1

OPERATION MANUAL

NR33 - 6000ATC - ESD

Automatic Tool Replacement Spindle

Thank you for purchasing the Automatic Tool Replacement Spindle " NR33-6000ATC-ESD ". This Spindle is

designed for cutting and separating PCB. The E3000 CONTROLLER, Brushless Motor and Air Line Kit are required

to drive this Spindle. Read this and all the associated component Operation Manuals carefully before use. Always

keep this Operation Manual in a place where a user can referred to for reference at any time.

000

1. CAUTIONS FOR HANDLING AND OPERATION

■Read these warnings and cautions carefully and only use in the manner intended.

■These warnings and cautions are intended to avoid potential hazards that could result in personal injury to the

operator or damage to the device. These are classified as follows in accordance with the seriousness of the risk.

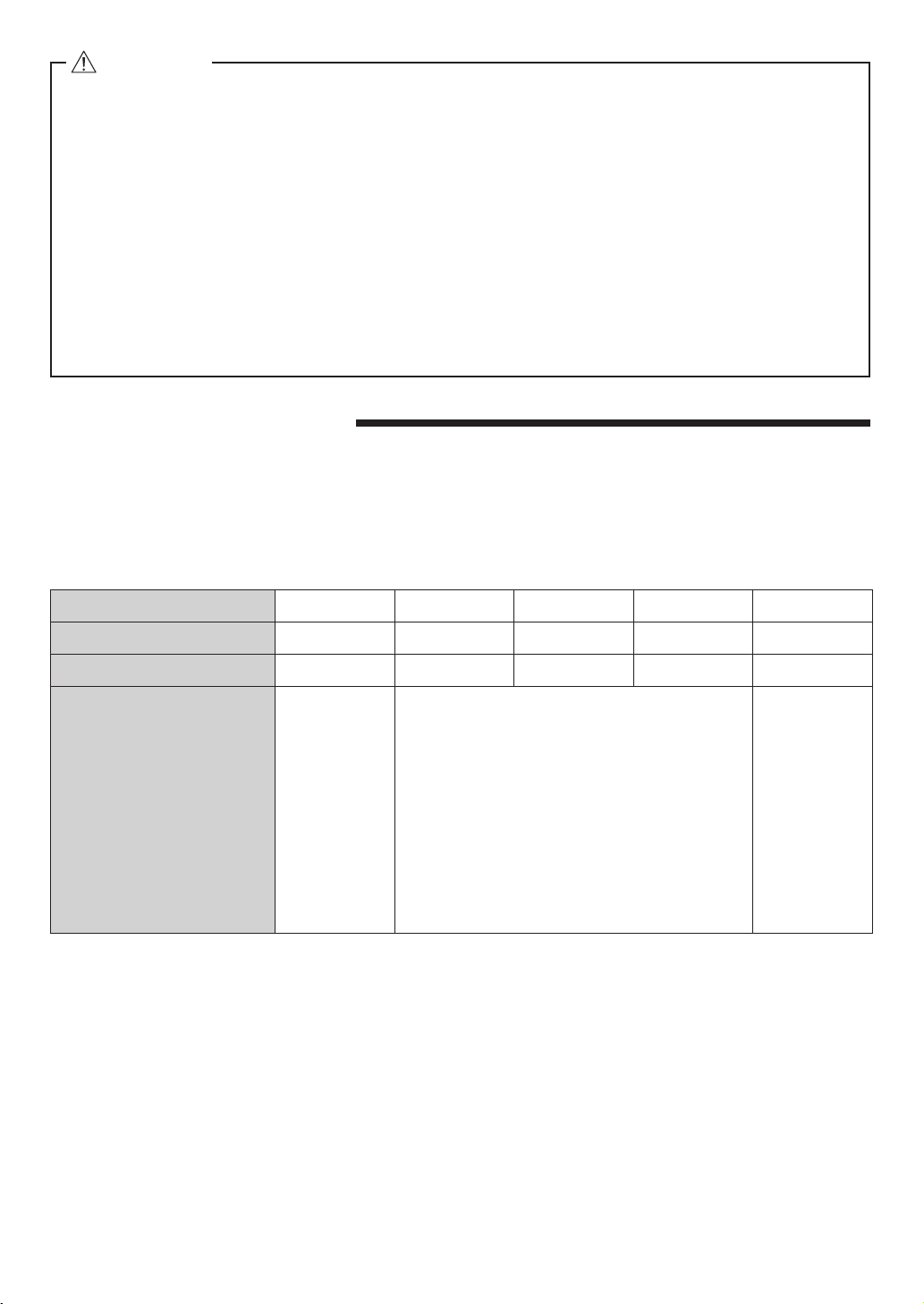

Class Degree of Risk

WARNING A safety hazard could result in bodily injury or damage to the device if

the safety instructions are not properly followed.

CAUTION A hazard that could result in light or moderate bodily injury or damage

to the device if the safety instructions are not followed.

WARNING

①This Spindle is not a hand tool. It is designed to be used on CNC machines or special purpose

machines.

②Do not touch the cutting tool while it is running. It is very dangerous.

③Wear safety glasses, dust mask, and use a protective cover around the Spindle whenever the

Spindle is rotating.

④Never connect, disconnect or touch the Power Cord Plug or Motor Cord Plug with wet hands.

This may cause an electric shock.

⑤Never operate or handle the brushless motor and Spindle until you have thoroughly read the

Operation Manuals and safe operation has been confirmed.

1)To prevent injuries / damages, check the Spindle, brushless motor and cutting tool for

proper installation, before operating the Spindle and brushless motor.

2)Before disconnecting the Spindle and brushless motor, always turn the control power off

and turn the compressed air supply to the CONTROLLER off. Then it is safe to remove the

Spindle and brushless motor.

⑥Whenever installing a Spindle to a fixed metal base, ensure that the fixed metal base is

grounded in order to avoid risk of an electric shock.

⑦When installing a tool, tighten the collet correctly and check again the collet before use. Do not

over-tighten the collet. This may cause damage to the Spindle.

⑧Do not open and close the collet while the brushless motor is runing.

⑨Do not use bent, broken, chipped, out of round or sub-standard tools, as this may cause them

to shatter or explode. Tools with fractures or a bent shank will cause injury to the operator.

When using a new tool, rotate it in a low speed and increase speed gradually for safety.

⑩Do not exceed the recommended maximum allowable speed of the tool. For your safety, use

speeds below the maximum allowable speed.

⑪Do not apply excessive force. This may cause injury to the operator by slippage or damage of

the tool, or loss of concentricity and precision of the Motor Spindle.

OM-KK0912EN

OM-KK0912EN000_NR33-6000ATC-ESD_200608_下版.indd 1 2020/06/05 16:47:51