2

Dear Customer:

Congratulations on the purchase of your new Tempo™ spotter. As you are

already aware, the scene of the equipment world is becoming more high tech, and

we at Mytee Products Inc. strive to keep you on the cutting edge with superior

quality and technology.

Keep in mind that the S-300H Tempo™ is a machine, so neglect or abuse

will cause unnecessary damage and void the warranty. However with simple

maintenance the S-300H will give quality performance for many years to come.

If warranty questions arise, please consult your user manual or get in touch with

your distributor. If you have questions about maintenance, replacing parts or

ordering parts, please call an authorized Mytee Products Inc. Service Center.

To see an updated list, visit our website at www.mytee.com

Before you begin cleaning, please read your manual thoroughly.

Sincerely,

Mytee Customer Care Dept.

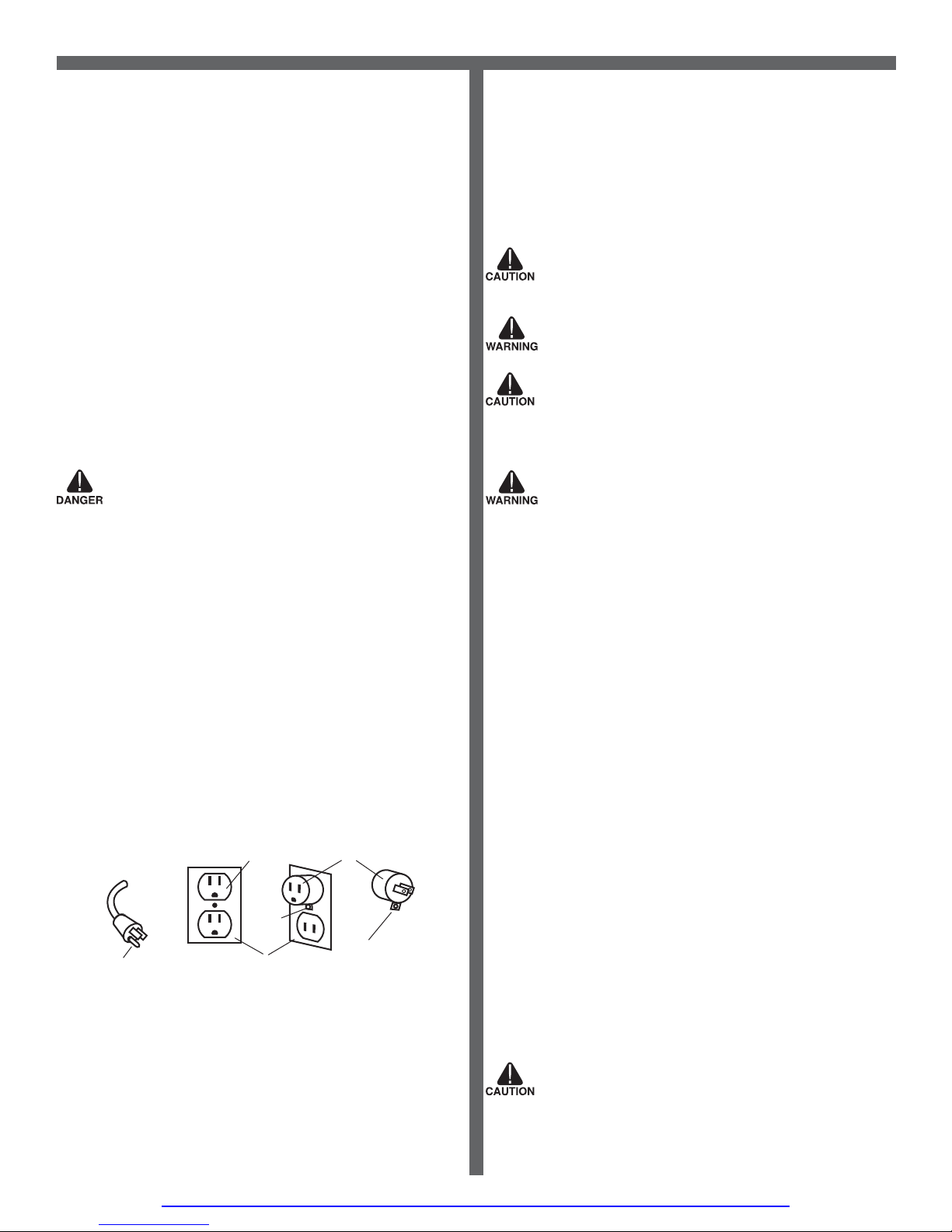

Grounding Instructions

This machine must be grounded. If it should malfunction or breakdown, grounding

provides a path of least resistance for electrical shock. This machine is equipped

