Rev 8, Dated 27-2-2018

10

Problem

3.

Speed and elevation not as per protocol through software

Solution 1. If conveyor belt is too tight then also this problem occurs. In

that case loosen the belt accordingly and put silicon oil (50-

100ml)under belt

2. Earth voltage should be less that 5V

3. Check continuity of TPC and serial port cable and re-solder if

needed (Refer fig 13 for Cable Details).

4. Check voltage setting of 10k 10 turn pot setting and speed

sensor alignment.

5. Calibrate the treadmill for speed and elevation.

6. Confirm that treadmill and PC, both are connected to one and

the same phase only. Always give power from one and the same

extension board to treadmill.

7. Though the treadmill and PC both are connected on the same

phase, there might be difference in earth to neutral voltage, so

short the both earth points with 24/36 wire externally.

8. Reload the software.

9. If still problem persists, change STWIN amplifier.

Material

Req.

ST Win amplifier, silicon oil (200ml).

Problem

4.

Speed goes on increasing when we switch on the treadmill

(Uncontrolled speed)

Possible cause:

1. When the stress test is started and the program goes into the

first stage, the treadmill should reach a speed of 2.7 km/hr

gradually.

2. But if the speed goes on increasing continuously more than

2.7km/hr (uncontrolled), it means that the feedback path is not

getting completed.

Solution:

1) For this do following steps one by one till the problem gets solved.

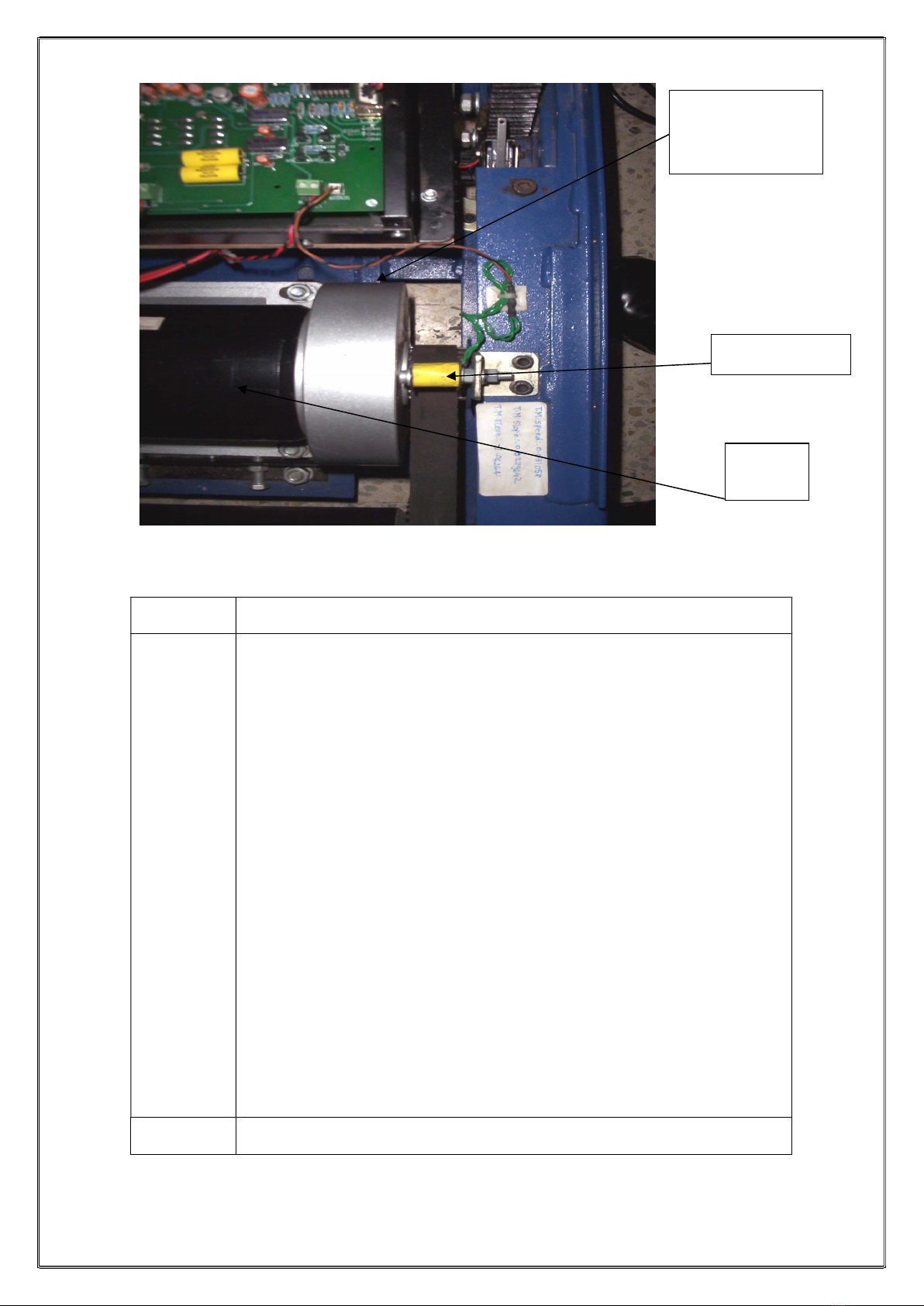

a) Check sensor connector is properly connected. Ensure that it is

not loose also.

b) Check continuity of treadmill to STWIN amplifier cable, if needed

re-solder the same.

c) Remove the speed sensor wires & ensure that resistance of

speed sensor is nearly equal to 14 ohms.

d) Check the position of magnet on flywheel and ensure that

magnet is present on flywheel.

e) Ensure that the (d 41) LED on AC/DC drive is blinking.

2) If points 1/2/3 as mentioned above are correct and still this LED is

not blinking, change the AC/DC drive.

(1) This problem also occurs due to failure of IC 324 or IC

374 and LM339 on PCB 141.

Material

Req.

Sensor coil, AC/DC drive, silicon oil (200ml).