Series 111 Accumulators

6

Introduction

Functional Description

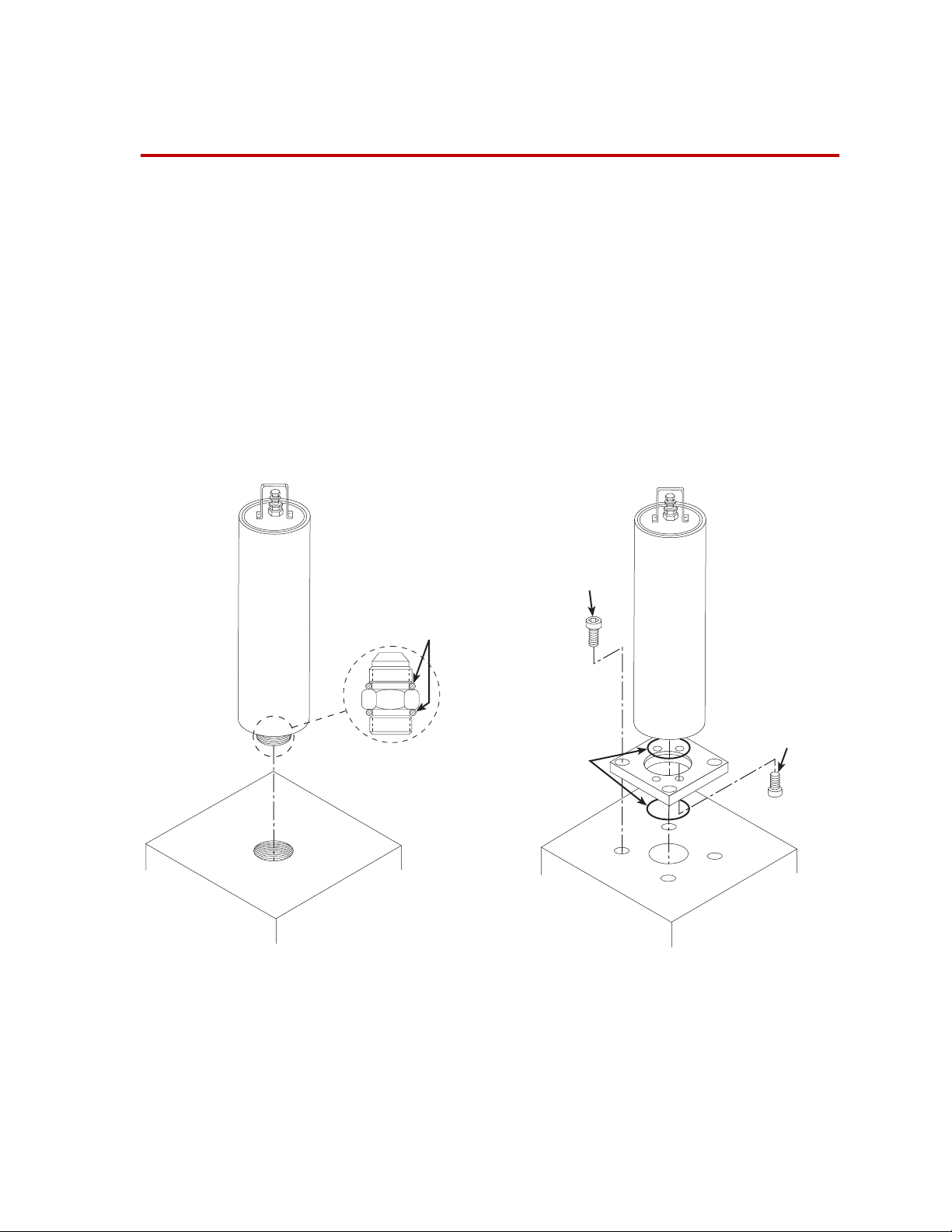

The MTS Series 111 Accumulators can reduce fluctuations hydraulic lines

due to sudden changes in hydraulic flow rate. They also act a short term

energy source for high-rate tests by providing additional hydraulic flow for

short periods to meet irregular peak demands. Like a capacitor,

accumulators filter out pulses in the hydraulic fluid to provide steady

hydraulic pressure.

Accumulators are like a hydraulic

version of a capacitor. They are

hydro-pneumatic devices located at

strategic points in a hydraulic

system. They may be connected to

the pressure line and to the return

line.

Accumulators are precharged with

pressure. Precharge pressure is the

pressure of the compressed gas

(usually nitrogen) before hydraulic

fluid is introduced.

Inserting accumulators into the

hydraulic lines permits some fluid to

be stored under pressure a short

distance from the servovalve and

actuator. This has the effect of

keeping fluid in the lines in motion

and reducing the inertia and line

restriction considerations. When the

servovalve opens and line pressure begins to drop, the accumulator in the

hydraulic service manifold (HSM) immediately supplies part of the fluid

volume and maintains the line pressure. Then, when the servovalve closes,

the hydraulic power supply (HPS) recharges the accumulator, causing fluid

in the lines to remain in motion.

The pattern and frequency of the signal that drives the servovalve will have

considerable effect on the HSM accumulator efficiency. Square wave

signals, for example, cause a greater demand than sine wave signals or

ramp signals.

At some frequencies, fluid flow in the lines may stop completely, and

overcoming the fluid inertia may become a more significant operational

factor.

An accumulator in the return line damps the pulsing effect caused by

“slugs” of fluid being injected into the line as the actuator moves.

Movement of hoses and/or hammering of hard lines is also reduced.

Nitrogen

Side

Fluid

Side

Hydraulic Fluid

Piston

Accumulator