7 VJ1626UH-I-00

ޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓޓVJ-1626UH INSTALLATION MANUAL

NOTE

CAUTION

CAUTION

NOTE

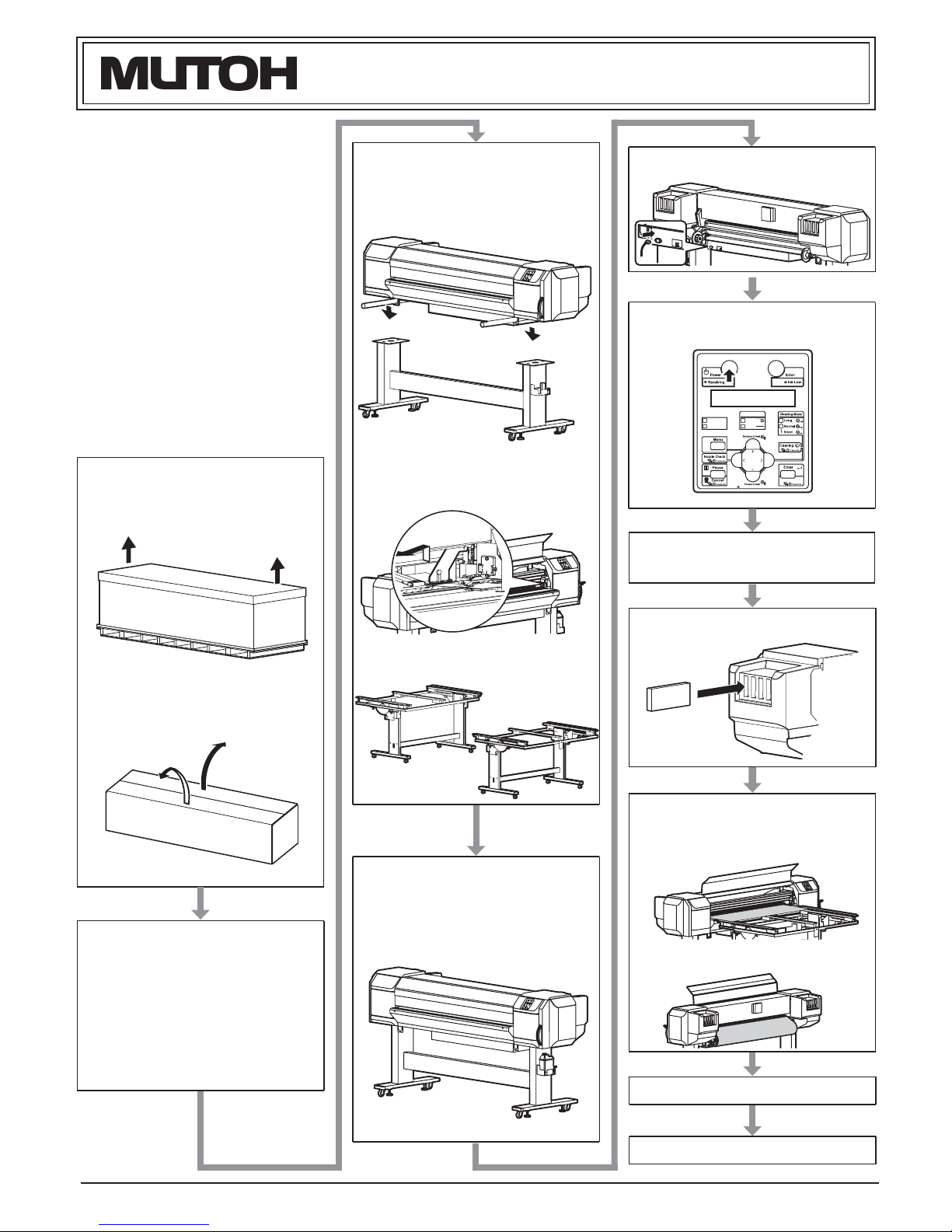

6 Turning the power ON/OFF

This section explains how to turn the printer

ON/OFF, and how to start the sleep mode.

