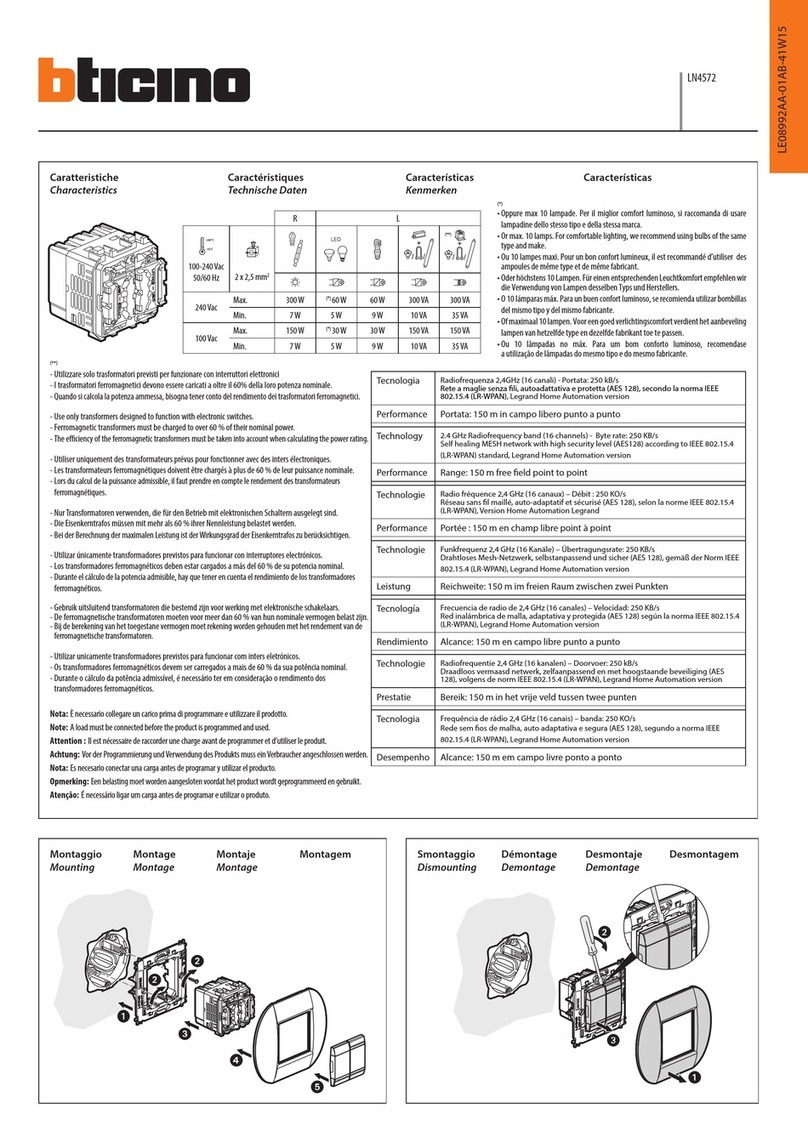

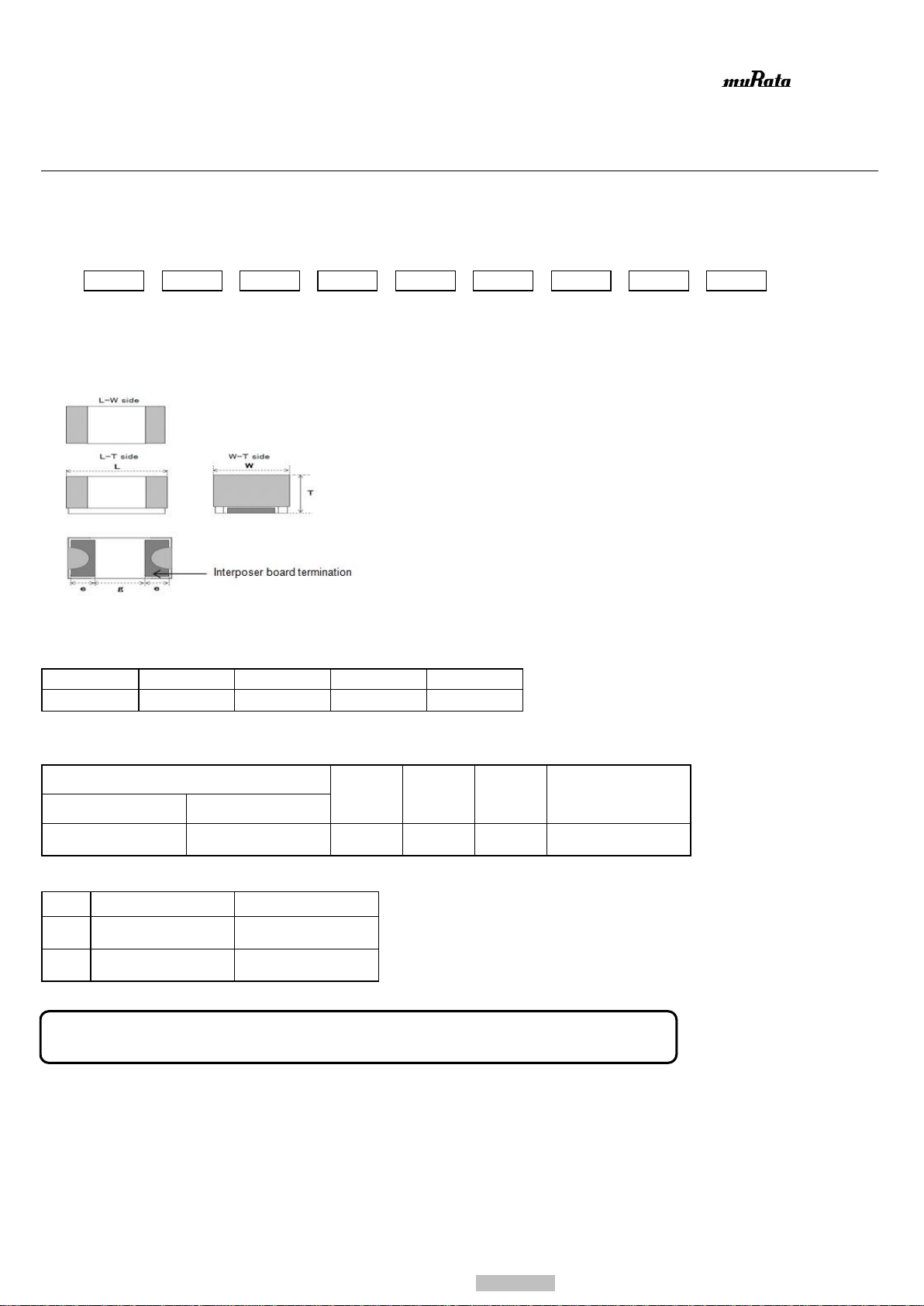

Murata ZRB15XR61A106ME01 Series User manual

Other Murata Industrial Electrical manuals

Murata

Murata GRT31CR60J476KE13 Series User manual

Murata

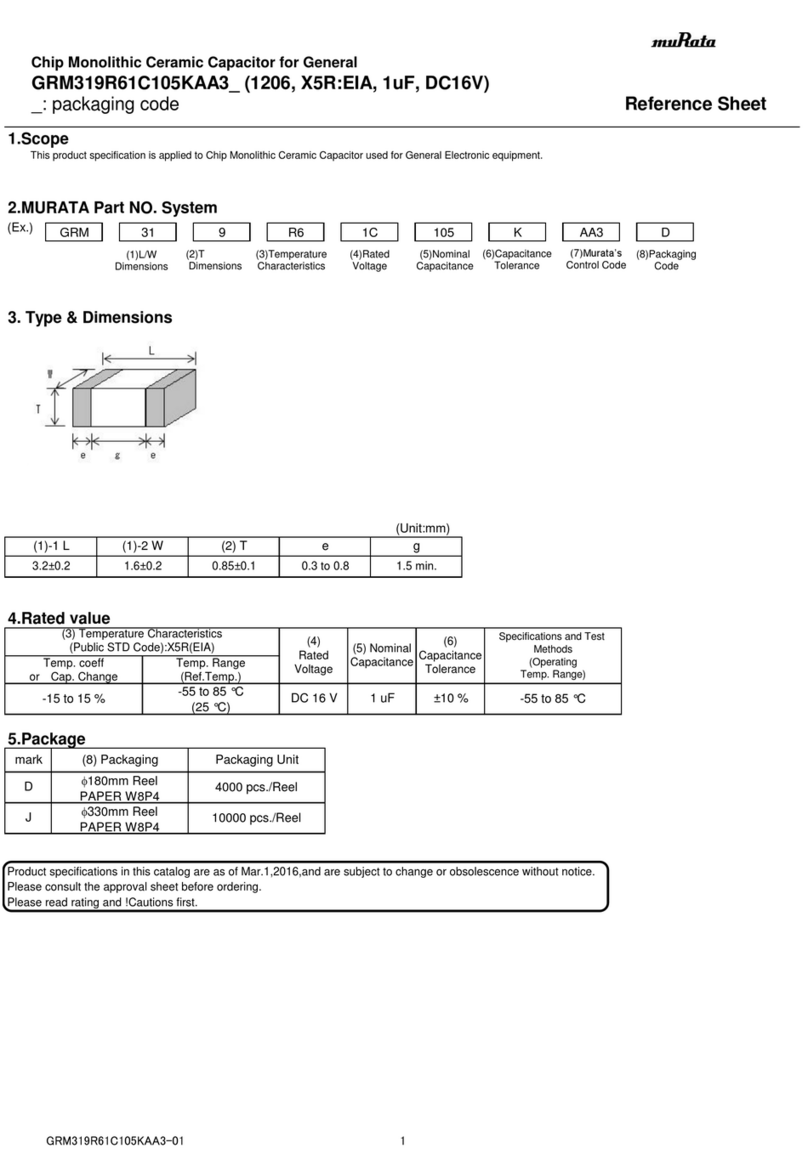

Murata GRM319R61C105KAA3 Series User manual

Murata

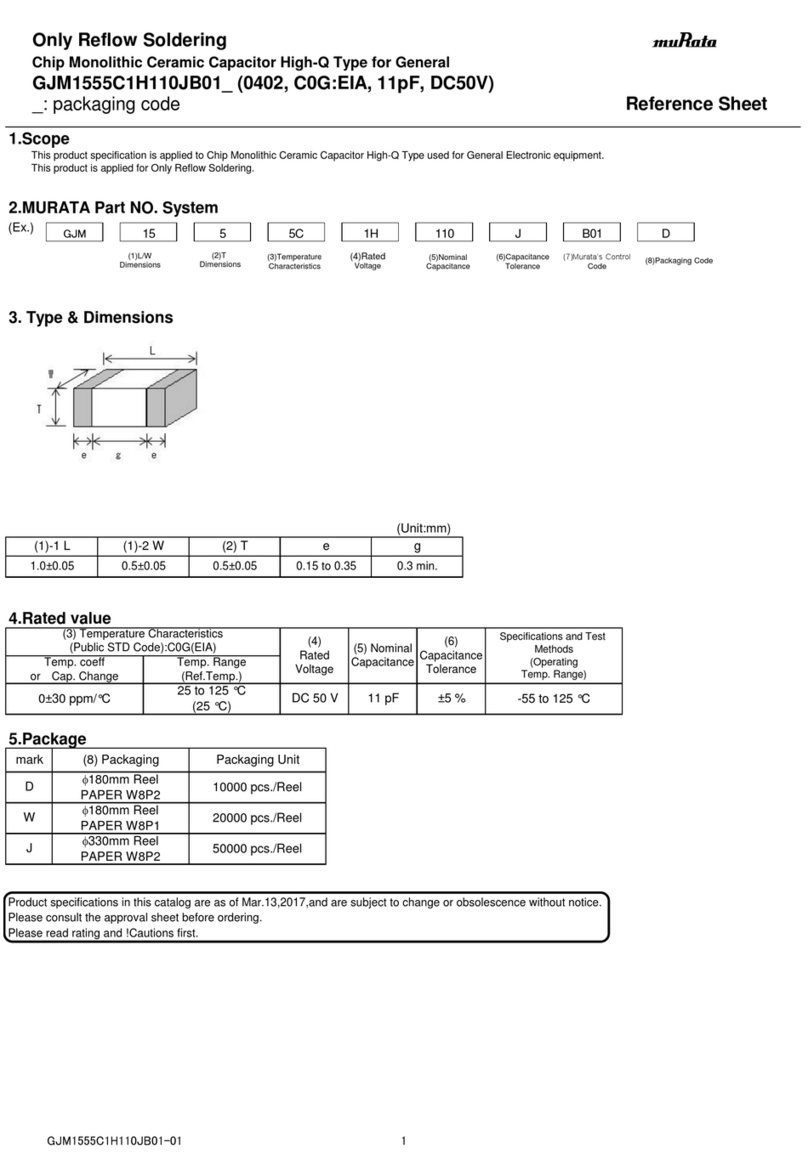

