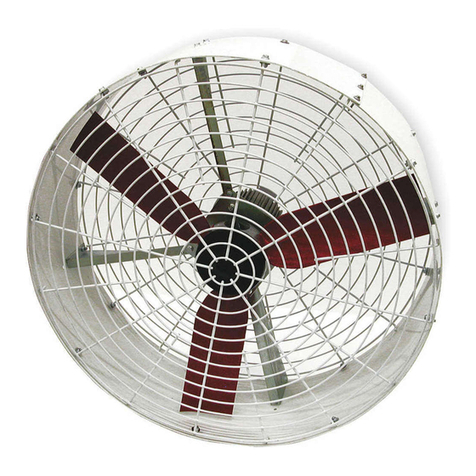

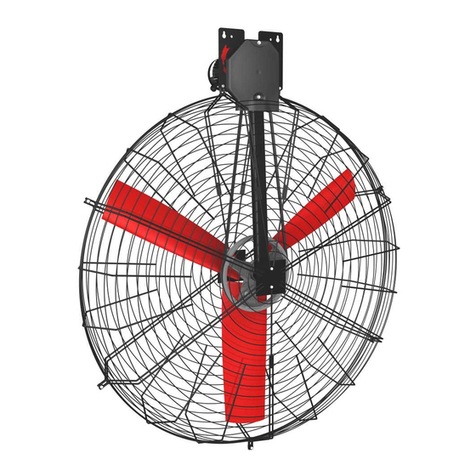

Galvanized Box Fan 130

2 | ENGLISH Original instructions INS00025-A

Table of Contents

1 Introduction ...........................................................................................2

2 Safety...................................................................................................... 2

3 Safety instructions................................................................................3

4 Assembly ...............................................................................................4

5 Information.............................................................................................4

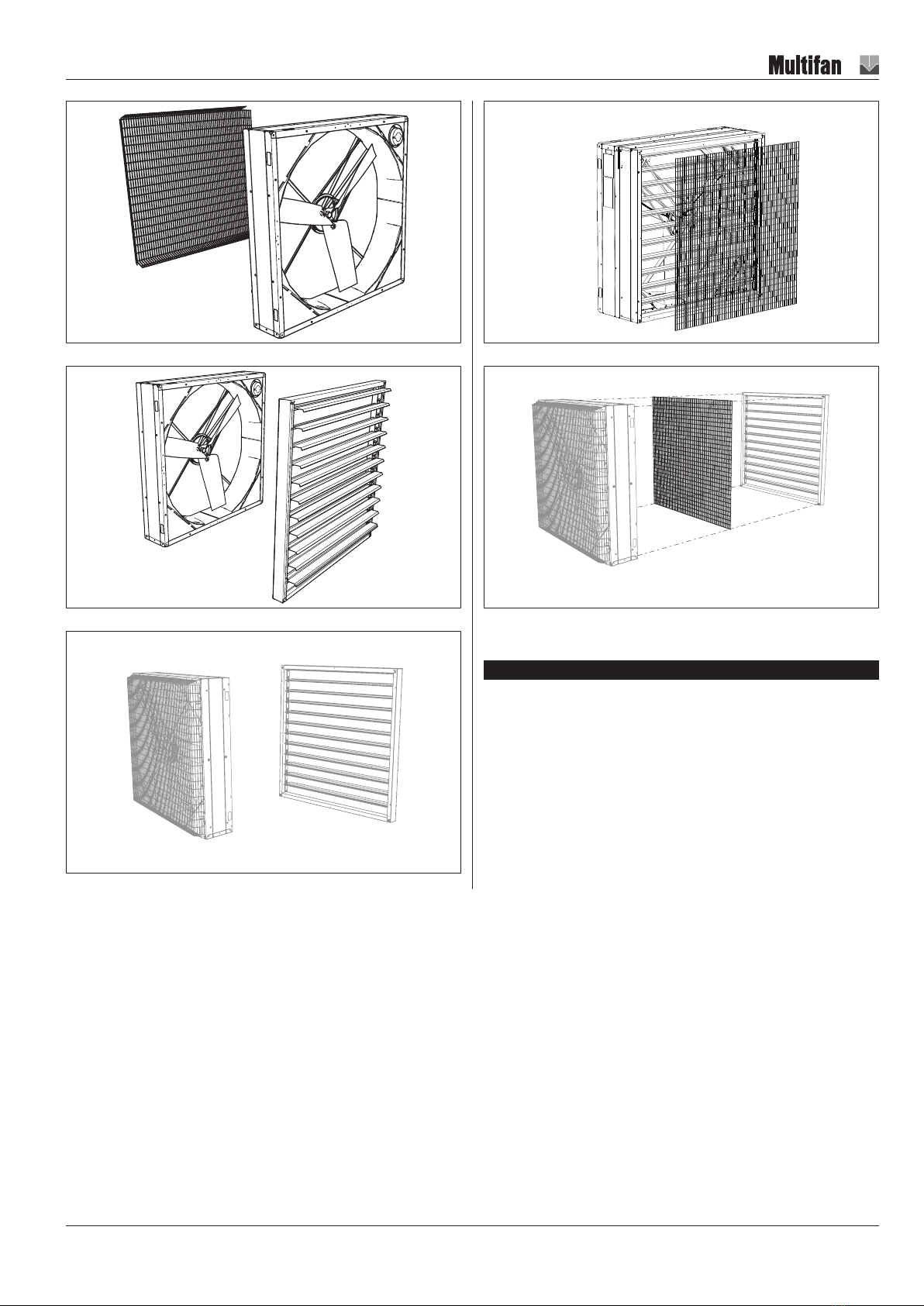

5.1 Overview .......................................................................................4

5.2 Options ..........................................................................................4

5.3 Identification of the product ...........................................................5

5.4 Intended use..................................................................................7

5.5 Technical information ....................................................................7

5.6 Other information...........................................................................7

6 Installation .............................................................................................7

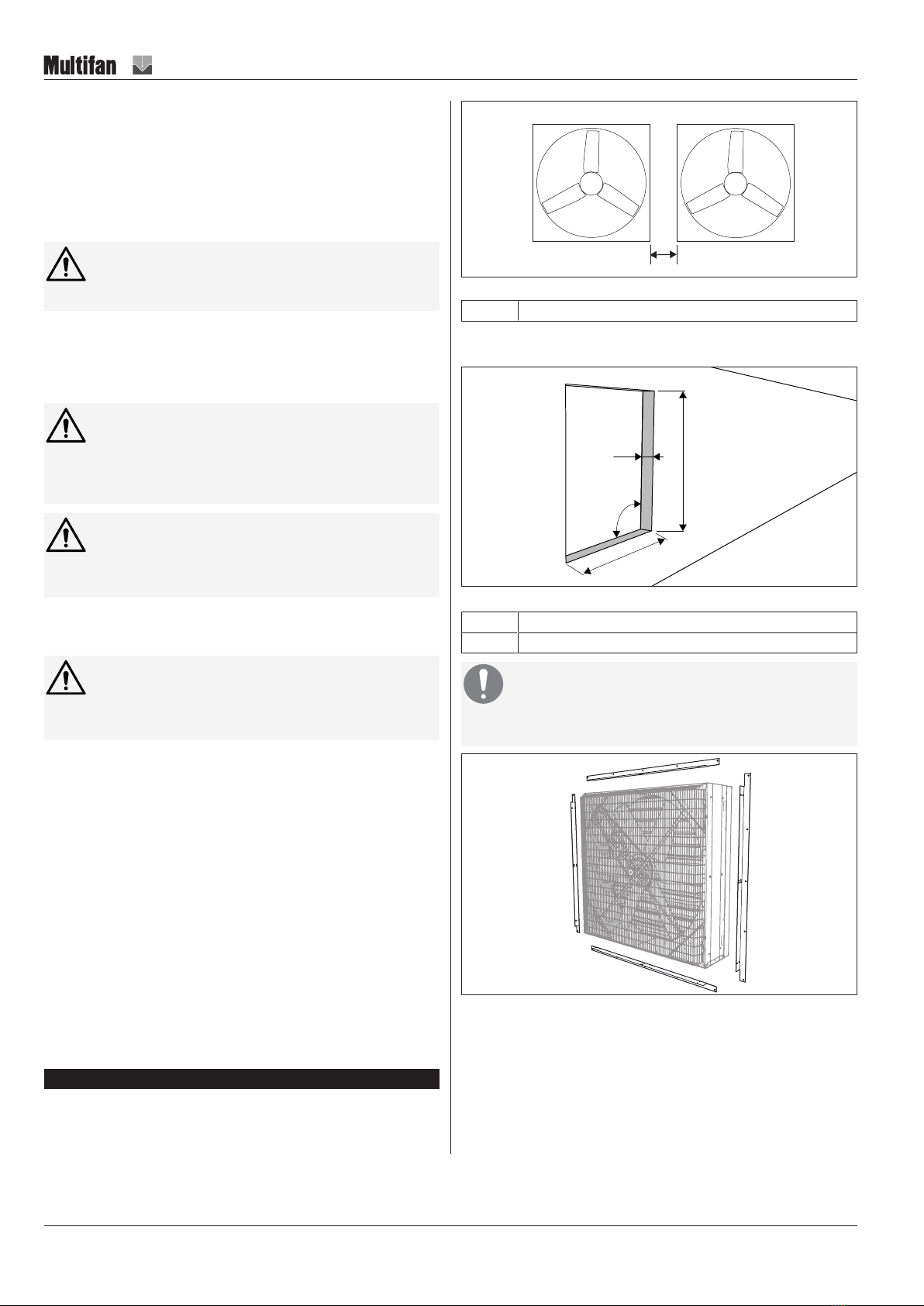

6.1 Mechanical ....................................................................................8

6.2 Electrical........................................................................................9

