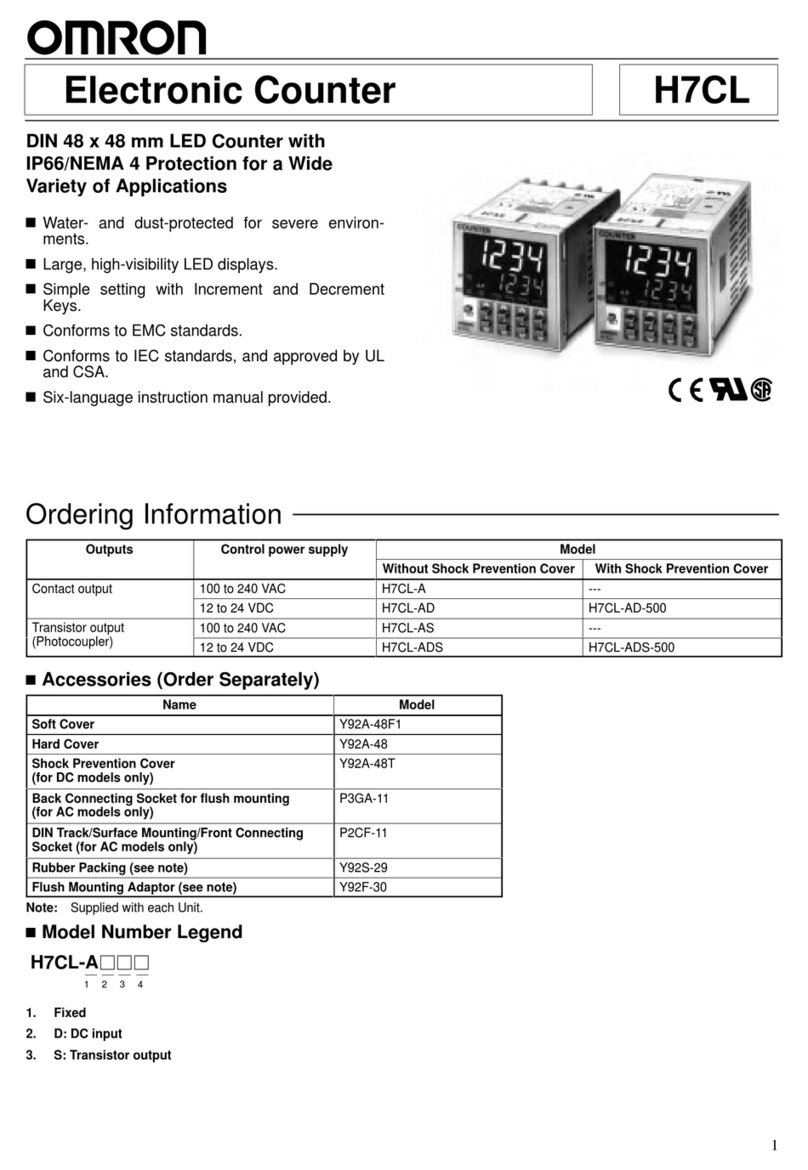

PC 1044

COUNT

SET COUNT

SET

ENT RESET

Allsafetyrelatedcodifications,symbolsandinstructionsthatappearinthisoperatingmanual

orontheequipmentmustbestrictlyfollowedtoensurethesafetyoftheoperatingpersonnelas

wellastheinstrument.

Ifalltheequipmentisnothandledinamannerspecifiedbythemanufacturer,itmightimpairthe

protectionprovidedbytheequipment.

Productimprovementandupgradeisaconstantprocedure.Soformoreupdatedoperatinginformationandsupport,

Pleasecontactourhelpline:+91-9978991474/76/82orEmailat

[email protected]Ver:05-2018

=> Readcompleteinstructionspriortoinstallationandoperationoftheunit.

WARNING: Riskofelectricshock.

