TECHNICAL MANUAL “ Brio Easy serving Espresso“

Manual Brio ESE 8 / 17

3 - AIR BREAK / BOILERS

The Brio ESE vending machine is fitted with

two boilers, each for a specific function.

A classic pressure boiler is used for Instant

selections, normally fitted on the Base Brio as

an all-purpose boiler, but it is kept at an internal

pressure of 10 bar by means of specific setting

of the by-pass valve.

A “flow-through” boiler is used for Espresso

selections; this boiler receives water from the

base pressure boiler preheated at a temperature

of approximately 80° C and then heats it up to

95-100° C.

This solution ensures a long operating life

without premature scaling problems.

It is well known that in flow-through boilers,

where water is heated from ambient

temperature to brewing temperature in a very

short time, very shortly there are problems with

excessive scaling.

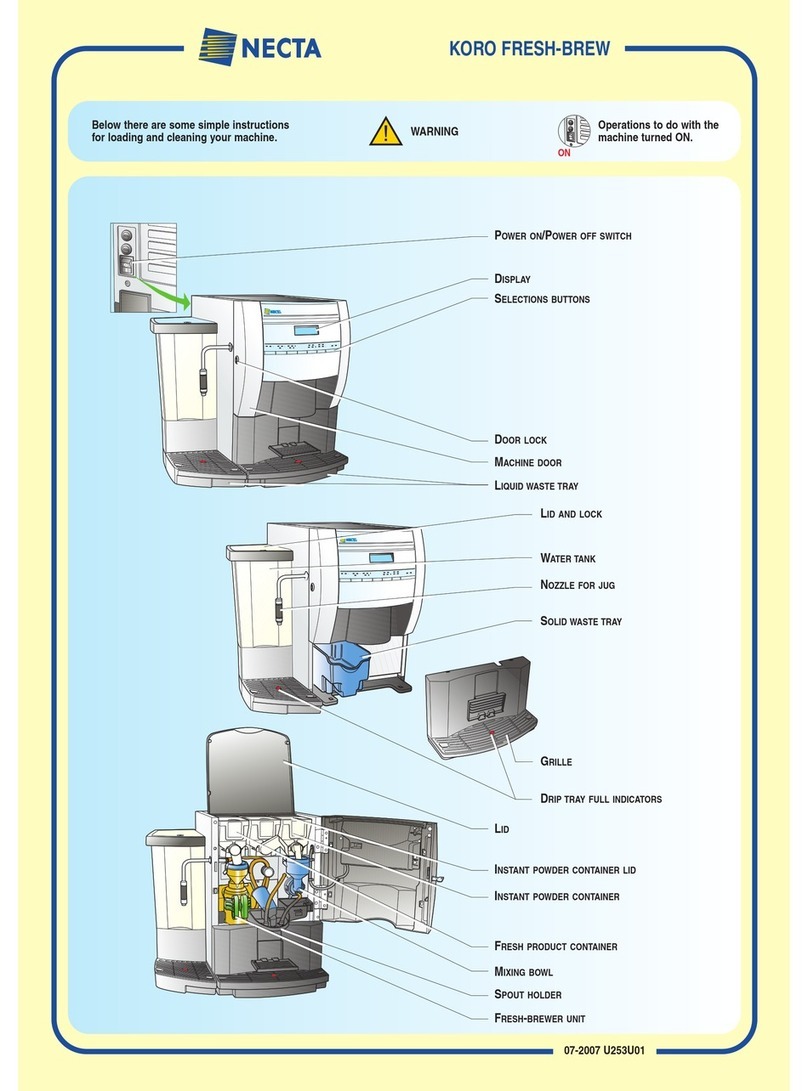

The hydraulic circuit is conceived as follows:

When the water in the air-break falls below the

minimum level, a float triggers a microswitch

that sends a signal to the board, which activates

the water inlet solenoid valve “A”, then the

water flows through the filter “B” and reaches

the air-break “C” until it is full to the max level,

controlled by the float and microswitch.

When a coffee selection is made, after

positioning the pod in the brewing chamber, the

pressure boiler two-way solenoid valves is

opened and the vibration pump is started for a

length of time determined by the volumetric

counter, that by computing the number of

rotations of an impeller wheel sets the exact

amount of water necessary for the selection.

The necessary amount of water is drawn from

the air-break and sent to the pressure boiler,

thus pushing out the same amount of hot water

(85° C) which is then delivered to the glow-

through boiler, and heated up to 95° C by

means of forced flow through a coil heated by

the Espresso boiler heating element. This water

is controlled by a pair of three-way solenoid

valves, allowing the flow of water for brewing

and for relieving the excess water in the pod,

thus leaving a perfectly dry pod

Pressure boiler

for instant

drinks

Air –break “C”

filter for

im