2

1. DESCRIPTION ......................................................................................................................................................3

2. TECHNICAL CHARACTERISTICS........................................................................................................................4

3. RECEIPT AND INSPECTION................................................................................................................................6

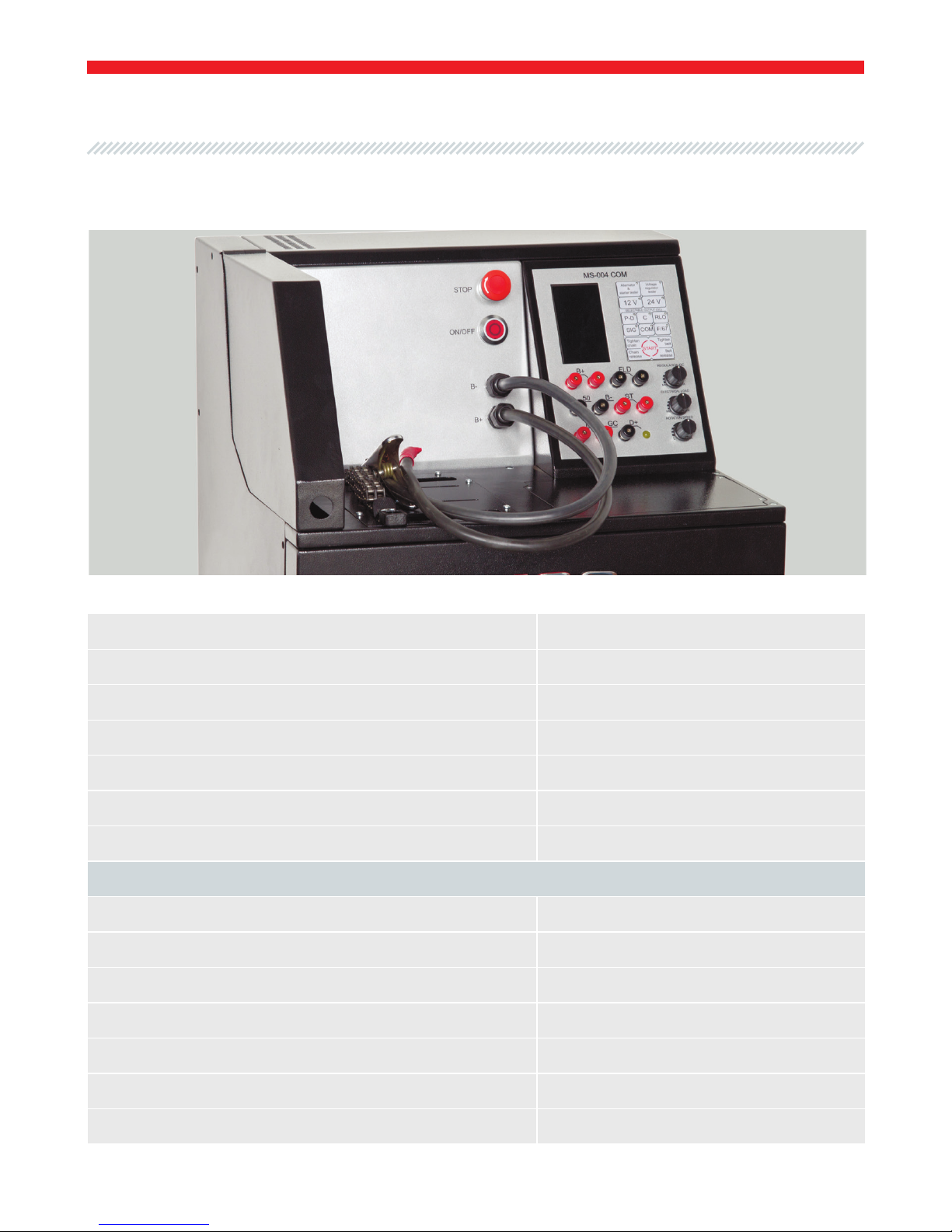

4. TEST BENCH DESCRIPTION...............................................................................................................................6

4.1 Mounting Face and Front Panel...........................................................................................................6

4.2 Control Units..............................................................................................................................................8

4.2.1 Display. Data Output...................................................................................................................9

4.2.2 Buttons............................................................................................................................................14

4.2.3 Terminals ........................................................................................................................................15

4.2.4 Adjustment Knobs........................................................................................................................16

5. SETTING INTO OPERATION..............................................................................................................................16

5.1 Connection.................................................................................................................................................16

6. STEP-BY-STEP INSTRUCTION..........................................................................................................................18

6.1 Alternator Testing.....................................................................................................................................18

6.2 Starter Testing ...........................................................................................................................................20

6.3 Voltage Regulator Testing......................................................................................................................20

7. TEST CERTIFICATE...............................................................................................................................................21

APPENDIX 1.................................................................................................................................................................22

APPENDIX 2.................................................................................................................................................................24

APPENDIX 3.................................................................................................................................................................27

User Manual - Test Bench MSG MS004 COM

CONTENTS