If working above the head, wear a protective helmet. When the movement of the

cutting disc stops, hold the disc all the time in such a position that it does not

come into contact with any object. The cut off tool can only be set down when the

cutting disc has come to a complete standstill. During cutting, the workpiece

should be supported in such a way that the cutting gap is maintained at a

constant or increasing width until the cutting is completed. If the cutting disc is

jammed in the cutting gap, switch off the tool and then release the cutting disc.

Before continuing to work, check whether the cutting disc is still correctly

mounted and has not been damaged. Cutting disc should not be used for lateral

grinding. Cut off tool must not be used beyond the maximum peripheral speed of

the cutting disc. The operator must ensure that there are no unauthorised

persons in the workplace area. Wear personal protective equipment such as:

fitted gloves, apron and a helmet. Sparks from work can ignite clothing and

cause severe burns. Make sure the sparks do not fall onto the clothing. Wear

fireproof clothing and keep a bucket of water near you.

Hazards connected with repetitive movements

When using an air tool for work entailing repetitive movements, the operator is

exposed to the discomfort of hands, arms, shoulders, neck or other parts of the

body. When using an air tool, the operator should take a comfortable posture

to ensure the feet are correctly positioned and avoid strange or unbalanced

postures. The operator should change the posture over a long period of time to

avoid discomfort and fatigue. If the operator experiences symptoms such as

persistent or repeated discomfort, pain, pulsating pain, tingling, numbness,

burning or stiffness, the operator is required to report the symptoms to the doctor.

The operator should not ignore them, should tell the employer about it and

consult a doctor.

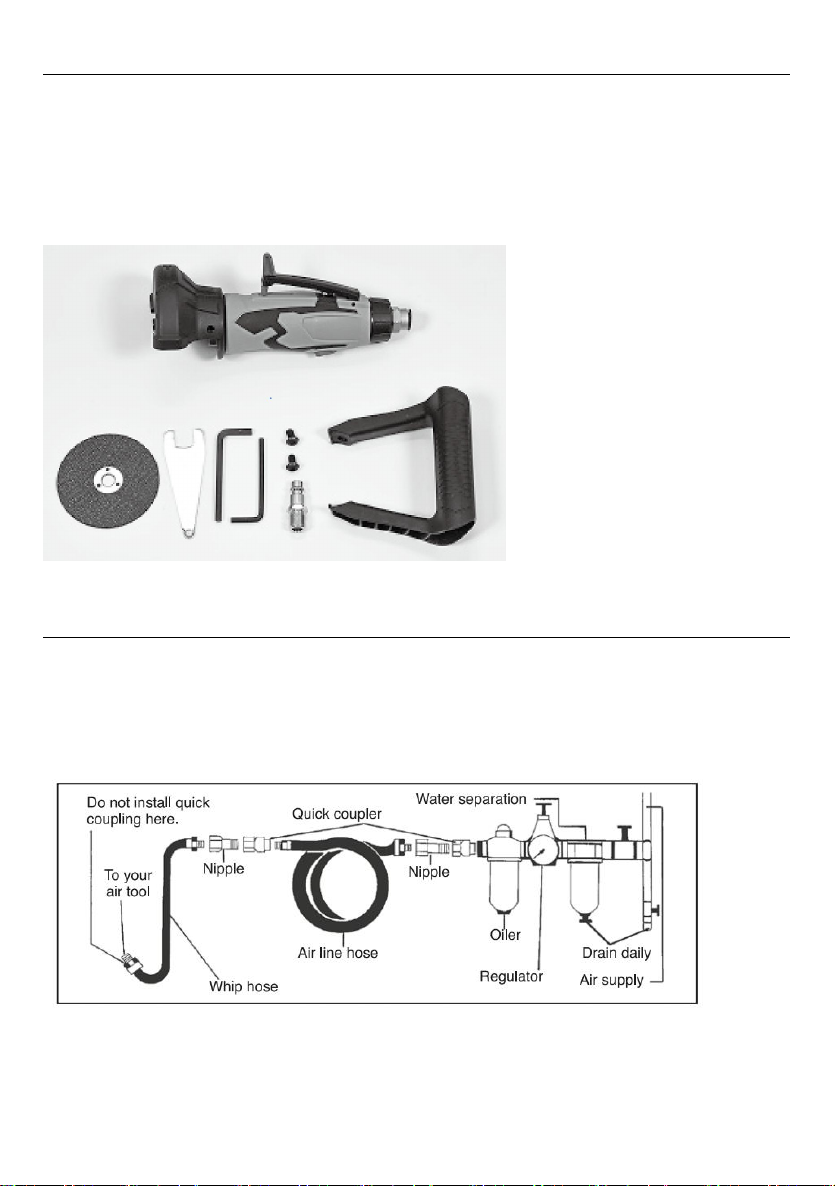

Hazards connected with accessories

Disconnect the tool from the power supply before replacing the inserted tool or

accessory. Use accessories and consumables only in the sizes and types

recommended by the manufacturer. Do not use other types or sizes of

accessories. Make sure that the dimensions of the cutting disc are compatible

with those of the air cut off tool and that the cutting disc fits the spindle of the

tool. Check the cutting disc before use. Do not use cutting discs which have