Cinebot Mini Quick Start Guide

iii

Cinebot Mini Model Mover Quick Start GuideCinebot MiniQuick Start Guide

Contents

Chapter 1 Quick Start..................................................................... 1

Important safety instructions ...............................................1

Power and connections................................................1

General care...................................................................1

Location .........................................................................2

Intellectual property .....................................................2

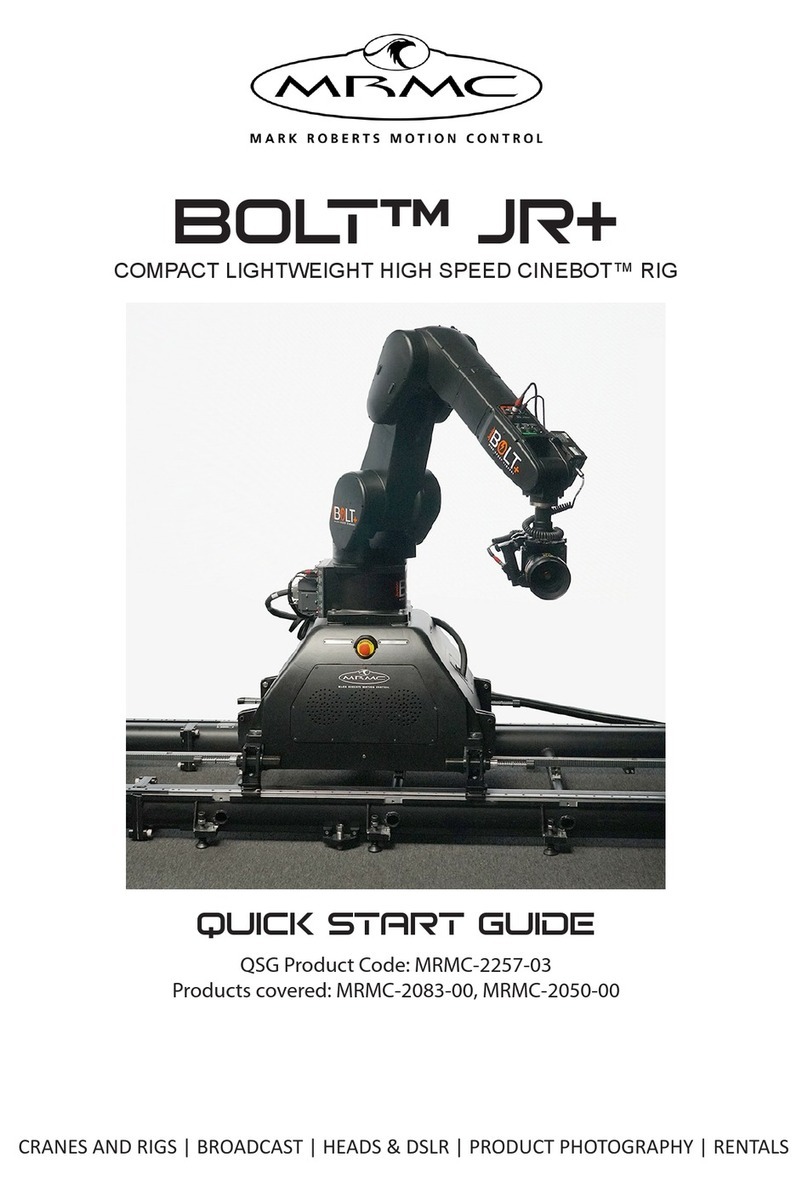

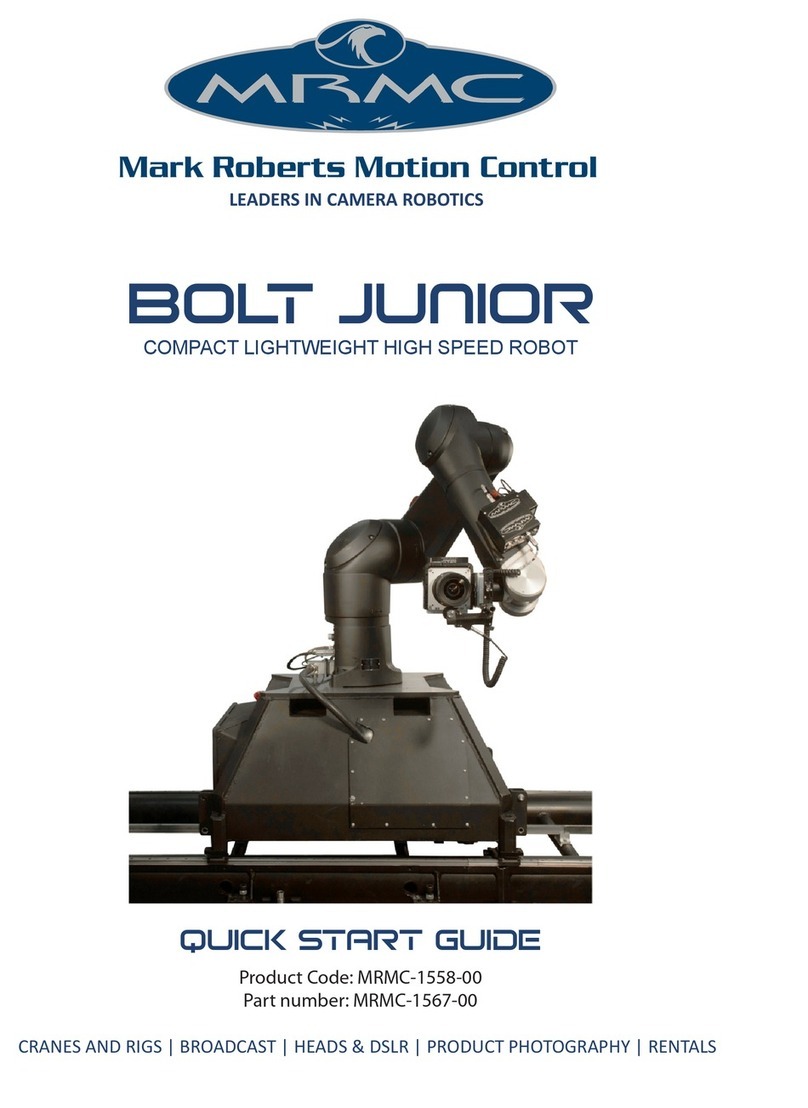

Overview ................................................................................. 3

Attaching the Pinchwheel Assembly to Cinebot Mini

on Track...................................................................................4

Removing/Adding the Wheel Units on the

Cinebot Mini on Track.................................................4

Mounting Cinebot Mini Arm on the Base .........................8

Removing Cinebot Mini Arm from the Base.....................9

Mounting Cinebot Mini Arm on the Columns ...............10

Mounting 300mm Column .......................................10

Mounting 500mm Column .......................................11

Laying the Track for Cinebot Mini on Track....................14

Laying subsequent track sections .............................14

Mounting bearing rail joints .....................................15

Datum Magnet ............................................................16

Connecting the cables (Cinebot Mini on Pedestal) -

Operator’s Position ..............................................................18

Connecting the cables (Cinebot Mini on Pedestal) –

Robot Base - Robot Arm.....................................................19

Connecting the cables (Cinebot Mini on Track) -

Operator’s Position ..............................................................20

Connecting the cables (Cinebot Mini on Track) –

Robot Base - Robot Arm.....................................................21

Starting up the Cinebot Mini on Pedestal system ...........23

Cinebot Mini on Pedestal start-up summary .........24

Shutting down the Cinebot Mini on Pedestal system .....25

Starting up the Cinebot Mini on Track system................26

Cinebot Mini on Track start-up summary..............27

Setting up a Lens in Flair Classic with Tilta motors........28

Setting the Payload for Cinebot Mini................................31

Flair Constraints Feature..................................40

Cinebot Mini remote interface functions.......41

Using Focus Assist with Cinebot Mini..............................42