English

Test bench MS006

6

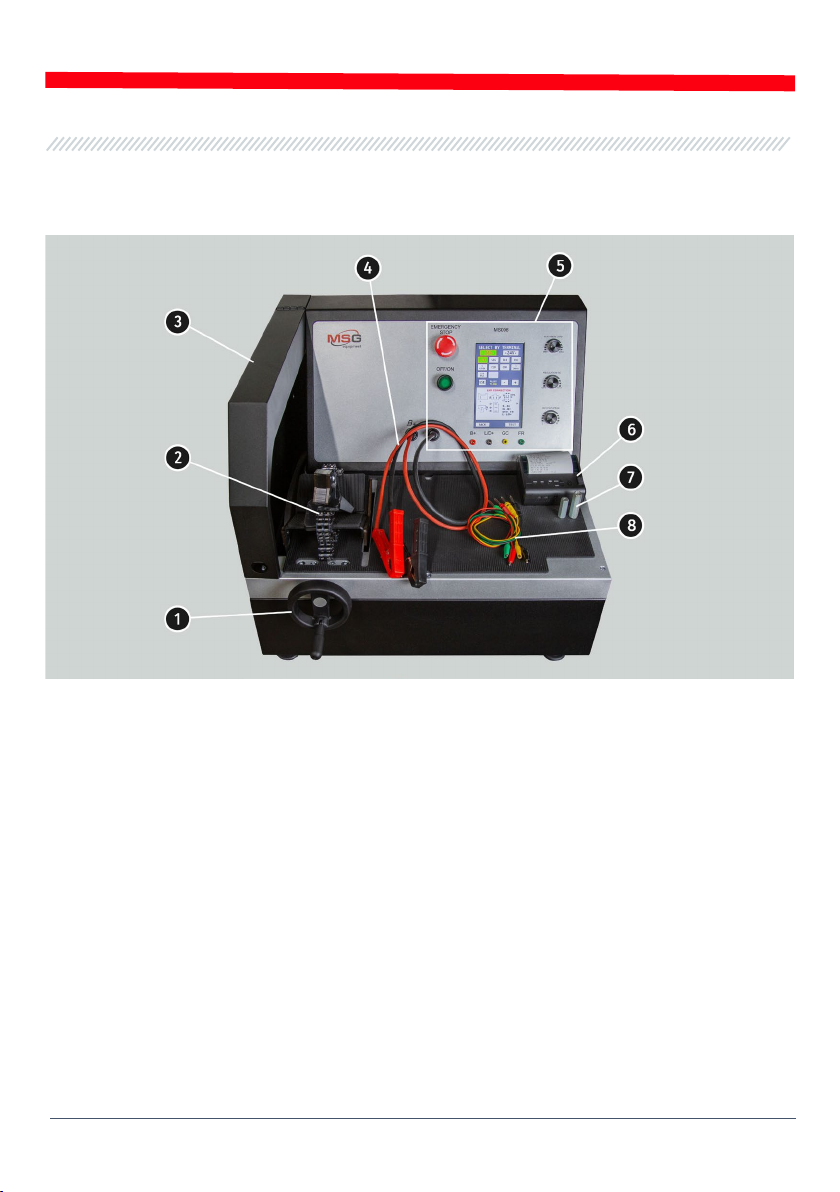

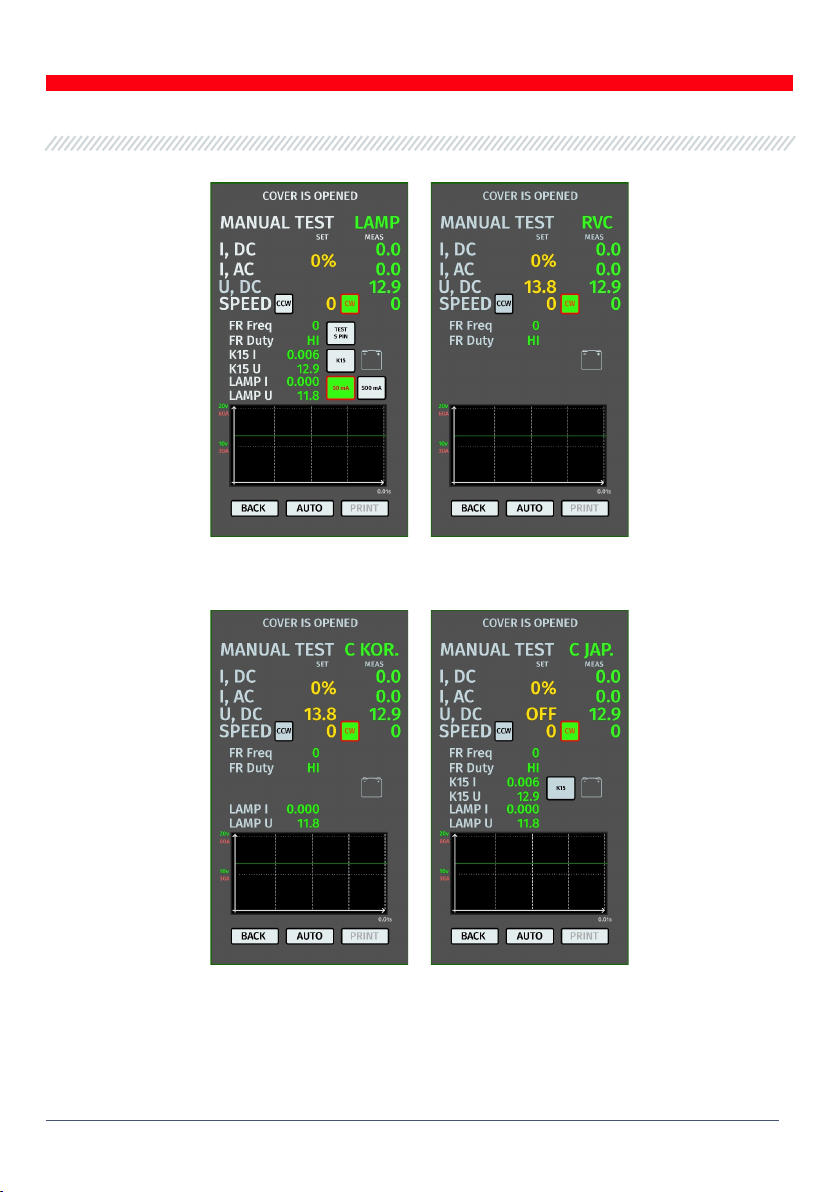

Main elements of the control panel (Fig.2):

Figure 2. Control panel

1 – Touch screen: screen to output the parameters of the tested alternator and control the test

bench operation.

2 – “OFF/ON”: button to turn the test bench off/on. Button “OFF/ON” is inoperative when the

“EMERGENCY STOP” button is pressed.

3 – “EMERGENCY STOP”: button for test bench emergency shutdown.

4 – Adjustment knobs: to set and adjust operating parameters:

• «ELECTRICAL LOAD»:knob to set electric load on an alternator (simulates vehicle power

consumers). Press the knob shortly to reset the load to zero smoothly.

• «REGULATION GC»:knob to set/adjust an alternator output voltage. It is used when the

alternator is connected to the “GC” terminal. Press the knob shortly to reset the preset voltage

to the default values (13.8V).

• «ROTATION SPEED»:knob to set/adjust the drive speed (RPM) and rotation direction. Press

the knob shortly to stop the drive.

5 – Diagnostic terminals: to connect the test bench to the voltage regulator terminals:

• «B+»:test bench terminal to connect to the alternator terminals: “B+”, “IG”, “S”, “AS’, “BVS”,

“A”, “15”;

• «L/D+»: output to the voltage regulator control lamp; it is connected to the following

terminals: “L”, “D+”, “I”, “IL”, “61”;

• «GC»:alternator control terminal. It is connected to the terminals “COM”, “LIN”, “D”, “RLO”, “C”,

“G”, “SIG”, “L(RVC)”, “RC”;