with a cord having an equipment-grounding conductor and grounding plug. The

plug must be plugged into an appropriate outlet that is properly installed in ac-

cordance with all local code and ordinances. Do not remove ground pin; if missing,

replace plug before use.

Improper connection of the equipment-grounding conductor can result in a risk

of electric shock. Check with a qualied electrician or service person if you are

in doubt as to whether the outlet is properly grounded. Do not modify the plug

provided with the machine. If it will not t the outlet, have a proper outlet installed

by a qualied electrician.

This appliance is for use on a nominal 120-volt circuit, and has a grounding plug

that looks like the plug illustrated in Figure 1 below. A temporary adapter illustrated

in Figures 2 and 3 may be used~to connect this plug to a 2-pole receptacle as

shown in Figure 2 if a properly grounded outlet is not available. The temporary

adapter should be used only until a properly grounded outlet (Figure 1) can be

installed by a qualied electrician. The green colored rigid ear, tab or the like

extending from the adapter must be connected to a permanent ground such as a

properly grounded outlet box cover. Whenever the adapter is used, it must be held

in place by a metal screw. Grounding adapters are not approved for use in Canada.

Replace the plug if the grounding pin is damaged or broken.

The Green (or GreenYellow) wire in the cord is the grounding wire. When replacing

a plug, this wire must be attached to the grounding pin only.

DO NOT use extension cords.

