3

© by N&W GLOBAL VENDING SpA 0603 265 - 00

POSITIONING THE VENDING MACHINE

The vending machine is not suitable for outdoor installa-

tion.Itmustbepositionedinadryroomwherethetempera-

tureremainsbetween2°Cand32°C,andnotwherewater

jets are used for cleaning (e.g. in large kitchens, etc.).

The machine can be placed close to a wall, but with the

back panel at a distance of at least 4 cm from it to ensure

correct ventilation. The machine must never be covered

with cloth or the like.

The machine should be positioned on a level surface.

Important notice!!

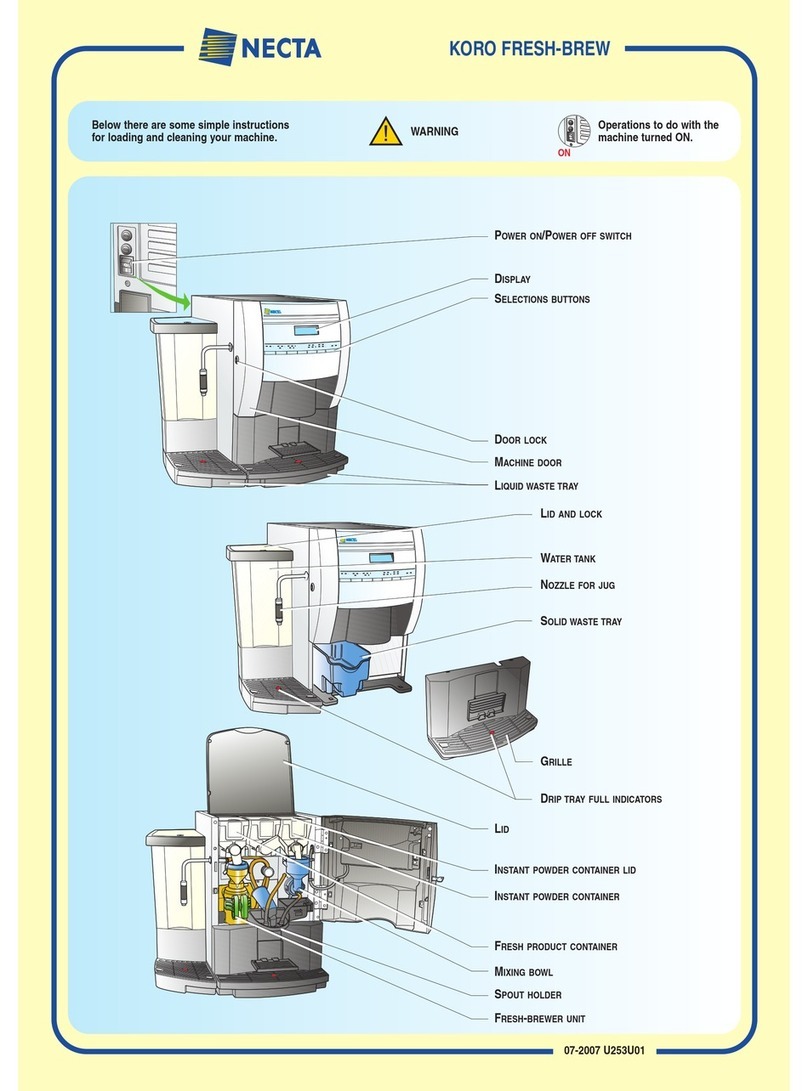

Access to the machine interior for maintenance and/or

repairs is via the back panel and from the side panels.

Therefore the machine is designed to be rotated, thus

allowingremovalofthebackpanelandofthesidepanels.

Installation on a cabinet

The machine can be installed on a table or on any other

suitable stand (recommended height is 830).

Ifpossible,itisadvisabletousethespecialcabinet,which

can house the liquid waste tray, the water supply kit, the

payment system and, in the case of very hard water, the

softener unit.

WARNING FOR INSTALLATION

The machine installation and the following mainte-

nance operations should be carried out by qualified

personnel only, who are trained in the correct use of

the machine according to the standards in force.

The machine is sold without payment system, therefore

theinstaller ofsuch systemhas soleresponsibility forany

damage to the machine or to things and persons caused

byfaulty installation.

The integrity of the machine and compliance with the

standardsoftherelevantsystemsmustbecheckedat

least once a year by qualified personnel.

All packing materials shall be disposed of in a manner

which is safe for the environment.

PRECAUTIONS IN USING THE MACHINE

The following precautions will assist in protecting the

environment:

- use biodegradable products only to clean the machine;

- adequately dispose of all containers of the products

used for loading and cleaning the machine;

- switch the machine off during periods of inactivity, thus

achieving considerable energy savings.

WARNING FOR SCRAPPING

Thesymbol indicatesthatthemachinemaynotbe

disposed of as ordinary waste; it must be disposed of in

accordance with the provisions of the European directive

2002/96/CE(WasteElectricalandElectronicsEquipments

-WEEE)andofanyresultingnationallaws,forpreventing

any possible negative consequences to the environment

and to health.

For correct disposal of the machine, contact our sales

organisation or our after-sales service, or an authorised

waste disposal facility.

TECHNICAL SPECIFICATIONS

DIMENSIONS

Height 500 mm

Width (with external tank) 508 mm

Depth 528 mm

Overall depth with door open 724 mm

Weight 28 Kg

Fig. 2

Power supply voltage 120 V~

Power supply frequency 60 Hz

Installed power 1300 W