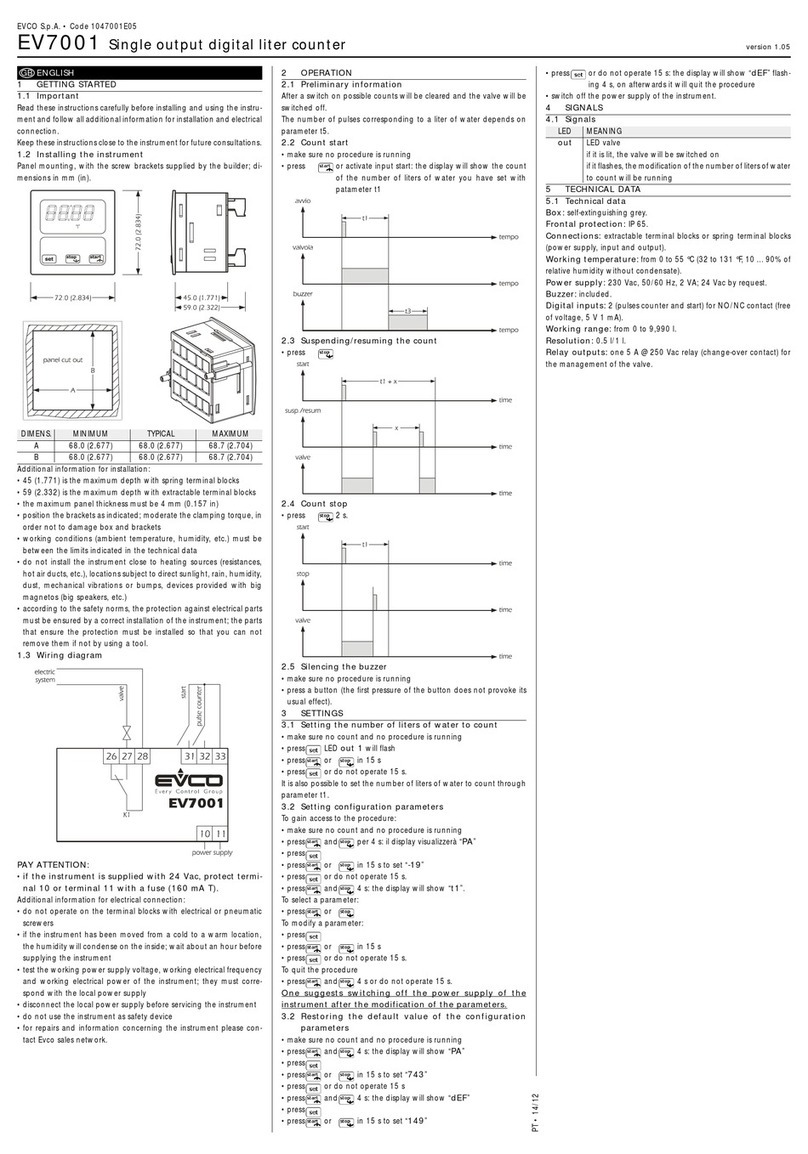

3)Cableusedforconnectiontopowersource,musthaveacrosssectionof1mmorgreater.Thesewires

shouldhaveinsulationscapacitymadeofatleast1.5kV.

2)Toreduceelectromagneticinterference,usewirewithadequateratingandtwistsofthesameofequalsizeshall

bemadewithshortestconnection.

4)Whenextendingthethermocoupleleadwires,alwaysusethermocouplecompensationwiresforwiringfortheRTD

type,useawiringmaterialwithasmallleadresistance(5maxperline)andnoresistancedifferentialsamong

threewiresshouldbepresent.

1)TopreventtheriskofelectricshockpowersupplytotheequipmentmustbekeptOFFwhiledoingthewiring

arrangement.Donottouchtheterminalswhilepowerisbeingsupplied.

5)Abetteranti-noiseeffectcanbeexpectedbyusingstandardpowersupplycablefortheinstrument.

1)Thisequipment,beingbuilt-in-type,normallybecomesapartofmaincontrolpanelandsuchincasethe

terminalsdonotremainaccessibletotheenduserafterinstallationandinternalwiring.

2)Donotallowpiecesofmetal,wireclippings,orfinemetallicfillingsfrominstallationtoentertheproduct

orelseitmayleadtoasafetyhazardthatmayinturnendangerlifeorcauseelectricalshocktotheoperator.

3)Circuitbreakerormainsswitchmustbeinstalledbetweenpowersourceandsupplyterminalto

facilitatepowerONorOFFfunction.Howeverthismainsswitchorcircuitbreakermustbe

installedatconvenientplacenormallyaccessibletotheoperator.

4)Useandstoretheinstrumentwithinthespecifiedambienttemperatureandhumidityrangesas

mentionedinthismanual.

WarningGuidelines

SafetyPrecautions

InstallationGuidelines

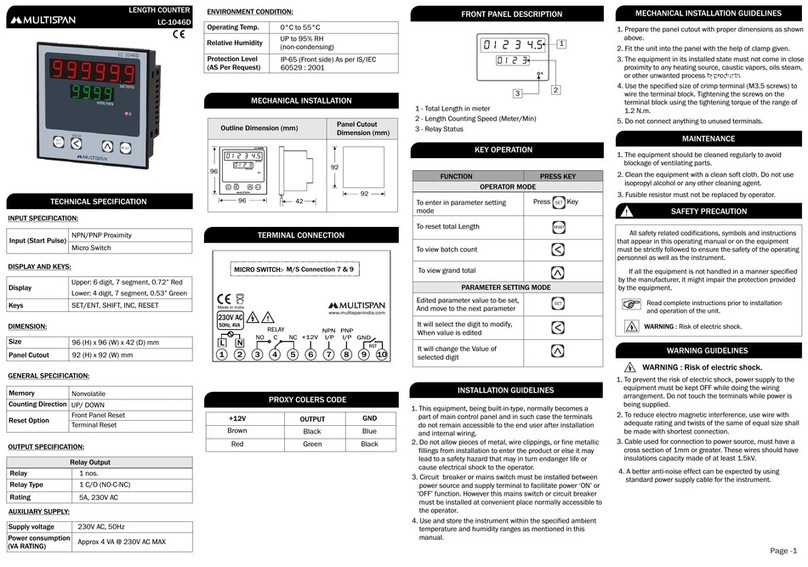

MechanicalInstallation

Maintenance

1)Preparethepanelcutoutwithproperdimensionsasshowabove.

2)Fittheunitintothepanelwiththehelpofclampgiven.

3)Theequipmentinitsinstalledstatemustnotcomeincloseproximitytoanyheatingsource,

causticvapors,oilssteam,orotherunwantedprocessbyproducts.

4)Usethespecifiedsizeofcrimpterminal(M3.5screws)towiretheterminalblock.Tighteningthe

screwsontheterminalblockusingthetighteningtorqueoftherangeof1.2N.m.

5)Donotconnectanythingtounusedterminals.

1)Theequipmentshouldbecleanedregularlytoavoidblockageofventilatingparts.

2)Cleantheequipmentwithacleansoftcloth.Donotuseisopropylalcoholoranyothercleaningagent.

3)Fusibleresistormustnotbereplacedbyoperator.

2

www.multispanindia.com

Page-4PC-1044

A

B

C

D

MODEL A

96mm 96mm 92mm 92mm 3mm 50mm

BC

D E

F

DIMENSIONS

136mm-5.35inches

120mm-4.72inches

EF