9

4.1 R I

4. SETTING INTO OPERATION

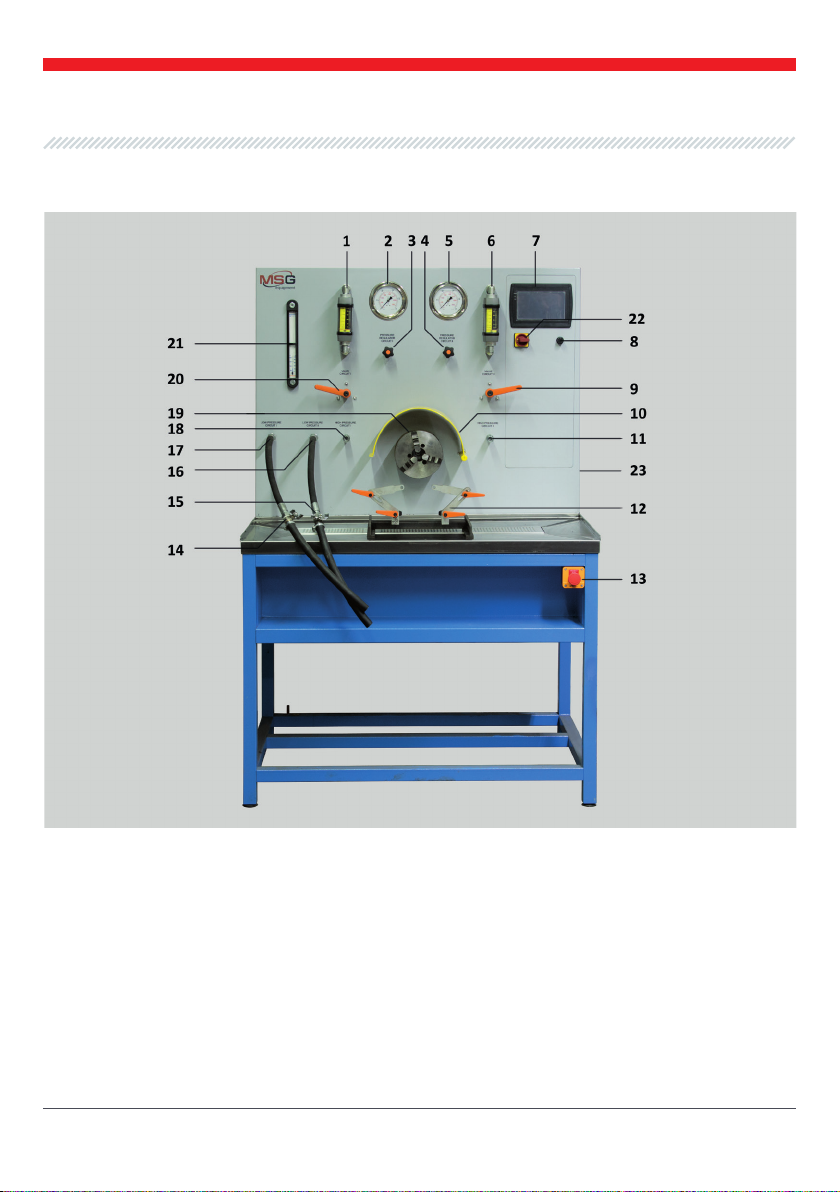

Check the set received. It must contain:

• test bench

• cables for connection to power supply

• 2 high-pressure hoses L-1.2 m

• 2 low-pressure hoses L-1 m

• set of fittings MS00555

• set of outside jaws and a jaw chuck key

• adapter for pump hubs

• User Manual.

Inspect the test bench for existence of damage. If it is found, please contact either the manufac-

turer or trade representative before launching the equipment.

WARNING! In case of obvious damage, use of equipment is forbidden.

4.2 C

4.3 S M

Install the bench in the premises with <90% humidity and temperature of 0-40°C. Make sure that

there is permanently no condensate on the bench.

Connect the test bench to 380 V (3L+N+Pe) three-phase alternating current.

WARNING! Work with unearthed device is strictly forbidden. Use socket of 3L+N+Pe type

(three contacts per phase, one zero and one earth contact), observe forward sequence of phases).

Fill in the tank through the filler neck with ATF oil for power steering gears up to 21 level.

WARNING! Use a new ATF oil only to avoid failures in operation of the test bench and tested

units.

It is strongly recommended to learn actual User Manual before launching the bench. Work with high-

pressure hydraulic equipment without learning safety measures instruction is strictly forbidden.

Tightening or unscrewing nuts in high-pressure hoses in the process of operation of the tester is

forbidden.

Removal of quick disconnect coupling in the process of operation of the tester is forbidden.

Usage of defective high-pressure hoses is forbidden.

Work with the tester must be carried out in rubber gloves.

In case of skin contact with power fluid, wash the place of impact with a soap.

WARNING! Power supply voltage must correspond to the technical characteristics of the

test bench.

User Manual - Test bench MSG MS604