ENC-03J type

4

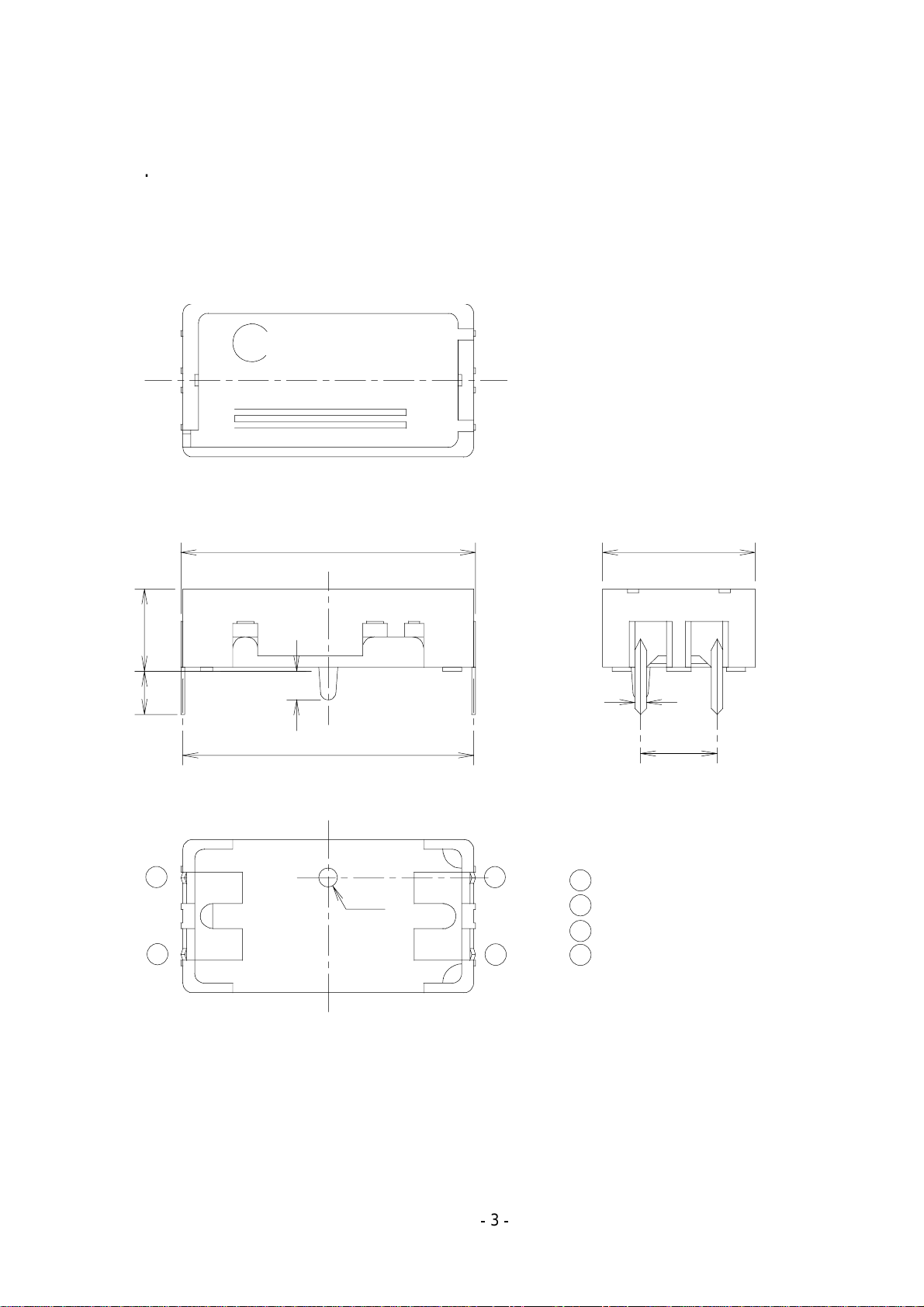

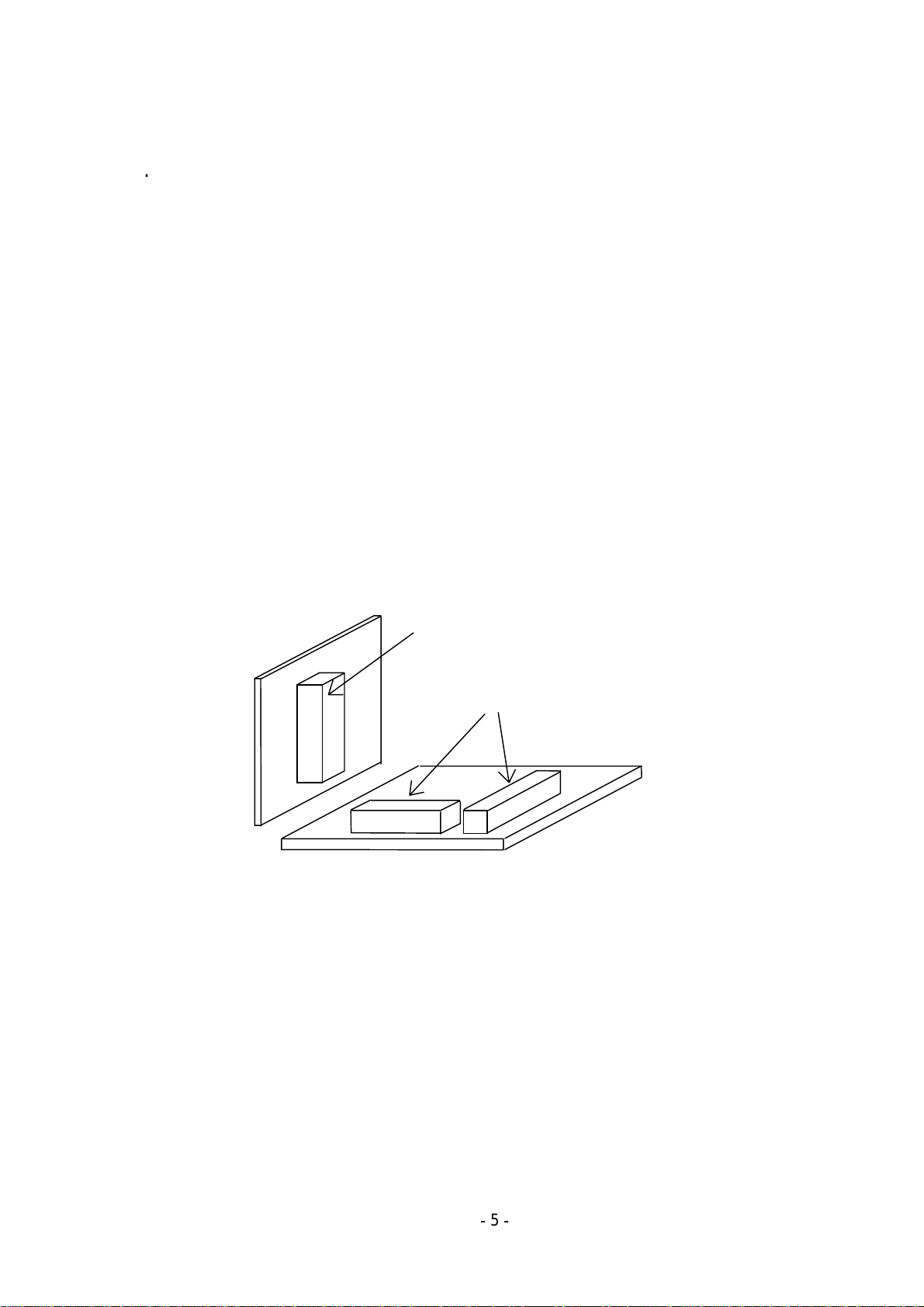

5. Installation

1) Install the sensor by using the bottom face as the reference point.

