Operation Instructions MC-Series cutting plotters

AP-75020, Rev. 1.0 - 18/12/98

TABLE OF CONTENTS

MC-SERIES MULTI-TOOL CUTTING PLOTTERS OPERATION

INSTRUCTIONS

SETTING UP THE CUTTER........................................................................1

PREPARING THE CUTTING ENVIRONMENT............................................................ 1

UNPACKING THE CUTTER........................................................................................ 2

WHAT’S IN THE BOX ?............................................................................................... 2

GETTING TO KNOW THE CUTTER PARTS .............................................................. 3

ASSEMBLING THE PLOTTER.................................................................................... 5

CONNECTING THE CUTTER TO THE COMPUTER.................................................. 8

CONNECTING THE POWER CABLE ......................................................................... 9

COMMUNICATION SETTINGS................................................................................... 9

CHANGING THE SET-UP LANGUAGE OF YOUR CUTTER.................................... 10

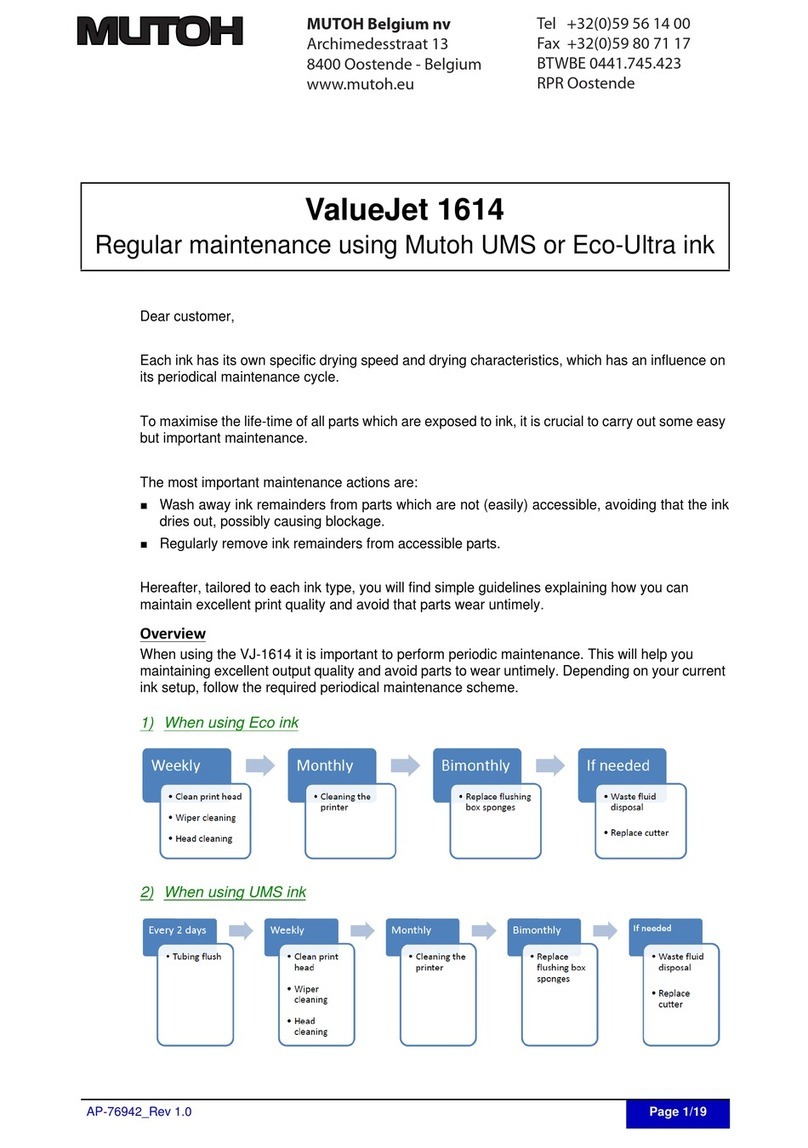

PREPARING FOR A JOB..........................................................................11

LOADING MEDIA...................................................................................................... 11

ADJUSTING THE KNIFE DEPTH.............................................................................. 14

INSTALLING A TOOL................................................................................................ 16

SETTING THE CUTTING FORCE / TEST SQUARES............................................... 18

OFFSET PRINCIPLE................................................................................................. 19

OFFSET EFFECT...................................................................................................... 19

OFFSET ADJUSTMENT PROCEDURE.................................................................... 20

PERFORMING A TEST............................................................................................. 23

FIXED KNIFE SYSTEM............................................................................................. 25

UNDERSTANDING THE KEYBOARD & MENU STRUCTURE................28

GUIDED TOUR AROUND THE KEYBOARD............................................................. 28

KEYBOARD CONCEPT ............................................................................................ 33

MENU STRUCTURE - OVERVIEW........................................................................... 34

OVERVIEW GENERAL SETTINGS........................................................................... 37