HIS

HIS Cable Puller

HIS Business Mfg. Co.(800) 292-9831 (619) 447-0009 (619) 447-4695 Fax HIS

HIS Cable Puller

HIS Business Mfg. Co.(800) 292-9831 (619) 447-0009 (619) 447-4695 Fax

H6000, H6000 DLX, H6000 SPCL H6000, H6000 DLX, H6000 SPCL

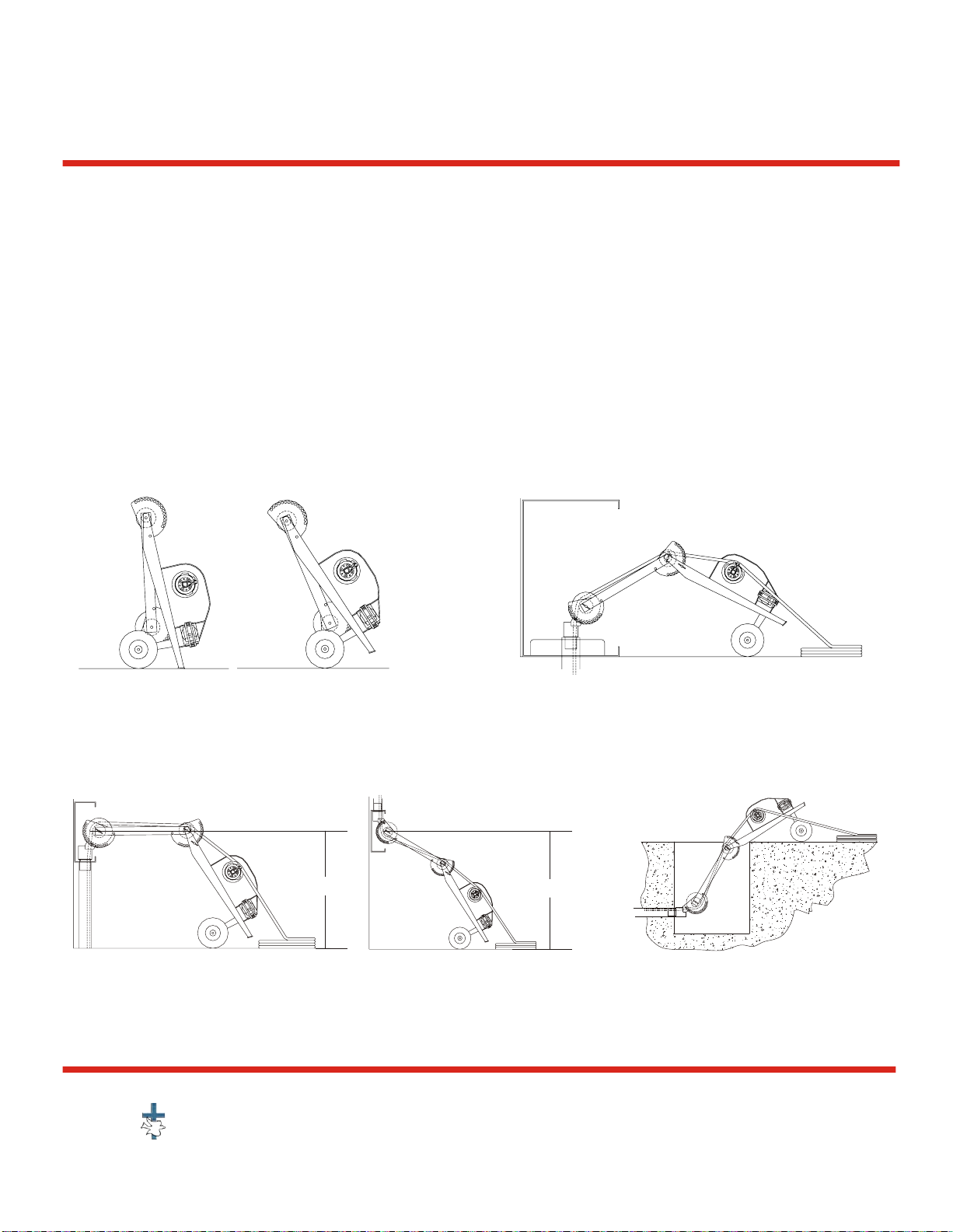

