11

English

1. CAUTIONS FOR HANDLING AND OPERATION

■Read these warnings and cautions carefully and only use in the manner intended.

■These warnings and cautions are intended to avoid potential hazards that could result in personal injury to the

operator or damage to the device. These are classied as follows in accordance with the seriousness of the risk.

Class Degree of Risk

WARNING A safety hazard could result in bodily injury or damage to the device if

the safety instructions are not properly followed.

CAUTION A hazard that could result in light or moderate bodily injury or damage to

the device if the safety instructions are not followed.

WARNING

①Handling

Connection to the Air Line Kit should be performed by a person with experience with

compressed air and air compressors.

②Air Pressure

Compressed air is required. Do not exceed an air pressure of 1.0MPa (145psi) at primary side

and 0.85MPa (123.3psi) at secondary side of the Air Line Kit.

③Use of Clean Air

Do not use compressed air contaminated with chemicals, oil compounds, organic solvents,

salinity or corrosive gasses in order to avoid damage to the device.

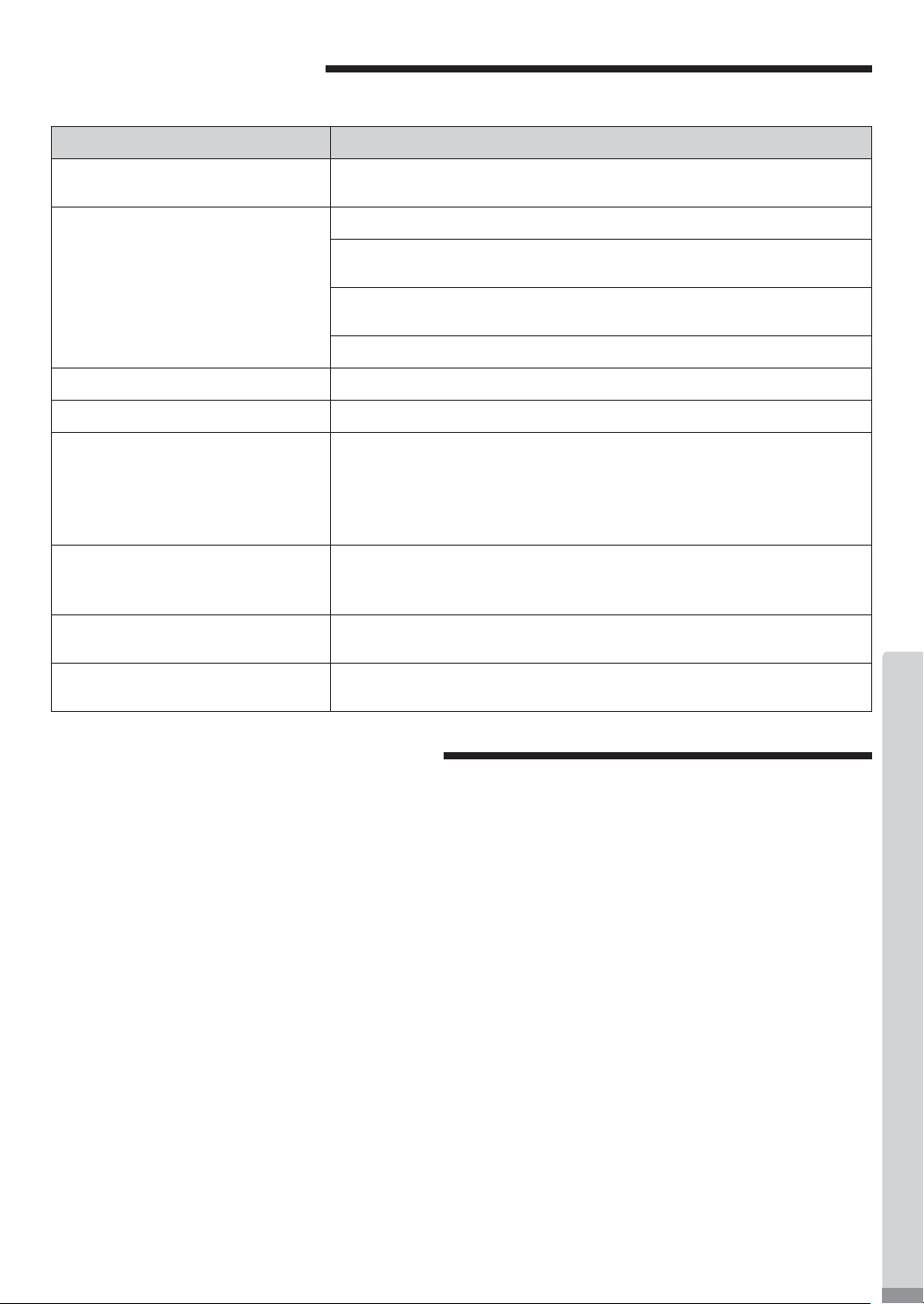

④Connection of connection hose and supply air / oil hose

Connect the input connection hose and supply air / oil hose securely to avoid accidental

disconnection during use. Input air pressure should never exceed 1.0MPa (145psi).

