4 Calibration

4.1 Factory Calibration

The module has been factory calibrated to alarm as indicated below or as marked on the calibration tag shipped with the

module.

Model Time Gas CC/Min

2001 30 sec 1000 ppm CH4 100

4.2 Frequency of Calibration

The manufacturer recommends that the calibration of each gas sensor module be verified monthly during the first three

months of operation and then quarterly. More frequent checks are necessary during periods of extreme humidity and

temperature changes. The monitor should have operated continuously (uninterrupted) for at least 24 hours prior to

calibration adjustment.

4.3 Calibration Process

The output signal of the gas sensor module is calibrated using a calibration gas mixture containing a known concentration of

the gas of interest and a balance of air. The concentration of the span gas must be within the full scale of the sensor module

and must be equal to the alarm point desired. Default setting is 1000 ppm Methane. Use cylinder types below for other alarm

settings.

Calibration requires application of the span gas to the sensor and adjustment of the sensitivity adjustment potentiometer.

Warning:During calibration the alarm will turn on and remote alarms connected to the alarm relays will be

activated. Disable the remote alarm if necessary.

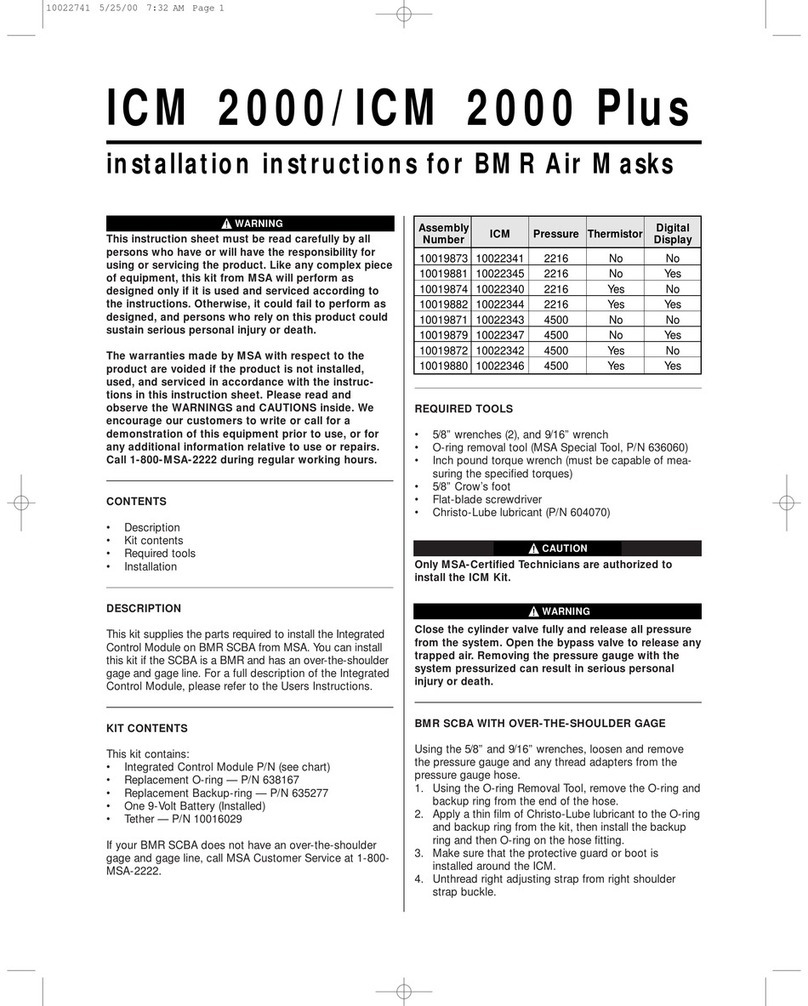

4.4 Equipment Required

The following tools and equipment will be required for calibration:

• Jewelers Screwdriver

• Calibration Gas

◦ 1260-08: 1000 ppm CH4 in Air

◦ 1260-09: 5000 ppm CH4 in Air

◦ 1260-11: 10000 ppm CH4 in Air

• Calibration gas delivery system Model # 1250-04

For accurate calibration use a gas mixture at the required concentration mixed in an air balance, rather than with an inert

gas like nitrogen. This gas and the required delivery equipment such as the Model 1250-04 Kit is available from MSA Safety.

4.5 Calibration Procedure

1. The monitor should be in the safe condition prior to calibration (green LED “ON”).

• Be sure that the area is non-hazardous before proceeding.

• Disable alarm devices

2. The sensor is in the lower right hand corner of the electronics board and the cover does not need to be removed.

3. Apply calibration gas directly to the sensor.

7 SMC 2001-00 Gas Alarm

US 4 Calibration