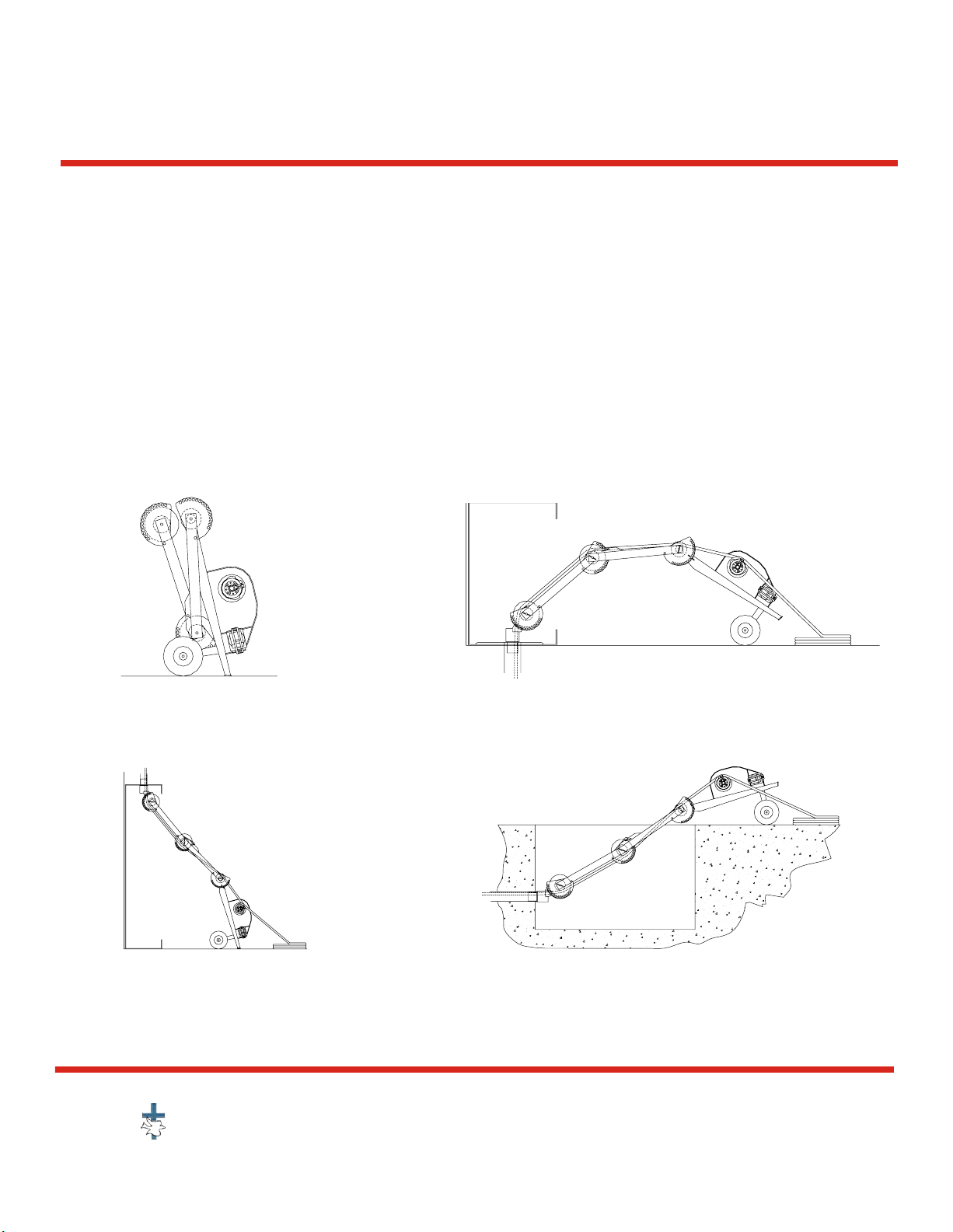

Safety and Transportation

HIS Cable Puller is uniquely designed to help make cable installation easier and less costly. The

“One-Man Operation” concept means that one person can transport easily, set up quickly and pull

cable efficiently.