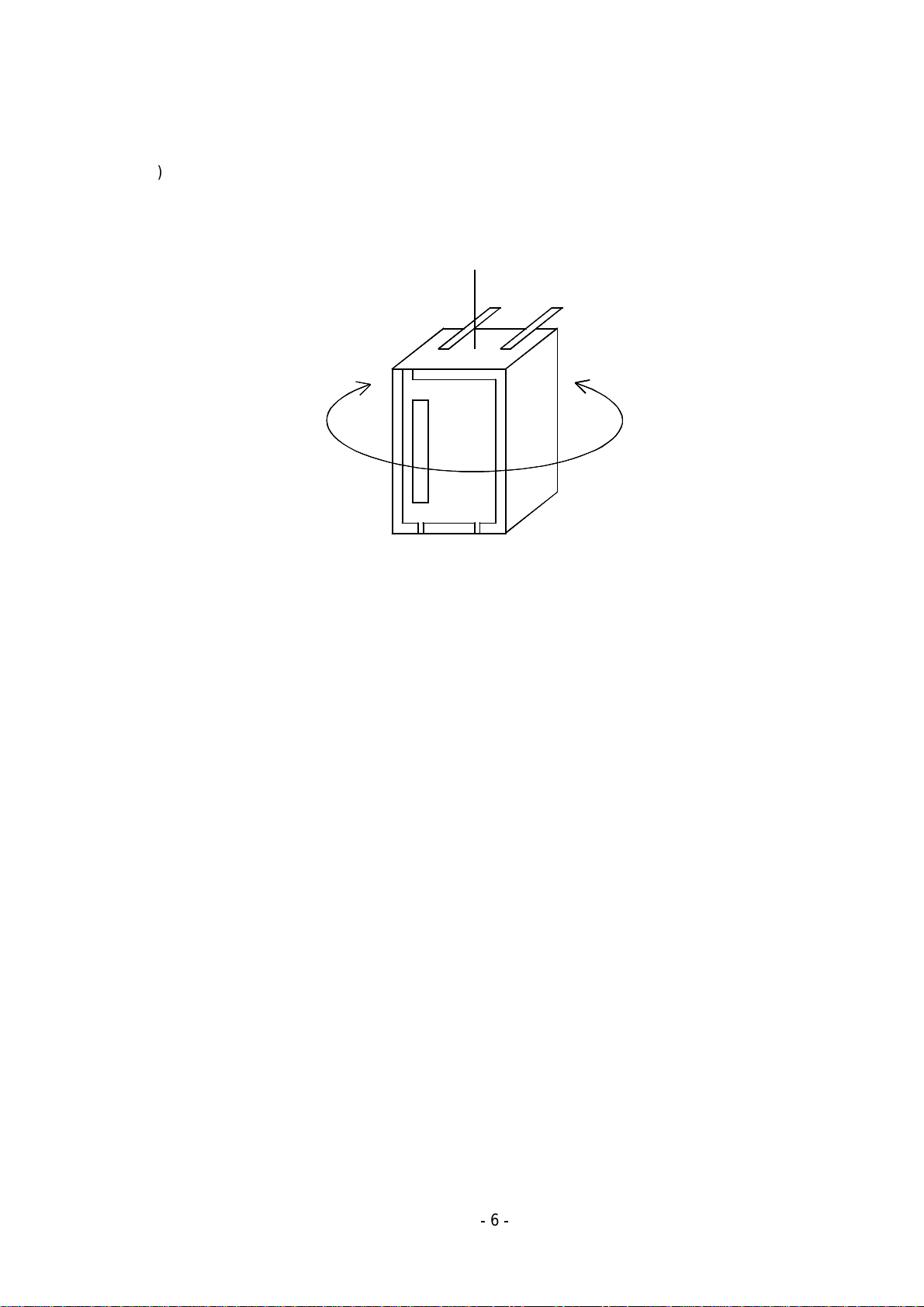

2) Install the sensor vertically with respect to the rotating surface. (90 +/- 5 deg )

3) Install the sensor in a location which minimizes excessive vibration (ex. Model helicopter

application) and use elastic materials to absorb external shock and vibration.

Typically, the sensor can withstand vibration that frequency 10~55Hz, amplitude 1.5mmp-p,

duration 2hours.

4) Install the sensor in a place which minimizes substantial temperature variations.

5) When installing the sensor, terminals should be hand soldered onto the PCB.

Observe the following guideline, otherwise, characteristics may vary due to excessive soldering

heat:

320 +/- 10deg C, 2s or less.

6) Do not bend terminals.