Please Note for America use only

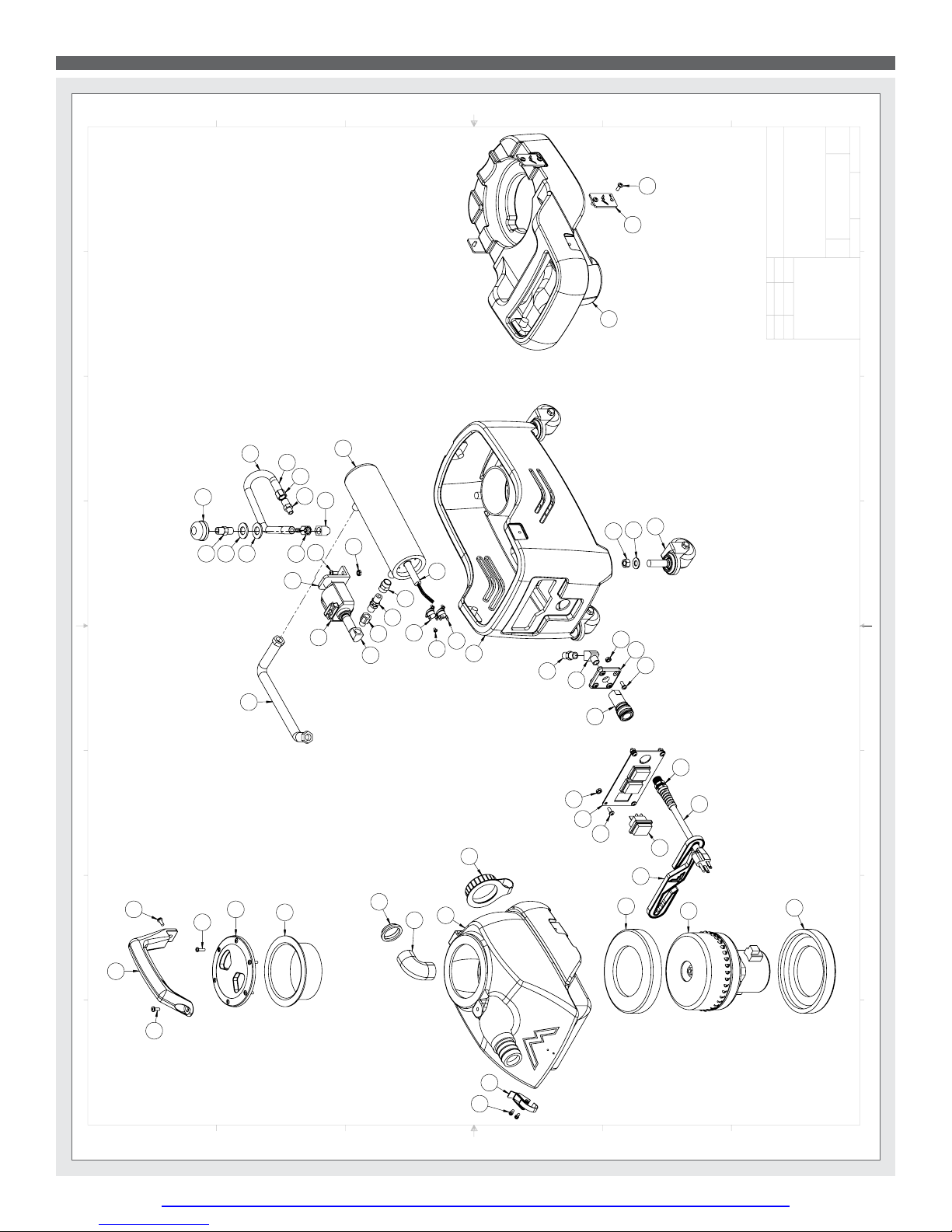

Parts and Service

Repairs, when required, should be performed by Mytee service personnel or Mytee

authorized Service Center using Mytee original replacement parts and accesso-

ries. Call your local service center for repair parts or service. Please specify the

Model and Serial Number when discussing your machine.

