Murata GRT155R61A225ME01 Series User manual

Other Murata Industrial Electrical manuals

Murata

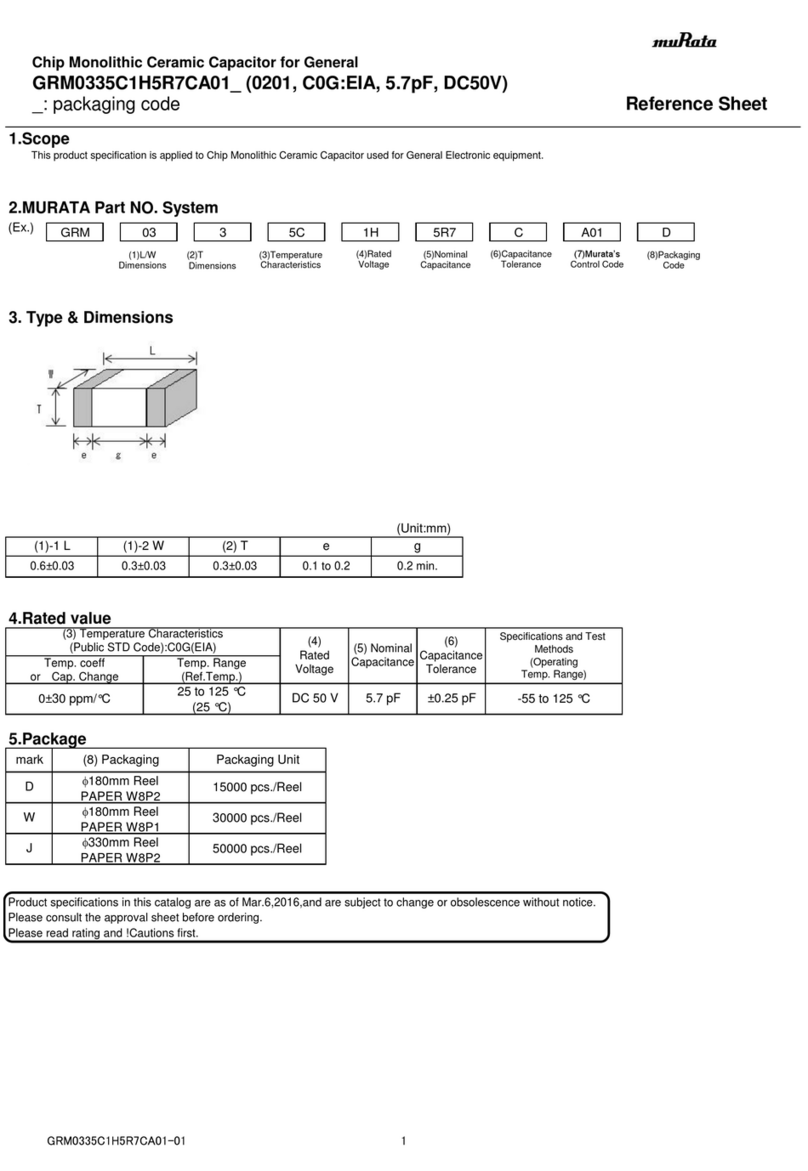

Murata GRM0335C1H5R7CA01 Series User manual

Murata

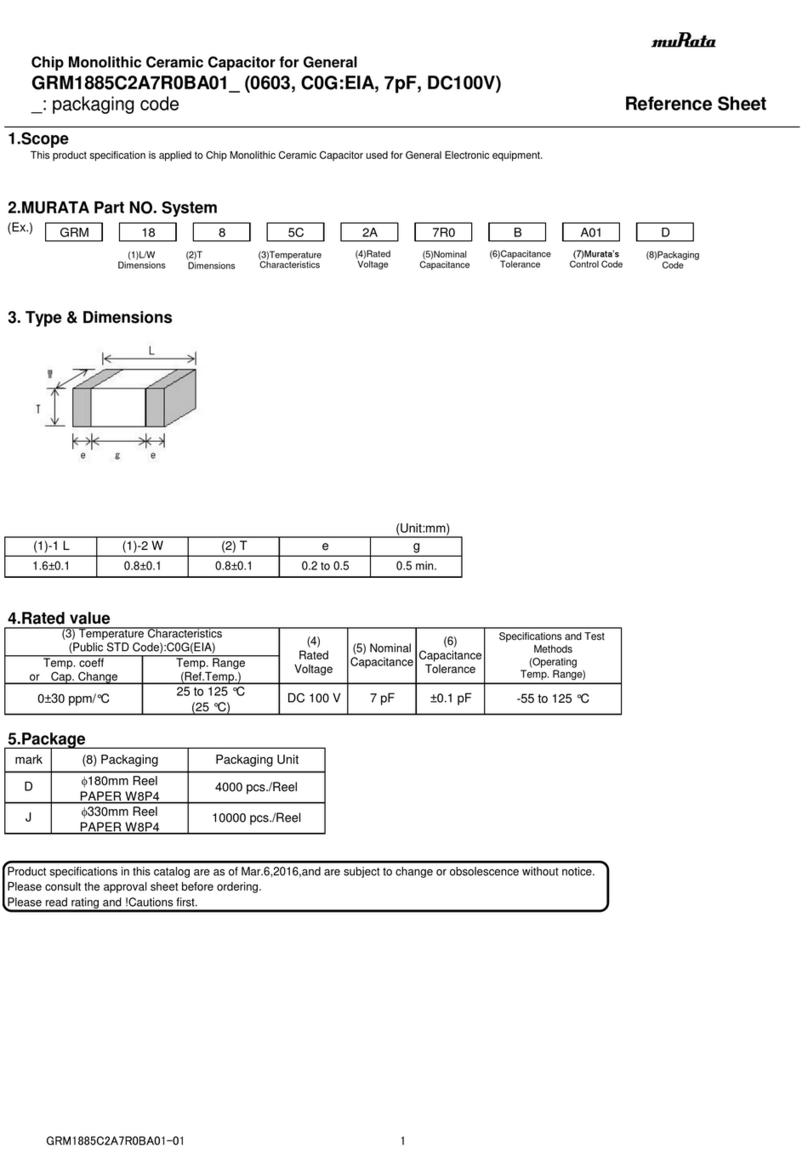

Murata GRM1885C2A7R0BA01 Series User manual

