Model 7475A Table ofContents

TABLE

OF

CONTENTS

Section

I

GENERAL

INFORMATION

. . . . . . . . . . . . .

1-1

1-1.

Introduction

. . . . . . . . . . . . . . . . . . . . . . .

1-1

1-6.

Specifications . . . . . . . . . . . . . . . . . . . . .

1-1

1-8.

Safety ConsidE!rations . . . . . . . . . . . . .

1-1

1-10.

Plotters Covered

by

Manual

. . . . . . . .

1-1

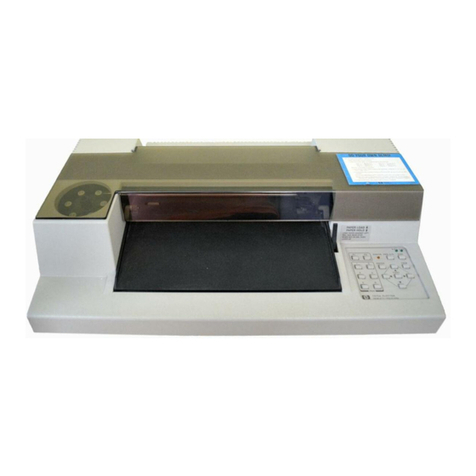

1-15. Description . . . . . . . . . . . . . . . . . . . . . . . .

1-2

1-19. Line Voltage

and

Fuse

Selection....

1-2

1-23.

Grounding

Requirements . . . . . . . . . .

1-3

1-25. Options . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3

1-29. Accessories Supplied . . . . . . . . . . . . . . .

1-6

1-31.

Recommended

Test

Equipment

. . . . .

1-6

1-33.

Packaging

for

Shipment

. . . . . . . . . . .

1-6

II

OPERATING

AND PERFORMANCE

TEST

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1

2-1.

Introduction

. . . . . . . . . . . . . . . . . . . . . . .

2-1

2-3.

Rear

Panel

Switches

(Option

001)

. . . . . . . . . . . . . . . . . . . . .

2-1

2-9.

Rear

Panel

Switches

(Option 002) . . . . . . . . . . . . . . . . . . . . .

2-1

2-13.

Basic

Operating

Test

. . . . . . . . . . . . . .

2-1

2-15. Hewlett-Packard

Graphics

Language

. . . . . . . . . . . . . . . . . . . . . . .

2-2

2-17.

Demonstration

Plot

. . . . . . . . . . . . . . . .

2-2

2-19.

Test

Program

. . . . . . . . . . . . . . . . . . . . . .

2-2

2-21.

Repeatability .

....

. . . . . . . . . . . . . .

..

.

2-2

III

ADJUSTMENTS.........................

3-1

3-1.

Introduction

. . . . . . . . . . . . . . . . . . . . . . .

3-1

IV

REPLACEABLE PARTS . . .

..

. . . . . . .

..

. . .

4-1

4-1.

Introduction

. . . . . . . . . . . . . . . . . . . . . . .

4-1

4-3.

Exchange

Assemblies . . . . . . . . . . . . . .

4-1

4-5.

Replaceable

Parts

Lists

. . . . . . . . . . . .

4-1

4-7.

Ordering

Information

. . . . . . . . . . . . . .

4-1

4-9.

Code

List

of

Manufacturers

. . . . . . . .

4-1

4-11.

Designations

and

Abbreviations . . .

4-1

V PRODUCT HISTORY

..

. . . . . . . . .

..

. .

....

.

5-1

5-1.

Introduction

.

~.....................

5-1

5-3.

History

of

Assemblies

by

Serial

Prefix

Number

. . . . . . . . . . . .

5-1

5-

7.

History

of

Printed

Circuit

Assemblies . . . . . . . . . . . . . . . . . . . . . .

5-1

Section

VI

SERVICE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-1.

Introduction . . . . . . . . . . . . . . . . . . . . . . .

6-1

6-3.

SimplifiedTheory

of

Operation . . . . .

6-1

6-7.