His Cable Puller is designed for productivity and safety. Always understand the function of the cable

puller before operating. Only experienced journeymen should operate cable pulling equipment.

Always read instructions before operating puller.

Always inspect puller before operating.

1. Inspect cable puller, power lines and surrounding area.

2. Clean-up cluttered work area before setting-up puller.

3. Inspect cable pulling rope. Rope and eyelet must be in excellent

condition. Use high quality, high grade low stretch cable pulling

rope.

4. Never stand on or near the coiled pulling rope as it lays on the

ground.

5. Always pay close attention to cable pulling. Never let anyone

or anything distract this operation, unless an emergency

situation occurs.

6. Never use in water or in dangerous environments.

7. Think SAFETY, SAFETY, SAFETY!

8. After pull is completed, dismount puller, clean-up and

inspect equipment before storing.

HAZARD AREAHAZARD AREA

The cable puller operator

should stand off to the side

of the puller away from the

line of pull. Always stay

clear of the hazard area.

When loading and unloading cable pullers using a hoist

secure one end of a strap to the handle on the capstan/motor

housing. Loop the other end through the locking axle shaft

connected to the sheave extension arm as shown in the

illustration.

Before moving the cable puller inspect the equipment to make

sure that the extension arms are secured in the locking position

using the locking axle shafts provided. Check to be sure power

cord and foot switch is contained with puller and not loose.

When rolling the cable puller steady the axle using your foot

as you lean the unit back to find it’s natural pivot point at about

waist high or 34”. The unit then becomes easy to transport in

either direction without exerting undo stress.

Transporting HIS Cable Puller

Note: When setting up cable puller and puller arms

be couscous of pinch points..