Murata

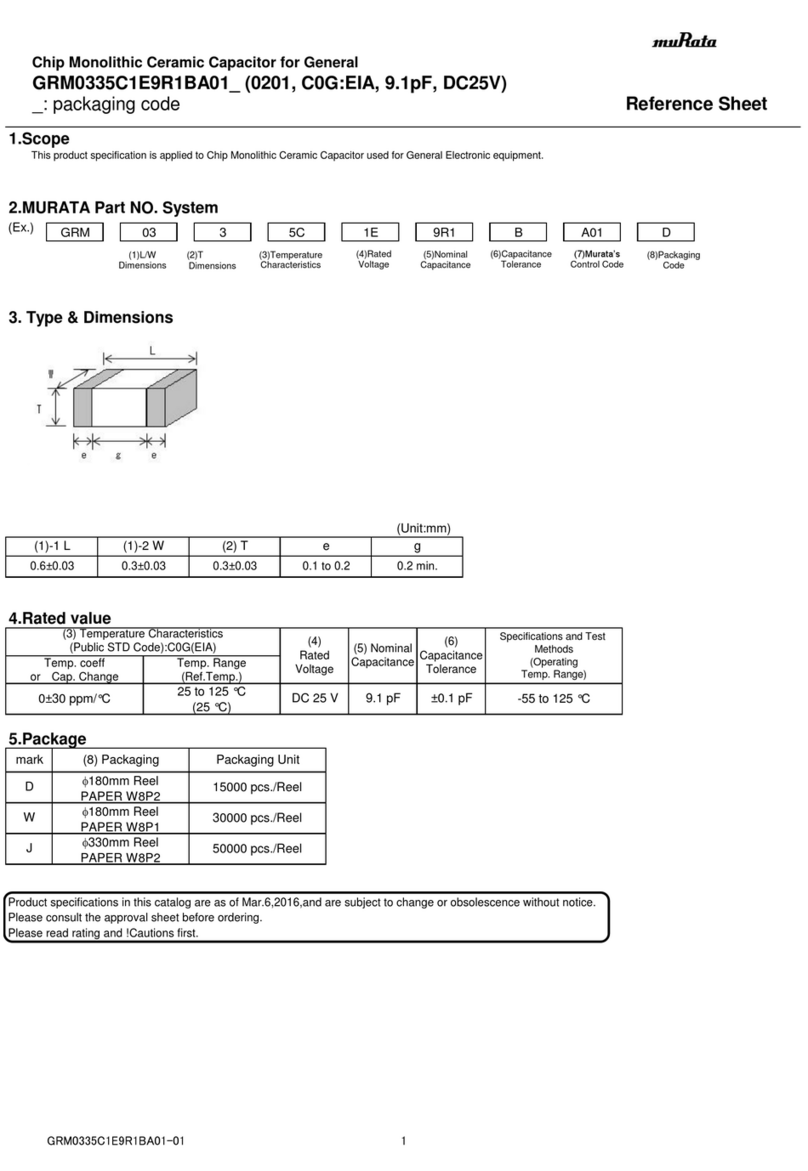

Murata GRM0335C1E9R1BA01 Series User manual

Murata

Murata GQM22M5C2H200GB01 Series User manual

Murata

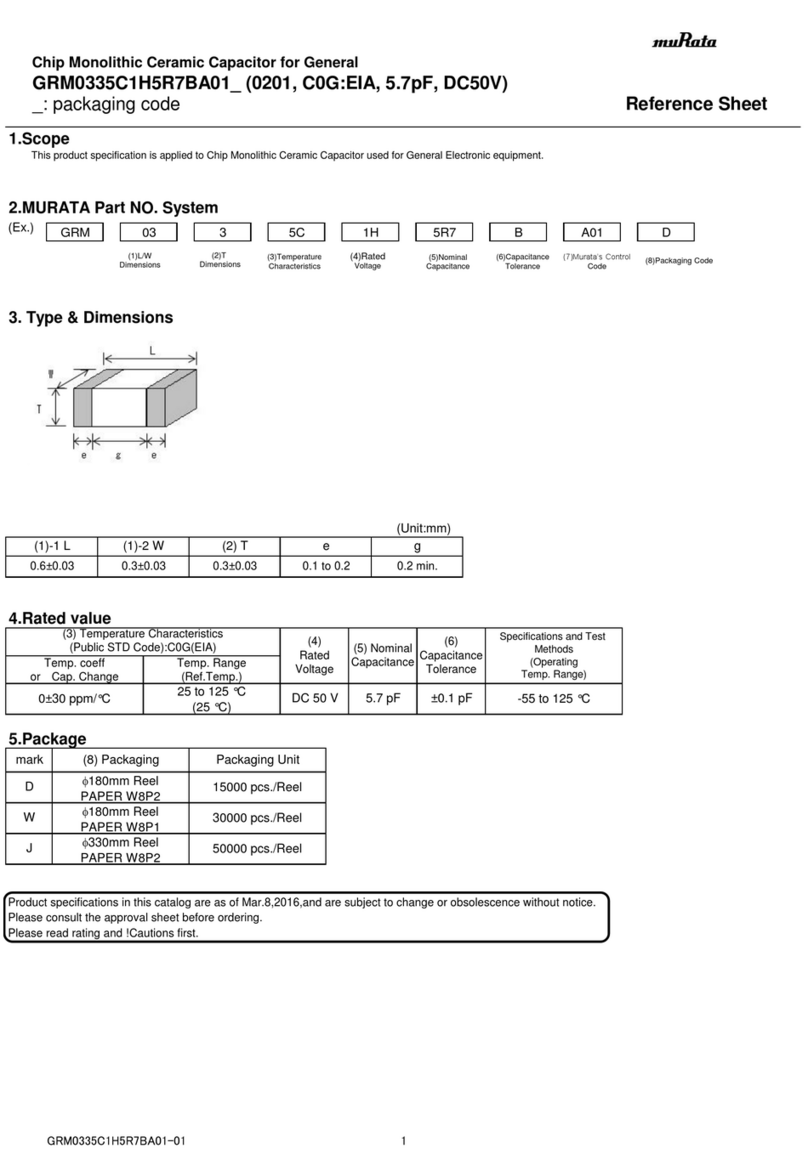

Murata GRM0335C1H5R7BA01 Series User manual