6.1 Turning the power ON

Follow the procedure below to turn the power ON.

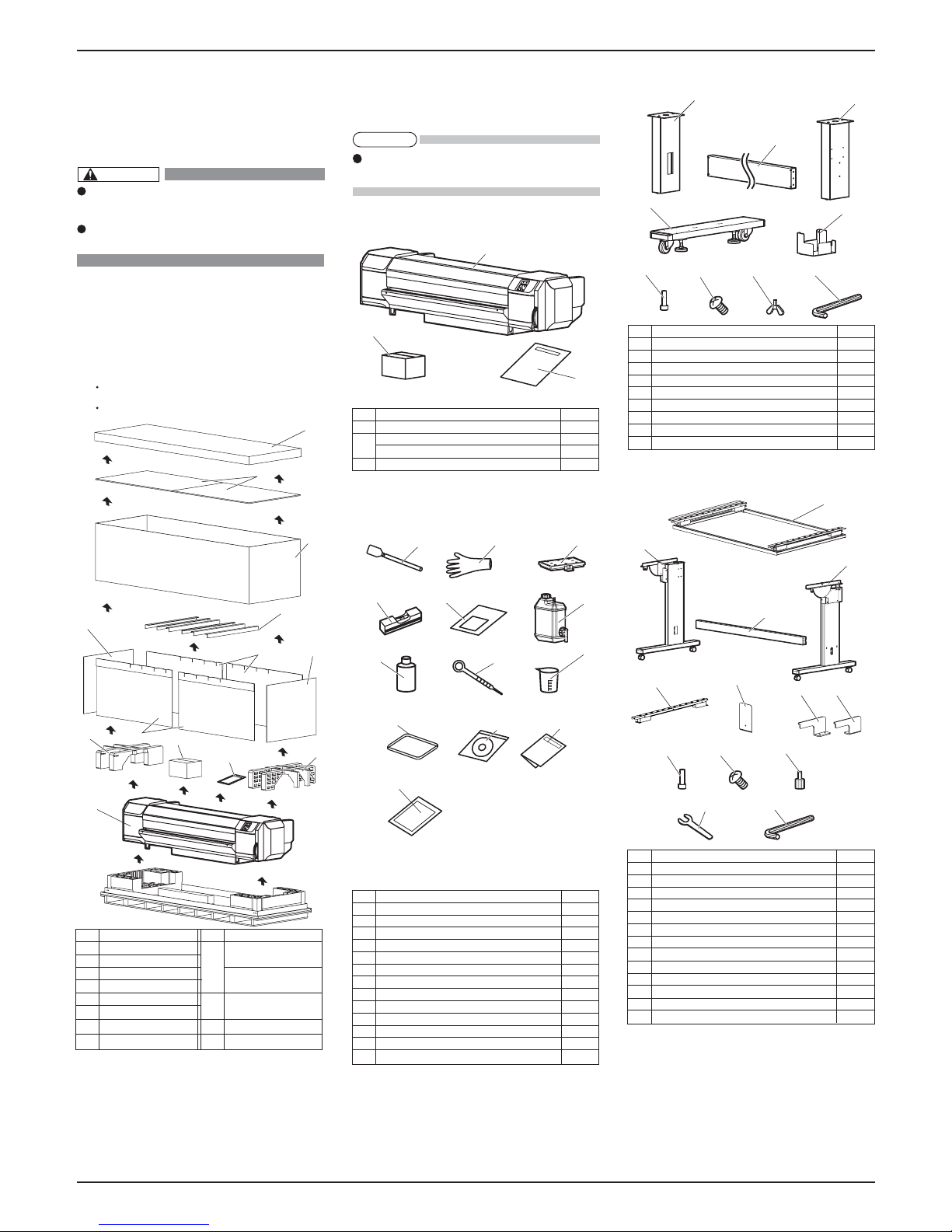

1. Press the [Power] key on the operation panel to

turn ON the printer.