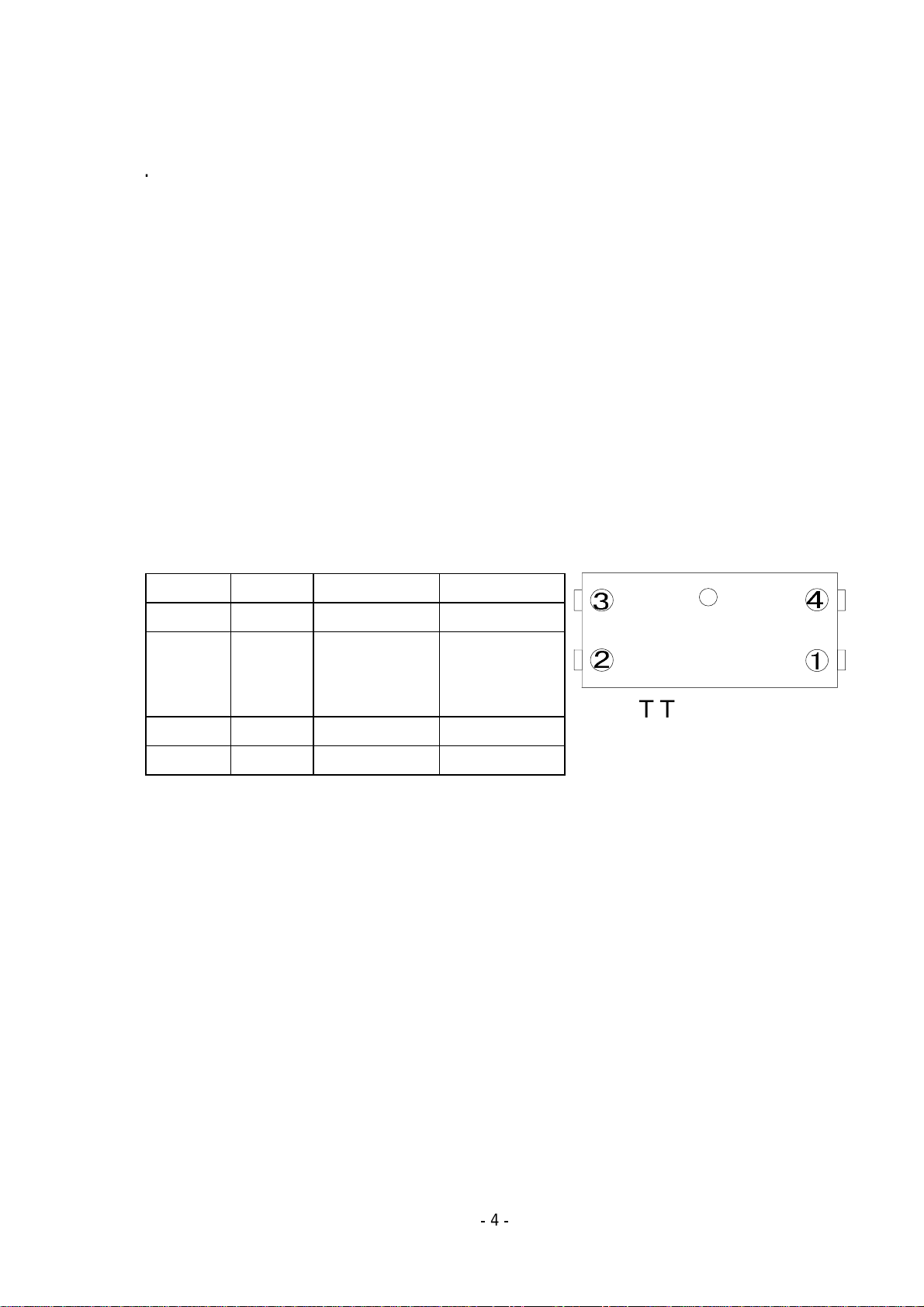

6. Terminal connection

Terminal Symbols Descriptions

1 +Vcc Supply voltage [input]

2 Vref Comparative

voltage(approx

.+1.35V)

[output]

3 GND Ground [common]

4 OUT Sensor output [output]

7. Connection

1) Operation voltage is +2.7V to +5.5V.

Use a stabilized power supply free from surge and ripple voltages. Also, Confirm proper power

supply polarity before connecting sensor.

2) Output voltage is relative to the angular velocity.

Output voltage = V0 + Sv x ω[V]

V0 :Static output [V] (at angular velocity is 0 [deg/s])

Sv :Scale factor [mV/deg/s]

: Angular velocity [angular velocity range : -90 to +90 deg/s]

3) Use a sensor output load resistance of 50kΩor more.

4) Comparative voltage (Vref) must be grounded with condenser of 4.7µF or more.

5) Comparative voltage is used as a reference voltage of amplification. (Refer to page 7)

BOTTOM VIWE