Murata

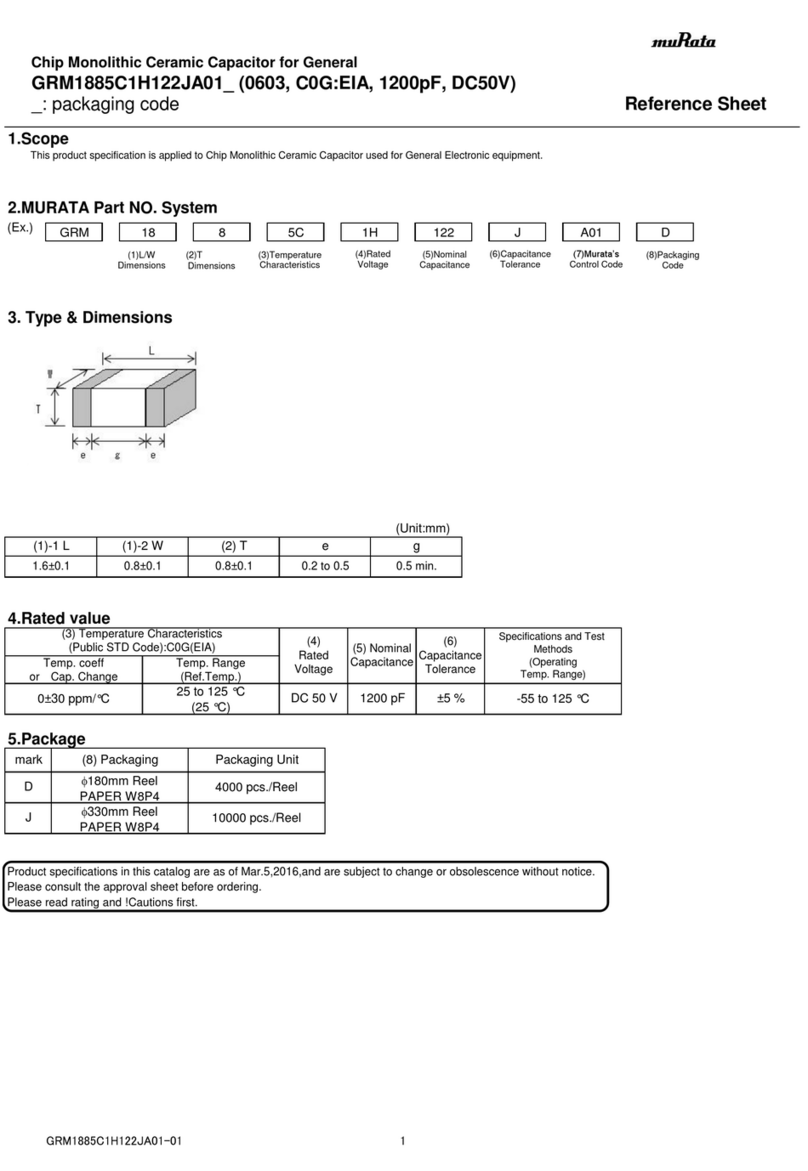

Murata GRM1885C1H122JA01 Series User manual

Murata

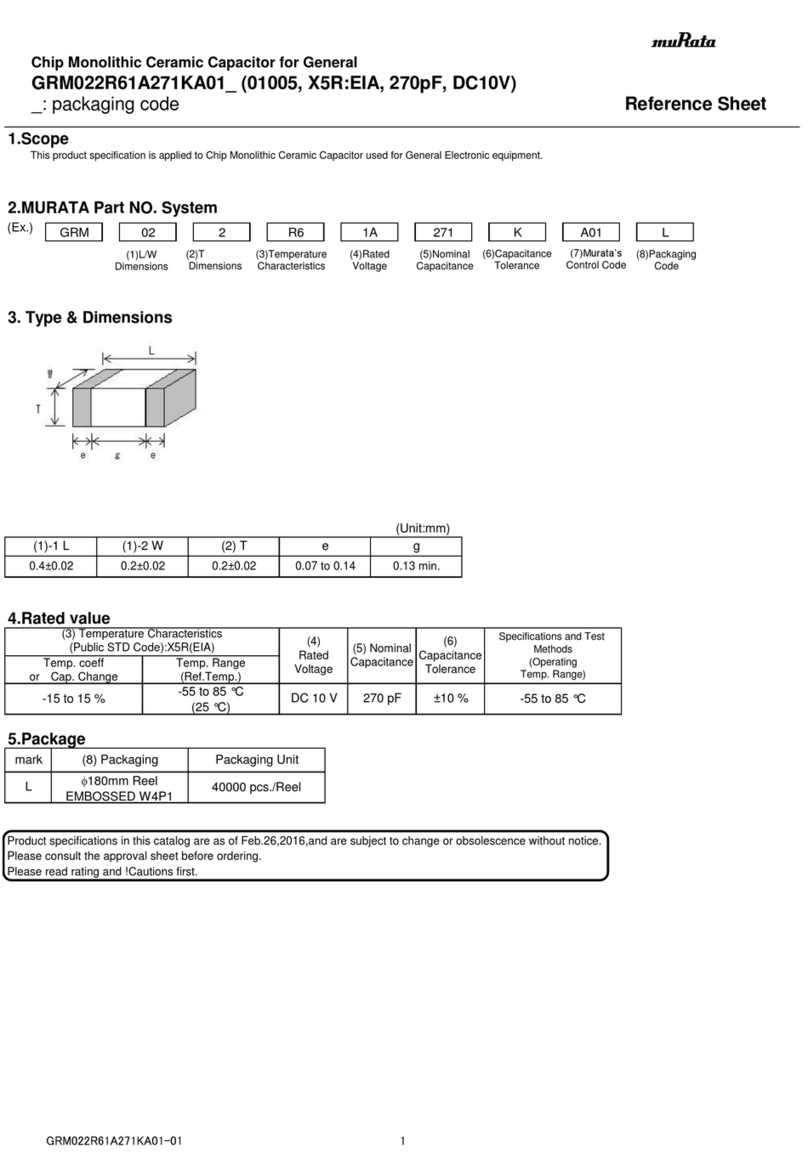

Murata GRM022R61A271KA01 Series User manual

Murata

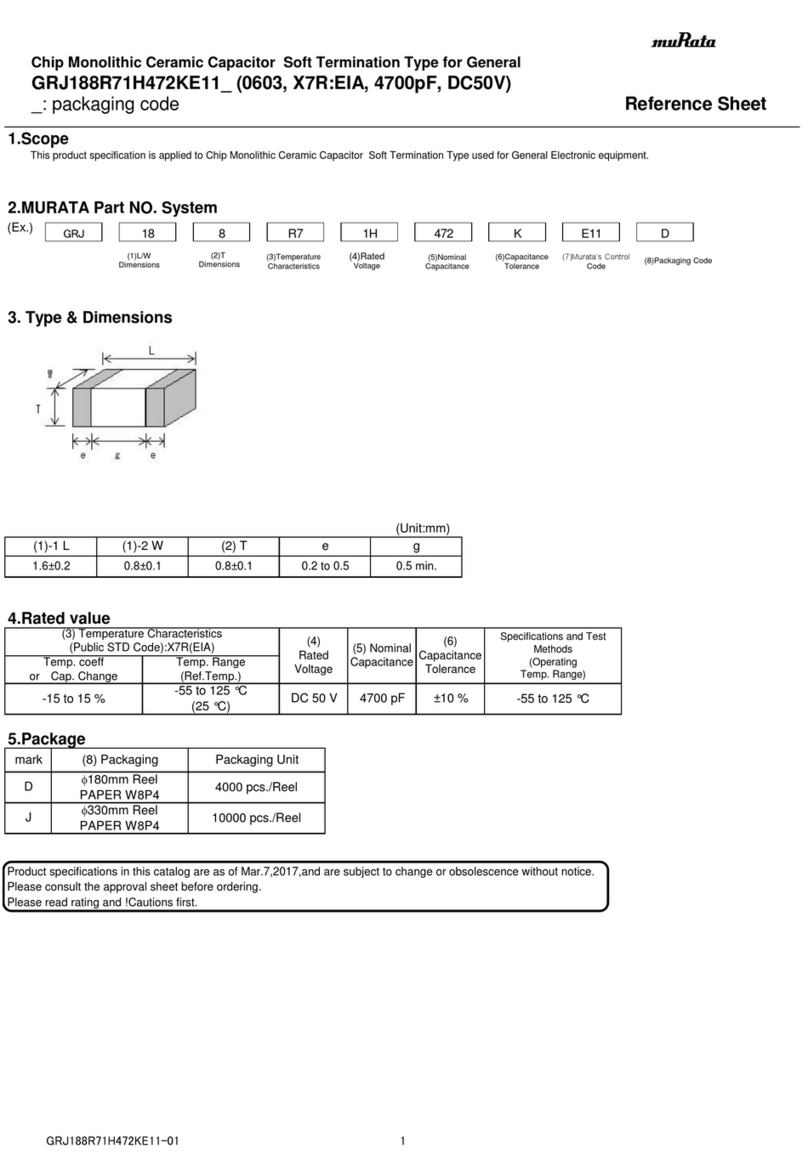