RS-232-C/CCITT V.24

Interface

Circuit (Option

001)

. . . . .. . . .. . . ..

6-1

6-14.

HP-IB Interface (Option 002) . . . . . . .

6-2

6-25.

Microprocessor Circuit . . . . . . . . . . . . .

6-5

6-29.

Read

Only

Memory Circuit . . . . . . . . .

6-5

6-31.

Random

Access Memory Circuit . . . .

6-5

6-33.

Gate

Arrays

A

and

B . . . .

..

.

..

. . . . .

6-5

6-35.

Pen

Carousel . . . .. . .. . . .. . . .. . . . .. .

6-5

6-37.

Motor Servo

Systems

. . . . . . . . . . . . . .

6-5

6-41. Motor Supply

Sensor

Circuit . . . . . . .

6-6

6-44. Motor

Current

Sensor

Circuit . . . . . . .

6-

7

6-46.

Pen

Down Circuit . . . . . . . . . . . . . . . . . .

6-

7

6-48.

Power Supplies

..

. . . . . . . . . .

..

. . . . . .

6-7

6-50. Recommended

Test

Equipment

. . . . .

6-

7

6-52.

Troubleshooting . . . . . . . . . . . . . . . . . . .

6-

7

6-54.

Exchange

Printed

Circuit

Assembly . . . . . . . . . . . . . . . . . . . . . . . .

6-7

6-56.

Drive Motors

and

Pen

Solenoid

....

.

6-

7

6-58.

Troubleshooting Table . . . . . . . . . . . . .

6-8

6-60.

Test

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-8

6-62.

Test

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-8

6-64.

Part

Removal

and

Replacement . . . .

6-9

6-65.

Top

Case

Removal . . . . . . . . . . . . . . . . .

6-9

6-66.

Pen

Carousel

Housing

Removal . . . .

6-9

6-67.

Paper

Drive Motor Assembly

Removal

.........................

6-10

6-68.

Pen

Solenoid . . . . . . . . . . . . . . . . . . . . . .

6-11

6-69.

Pen

Drive Motor

and

Belt . . . . . . . . . .

6-11

6-72.

Pen

Carriage, Penholder,

and

Damper

Removal . . . . . . . . . . . . . . . . 6-13

6-

75.

Pinch

Rollers Removal

and

Replacement . . . . . . . . . . . . . . . . . . . . . 6-14

6-76.

Printed

CircuitAssembly

Removal . . . . . . . . . . . . . . . . . . . . . . . . . 6-14

6-77.

Pinch

Roller

Mechanism

Removal . .

6-15

6-79.

Paper

Drive

Shaft

and

Coupler

Removal . . . . . . . . . . . . . . . . . . . . . . . . . 6-15

6-80. Power Module

and

Transformer

. . . .

6-16

6-81. Power Module Wiring . . . .

........

. . 6-16

6-83.

Cleaning

. .

..

. . . . . . . . . . . .

....

. . . . . . 6-16

6-85.

Pen

Stall

Cleaning

. . . . . . .

..

. . . . . . . . 6-17

6-87.

Diagrams

. . . . . . . . . . . . . . . . . . . . . . . . . 6-17

TABLES

Table

1-1.

Specifications

........................

.

1-2.

Line Voltage Selection

................

.

1-3.

Line

Fuses

............................

.

1-4.

Accessories Supplied

..................

.

1-5.

Recommended

Test

Equipment

........

.

2-1.

Baud

Rate

Selection

..................

.

2-2.

7475A

HP-GL

Instruction

Set

.........

.

1-1

1-3

1-3

1-6

1-6

2-1

2-3

Table

4-1.

Parts

List,

Main

PCA, RS-232-C,

Option

001 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2

4-2.

Parts

List,

Main

PCA, HP-IB

Option 002 . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5

4-3.

Parts

List, Mechanical

Parts

. . . . . . . . . . .

4-8

4-4.

Parts

List,

Pen

Carousel

Parts

. . . . . . . . .

4-10

4-5.

Code

List

of

Manufacturers

. . . . . . . . . . . .

4-11

i