Pressure exceeding 1.0MPa (145psi) may cause the connection hose and supply air / oil hose

to rupture.

⑤Inlet and Outlet Connections

Do not hit, impact or cause shock to the Inlet or Outlet Connector Connections. Never put undo

stress or load on the Inlet or Outlet Connector Connections. Any damage to these components

can cause air leakage and the inability of the inlet or outlet quick disconnect to adequately

secure the connection hose and supply air / oil hose.

⑥Mounting the Air Line Kit

When installing the Air Line Kit, securely install the Air Line Kit by mounting it on a at, level

surface. If the Air Line Kit is dropped, damage to the Air Line Kit and injury to the operator is

possible.

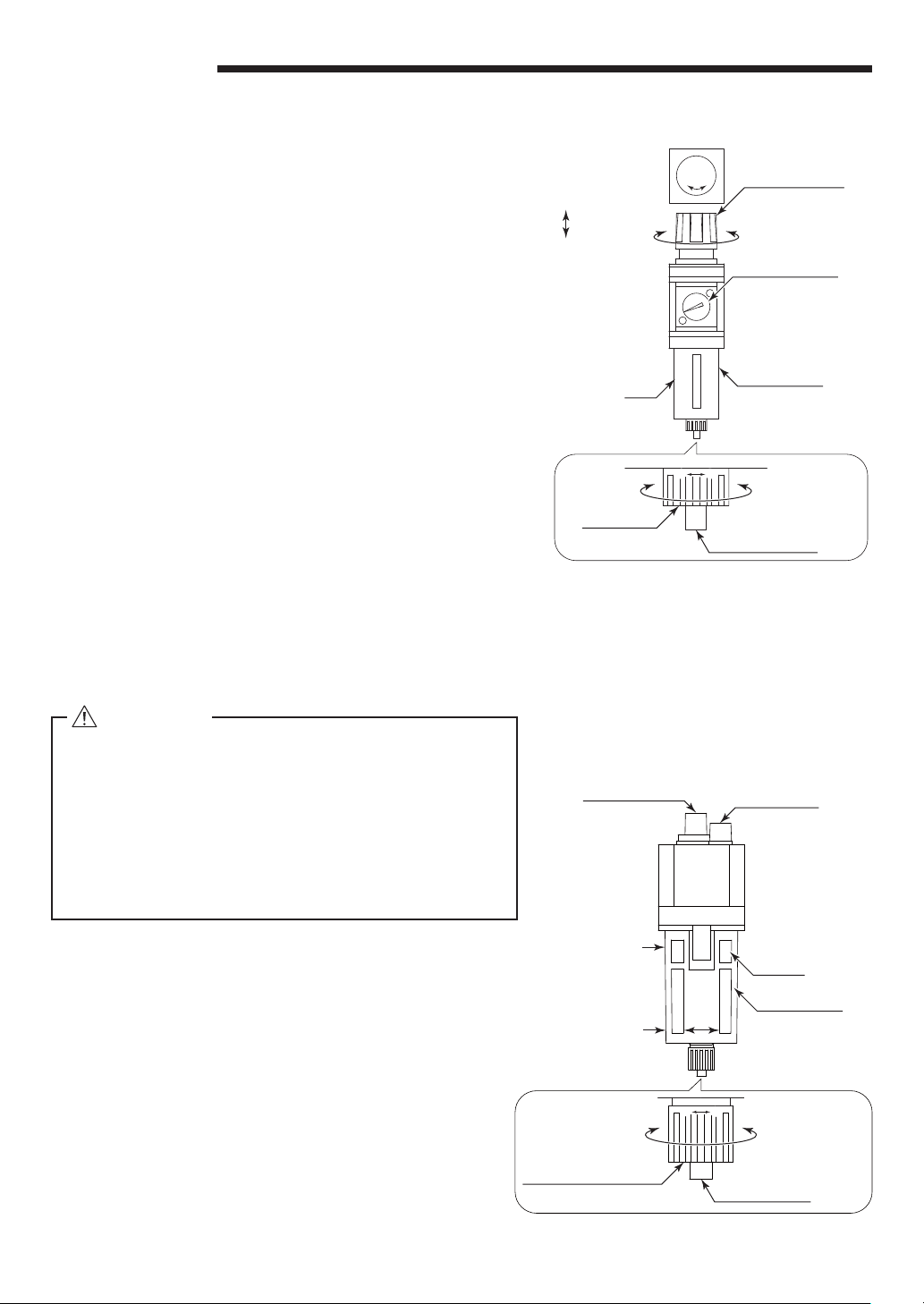

⑦Filter Regulator Bowl

・The bowl is made of a polycarbonate.