Murata GRJ188R71H472KE11 Series User manual

Murata

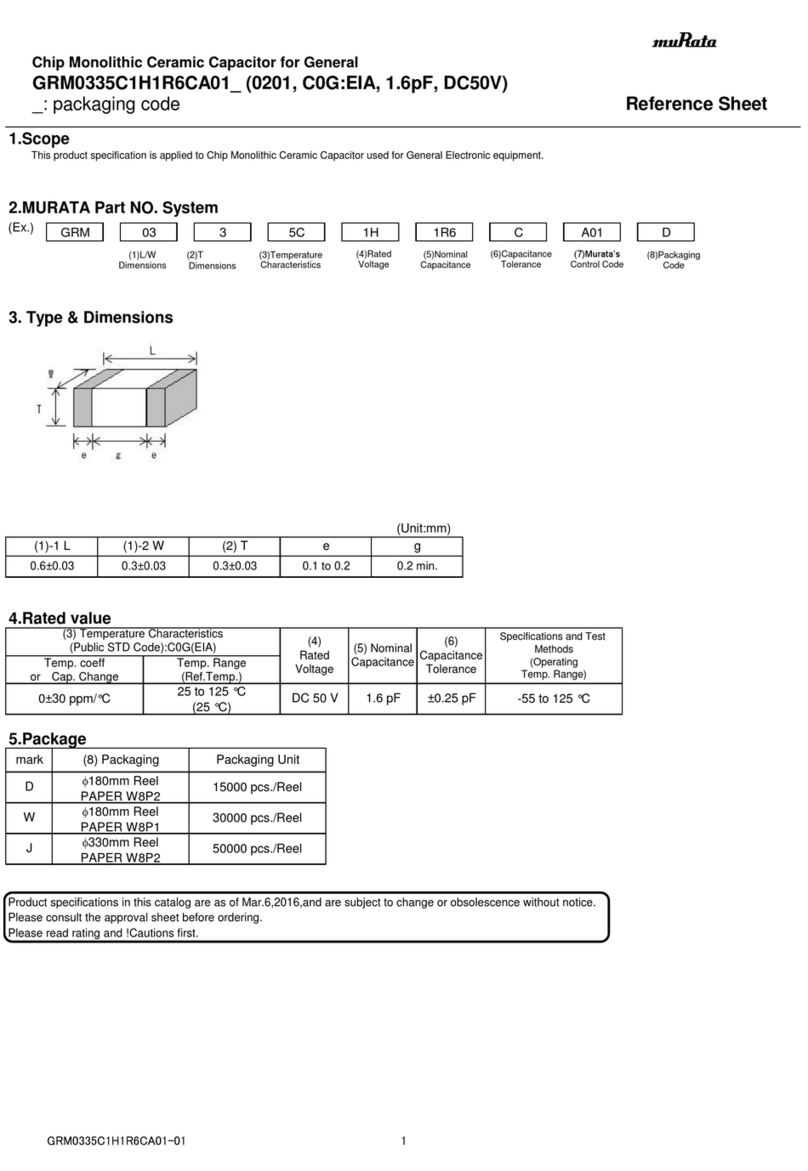

Murata GRM0335C1H1R6CA01 Series User manual

Murata

Murata GQM22M5C2H300GB01 Series User manual

Murata

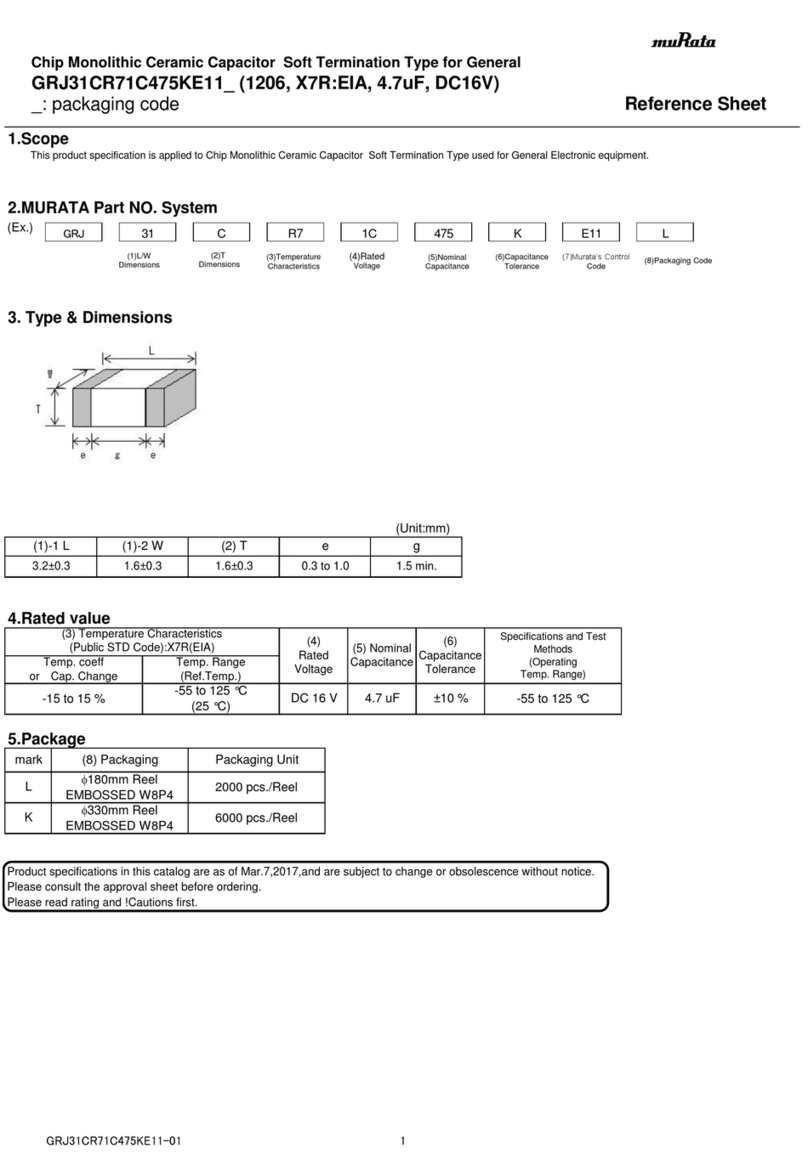

Murata GRJ31CR71C475KE11 Series User manual