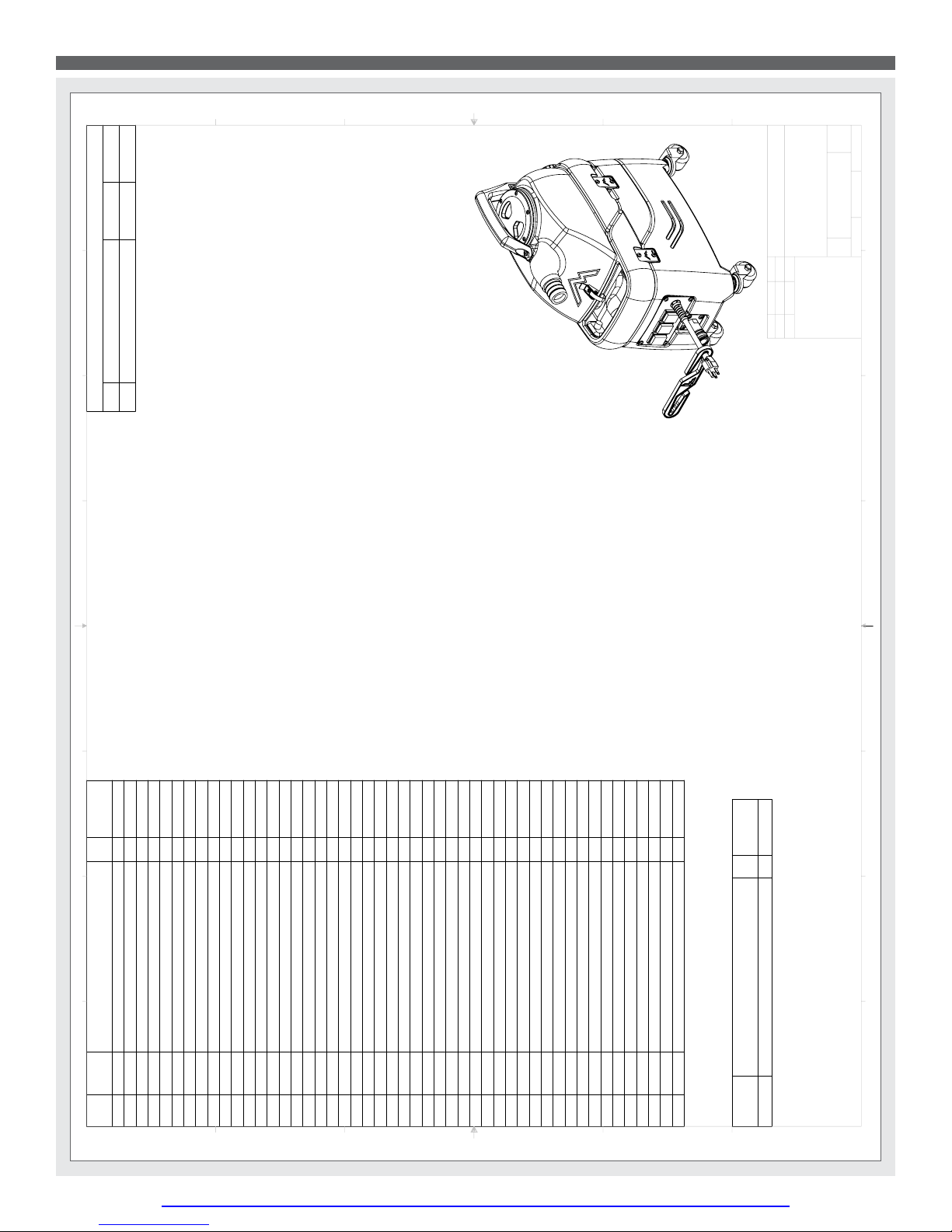

Name Plate

The Model and Serial Number of your machine are shown on the Nameplate on the

back panel of the machine. This information is needed when ordering repair parts

for the machine. Use the space provided on the front cover to note the Model and

Serial Number of your machine for future reference.

Unpacking the Machine

When the machine is delivered, carefully inspect the shipping carton and the

machine for damage. If damage is evident, save the shipping carton so that it can

be inspected by the carrier that delivered it. Contact the carrier immediately to le

a freight damage claim.

Caution and Warnings

Symbols

Mytee uses the symbols below to signal potentially dangerous conditions. Always

read this information carefully and take the necessary steps to protect personnel

and property.

Is used to warn of immediate hazards that will cause severe personal injury or

death.

Is used to call attention to a situation that could cause severe personal injury.

Is used to call attention to a situation that could cause minor personal injury or

damage to the machine or other property. When using an electrical appliance, ba-

sic precautions should always be followed, including the following: Read all instruc-

tions before using this machine. This product is intended for commercial use only.

To reduce the risk of re, electrical shock, or injury:

1. Read all instructions before using equipment.

2. Use only as described in this manual. Use only manufacturer’s recommended

attachments.

3. Always unplug power cord from electrical outlet before attempting any adjust-

ments or repairs.

4. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

5. Do not pull or carry by cord. Do not close a door on cord or pull cord around

sharp edges or corners.

6. Do not run appliance over cord. Keep cord away from heated surfaces.

7. Do not use with damaged cord or plug. If cord is damaged, repair immediately.

8. Do not use outdoors or on wet surfaces and or standing water.

9. Always unplug or disconnect the appliance from power supply when not in use.

10. Do not allow to be used as a toy. Close attention is necessary when used by or

near children.

11. Do not use in areas where ammable or combustible material may be present.

12. Do not leave the unit exposed to harsh weather elements. Temperatures below

freezing may damage components and void warranty.

13. Use only the appropriate handles to move and lift unit. Do not use any other

parts of this machine for this purpose.

14. Keep hair, loose clothing, ngers, and all parts of the body away from all

openings and moving parts.

15. Use extra care when cleaning on stairs.

16. To reduce the risk of re or electric shock, do not use this machine with a solid-

state speed control device.

17. The voltage and frequency indicated on the name plate must correspond to the

wall receptacle supply voltage.

18. When cleaning and servicing the machine, local or national regulations may

apply to the safe disposal of liquids which may contain: chemicals, grease, oil,

acid, alkalines, or other dangerous liquids.