Murata GJM1555C1H110JB01 Series User manual

Murata

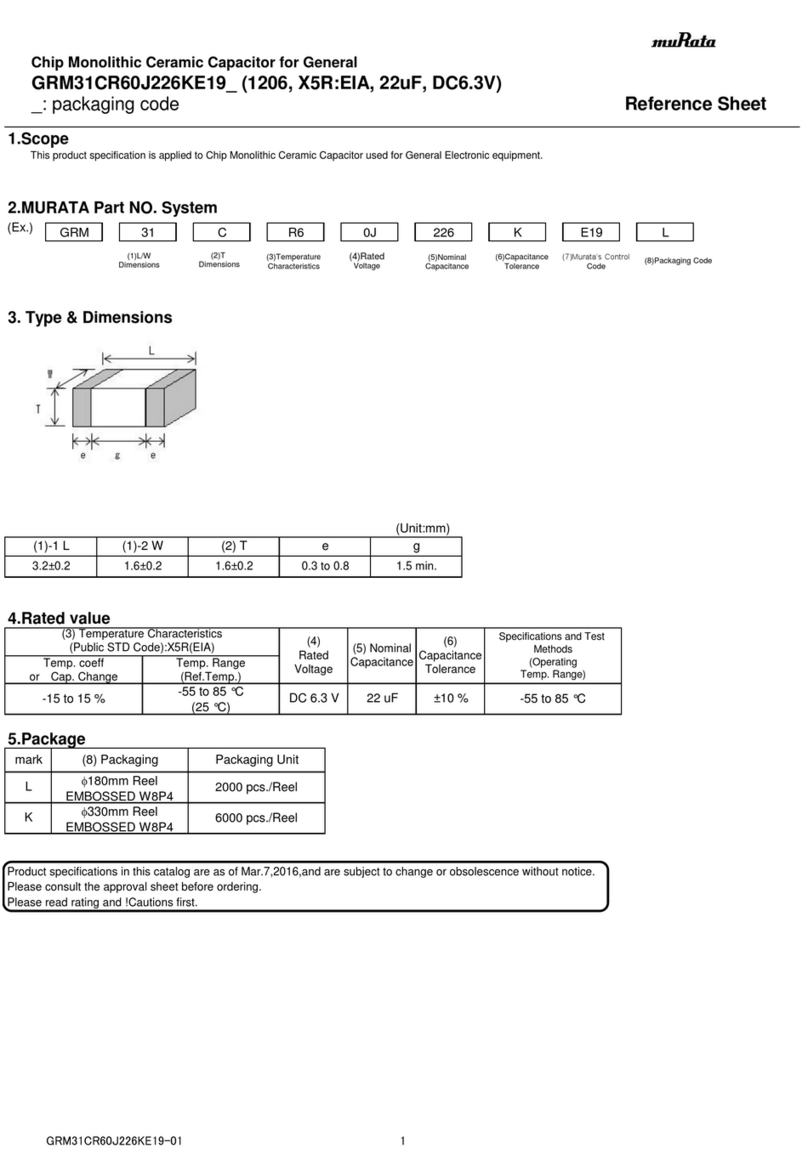

Murata GRM31CR60J226KE19 Series User manual

Murata

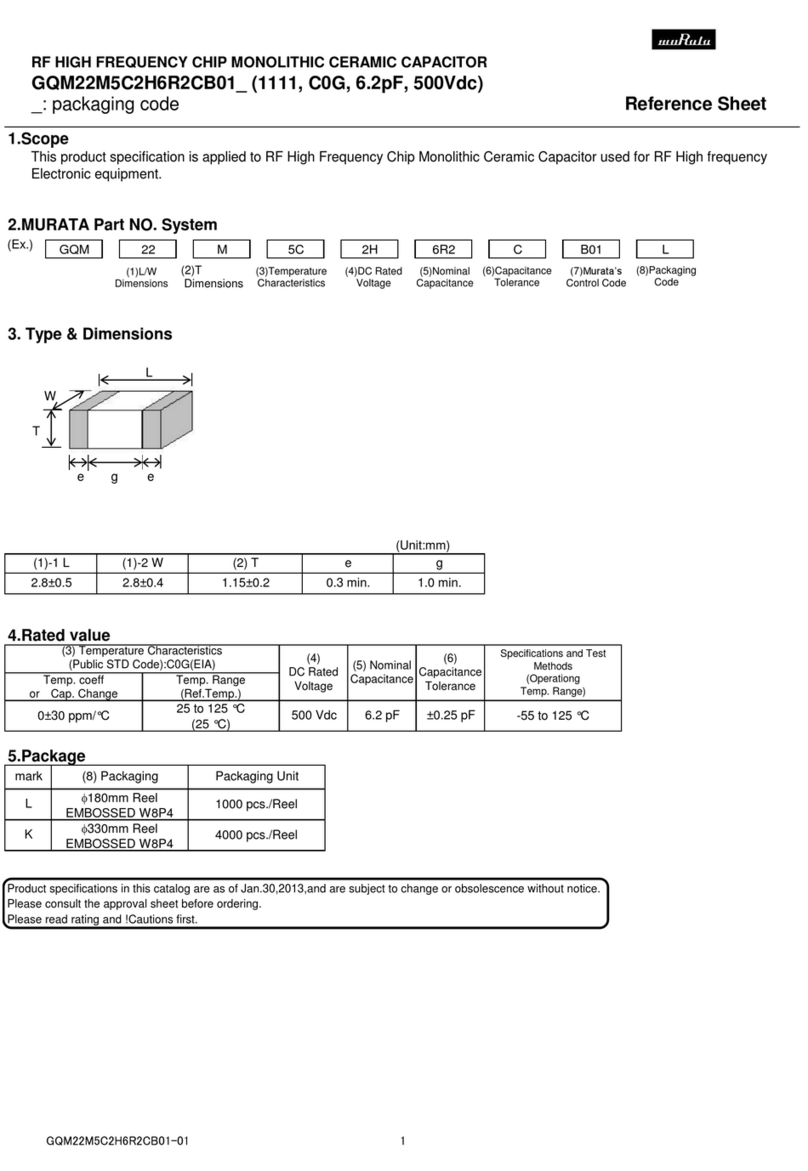

Murata GQM22M5C2H6R2CB01 Series User manual

Murata

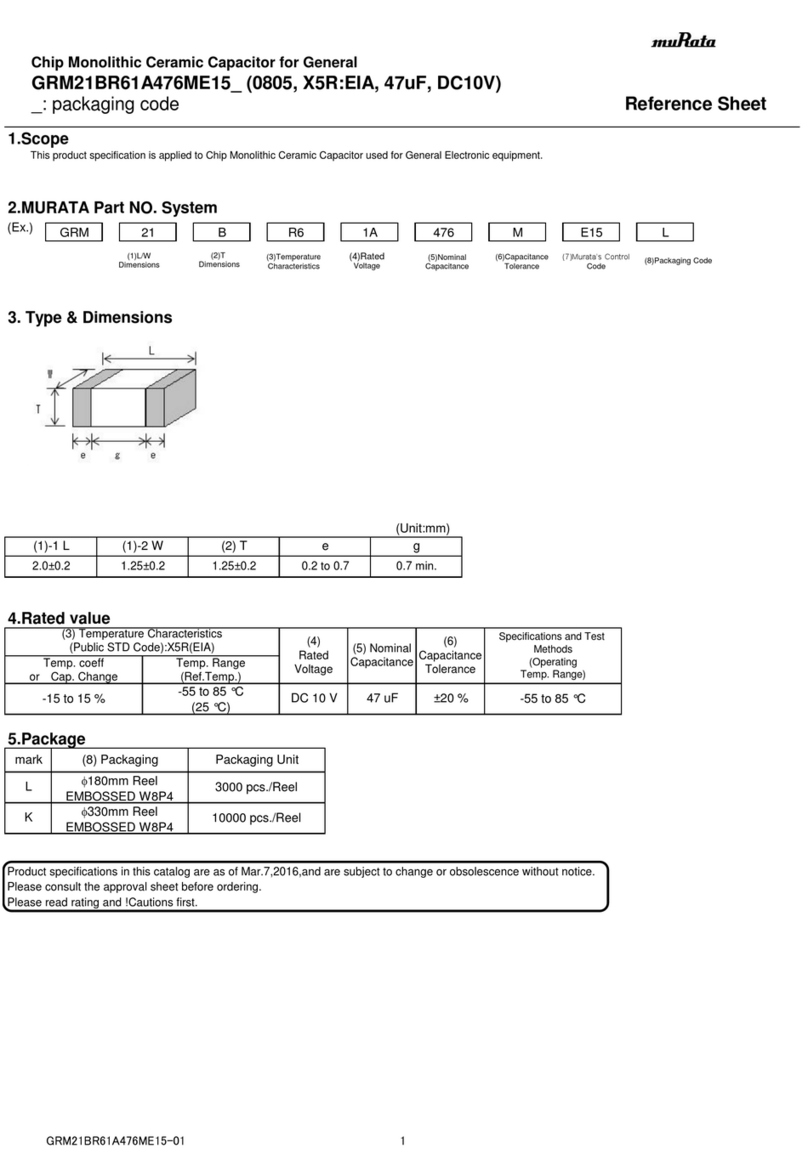

Murata GRM21BR61A476ME15 Series User manual

Murata