Murata

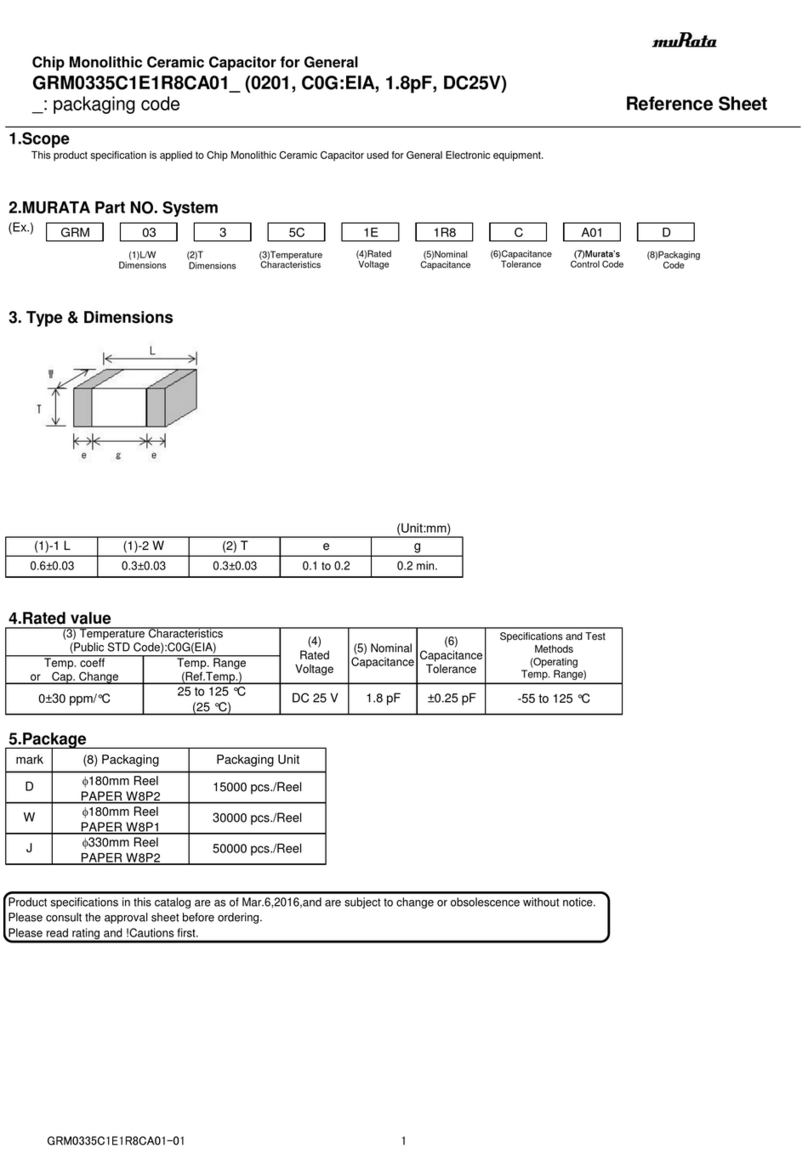

Murata GRM0335C1E1R8CA01 Series User manual

Murata

Murata GRM155F50J104ZA01 Series User manual

Murata

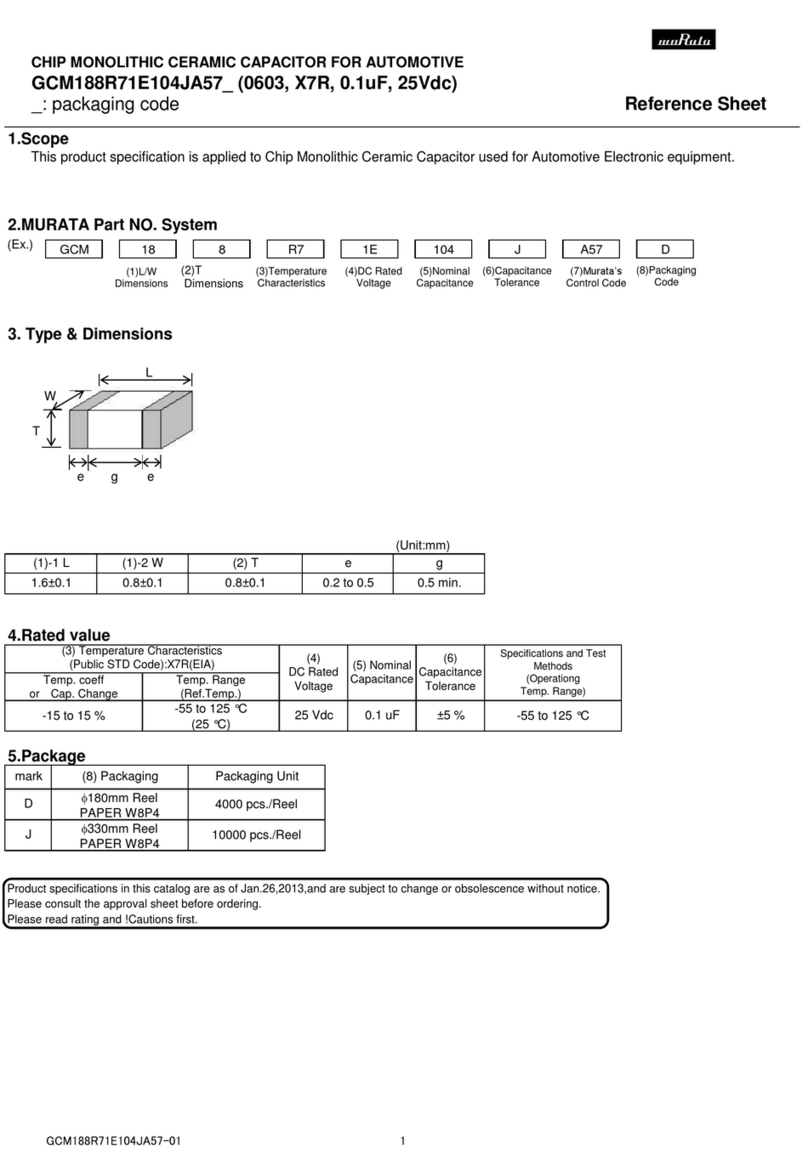

Murata GCM188R71E104JA57 Series User manual

