● Extra long timing up to 999

hours

● Soft start and smooth

acceleration

● Open door cut-off switch

● Sliding rail design of the

shaking platform

● Open door light-on switch

● Automatic adjustment of

PID parameters

● Drainage groove

● Multiple safety features

● Stackable instrument

● Automatic defrost

Minimizes the need to open the lid.

Displays settings and measurements.

Enables intuitive control panel and menu

selections.

Automates operation under different sample

treatment needs.

LCD displays remaining time, end-of-study sound

and light alarm.

Soft start technique guarantees smooth acceleration

and prevents samples from spilling.

Stops motion when opening the chamber door to

protect users from potential accidental injury.

Convenient replacement of clamps.

Lamp is automatically turned on when opening the

door to help user handle various operations.

Note: The lighting switch is deactivated when the

chamber door is open; The lamp will always be on.

PID parameters are automatically adjusted

according to different conditions.

Built-in drainage groove makes it easy for getting

the liquid outside of the chamber when cleaning the

instrument.

Safety lock control, refridgerator overload protection,

overtemperature protection, overtemperature alarm,

thermal runaway protection, sensor malfunction

alarm, and automatic shut-down system when

malfunctioning ensures safe operation.

Saves floor space.

Automatically defrosts the evaporator in the

refrigerator; no need to manually defrost the frost

buildup. Temperature rise is less than 1.5 °C during

defrosting.

4