10

6.1 Preparation of Flushing Stand to Operation

Connect the stand to air-supply system. Pressure in air-supply system must correspond to the

parameters, described in ‘Technical Characteristics’.

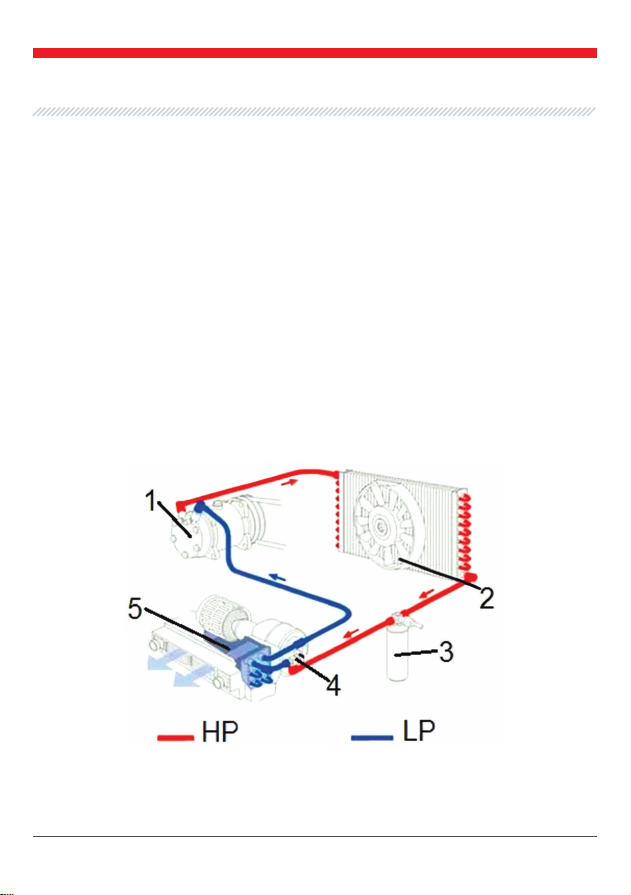

Power activation valve (1) must be switched off. Valves 2 and 5 must be switched off, set in the

position ‘-’.

The tank must be filled with flushing fluid (5 to 10 l) through the filler neck 3.

Polypropylene filter element is fixed in the filler neck 3, the filter element cover is twisted (3).

6.2 Connection to Air Conditioning Sys temand

Work with Flushing Stand

The following actions must be conducted before connection of the flushing stand to air condition-

ing system:

- remove coolant out of air conditioning system with a special tool for gathering coolant.

- dismount component parts of air conditioning system, which are not to be flushed (expansion

valve (EV), compressor, dryer, condenser).

Connect HP and LP hoses through specialized connectors to high-pressure and low-pressure lines

of air conditioning system.

To provide circulation of flushing fluid, activate HP valve (2) on the stand (set in position ‘+’).

To supply flushing fluid to air conditioning system, activate the pump with the valve 1. Pump per-

formance is regulated by the same valve, if necessary.

Air conditioning system goes through several cycles of flushing.

The first cycle is the quickest one: activate the stand for 10 minutes, then deactivate and check its

filter element for contamination, gathered on it. If large dispersing parts of contamination (alumi-

num chip) are observed, replace the filter element and continue flushing.

Quantity of cycles depends on contamination degree of the system, but not less than 2. If neces-

sary, change flushing fluid, the filter element and repeat flushing.

English

User Manual - Stand MSG MS101P