Murata GRM0335C1H6R7CA01 Series User manual

Murata

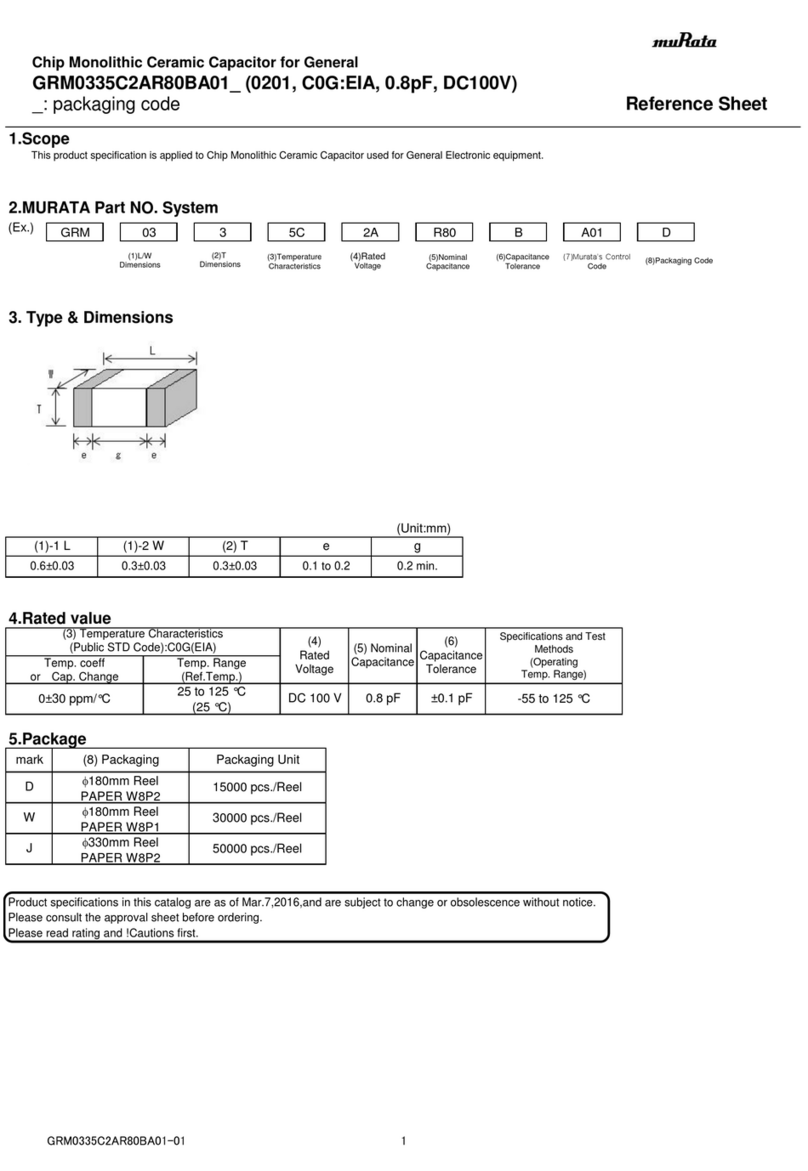

Murata GRM0335C2AR80BA01 Series User manual

Murata

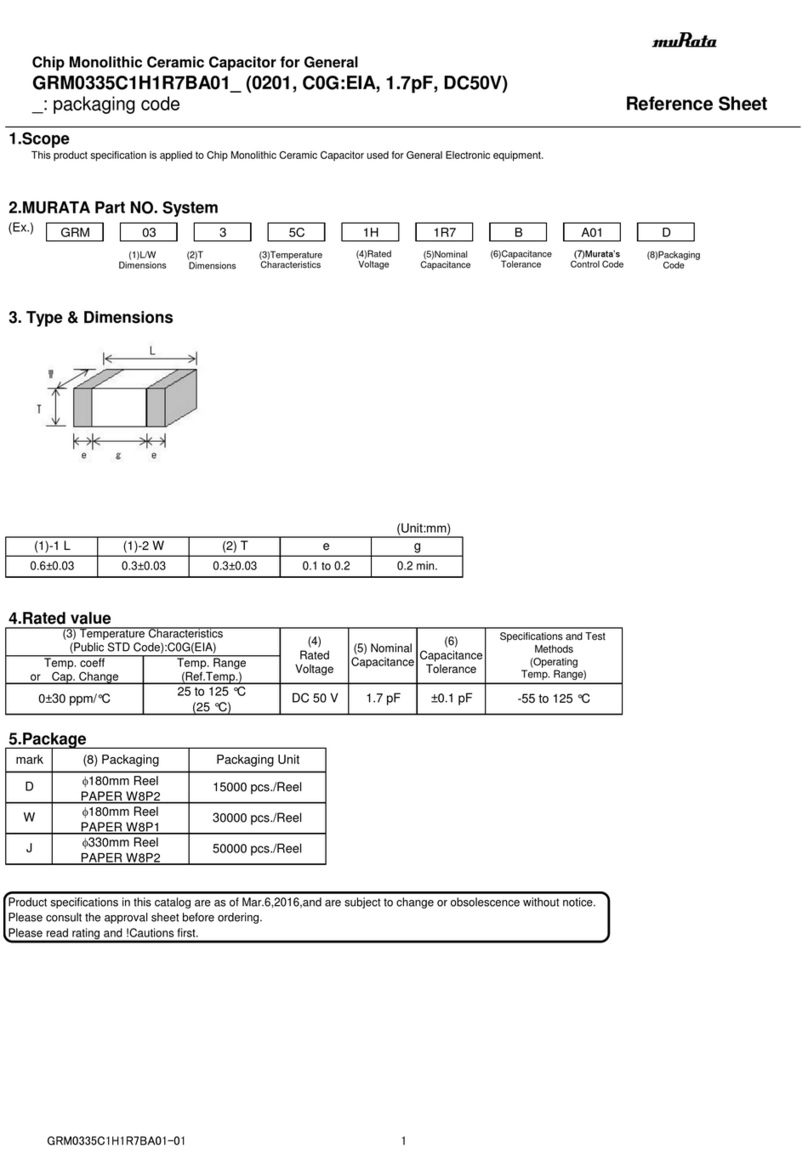

Murata GRM0335C1H1R7BA01 Series User manual

Murata

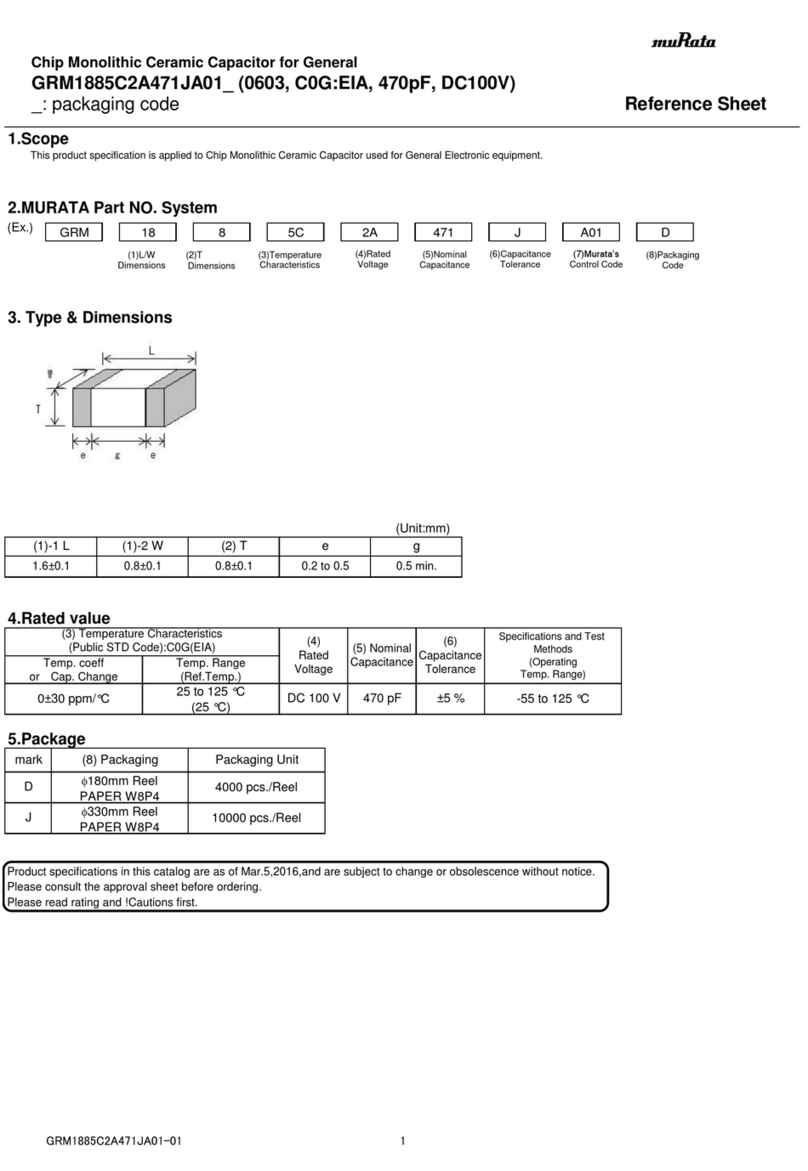

Murata GRM1885C2A471JA01 Series User manual

Murata

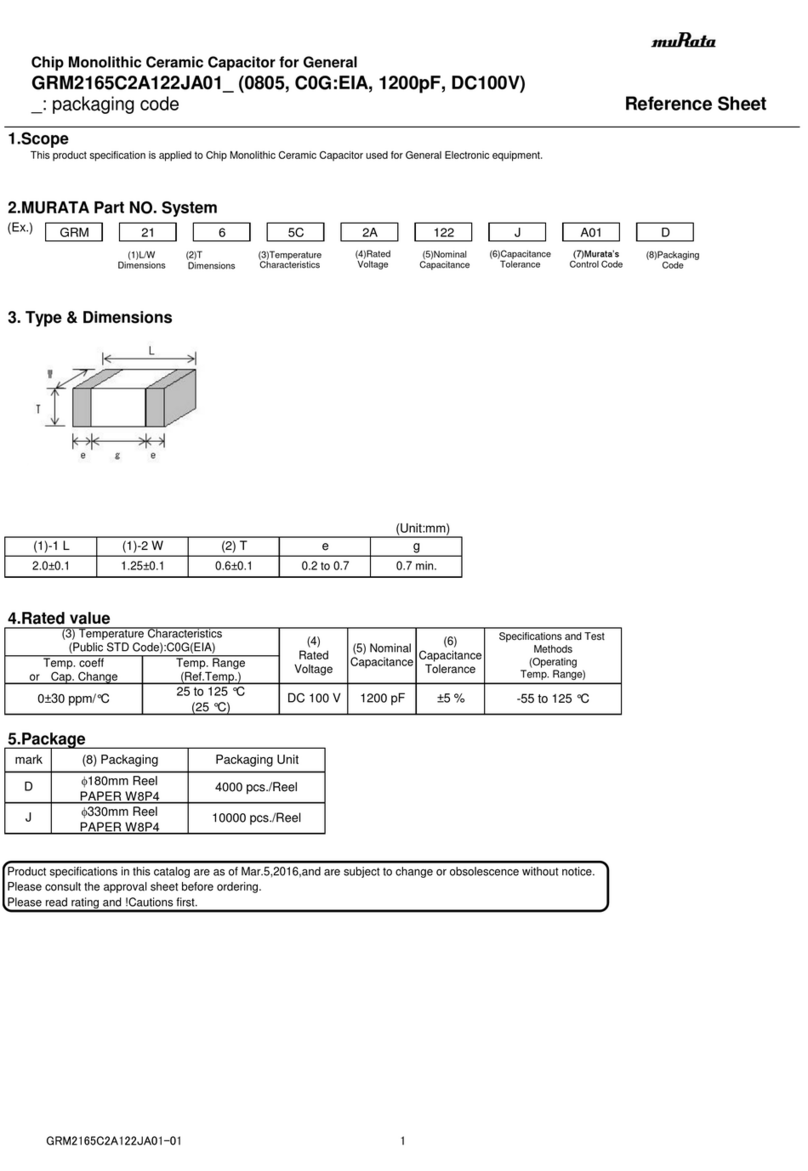

