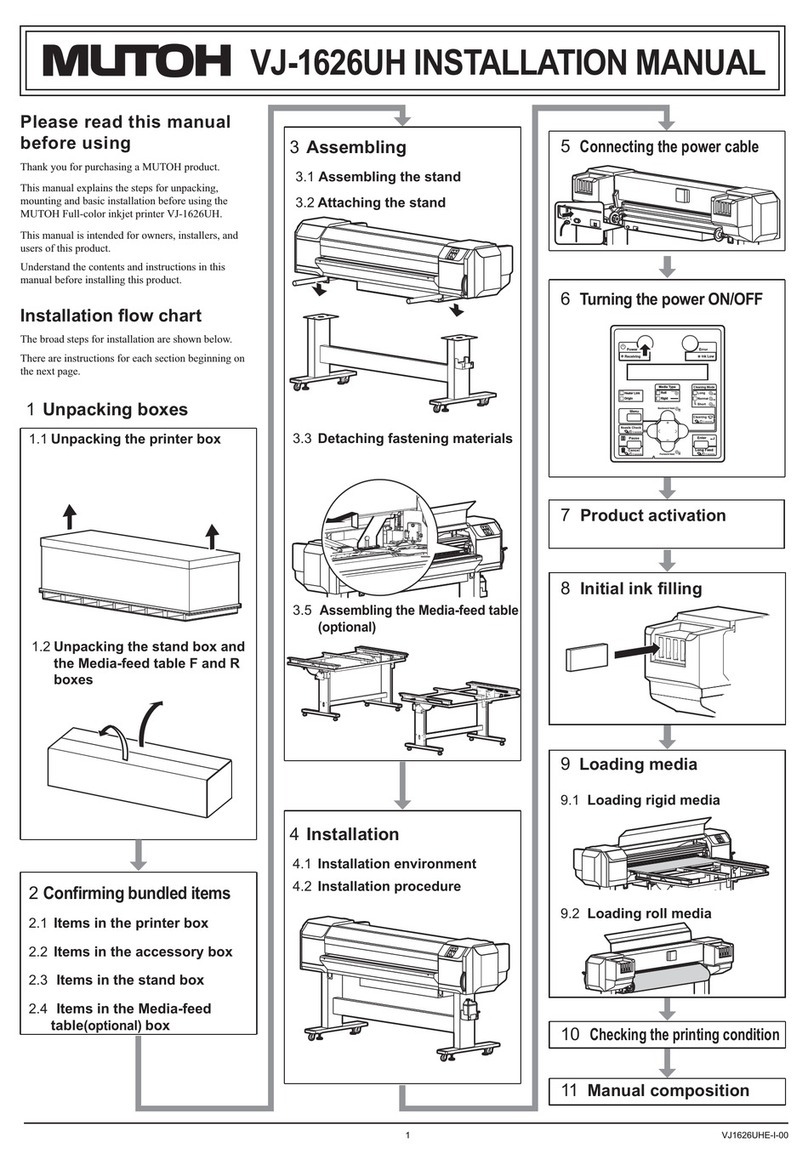

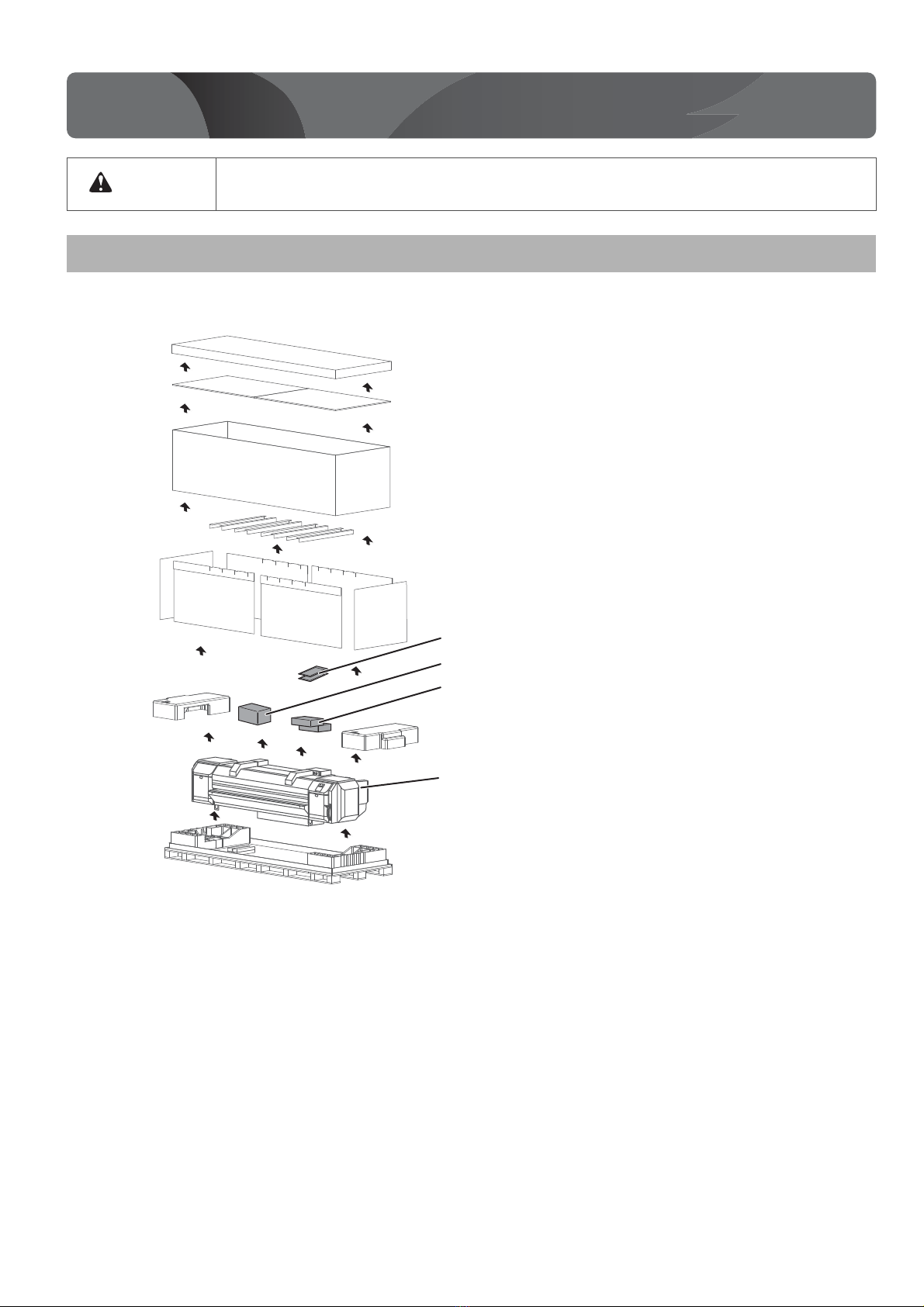

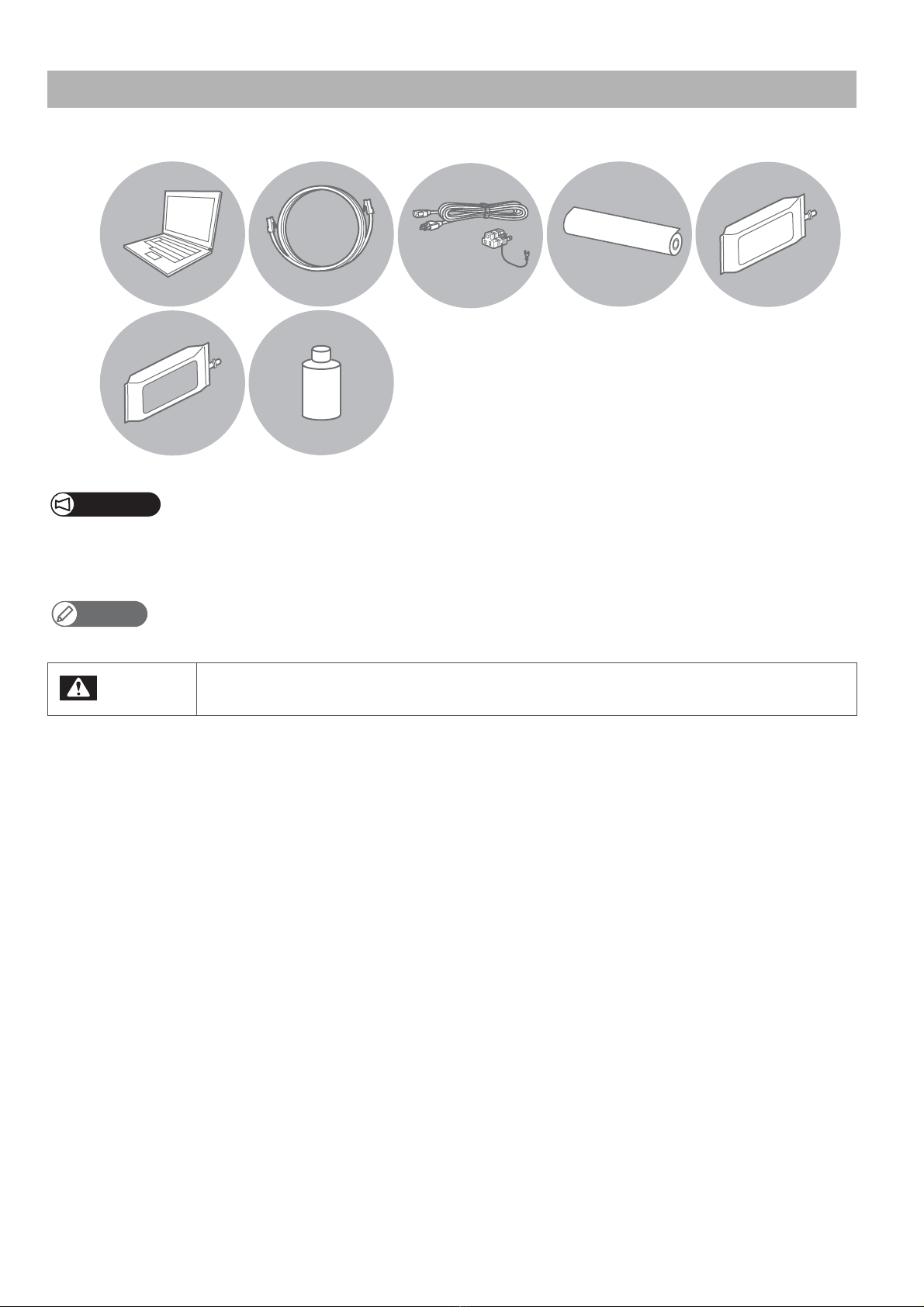

Unpacking 7

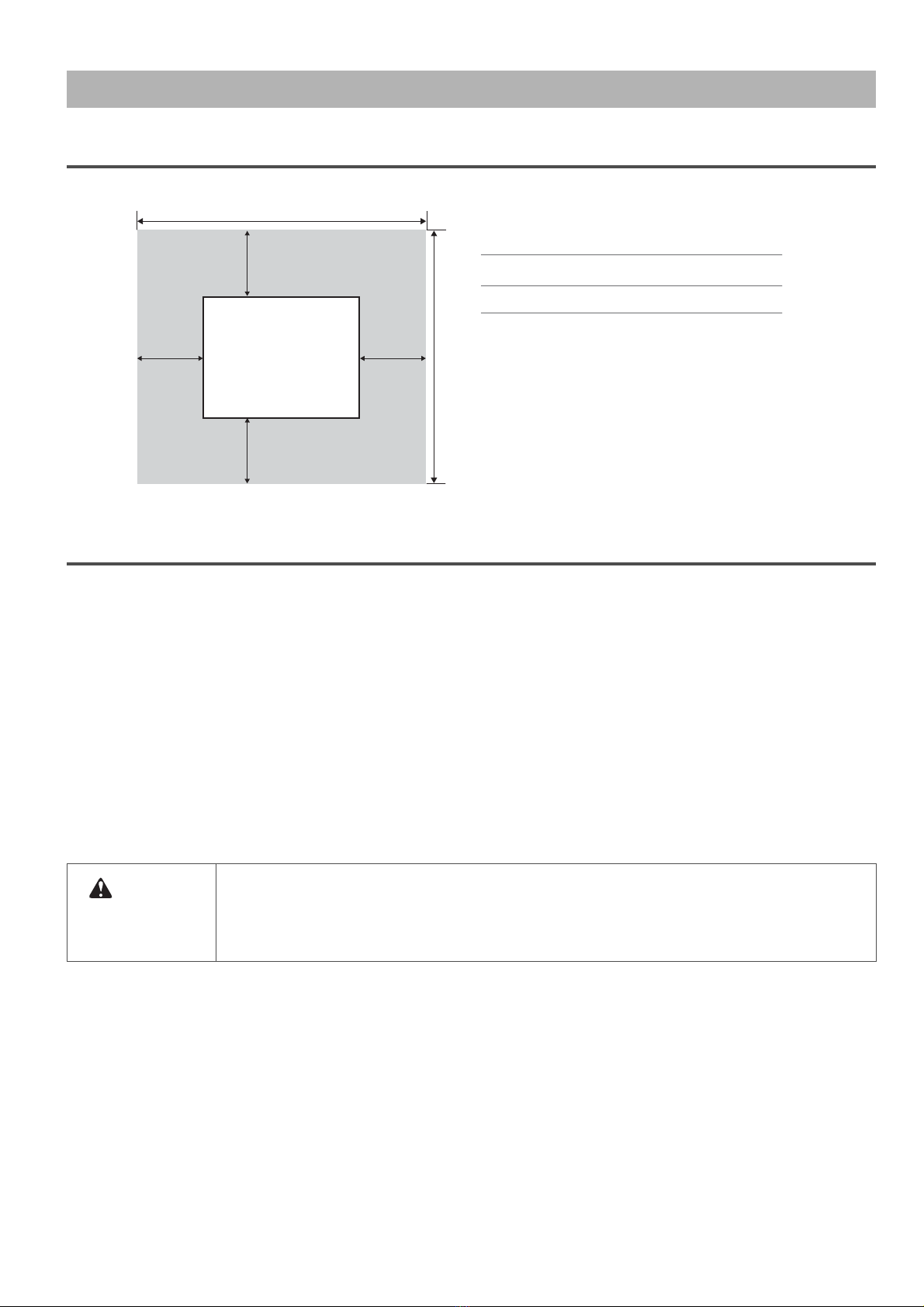

Install the product in an environment that satisfies the conditions in the table below.

Installation environment conditions

Power supply

specifications

Printer Voltage: AC 100 V to 240 V ±10%

Frequency: 50/60 Hz ±1 Hz

Capacity: No less than 3 A

Heater ×2 Voltage: AC 100 V to 120 V ±10% / AC 200 V to 240 V ±10%

Frequency: 50/60 Hz ±1 Hz

Capacity

• Heater 1: No less than 10 A (AC 100V to 120V)

• Heater 1: No less than 10 A (AC 200V to 240V)

• Heater 2: No less than 10 A (AC 100V to 120V)

• Heater 2: No less than 0 A (AC 200V to 240V)

Environmental

conditions

Operating environment Temperature 20 to 28 °C, Humidity 40 to 60%

No condensation

Recommended Printing

Environment

Temperature 22 to 28 °C, Humidity 40 to 60%

No condensation

Environment for storage • Storage without ink charging: up to 6 months

Temperature -20 to +60 °C, Humidity 20 to 80%

• Storage with ink charging: up to 30 days *1*2

Temperature 5 to 30 °C, Humidity 20 to 80%

*1Perform the Daily Maintenance instructed in the Operation

manual.

*2Always leave the printer in sleep mode and check the

remaining ink level once a week.

Agitate ink in the cartridge once a week as instructed.