ޓThe Power lamp on the operation panel lights up

in blue.

ޓThe printer starts initial operation.

ޓWhen the initial operation is complete, the

printer enters Normal.

You need to let the ink flow inside the printer

regularly, therefore, do not turn OFF the

printer after regular operation; make sure

you use the sleep mode.

If you have to turn OFF the printer, read

“3.2.2 Turning the power OFF” in the

Operation Manual.

The procedures to turn OFF the printer

are different for 4-color set usage and

5-color set usage.

Long Feed

Roll

Rigid

Media Type

Heater Link

Origin

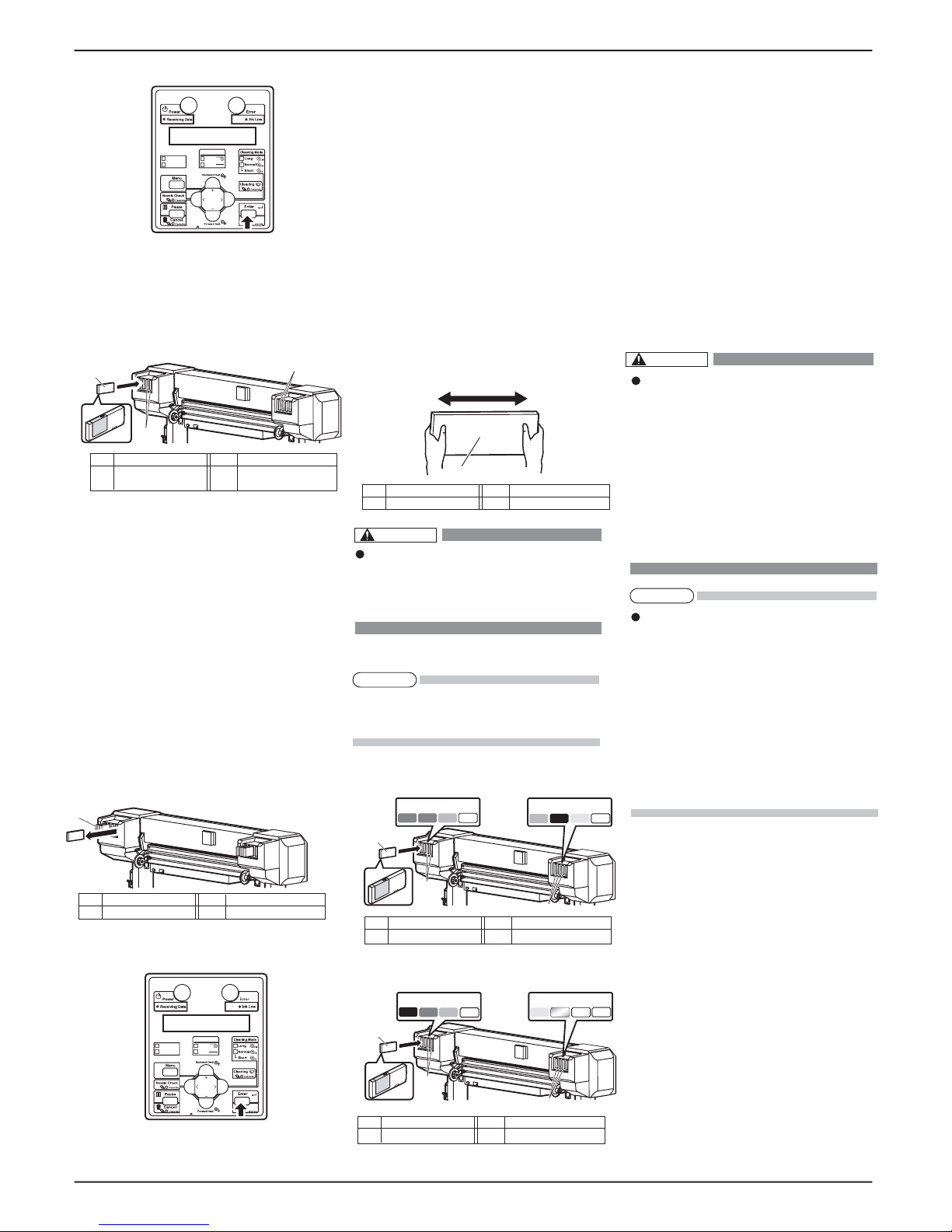

6.2 Set sleep mode on the printer

1. Make sure that the printer's operating condition is

as follows:

• Printing or other operation is not in progress.

• Operation panel display is in the Normal condition.

• There is ample amount of ink in the ink packs.

Operation Manual 5.3.15 Ink Status menu

Operation Manual 6.4.1 Replacing ink bags

• There is enough free space in the waste fluid bottle.

Operation Manual 6.6 Disposal the waste fluids

• Front cover is closed.

• Media loading lever is lowered

(Media loading lever on the rear side is raised).

2. Press the [Menu] key on Operation panel.

ޓ"Menu1: Sleep Mode" is displayed on Operation

panel.

3. Press the [>] key on Operation panel.

ޓ"Sleep Mode1: Timer Set" is displayed on

Operation panel.

4. Press the [Enter] key on Operation panel.

ޓ"Timer: Off" is displayed on Operation panel.