Murata

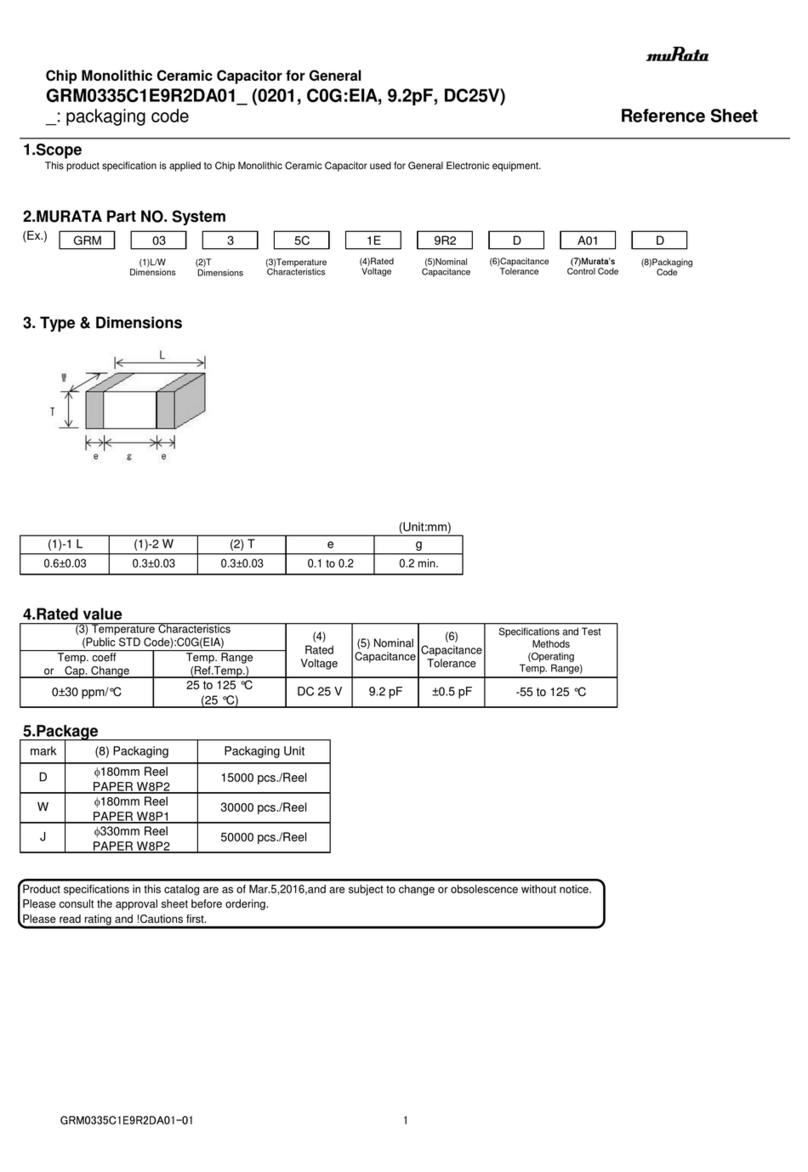

Murata GRM0335C1E9R2DA01 Series User manual

Murata

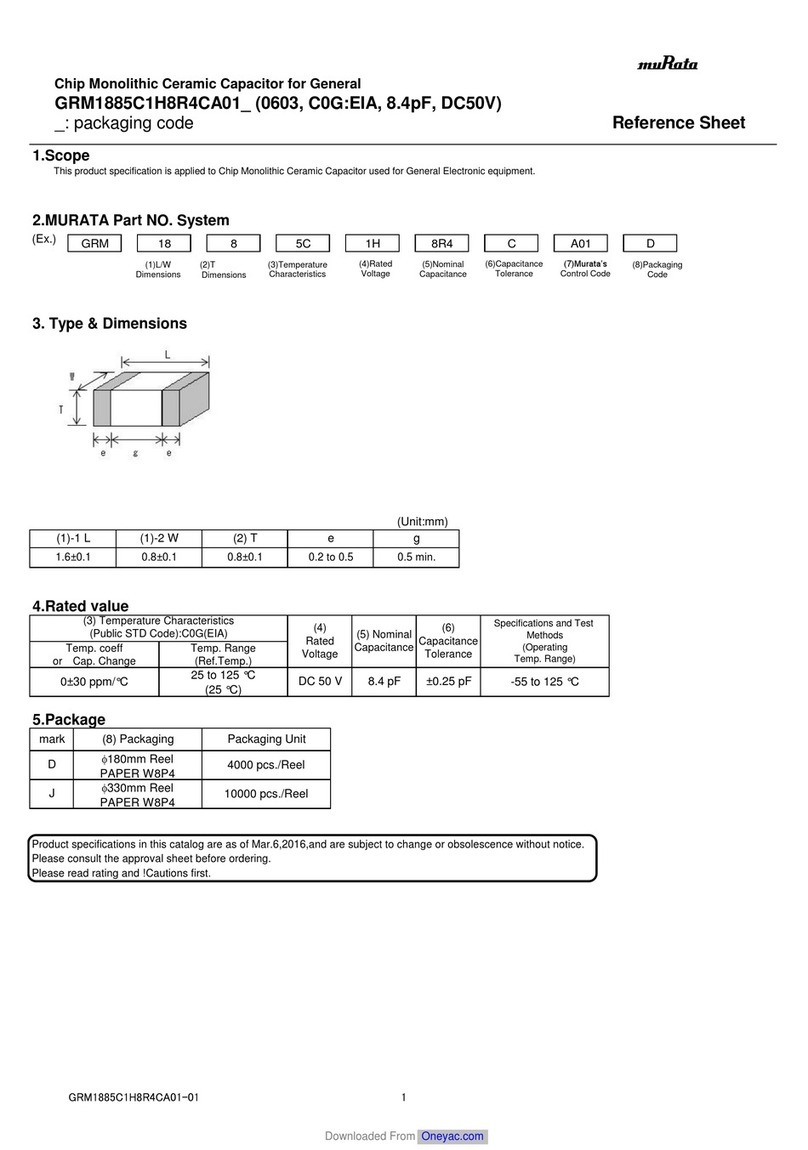

Murata GRM1885C1H8R4CA01 Series User manual

Murata

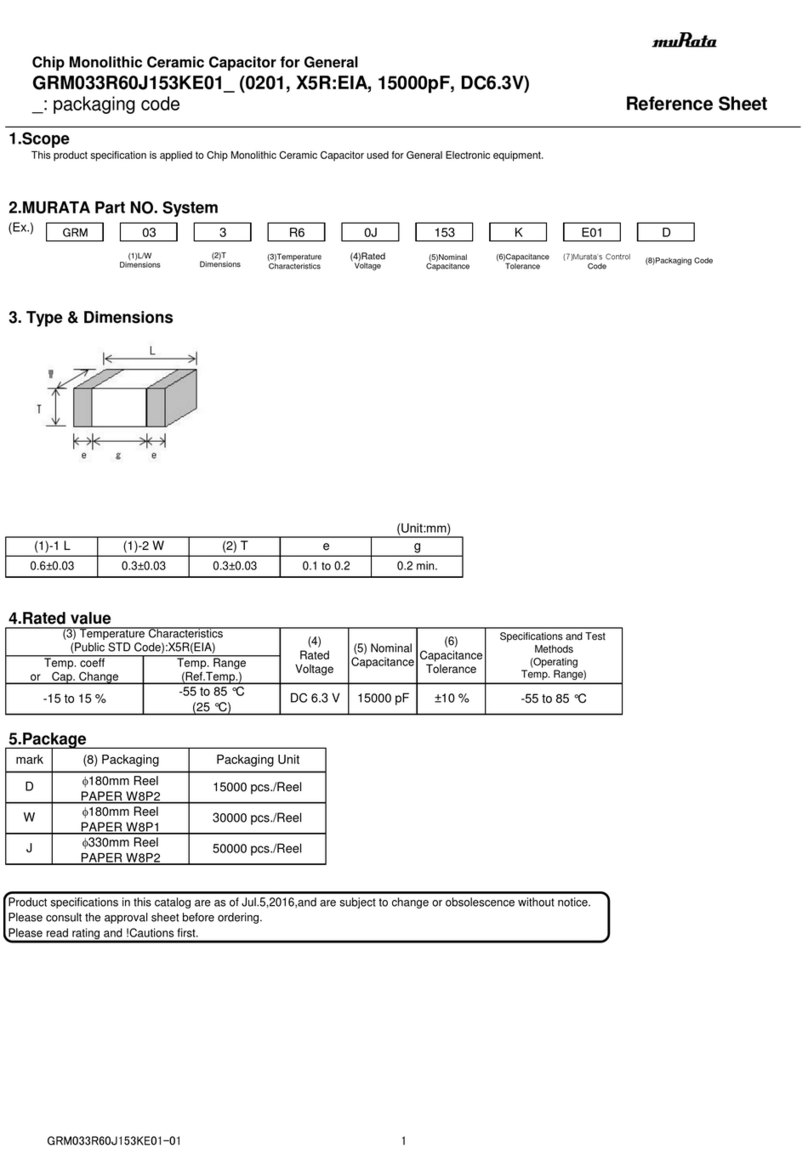