Murata GRM2165C2A122JA01 Series User manual

Murata

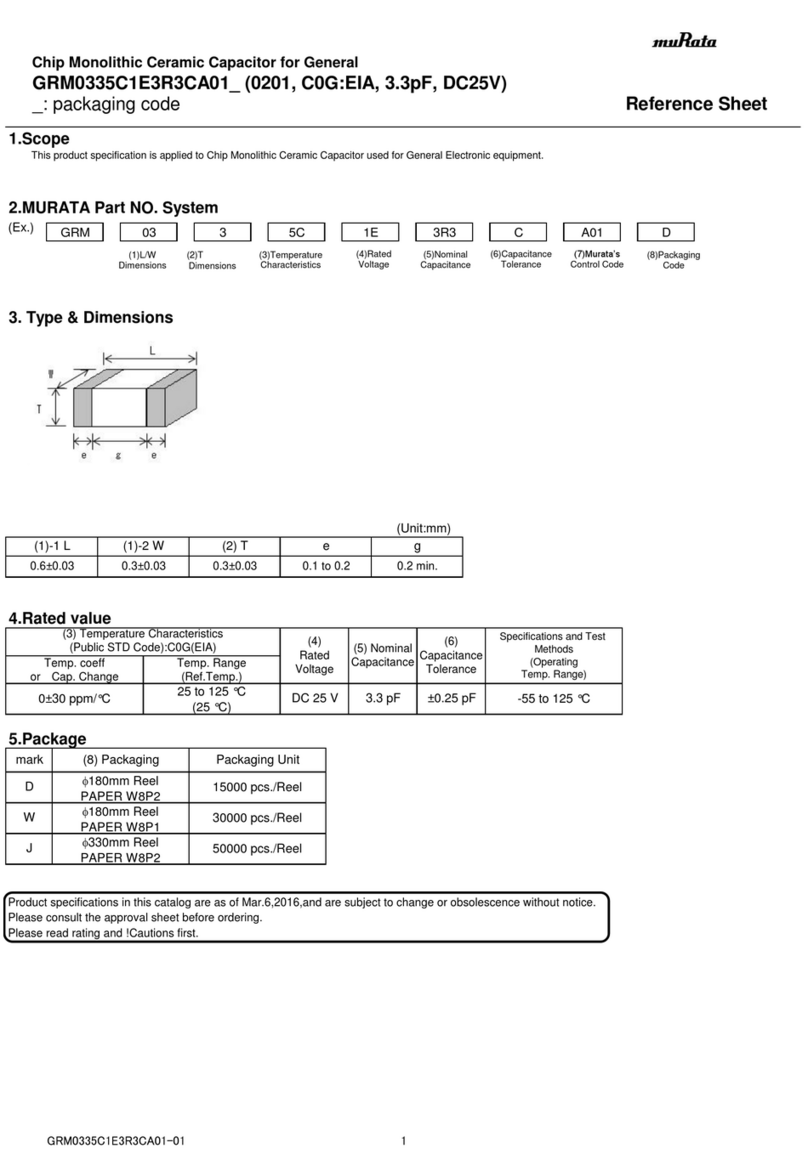

Murata GRM0335C1E3R3CA01 Series User manual

Murata

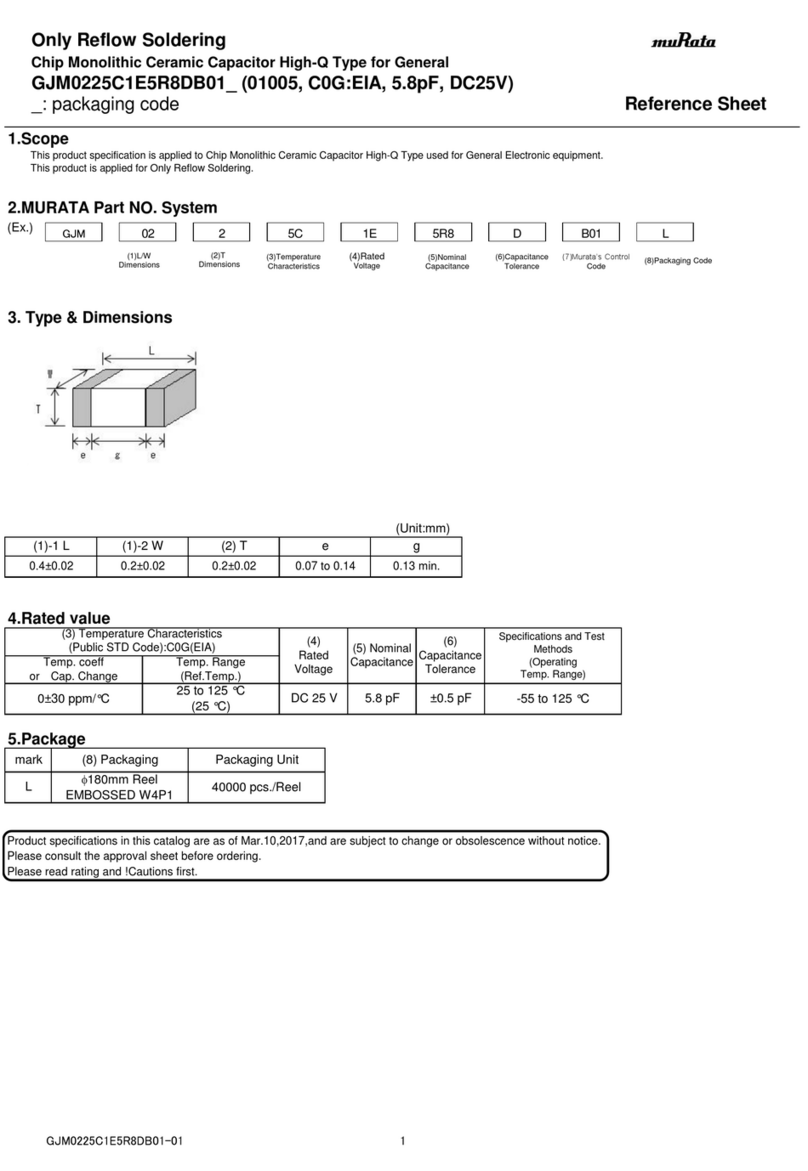

Murata GJM0225C1E5R8DB01 Series User manual

Murata

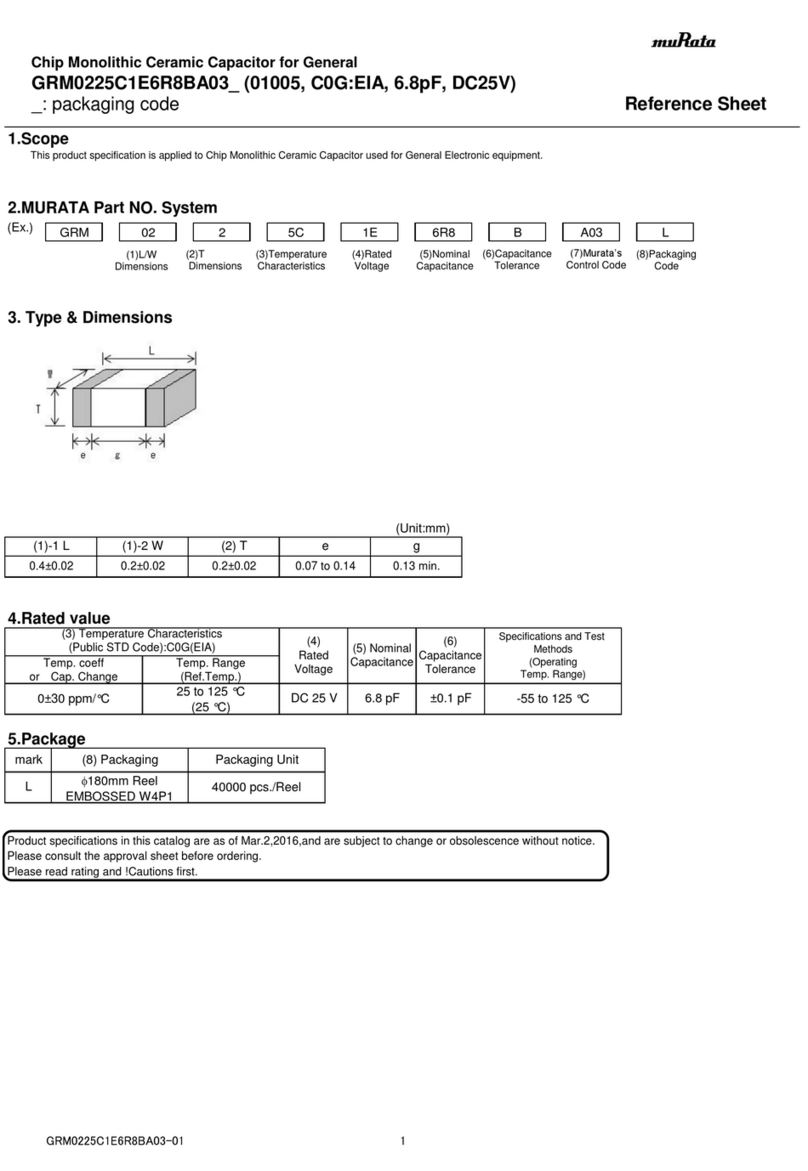

Murata GRM0225C1E6R8BA03 Series User manual

Murata

