2

Table of content

INTRODUCTION.........................................................................................................................3

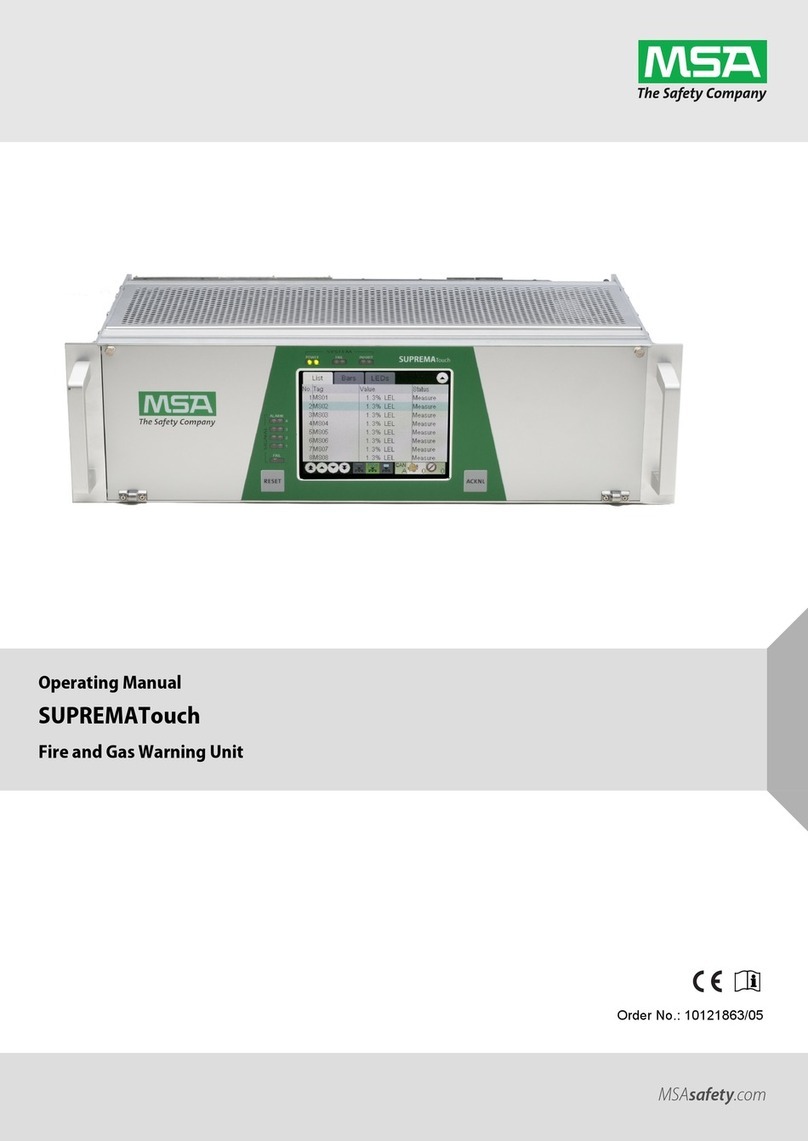

1DESCRIPTION AND OPERATION OF THE PRODUCT...............................................4

1.1 Description............................................................................................................................4

1.2 Main technical specifications................................................................................................4

1.3 Operation and structure of the Product .................................................................................5

1.4 Measurement tools, instruments and appliances.................................................................10

1.5 Marking and sealing............................................................................................................10

1.6 Packaging............................................................................................................................10

2INTENDED USE OF THE PRODUCT..............................................................................11

2.1 Operational constraints........................................................................................................11

2.2 Usage preparations..............................................................................................................11

2.3 Usage of the product ...........................................................................................................12

3TECHNICAL SERVICE......................................................................................................13

3.1 General description .............................................................................................................13

3.2 Safety features.....................................................................................................................13

3.3 Maintenance routine............................................................................................................13

3.4 Preservation.........................................................................................................................15

4CURRENT REPAIR OF THE PRODUCT........................................................................16

4.1 General description .............................................................................................................16

4.2 Safety features.....................................................................................................................16

4.3 Current repair ......................................................................................................................16

5STORAGE.............................................................................................................................17

6TRANSPORTATION...........................................................................................................18

7DISPOSAL.............................................................................................................................19

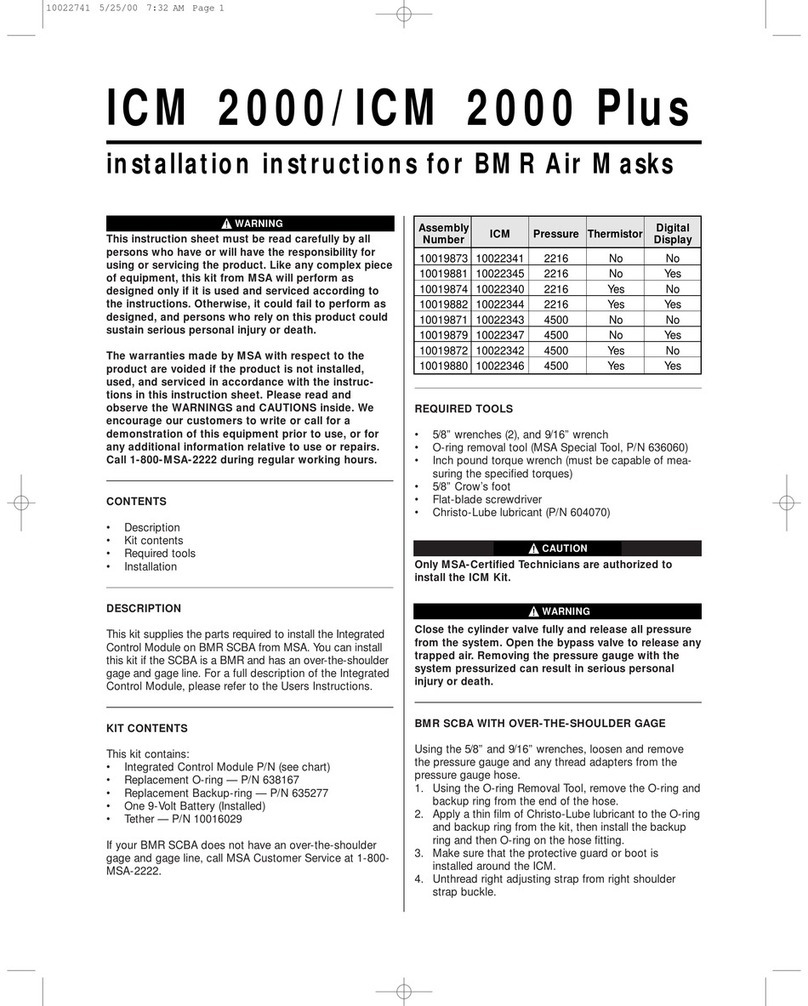

ANNEX A (MANDATORY) OUTLINE AND INSTALLATION DIMENSIONS.............20