Do not use the Air Line Kit in conditions where chemicals or organic solvents are present in

the atmosphere.

・Do not remove the bowl guard. Using the Air Line Kit without the bowl guard may cause

injury to the operator should the bowl burst.

・When removing the bowl from the regulator, remove all pressure from the Input and Outlet

sides of the Air Line Kit.

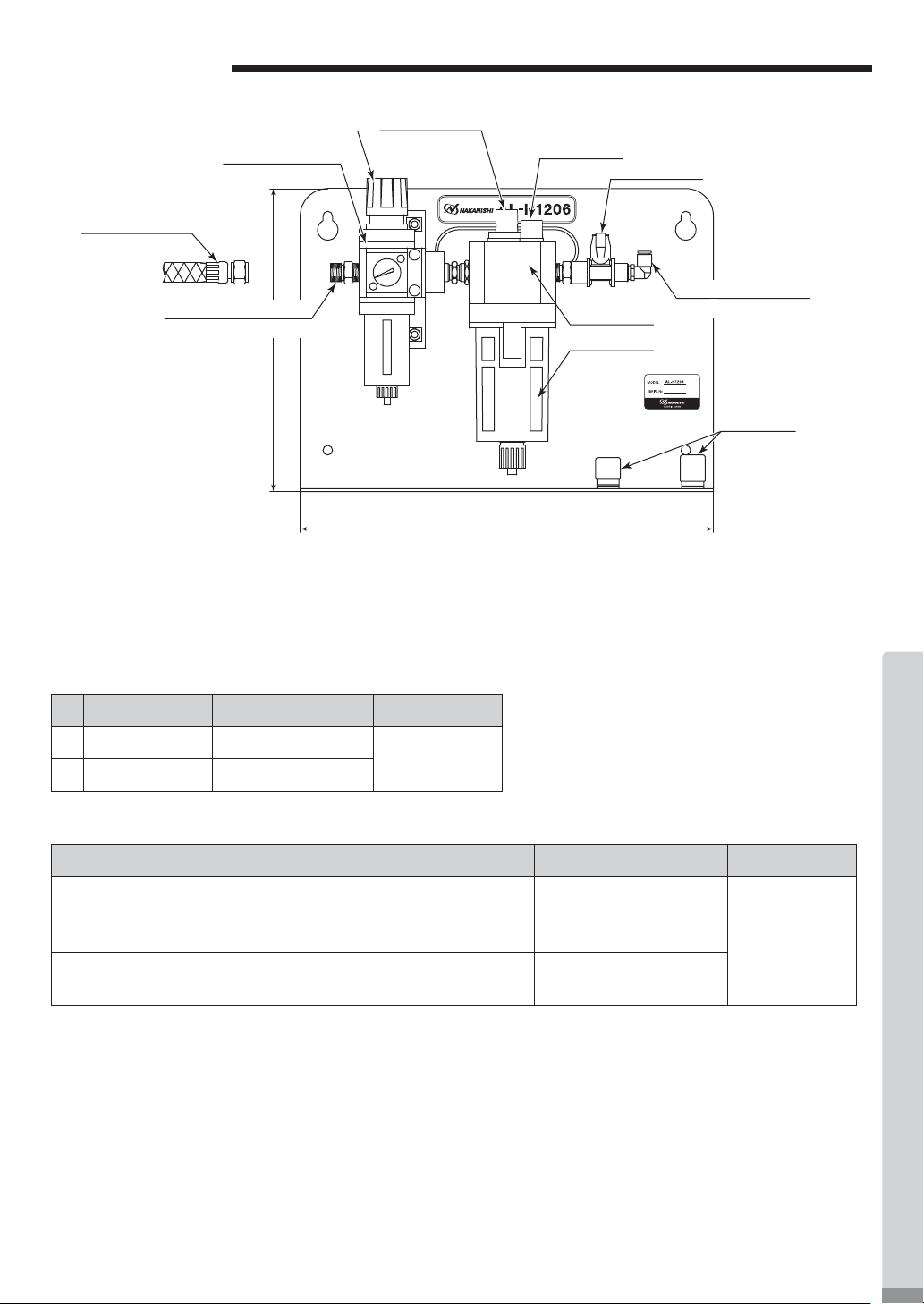

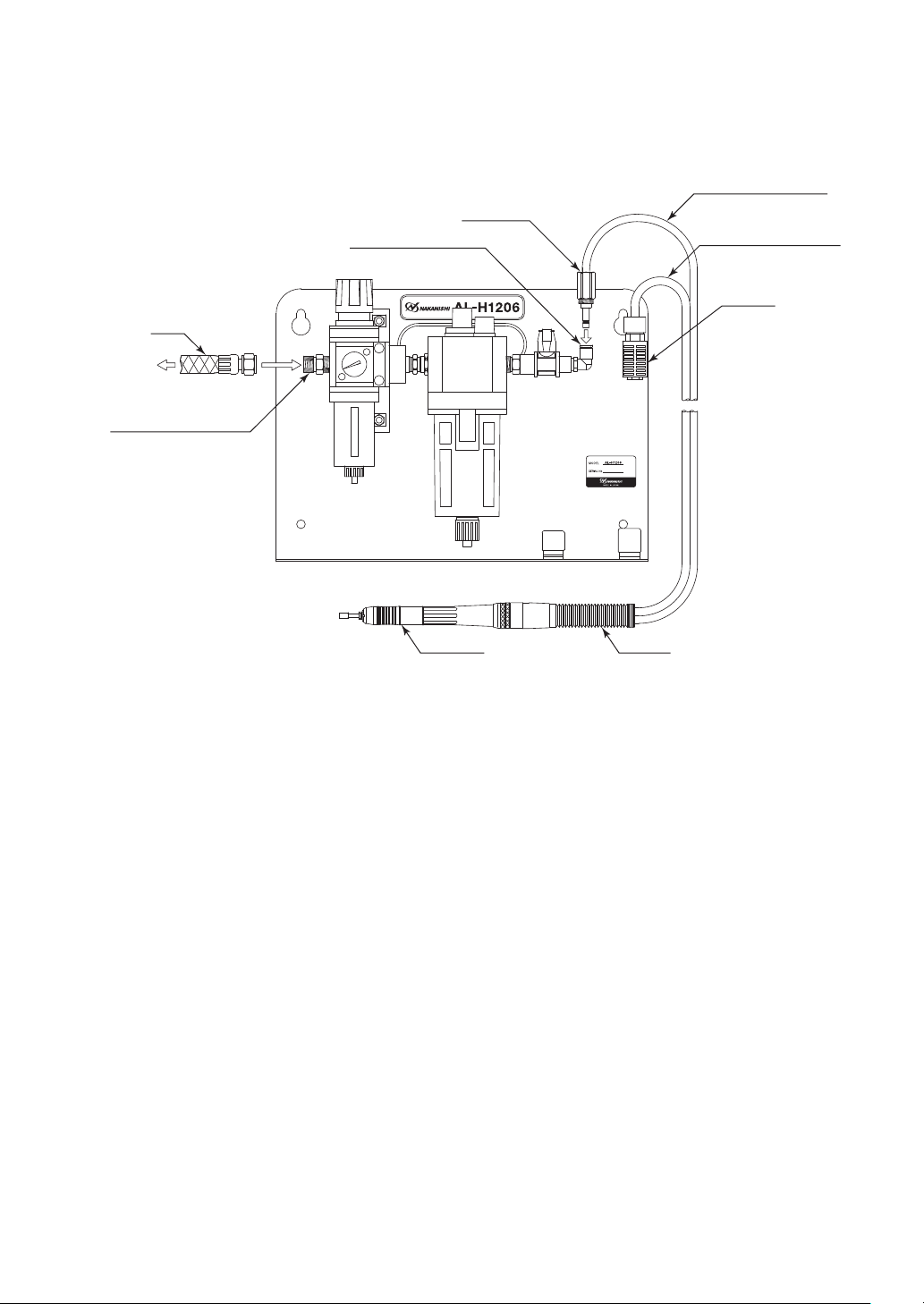

Thank you for purchasing the " AL - H1206 " Air Line Kit. This Air Line Kit designed for adjust the air supply ow and

oil amount for automatic mist lubrication to Air Grinder. The Air Grinder and a Compressor are required in addition

to this Air Line Kit. Read this and all the associated component Operation Manuals carefully before use. Always

keep this Operation Manual in a place where a user can referred to for reference at any time.