19. Do not leave operating unattended.

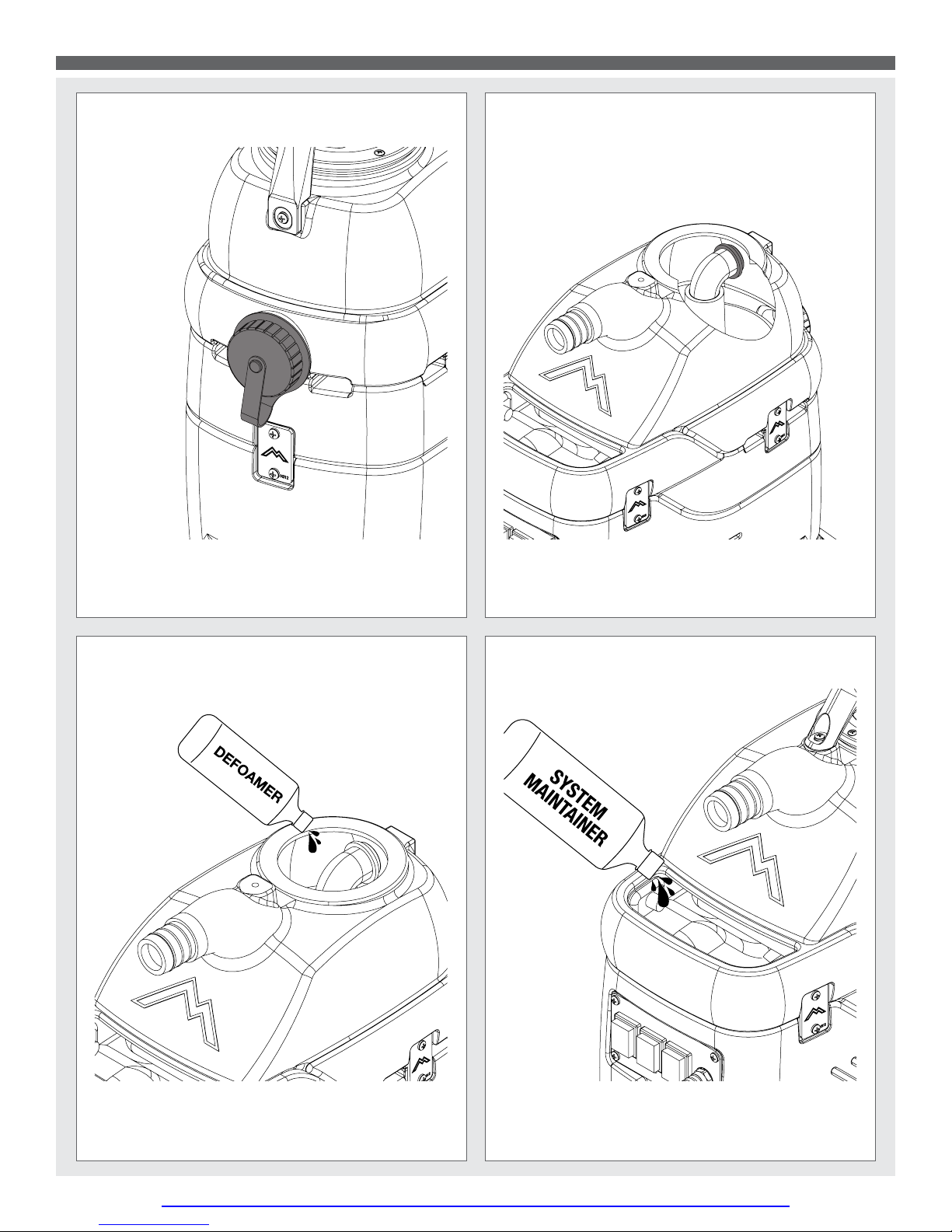

Filling the Solution Tank

1. Fill the solution tank with the approved cleaning solution.

2. Do not ll up the solution tank completely: 1” should be left free at the top.

3. Typically, the solution should be a mixture of water and a cleaning chemical

appropriate for the type of job.

4. Always follow the dilution instructions on the chemical container label.

5. The temperature of the cleaning solution must not exceed 70°C/160°F.

Use only non-ammable liquid in this machine.