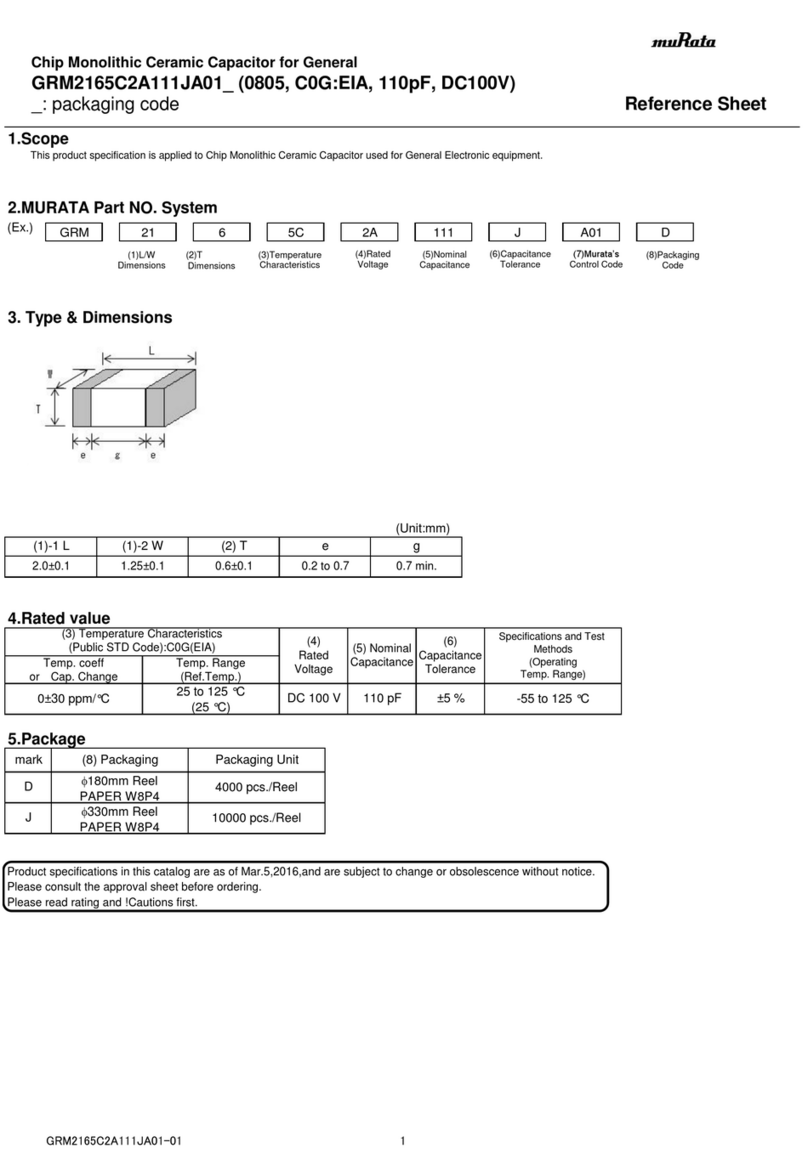

Murata GRM2165C2A111JA01 Series User manual

Murata

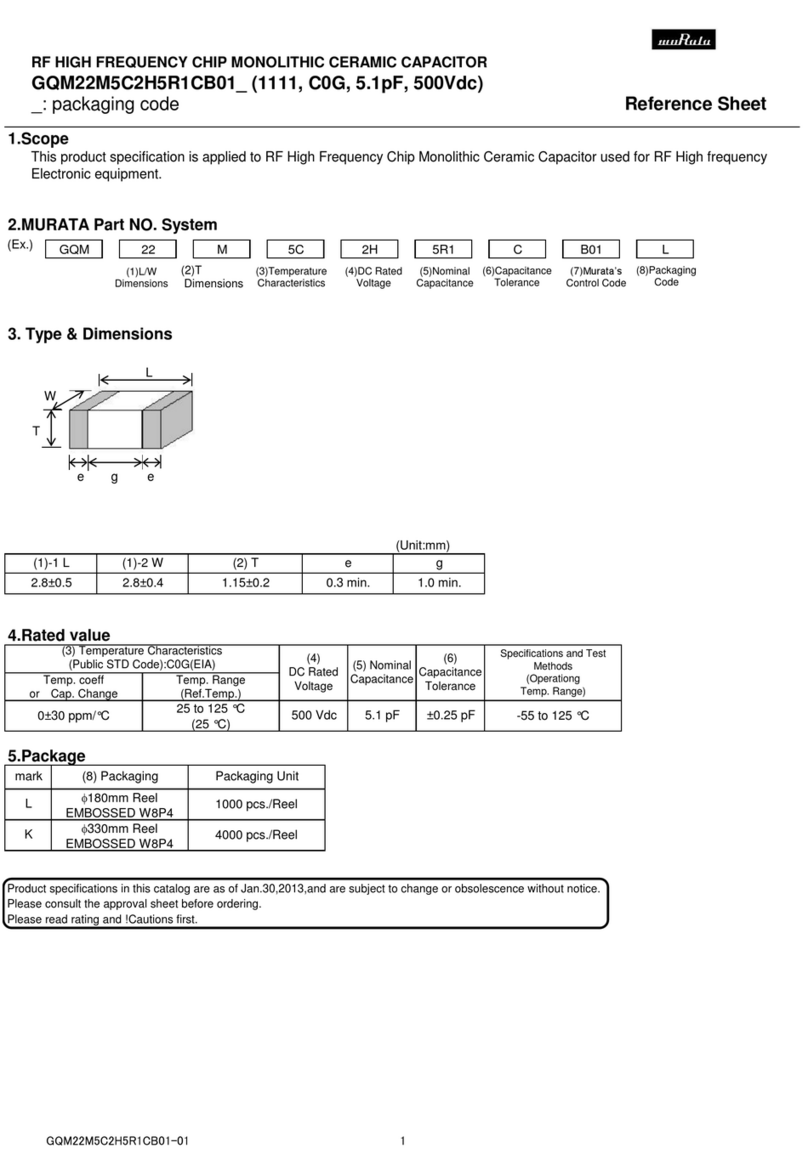

Murata GQM22M5C2H5R1CB01 Series User manual

Murata

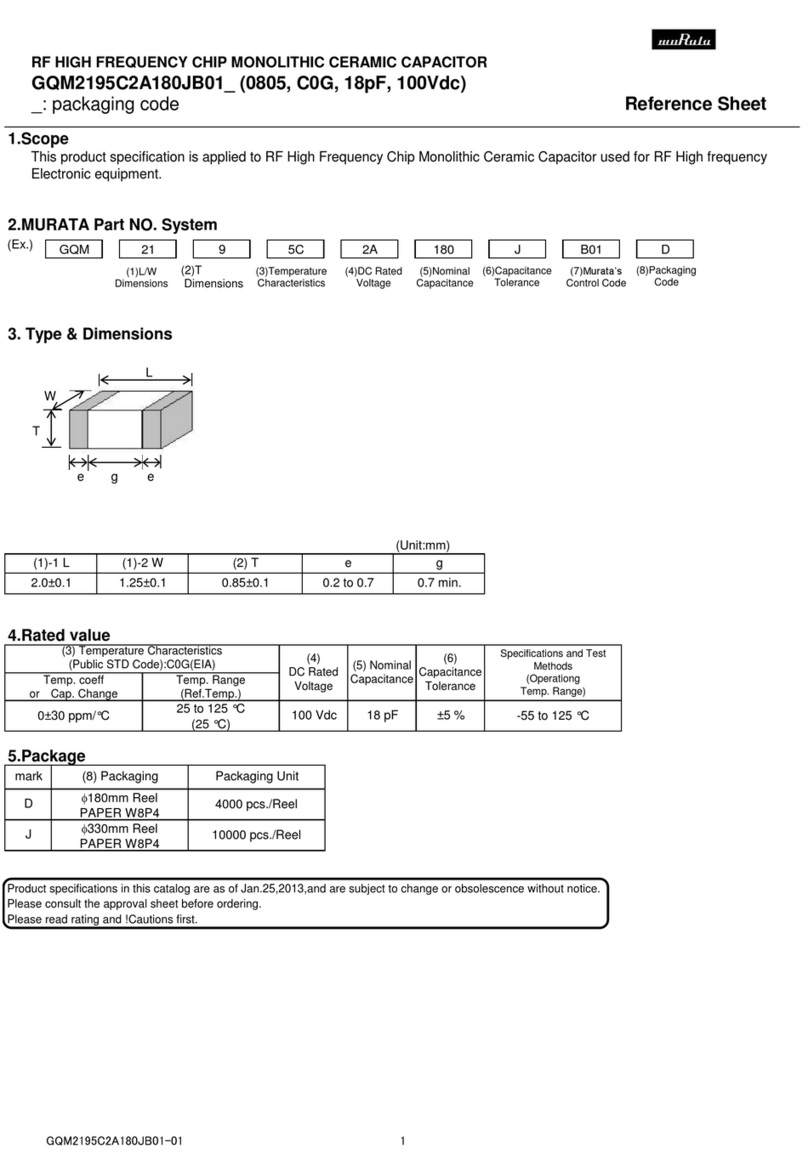

Murata GQM2195C2A180JB01 Series User manual

Murata

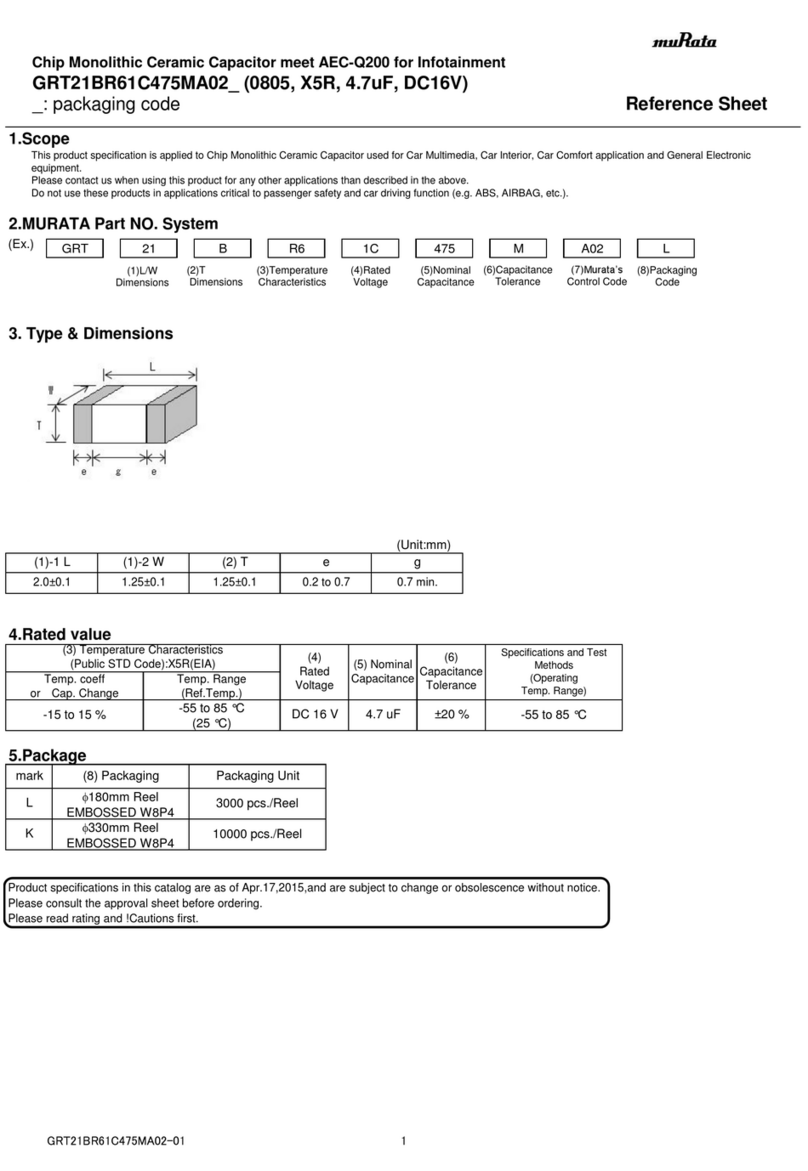

Murata GRT21BR61C475MA02 Series User manual