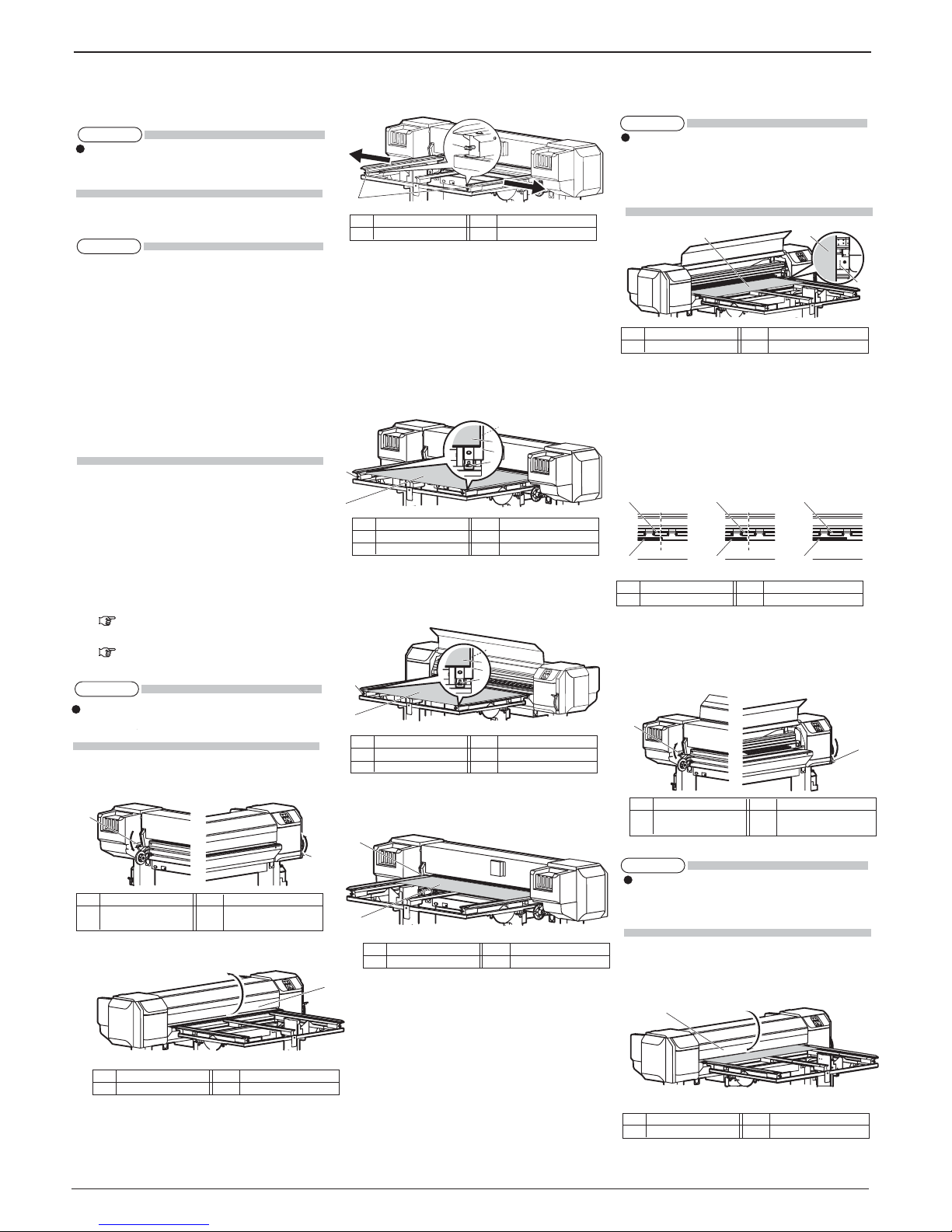

Long Feed

Roll

Rigid

Media Type

Heater Link

Origin

Long Feed

Roll

Rigid

Media Type

Heater Link

Origin

Long Feed

Roll

Rigid

Media Type

Heater Link

Origin

• If there is a problem during the initial

operation, a message is displayed on the

operation panel and the printer may stop

operating.If operation stops, refer to

"7 Troubleshooting"and deal with the problem.

ޓ

Do not pull out or insert the power plug with

a wet hand.

This could lead to an electric shock.

Make sure to use only the specified power

supply (AC 100 V to 120 V or AC 220 V to

240 V).If a power supply other than the

specified voltage is used, it could cause an

electric shock and fire.

Take power for the printer directly from

the power socket (AC 100 V - 120 V or AC

220 V - 240 V).Do not use multiple plugs

on the same socket.This could generate

heat and might cause fire.

Be sure to use a dedicated power socket

with earth wire for the power supply, and

connect it to the earth wire.

If the earth wire is not connected, an

electric shock or fire may occur.

Do not connect an earth wire to the following

places.

• Gas pipe

There is a possibility of ignition and explosion.

• Earth wire of telephone cables and

lightning rods

Heavy current might flow whenever lightning

strikes.

Water pipe and faucet

The earth might not work if a plastic pipe

is connected in the middle of the metal pipe.

Contact the retail outlet of purchase if the

ޓearth connection cannot be established,

or if the earth connection is not given.

When the power supply of the printer is

ON, do not pull out the power cable from

the power socket.Whenever the plug is

pulled out from the power socket, allow

one minute or more before inserting the

plug in the power socket again.

3. Insert the power cable plug firmly in the socket.

• Pay attention to the following points

when handling the power supply plug.

Any mishandling of the power cable could

cause a fire.

• Make sure that no foreign substances such

as dust etc. are stuck to the power plug.

• Make sure that the power plug is firmly

inserted to the edge of the power socket.

• When you do not use the printer for a

long period, make sure to pull out the

power plug from the power socket for safety.

• If you are leaving the printer unplugged

for a long time, follow the procedure in

"6.3.1 Operation procedure for long storage"

to turn the power OFF, and then unplug the

power plug.

• Make sure to connect an earth wire to the

earth connection that meets the following

standards.

• Earth terminal of power socket

• Earth wire with copper plate which is

buried at 650 mm or more, deep in the

ground.

• Earth wire with copper plate which is

buried at 650 mm or more, deep

WARNING