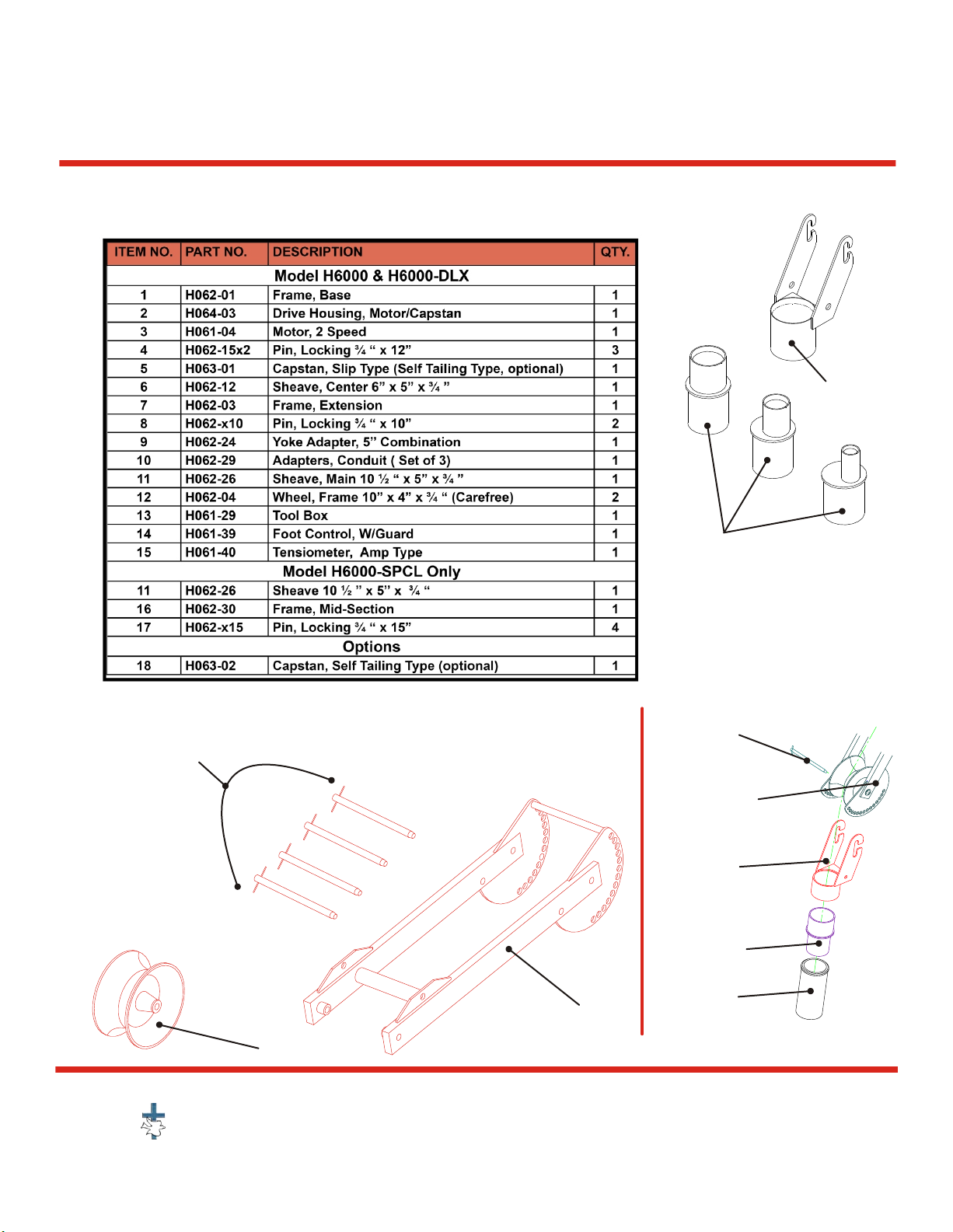

H6000 Parts List

Special “Mid-Arm” Extension

and Additional Parts Included with

H6000-SPCL

3/4”Dia x 15”Lg

(4pcs)

H6000-SPCL

Only

Conduit Adapters:

1-2”, 1-3” & 1-4”

(2 ½” Optional)

99

1010

CONDUITCONDUIT

4’ CONDUIT

ADAPTER

4’ CONDUIT

ADAPTER

YOKE/ 5”

CONDUIT

ADAPTER

YOKE/ 5”

CONDUIT

ADAPTER

EXTENSION

ARM

EXTENSION

ARM

3/4” LOCKING PIN3/4” LOCKING PIN

16

11

17

WARNING! Not intended to be used for pulling live electrical cable.

3 8

ITEM NO. PART NO. DESCRIPTION QTY

Model H6000 & H6000-DLX

1 H062-01 Frame, Base 1

2 H064-03 Drive Housing, Motor/Capstan 1

3 H061-04 Motor, 2 Speed 1

4 H062-15x2 Pin, Locking ¾ “ x 12” 3

5 H063-01 Capstan, Slip Type (Self Tailing Type, optional) 1

6 H062-12 Sheave, Center 6” x 5” x ¾ ” 1

7 H062-03 Frame, Extension 1

8 H062-x10 Pin, Locking ¾ “ x 10” 2

9 H062-24 Yoke Adapter, 5” Combination 1

10 H062-29 Adapters, Conduit ( Set of 3) 1

11 H062-26 Sheave, Main 10 ½ “x 5”x ¾ ” 1

12 H062-04 Wheel, Frame 10” x 4” x ¾ “ (Carefree) 2

13 H061-29 Tool Box 1

14 H061-39 Foot Control, W/Guard 1

15 H061-40 Tensiometer, Amp Type 1

Model H6000-SPCL Only

11 H062-26 Sheave 10” x 5 ¾ “ 1

16 H062-30 Frame, Mid-Section 1

17 H062-x15 Pin, Locking ¾ “ x 15” 4

Options

18 H063-02 Capstan, Self Tailing Type (optional) 1

Yoke and Conduit

Adapter Set-up