Murata

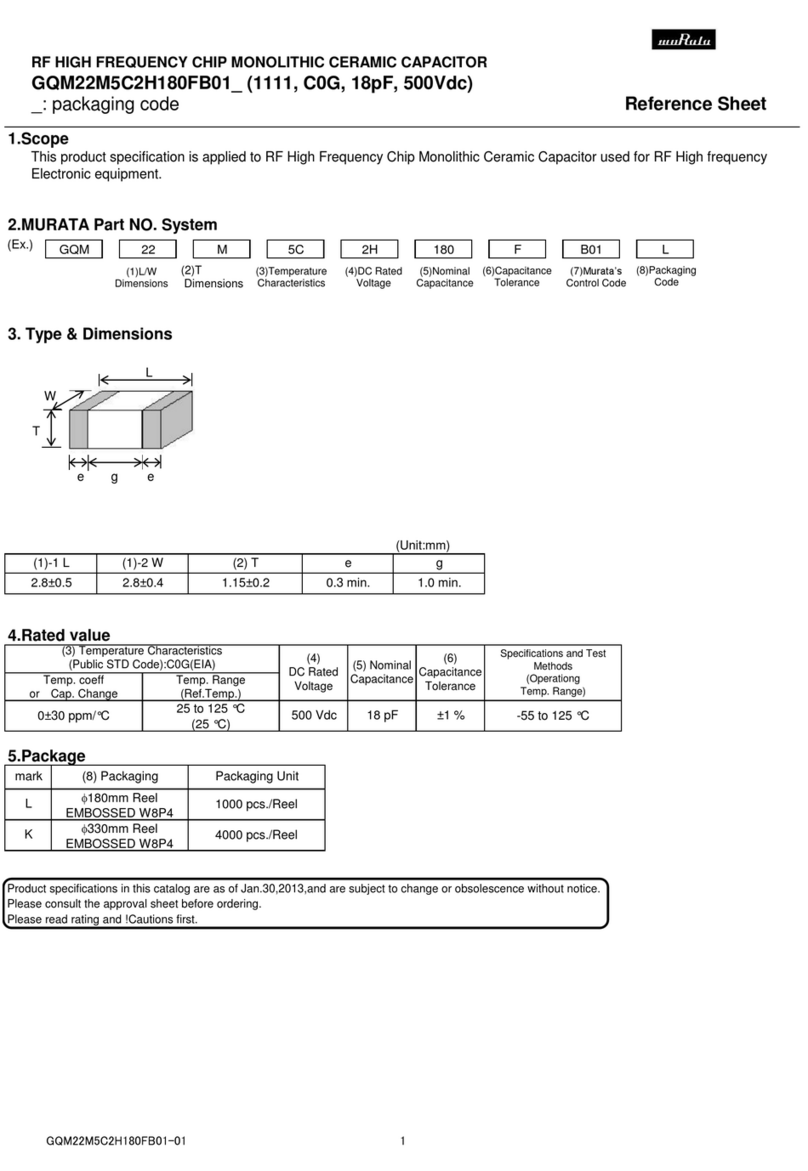

Murata GQM22M5C2H180FB01 Series User manual

Murata

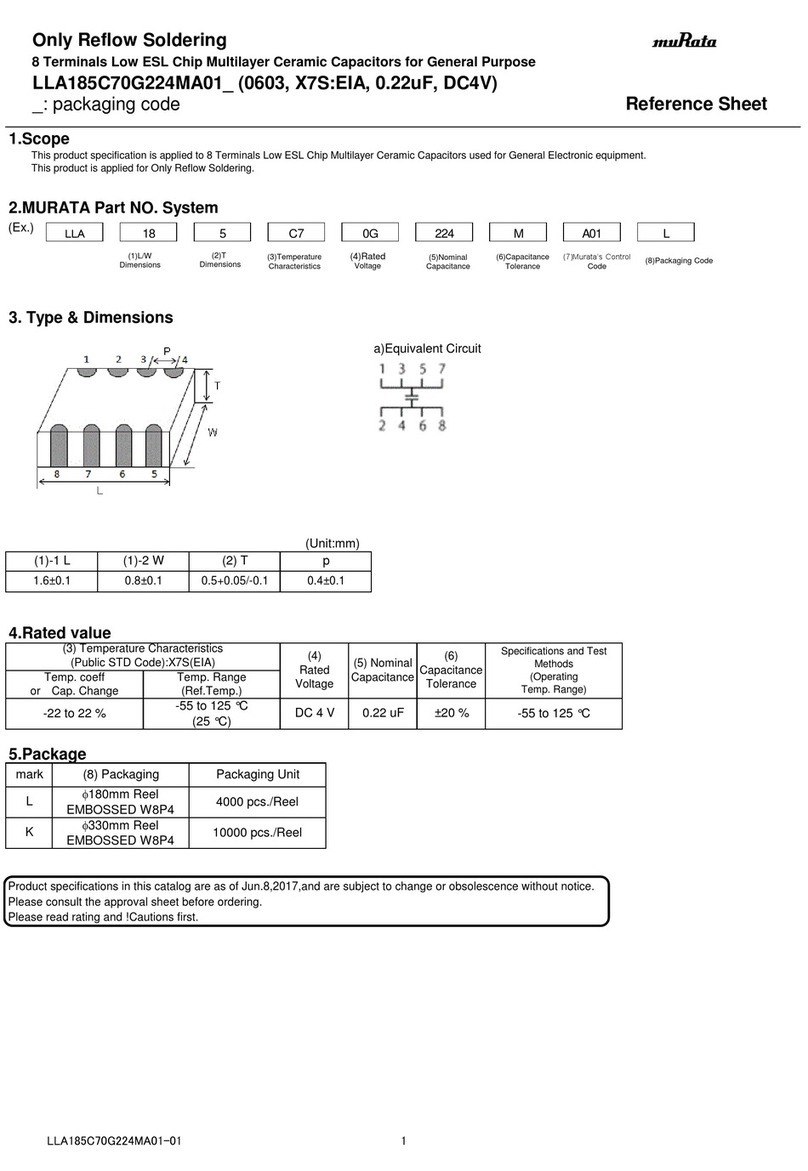

Murata LLA185C70G224MA01 Series User manual

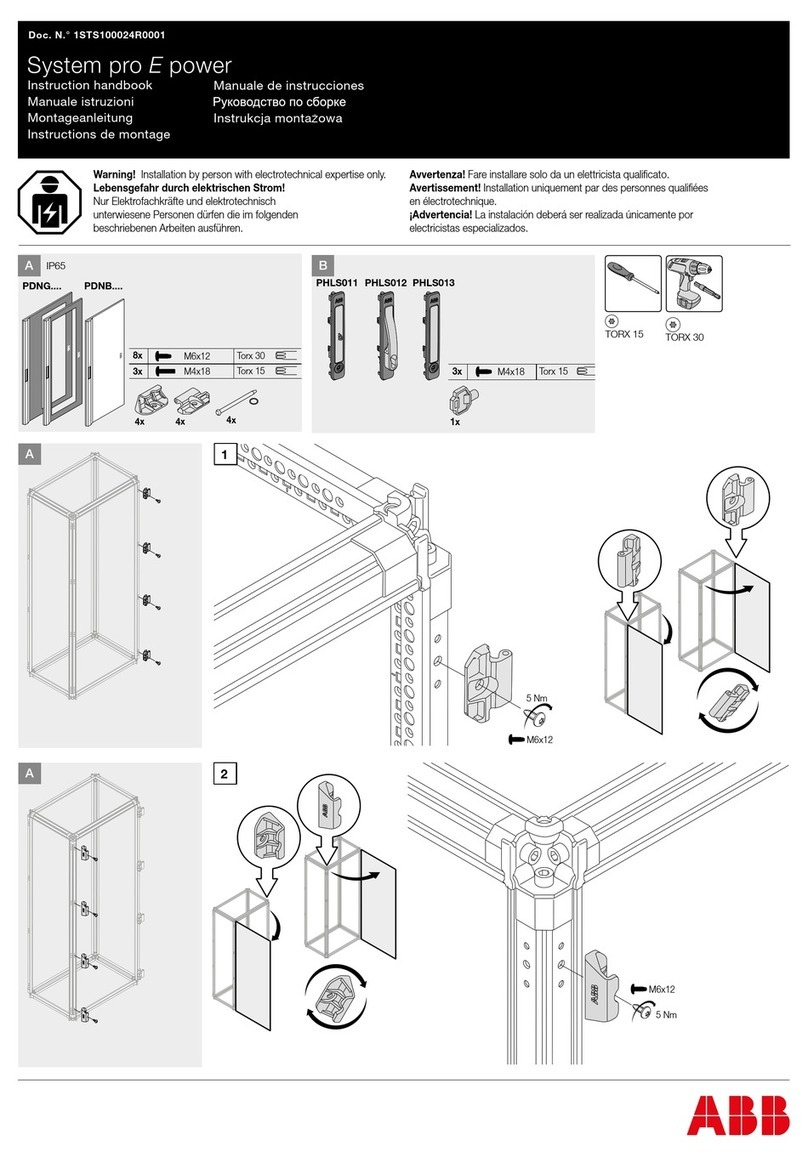

Popular Industrial Electrical manuals by other brands

Rexroth Indramat

Rexroth Indramat DURADRIVE SYSTEM200 Project planning manual