Murata GRM033R60J153KE01 Series User manual

Murata

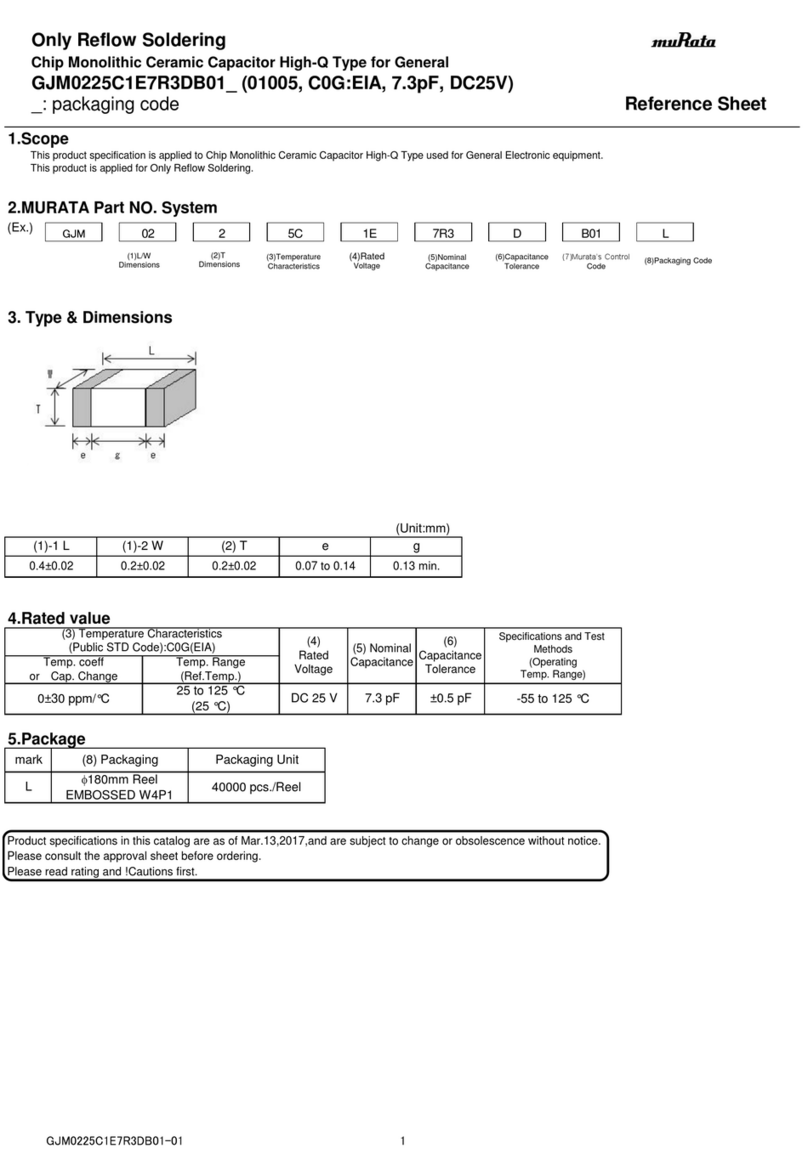

Murata GJM0225C1E7R3DB01 Series User manual

Murata

Murata GRM155R71H473KE14 Series User manual

Murata

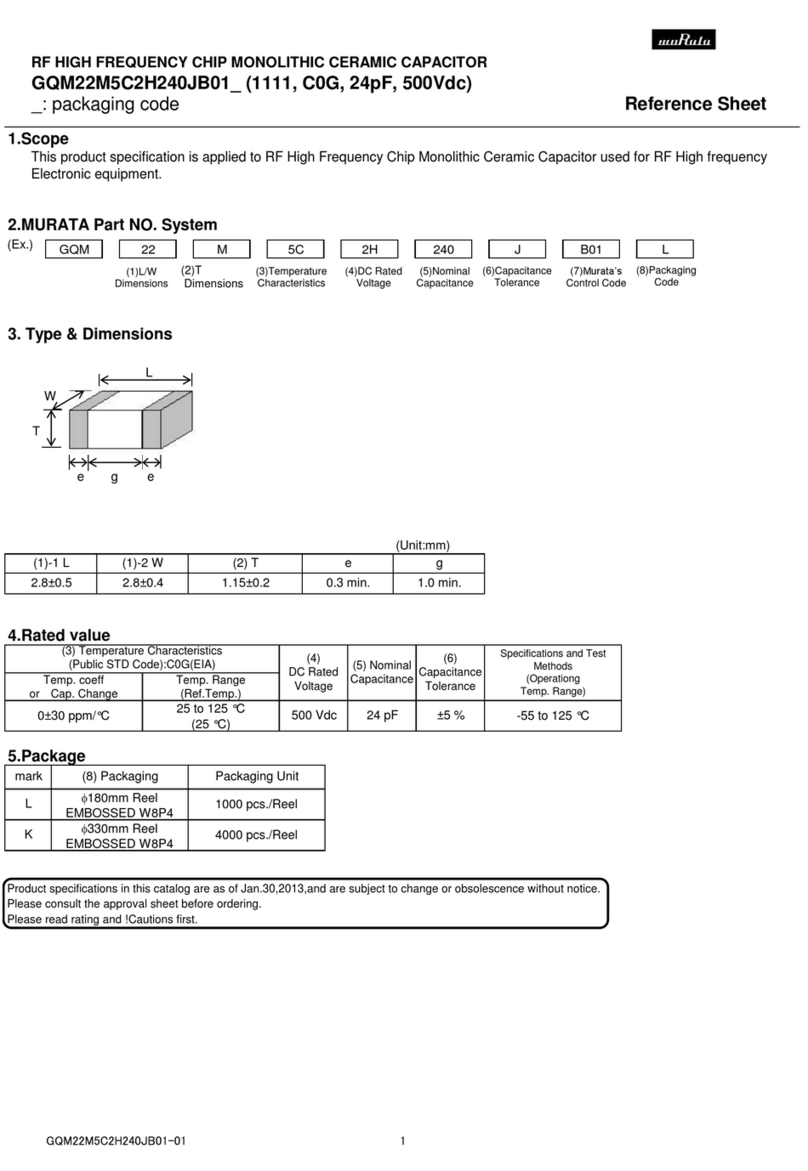

Murata GQM22M5C2H240JB01 Series User manual

