M0160.docx | Rev 1.3 | Last modified 19/05/2020 | © Remote Control Technologies Pty Ltd

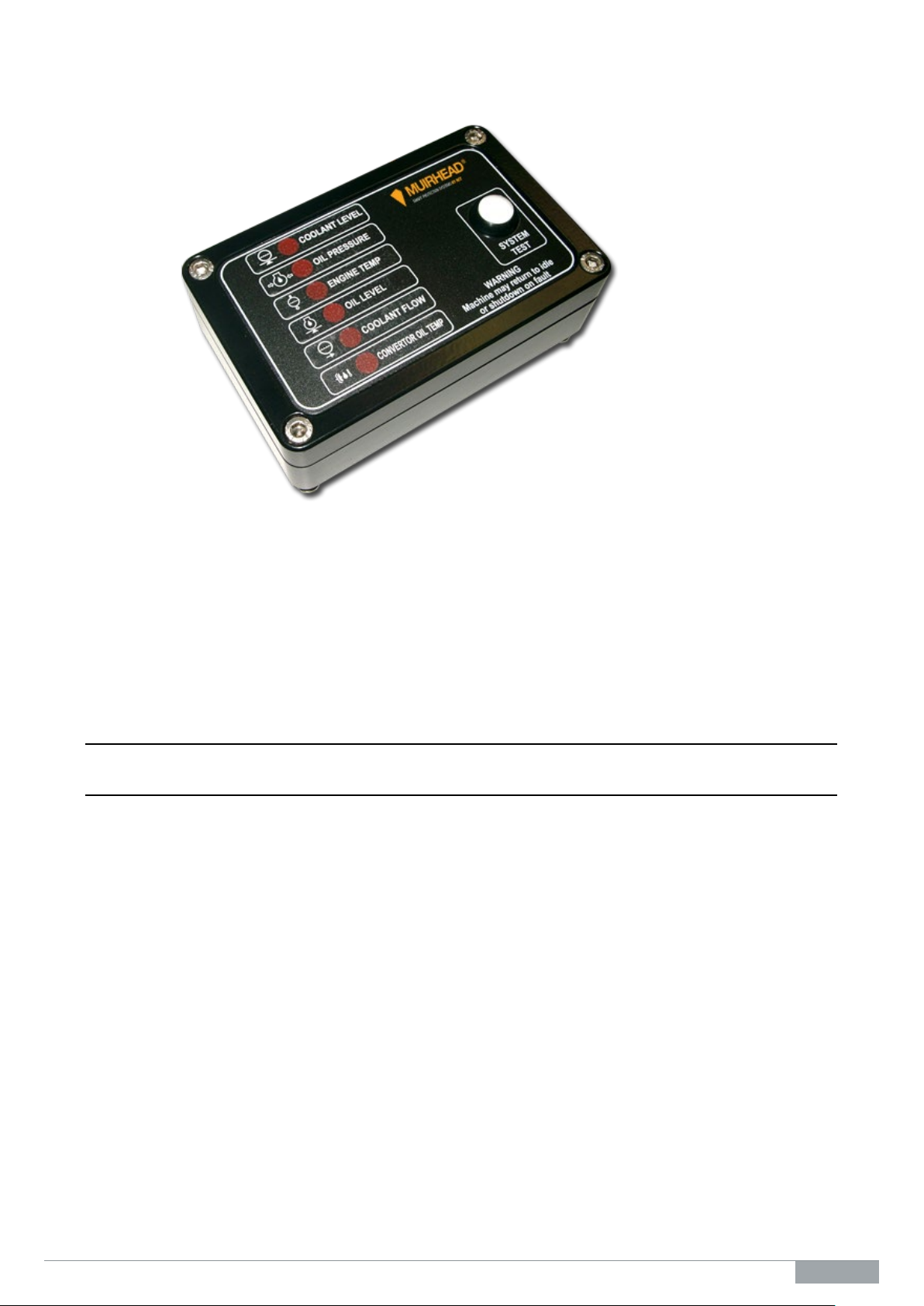

Inputs

The following input functions show the factory defaults with all inputs and outputs being configurable. Refer to

document number P0021 for advanced programming information. Contact your local RCT branch or distributor

for a copy of the document or for more information.

Function 1

This input is configured to have a five-second delay prior to pulsing the alert indicator and activating the alarm.

After a further 10 seconds, the alert indicator will come on solid, the alarm will remain on and activate the idle

and ETR control circuits. This circuit activates when the circuit changes state and becomes open. This input

is specifically designed for coolant level detection. If this function is not required, pin 7 must be connected to

ground.

Note: This function uses an AC (alternating current) circuit. This reduces electrolysis and corrosion of the

coolant level sensor. This will help to keep the probe in good working order.

Function 2

This input is configured to have a one-second delay prior to activating the corresponding alert indicator,

external audible alarm, idle and ETR control circuits. This circuit activates when the circuit changes state and

becomes open. If this function is not required, pin 8 must be connected to ground.

Typical use: Low engine oil pressure

Function 3

This input is configured to have a one-second delay prior to activating the corresponding alert indicator,

external audible alarm, idle and ETR control circuits. This circuit activates when the circuit changes state and

becomes open. If this function is not required, pin 9 must be connected to ground.

Typical use: High engine temperature

Function 4

This input is configured to have a one-second delay prior to activating the corresponding alert indicator,

external audible alarm, idle and ETR control circuits. This circuit activates when the circuit changes state and

becomes open. If this function is not required, pin 10 must be connected to ground.

Typical use: Low engine oil level

Function 5

This input is configured to have a one-second delay prior to activating its corresponding alert indicator, external

audible alarm, idle and ETR control circuits. This circuit activates when the circuit changes state and becomes

open. If this function is not required, pin 11 must be connected to ground.

Typical use: Coolant flow

Function 6

This input is configured to have a one-second delay prior to activating its corresponding alert indicator, external

audible alarm, idle and ETR control circuits. This circuit activates when the circuit changes state and becomes

open. If this function is not required, pin 12 must be connected to ground.

Typical use: Convertor oil temperature