Abtech

Abtech HVJB Series Installation, operation & maintenance instructions

SAF-HOLLAND

SAF-HOLLAND CBX 5415.5 Installation and operation manual

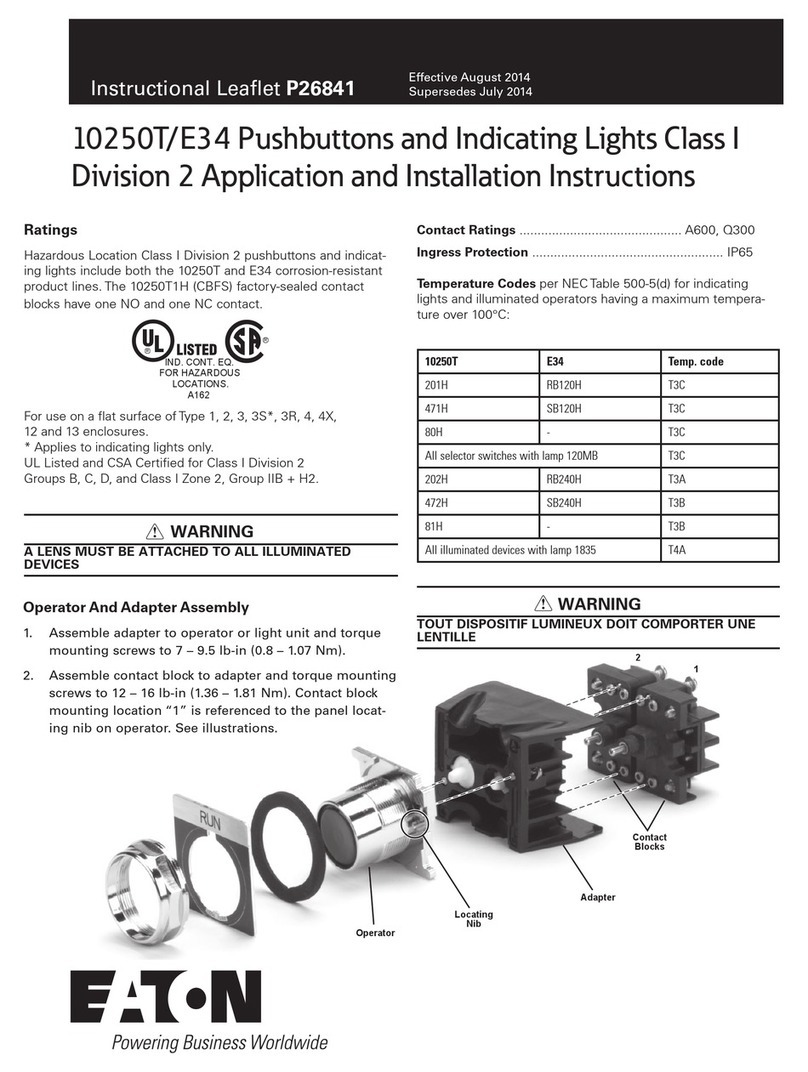

Eaton

Eaton Ulusoy HMH24-04 user manual

Newlong

Newlong NP-7H NSTRUCTION MANUAL/PARTS LIST

Stahl

Stahl 8575/12 operating instructions

SI