GENERAL INFORMATION

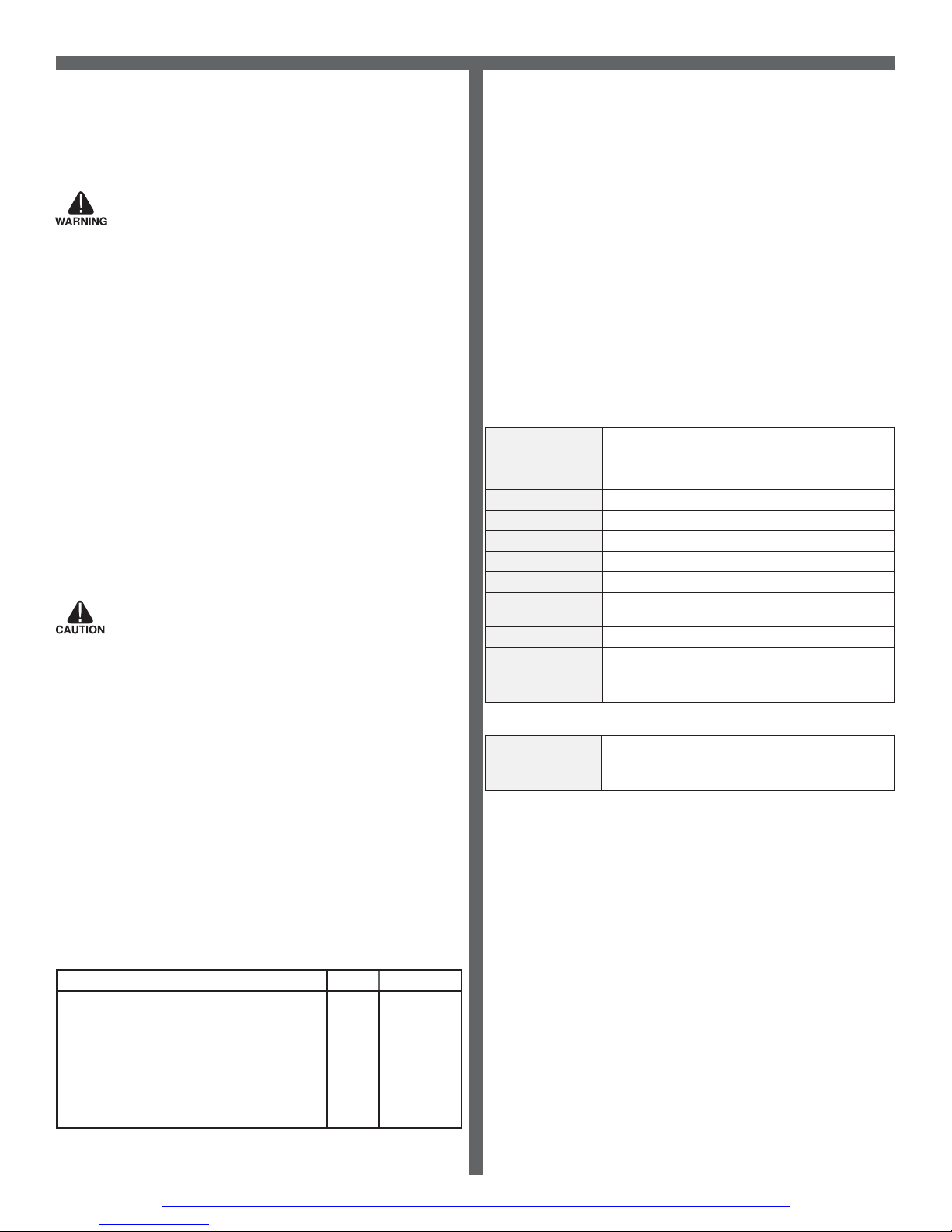

Figure 1

Grounding Pin

Grounded Outlet

Grounded Outlet Box

Adapter

Tab for Grounding

Screw

Metal

Screw

Figure 2 Figure 3

New & Reconditioned Equipment & Parts - www.southeasternequipment.net