8NARVON

3. SAFETY

3.1 General safety rules

• Carefullyreadthewholeinstruconmanual.

• Theconnecontotheelectricitymainsmustcomplywith

the current safety standards in the user’s country.

• The machine must be connected to an electric outlet

thatis:

- compablewiththeplugprovidedwiththemachine;

- ofdimensions conforming to the data shown on the

rangplateonthesideofthemachine.

- properlygrounded;

- connectedtoasystemprovidedwithadierenal

switch and circuit breaker.

• Thepowercordmustnotbe:

- allowedtocomeintocontactwithanykindofliquid:

thiscancauseelectricshocksand/orre;

- crushedand/orbroughtintocontactwithsharp

surfaces;

- usedtomovethemachine;

- usedifitshowsanydamage;

- handledwithdamporwethands;

- woundintoacoilwhenthemachineison.

- tamperedwith.

• DONOT:

- installthemachineinamannerotherthanthat

describedinSecon5.

- installthemachineinaplacewhereitmaybeexposed

to any kind of water or liquid.

- usethemachinenearinammableand/orexplosive

substances.

- leaveplascbags,polystyrene,nails,oranyparts

withinchildren’sreach,sincetheyarepotenal

sources for danger.

- allowchildrentoplayorstaynearthemachine.

- usesparepartsotherthanthoserecommendedbythe

manufacturer.

- makeanytechnicalchangestothemachine.

- immersethemachineinanykindofliquid.

- spraywateronthemachinetowashit.

- usethemachineotherthanasdirectedinthismanual.

- usethemachinewhennotinfullpossessionofyour

mentalandphysicalfacules:undertheinuenceof

drugs,alcohol,etc.

- installthemachineontopofotherequipment.

- usethemachineinanexplosiveatmosphereorin

thepresenceofahighconcentraonofdustoroily

substancessuspendedintheair;

- usethemachineinaplacewherethereisariskofre;

- usethemachinetodispensesubstancesthatarenot

compablewiththemachine’sspecicaons;

• Beforecleaningthemachine,makesurethatitis

unplugged;donotcleanthemachinewithgasolineand/

or solvents of any kind.

• Repair work may be performed only by a service center

memberauthorizedbytheManufacturerand/orbya

specialized,trainedpersonnel.

• Do not obstruct the grill vents on the side of the

machine.

• Donotplacethemachinenearheangequipment

(stoves or radiators).

• Incaseofre,usecarbondioxide(CO2)exnguishers.

Donotusewaterorpowderexnguishers.

In the event of improper use, all warranty

rights will be forfeited and the manufacturer

will accept no liability for injury or damage to

persons and/or property.

The following are to be considered improper use:

- any use other than the intended use and/or with methods

other than those described herein;

- any operaon on the machine that is in contrast with the

direcons provided herein;

- use of the machine aer any components have been

tampered with and/or safety devices have been changed;

- use of the machine aer it has undergone repair with

components not authorized by the manufacturer;

- outdoor installaon of the machine.

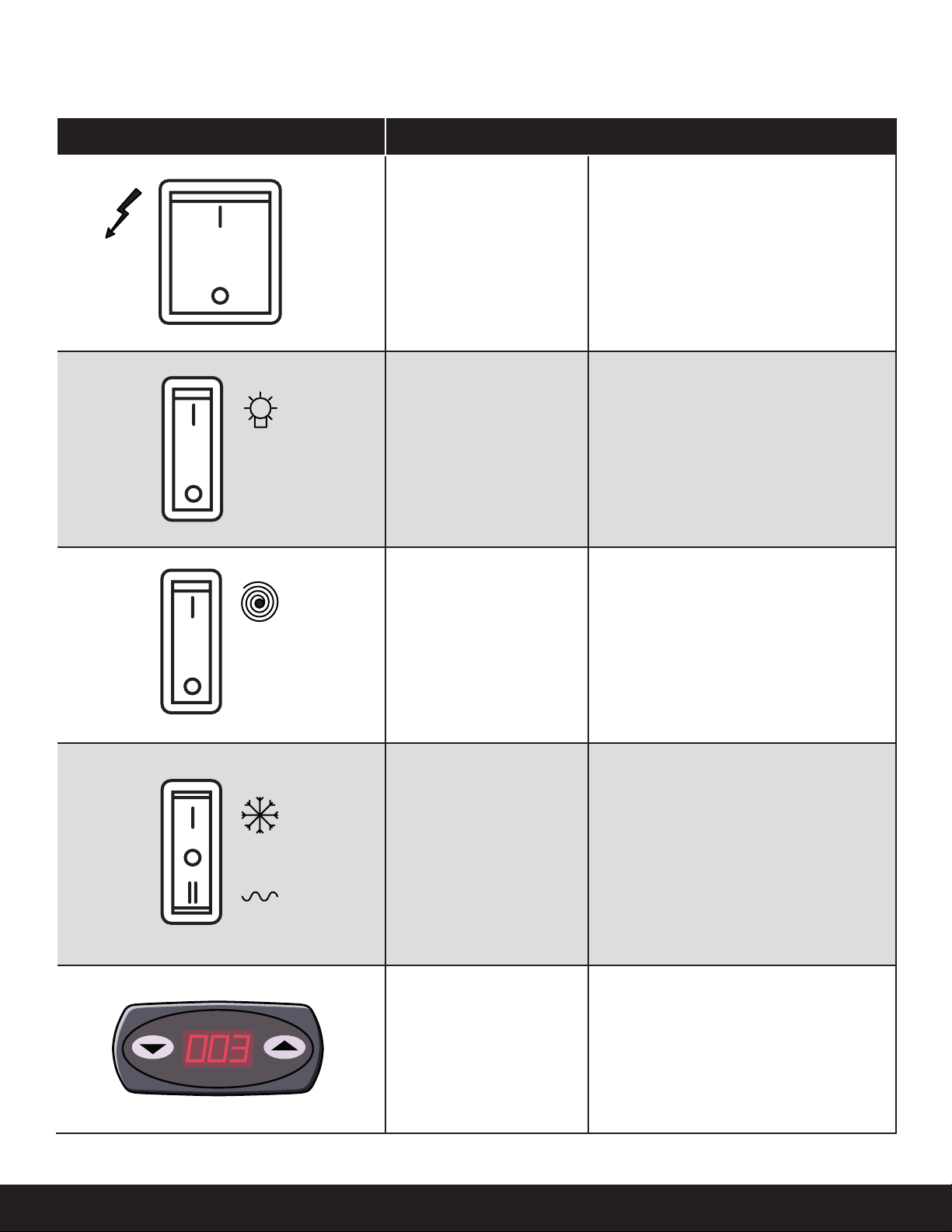

3.2 Stop functions

The machine is shut down by turning o the main switch.

3.3 Plates

NONE OF THE PLATES OR LABELS APPLIED ON

THE MACHINE MUST BE REMOVED, COVERED OR

DAMAGED, ESPECIALLY THOSE RELATING TO SAFETY.

4. HANDLING

AND STORAGE

All the operations described in Section 4 may

be carried out exclusively by technicians who

are also specialized in the lifting and handling

of packed or unpacked machines. They must

organize all the operational sequences and

use suitable equipment, according to the

characteristics and weight of the object to

be handled and in strict compliance with the

applicable regulations currently in force.