SI Pegasus installation instructions

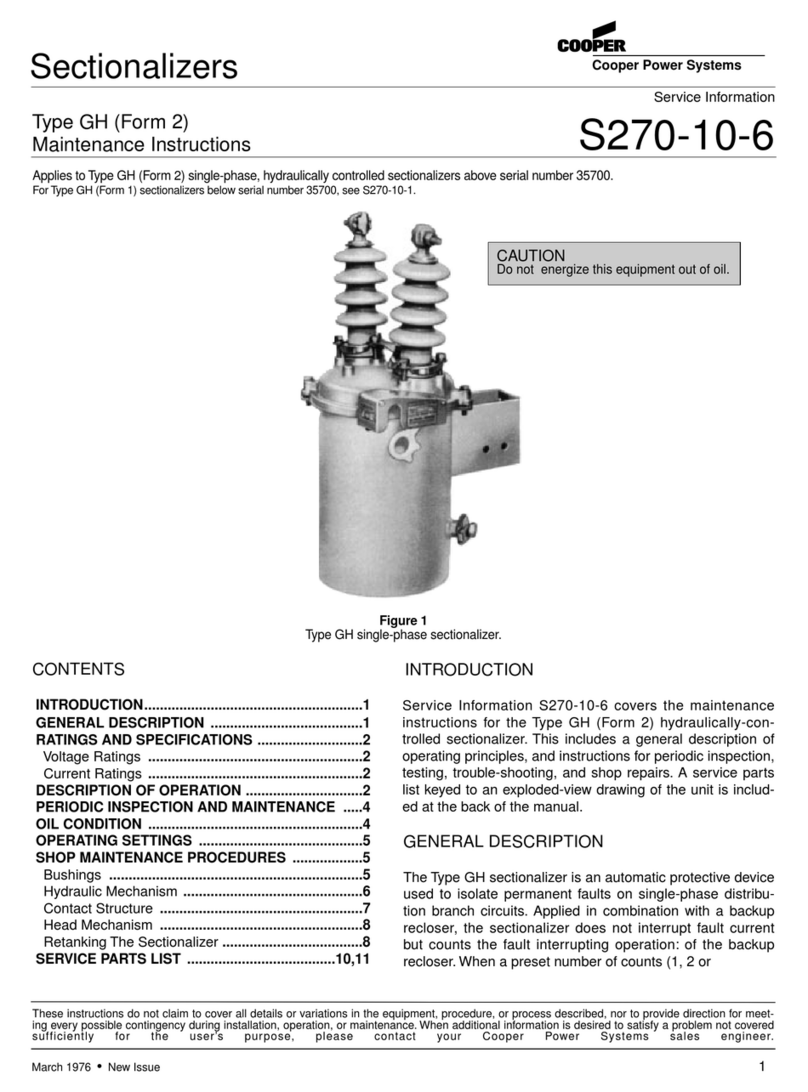

Cooper Power Systems

Cooper Power Systems VXE15 Installation and operation instructions

S&C

S&C Vista SD manual

Siemens

Siemens 3VA9988-0BM10 operating instructions

Siemens

Siemens SITRANS LVS100 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MP-Series installation instructions