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

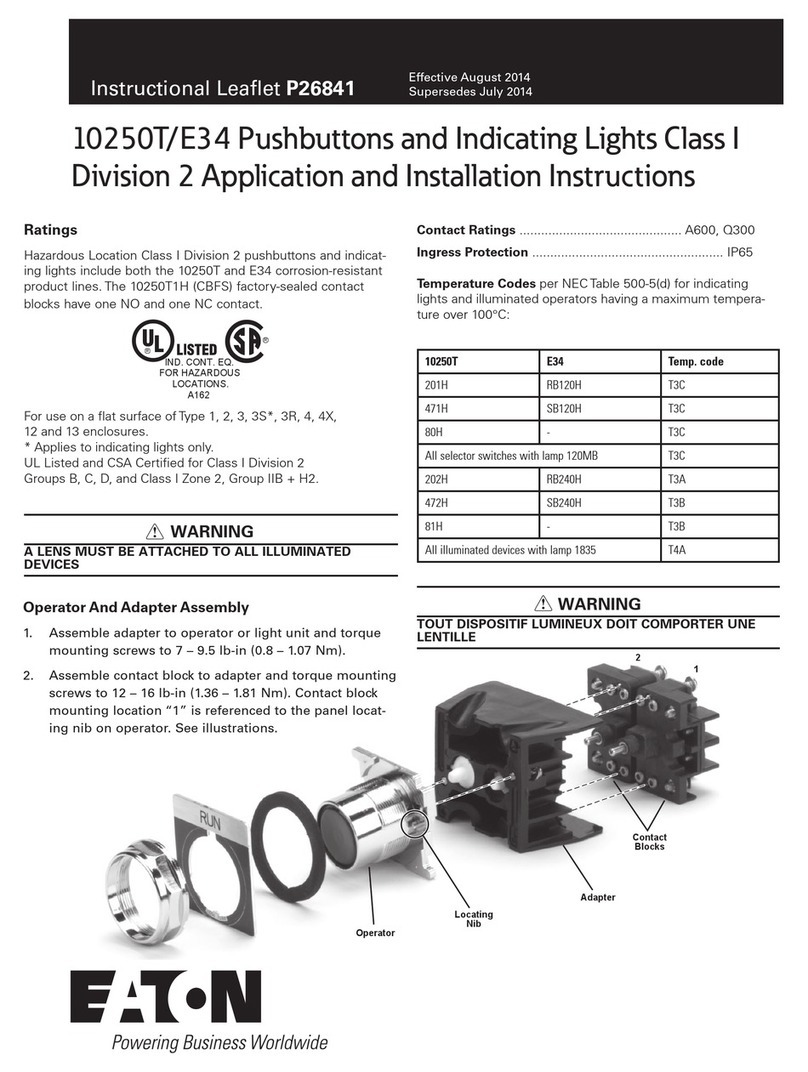

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

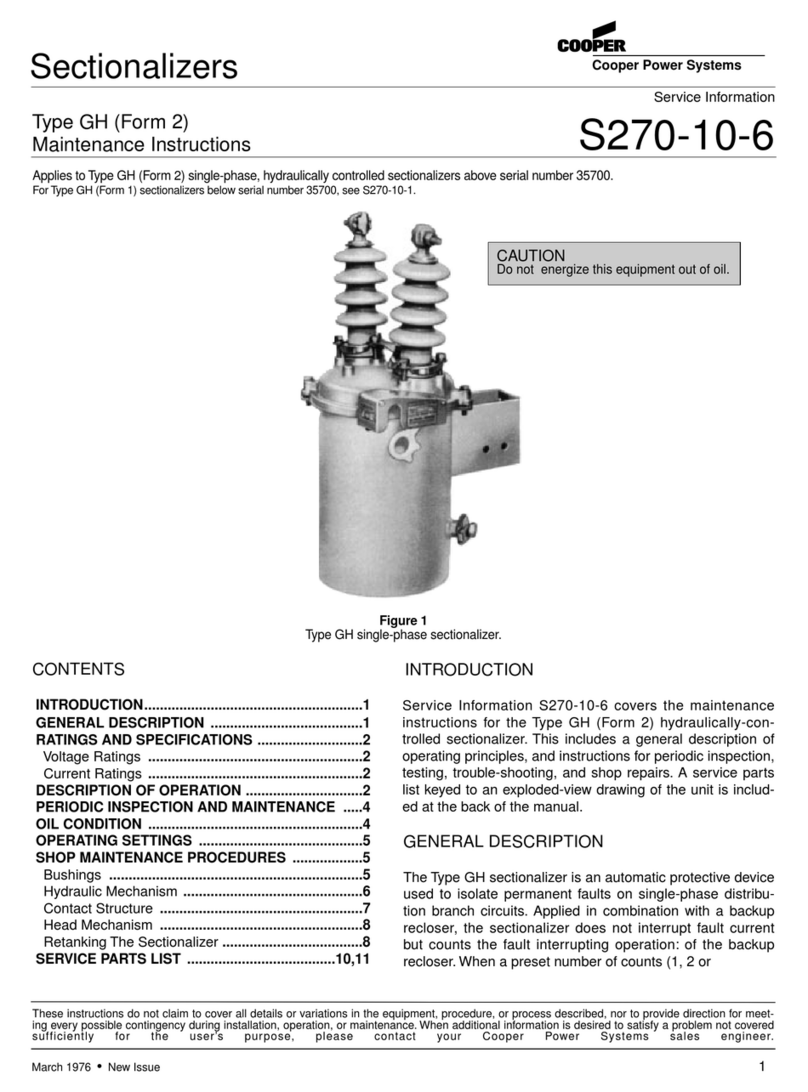

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions