©Ecoflo Wastewater Management Pty LtdIMNL-009-2024-01-09 Page 1

TOOLS REQUIRED

PVC

CEMENT

SILICONE

Marker Tape Measure Shovel Hand Saw

JigsawPlumb BobPVC CementCaulk Gun

Power Drill Philips Drill Bit Masonry and Brad

Point Drill Bits Hole Saw

Drill Bit

ITEMS REQUIRED (NOT INCLUDED)

Please check the packing slip to ensure everything has been delivered. If anything is missing, please

notify Ecoflo within 72 hrs of receipt.

You will need the following items to complete your installation.

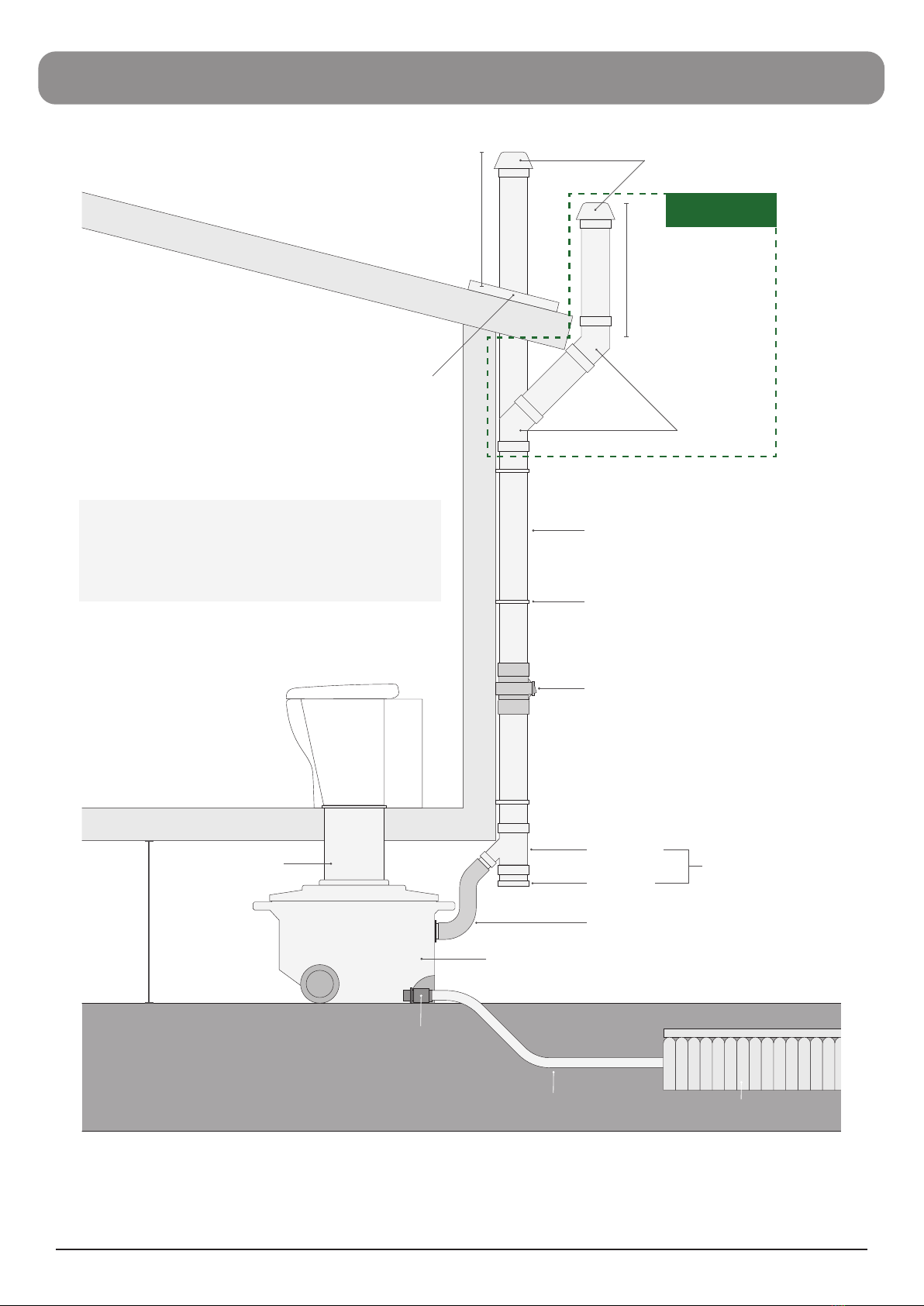

Vent items

• Wall brackets to fix the vent pipe to the building

• A length of 100mm DWV vent pipe to connect to the air exhaust (length depends on specific

installation)

• Dektite if DWV vent pipe will penetrate the roof

Leachate drain items (please check with your local authority)

• Ø100mm Agricultural pipe

• 1.5m x 0.5m Synthetic or Hessian geotextile mat

• 50mm PVC pipe to connect the hose to the agricultural pipe

• 0.30m³ 20mm Aggregate

A vent kit and drain kit are available to purchase separately from Ecoflo.