Remove bolts and nuts securing the cover and open the two ends of the

cover. Remove packing materials and the spare gaskets if provided. Save

the gaskets for possible later use.

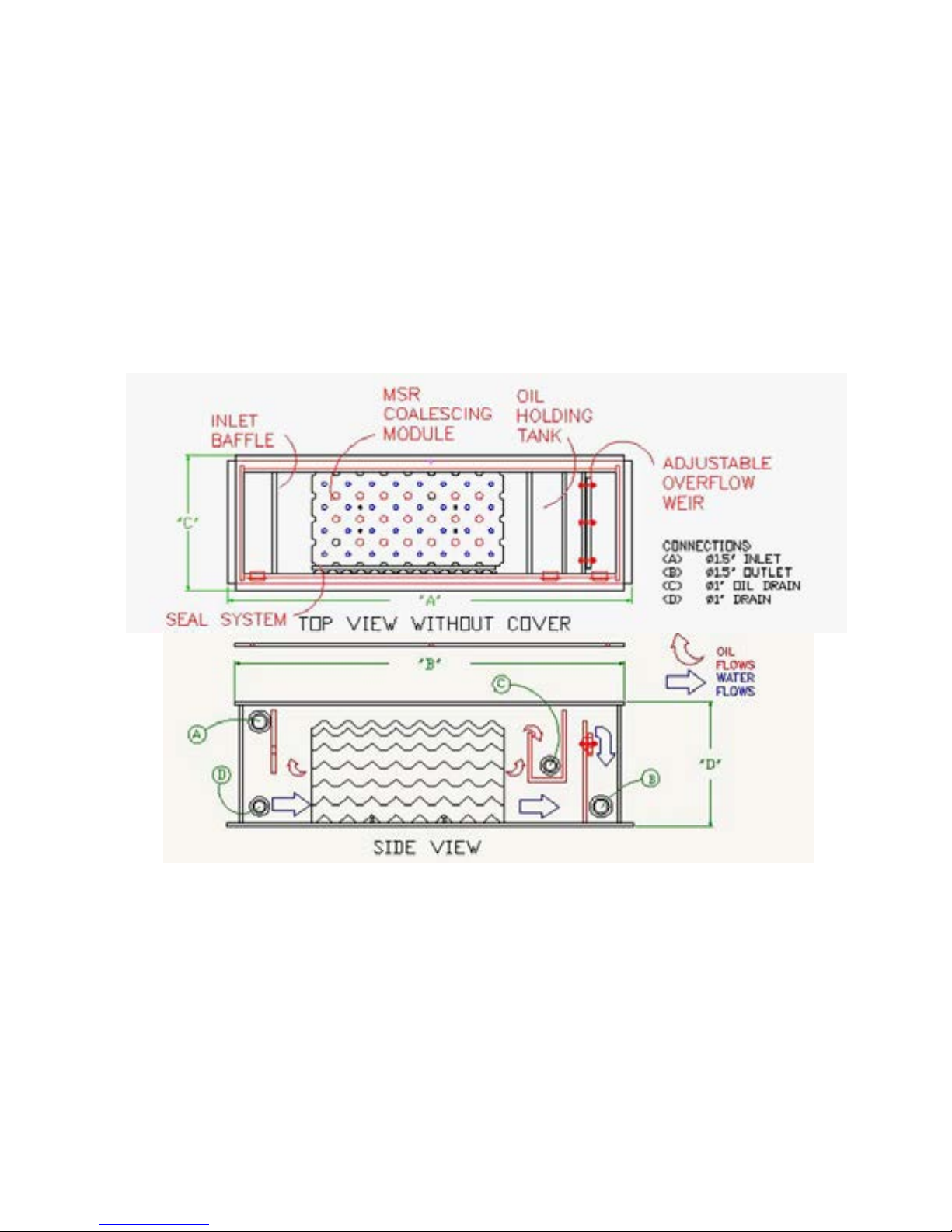

Check to ensure that the module has not moved out of place. The module

should be positioned so that it is correctly in position as shown on the

drawing.

Ensure that the corrugated and flat plastic side seal plates are correctly

installed. It is important that both of these should be flush against the

bottom of the separator. A small piece of wood such can be a convenient

way to push down on the top of the corrugated plates to get them to the

bottom of the separator without damaging the corrugations.

INITIAL START-UP

This procedure is to be followed after the installation of the separator or after the

separator has been drained and is ready to be restarted.

Before starting the flow to the unit, open or remove the cover and ensure

that the coalescing module has not shifted and that the corrugated plastic

is in place. The separator should contain one coalescing module, and the

corrugated plastic sheet between the module and the tank wall.

Ensure that there are no obstructions in the water outlet hose/piping and

that adequate oil disposal facilities are provided. Note: Pump adjustment will

be required (if provided), so it is advisable not to hard pipe the outlet water flow at

this time.

Fill the separator tank with clean water to avoid contaminating the

downstream end of the separator with oil. This should be filled to the point

where it overflows the outlet weir into the sewer.

Provide a source of clean water for flow adjustment.

Adjust the pump flow to 15 US GPM (or lesser desired flow). Test flow by

using the “bucket and stopwatch” method. Greater flows may damage

separation efficiency.

Adjust for the desired flow rate as above and allow unit to stabilize for a

few minutes.

Check to ensure that the stabilized water level is at least 1/8" below the oil

overflow weir. Water should not overflow into the oil collection tank – if this

happens, the flow is too great, the system is not level, or the overflow weir

is adjusted incorrectly.

Check for leaks, both external and internal and remedy any found.

At this point, the separator is ready for actual use. The only difference between

operations and the flow setting above is that oil will build up on the surface of the

water and eventually overflow into the oil collection tank.

Check to ensure that oil is building up on the surface of the water. If oil

buildup is very slow, ensure that there is no oil in the outlet water flow. If