6.2.1 Thermal protection........................................................11

6.2.2 Speed control ...............................................................11

7 Commissioning ...................................................................................11

8 Operation .............................................................................................12

9 Maintenance.........................................................................................12

9.1 Maintenance schedule ................................................................12

9.2 Maintenance subjects..................................................................12

10 Troubleshooting and repairs..............................................................13

11 End of life.............................................................................................14

12 EU Declaration of Conformity ............................................................14

Glossary...............................................................................................15

1 Introduction

Thank you for choosing this Galvanized Box Fan 130.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY BEFORE USE

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

LIRE ET CONSERVER CES INSTRUCTIONS

These instructions are a part of this fan and must be passed on to any

subsequent owner and/or user.

Contact your supplier if there are parts of these instructions that you do not

understand. Compliance with these instructions will ensure a safe and correct

use of this fan.

NOTICE

This fan is for industrial, commercial and professional use

only.

Packaging

If packaging materials are no longer required, dispose of them in accordance

with regulations that apply in your area.

Modification of this fan

Modifying this fan without written permission of Vostermans Ventilation B.V. is

not permitted.

Warranty will be void when this fan is modified without permission.

The EU Declaration of Conformity is no longer valid if this fan is modified

without permission.

Legal notice / Disclaimer

The scope of delivery may vary from product images shown. This document

was created with all due care. The information, instructions and parts listed

are current on the date this document was issued.

Improper use

No liability is accepted for damages resulting from improper use.

2 Safety

Safety messages

Your safety and the safety of others are very important. Important safety

messages are provided in these instructions.

READ THESE MESSAGES CAREFULLY

A safety message alerts you to potential hazards that could hurt you or

others. Each safety message is preceded by a safety symbol and one of four

signal words: DANGER, WARNING, CAUTION or NOTICE.

Explanation of the signal words used in this document

DANGER : You will be killed or seriously hurt if you do not follow instructions.

WARNING : You can be killed or seriously hurt if you do not follow

instructions.

CAUTION : You can be hurt if you do not follow instructions.

NOTICE : Is used to address practices not related to physical injury.

Explanation of the safety symbols used

General warning symbol

Warning for electricity

Warning for hot surfaces

Warning for sharp elements

Warning for automatic activation

Warning for explosive materials

General mandatory action sign

Remark: not all of the listed symbols may be used in this document