1

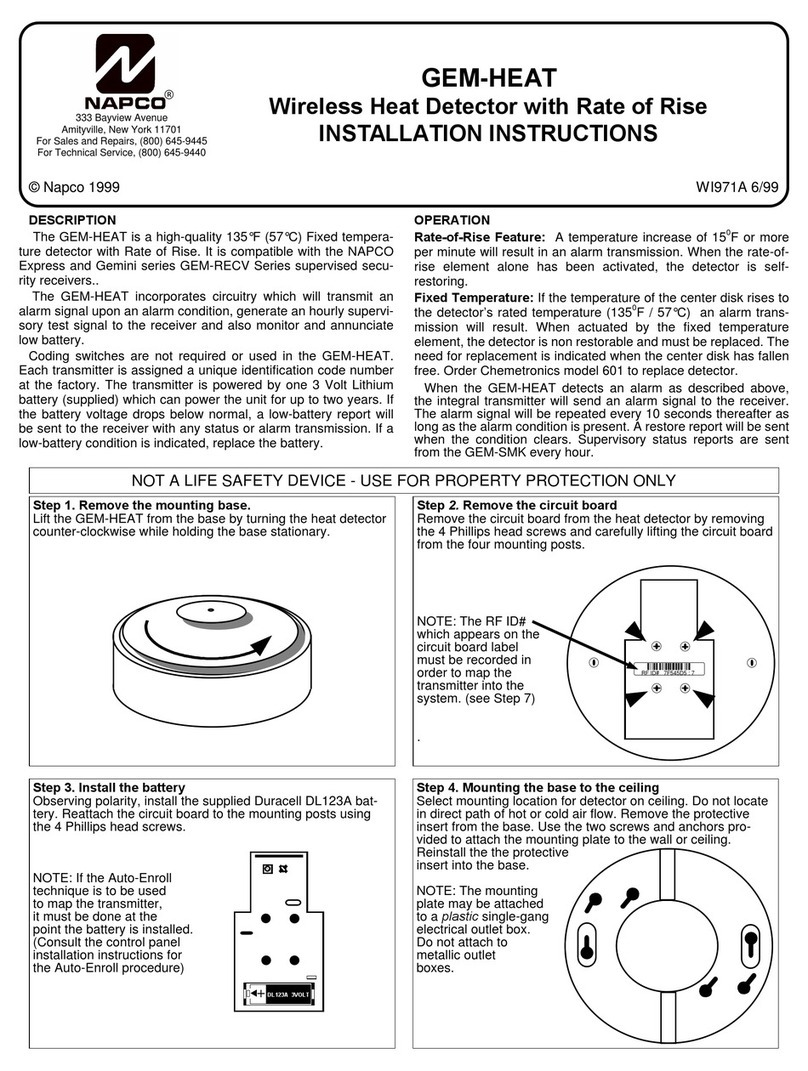

GENERAL DESCRIPTION

The NAPCO NetLink™ GEMC-NL-MOD is a device that al-

lows the reporting of alarms over a TCP/IP based (Intranet or

Internet) network. Alarm reporting, previously performed via

Telco only, can now be performed over both a TCP/IP net-

work and/or Telco, or via the TCP/IP network as a backup.

The GEMC-NL-MOD is housed in a separate plastic enclo-

sure, and is connected to the Local Download receptacle for

the Gemini C-Series control panels.

The GEMC-NL-MOD is supported by PCD-Windows Quick-

loader download software version 6.0 or greater. For the pan-

els listed above, the Quickloader software will support

downloading through the Internet or an intranet, as well as the

uploading of logs and other data.

The GEMC-NL-MOD includes a small transient protection de-

vice (named the NL-ULBD) inside its enclosure. In addition,

the GEMC-NL-MOD is one part of a larger system which in-

cludes a software package to allow its configuration before

use (the NL-MODCONFIG) and a rack-mountable Receiver

(the NL-RCV-RMPCUL) to allow the receipt of alarms, status

and supervisory data. A short description of each is provided

below:

NL-MODCONFIG Software (version 2.0 or greater):

NL-MODCONFIG is a software program allowing the con-

figuration of the GEMC-NL-MOD with appropriate informa-

tion (such as the static IP address of the module, static IP

address of the NL-RCV-RMPCUL Receiver, etc.). The NL-

MODCONFIG software is run on a PC (see System Re-

quirements) and connects to the GEMC-NL-MOD via its

network connection. In addition, NL-MODCONFIG allows

the updating of the GEMC-NL-MOD firmware. Note: The

NL-MODCONFIG software and its database should be re-

tained if future access is necessary. For more information,

see WI1243.

Central Station Receiver (NL-RCV-RMPCUL)

The NAPCO Net.Link™ NL-RCV-RMPCUL (Receiver) is a

fully UL compliant central station receiver platform. This

Receiver is rack-mountable in a standard 4U configuration.

The NL-RCV-RMPCUL (Receiver) can supervise each

GEMC-NL-MOD, receive alarms, provide a means of

maintaining accounts and provide a means of displaying

alarms and event history (opening/closing, etc.). For more

information, see the NL-RCV-RMPCUL Installation and

programming manual, WI1491.

Transient Protection (NL-ULBD)

The GEMC-NL-MOD includes electromagnetic protection

and meets direct and indirect ESD requirements for Infor-

mation Technology Equipment (ITE), however, burglary

applications may call for better protection.

The NL-ULBD is a small device which gives added tran-

sient protection and mounts entirely inside the GEMC-NL-

MOD housing. The NL-ULBD protects the GEMC-NL-

MOD from significantly larger transients and surges which

may emanate from the network cable or associated de-

vices. It is connected in series between the Ethernet cable

that provides network access and the RJ45 connector in

the GEMC-NL-MOD. The NL-ULBD is required for UL

compliant installations.

SPECIFICATIONS

Electrical Ratings

Input Power: Nominal 12VDC, 85mA.

Note: 12V power must be supplied from GEMC-

Series motherboard AUX PWR terminals. Available

panel 12V combined auxiliary current is reduced by

85mA.

Output Power: PGM-style open collector (negative

trigger) with a maximum sink current of 50mA. Wire

only to power-limited circuits less than 14VDC.

Dimensions: 1½" x 7" x 4¾" (H x W x D)

MAXIMUM WIRE LENGTH

The GEMC-NL-MOD must be mounted inside the NAPCO

Gemini GEMC-Series control panel enclosure. For Fire Alarm

control panels, the GEMC-NL-MOD must be installed inside a

separate UL 864 Listed enclosure. In addition, no more than

20 feet of conduit can be used if connected to a fire alarm con-

trol panel. NOTE: For a UL Supplemental Listing, the wire

length (GEMC-NL-MOD to control panel) must be no more

than 20 feet and the panel shall reside in the same room as

the GEMC-NL-MOD with no intervening walls or barriers.

NOTE: For best results when making RJ-45 cable assem-

blies, it is recommended to use an AMP Brand Professional

crimping tool (part # 3-231652-0), and to always match the

type of cable used (stranded or solid) with the correct type of

RJ-45 plug.

SYSTEM REQUIREMENTS

System Hardware:

•Compatible Gemini C-Series Control Panel.

•W1077 harness (see wiring diagram).

•Access to the local area network.

NL-MODCONFIG Software:

•Windows®XP Professional or Windows®2000.

(Windows®XP Home Edition is not supported).

NL-RCV-RMPCUL Rack-Mount Receiver or NL-CSRCV

Software (software not for UL installations):

•See WI1491 for the NL-RCV-RMPCUL installation and

programming instructions.

R

333 Bayview Avenue

Amityville, New York 11701

For Sales and Repairs, (800) 645-9445

For Technical Service, (800) 645-9440

Publicly traded on NASDAQ Symbol: NSSC

© NAPCO 2010 WI1754 08/10

NAPCO GEMC-NL-MOD

Network Communication Module

INSTALLATION INSTRUCTIONS