Neles Easyflow J7 Series Operating and maintenance manual

Easyow by Neles™

J7 Series Reduced bore

anged ball valve

DN15 - DN200 (1/2” - 8”)

Installation, Maintenance and

Operating Instructions

IMO-240 EN Issue 7/2020

IMO-240 EN - Issue 7/20202

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and

operation of the valve.

If you require additional assistance, please contact the

manufacturer or manufacturer’s representative.

SAVE THESE INSTRUCTIONS!

Addresses and phone numbers are printed on the back cover.

Table of contents

GENERAL 3

Scope of the Manual 3

Valve markings 3

Safety Precautions 3

TRANSPORTATION

AND STORAGE 3

INSTALLATION 3

General 3

Installing in the Pipeline 4

Valve Insulation 4

Actuator 4

Commissioning 4

MAINTENANCE 4

General 4

Actuated Valve 4

Valve Disassembly 5

Checking Parts 5

Valve Assembly 5

Testing the Valve 6

ACTUATOR 6

Actuator Mounting Instructions 6

SERVICE / SPARE PART 7

EXPLODED VIEW 8

TYPE CODE 9

3IMO-240 EN - Issue 7/2020

1. GENERAL

1.1 SCOPE OF THE MANUAL

This instruction manual contains important information regarding

the installation, operation and maintenance of Easyow by Neles™

J7 Series reduced bore anged seat supported ball valves. Please

read these instructions carefully and save them for future reference.

WARNING:

THE USE OF THE VALVE IS APPLICATION SPECIFIC.

BE SURE THAT THE VALVE IS SUITABLE FOR ITS

INTENDED SERVICE. IF YOU HAVE ANY QUESTIONS

CONCERNING THE USE, APPLICATION OR

COMPATIBILITY OF THE VALVE WITH THE INTENDED

SERVICE, CONTACT NELES FOR MORE INFORMATION.

1.2 VALVE MARKINGS

The valve has a name plate attached to the valve body. The name

plate markings identify the size, materials of construction, pressure

rating, month and year of construction, and a unique manufacturing

order number.

1.3 SAFETY PRECAUTIONS

WARNING:

DO NOT EXCEED THE VALVE PERFORMANCE

LIMITATIONS!

EXCEEDING THE PRESSURE OR TEMPERATURE

LIMITATIONS MARKED ON THE VALVE NAME PLATE

MAY CAUSE DAMAGE AND LEAD TO UNCONTROLLED

PRESSURE RELEASE. DAMAGE OR PERSONAL INJURY

MAY RESULT.

WARNING:

SEAT AND BODY RATINGS!

THE PRACTICAL AND SAFE USE OF THIS PRODUCT IS

DETERMINED BY BOTH THE SEAT AND BODY RATINGS.

READ THE NAME PLATE AND CHECK BOTH RATINGS.

SOME SEAT MATERIALS HAVE PRESSURE RATINGS THAT

ARE LESS THAN THE BODY RATING. ALL OF THE BODY

AND SEAT RATINGS ARE DEPENDENT ON VALVE TYPE

AND SEAT MATERIAL. DO NOT EXCEED THESE RATINGS!

WARNING:

BEWARE OF BALL MOVEMENT!

KEEP HANDS, OTHER PARTS OF THE BODY, TOOLS

AND OTHER OBJECTS OUT OF THE OPEN FLOW

PORT. LEAVE NO FOREIGN OBJECTS INSIDE THE

PIPELINE. WHEN THE VALVE IS ACTUATED, THE BALL

FUNCTIONS AS A CUTTING DEVICE. DISCONNECT ANY

PNEUMATIC SUPPLY LINES, ANY ELECTRICAL POWER

SOURCES AND MAKE SURE SPRINGS IN SPRING-

RETURN ACTUATORS ARE IN THE FULL EXTENDED/

RELAXED STATE BEFORE PERFORMING ANY VALVE

MAINTENANCE. FAILURE TO DO THIS MAY RESULT IN

DAMAGE OR PERSONAL INJURY!

WARNING:

WHEN HANDLING THE VALVE OR VALVE/ACTUATOR

ASSEMBLY, TAKE ITS WEIGHT INTO ACCOUNT!

NEVER LIFT THE VALVE OR VALVE/ACTUATOR

ASSEMBLY BY THE ACTUATOR, POSITIONER, LIMIT

SWITCH OR THEIR PIPING / BRACKETS. PLACE LIFTING

DEVICES SECURELY AROUND THE VALVE BODY.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN DAMAGE OR PERSONAL INJURY FROM

FALLING PARTS (SEE FIGURE 1).

Figure 1. Lifting of the valve assembly

2. TRANSPORTATION AND

STORAGE

Check the valve and the accompanying devices for any damage

that may have occurred during transport.

Store the valve carefully. Store indoors in a cool, dry place.

Do not remove the ow port protectors until installing the valve.

Move the valve to its intended location just before installation.

If the valve(s) are to be stored for a long duration, follow the

recommendations of IMO-S1.

3. INSTALLATION

3 .1 GENERAL

Remove the ow port protectors and check that the valve is clean

inside. Clean valve if necessary.

Flush the pipeline carefully before installing the valve. Foreign

objects, such as sand or pieces of welding electrodes, will damage

the ball and seats.

IMO-240 EN - Issue 7/20204

3.2 INSTALLING IN THE PIPELINE

WARNING:

THE VALVE SHOULD BE TIGHTENED BETWEEN

FLANGES USING GASKETS AND FASTENERS

COMPATIBLE WITH THE APPLICATION, AND IN

COMPLIANCE WITH APPLICABLE PIPING CODES

AND STANDARDS. CENTER THE VALVE AND FLANGE

GASKETS CAREFULLY BETWEEN FLANGES. DO NOT

ATTEMPT TO CORRECT PIPELINE MISALIGNMENT BY

MEANS OF FLANGE BOLTING!

The valve may be installed in any position and oers tight

shut-o in either ow direction. When in a horizontal line, it is not

recommended to install a valve with the stem on the underneath

side as debris in the pipeline may enter the body cavity and damage

the gland packing.

Refer to Section 4, MAINTENANCE for stem seal adjustment. If

there is seepage past the stem seal upon installation, it means

the valve may have been subject to wide temperature variations in

shipment. Leak-tight performance will be restored by a simple stem

seal adjustment described in the MAINTENANCE section.

3.3 VALVE INSULATION

Easyow by Neles™ ball valves do not require insulation. If desired,

the valve may be insulated; however, the insulation must not continue

above the upper level of the valve. See Figure 2.

Figure 2. Insulation of the valve

3.4 ACTUATOR

WARNING:

WHEN INSTALLING THE ACTUATOR ON THE

VALVE, MAKE SURE THAT THE VALVE ASSEMBLY

FUNCTIONS PROPERLY. INFORMATION ON ACTUATOR

INSTALLATION IS GIVEN IN SECTION 7 OR IN THE

SEPARATE ACTUATOR INSTRUCTIONS.

The actuator should be installed in a manner that allows plenty of

room for its removal.

The actuator must not touch the pipeline, tanks, walls, or other

equipment because vibration may interfere with its operation.

3.5 COMMISSIONING

Ensure that there is no dirt or foreign objects left inside the valve

or pipeline. Flush the pipeline carefully. Make sure that the valve is

fully open when ushing.

Ensure that all nuts, ttings, and cables are properly fastened.

If so equipped, check that the actuator positioner and/ or switch(s)

are correctly adjusted. Actuator adjustment is in Section 5. To

adjust any accompanying device(s) refer to the separate control

equipment instruction manuals.

4. MAINTENANCE

4.1 GENERAL

Although Easyow by Neles™ valves are designed to work under

severe conditions, proper preventative maintenance can signicantly

help to prevent unplanned downtime and reduce the total cost of

ownership. Neles recommends inspecting valves at least every ve

(5) years. The inspection and maintenance frequency depend on

the actual application and process condition. Routine maintenance

consists of tightening the gland ange bolts (item 16 in exploded

view) periodically to compensate for stem seal wear.

Always loosen and tighten fasteners with the appropriate wrench to

avoid damaging the valve, handle, linkage, actuator, ttings or ats.

Overhaul maintenance consists of replacing seats and seals.

These parts may be obtained from Neles or an Authorized Neles

Distributor.

WARNING:

FOR YOUR SAFETY, IT IS IMPORTANT THE FOLLOWING

PRECAUTIONS BE TAKEN PRIOR TO REMOVAL OF

THE VALVE FROM THE PIPELINE OR BEFORE ANY

DISASSEMBLY:

1. BE SURE YOU KNOW WHAT FLUID IS IN THE

PIPELINE. IF THERE IS ANY DOUBT, DOUBLE-

CHECK WITH THE PROPER SUPERVISOR.

2. WEAR ANY PERSONAL PROTECTIVE EQUIPMENT

(PROTECTIVE CLOTHING OR EQUIPMENT)

REQUIRED WHEN WORKING WITH THE FLUID

INVOLVED.

3. DEPRESSURIZE THE PIPELINE AND CYCLE THE

VALVE AS FOLLOWS:

A. PLACE THE VALVE IN THE OPEN POSITION

AND DRAIN THE PIPELINE.

B. CYCLE THE VALVE TO RELIEVE RESIDUAL

PRESSURE IN THE BODY CAVITY BEFORE

REMOVAL FROM THE PIPELINE

C. AFTER REMOVAL AND BEFORE DISASSEMBLY,

CYCLE THE VALVE AGAIN SEVERAL TIMES.

4.2 ACTUATED VALVE

It is generally most convenient to detach the actuator and its auxiliary

devices before removing the valve from the pipeline. If the valve

package is small or if it is dicult to access, it may be more practical

to remove the entire assembly.

NOTE: To ensure proper reassembly, observe the position of the

actuator and positioner/limit switch with respect to the valve before

detaching the actuator.

5IMO-240 EN - Issue 7/2020

WARNING:

ALWAYS DISCONNECT THE ACTUATOR FROM ITS POWER

SOURCE, PNEUMATIC, HYDRAULIC OR ELECTRICAL,

BEFORE ATTEMPTING TO REMOVE IT FROM THE VALVE!

WARNING:

DO NOT REMOVE A SPRING-RETURN ACTUATOR UNLESS

A STOP-SCREW IS CARRYING THE SPRING FORCE!

1. Detach the air supply, electrical supply, hydraulic supply and

control signal cables or pipes from their connectors.

2. Remove the actuator mounting bracket screws.

3. Lift the actuator straight up in line with the valve stem until

the connection between actuator drive and valve stem is

completely disengaged.

4. Place actuator in a safe location to avoid damage or

personal injury.

4.3 VALVE DISASSEMBLY

NOTE: It is good practice to replace all seats and seals any time a

valve is disassembled.

NOTE: Always use original OEM parts to make sure that the valve

functions properly.

Numbers in ( ) refer to items shown in the exploded view

1. Follow the steps in all the WARNING sections above before

performing any work on the valve.

2. Open the valve.

3. Place the valve on a bench or other suitable working space.

4. Secure tank side ange to working surface to prevent

movement during disassembly.

5. Remove body nuts (20).

6. Lift end piece (2), body seal (17), body gasket (18), and seat

(4) from valve.

7. Close ball (3) by rotating stem (5) and lift ball (3) from body.

8. Remove lower seat (4) from valve body, being careful not to

scratch the body sealing surface behind the seat.

9. Remove gland nuts (16), gland ange (14), disc spring (13),

stem retainer 2 (10), v-ring stem seal (9), stem retainer 1

(8), and stem seal (6). Use caution to prevent denting or

scratching the sealing surface inside the packing bore.

10. Push stem (5) into valve body and carefully remove. Avoid

denting or scratching the sealing surface on the stem.

11. Remove bottom stem washer (7) from the body.

4.4 CHECKING PARTS

1. Clean all disassembled parts.

2. Check the stem (5) and ball (3) for damage. Pay particular

attention to the sealing areas.

3. Check all sealing and gasket surfaces on the body (1) and

end piece (2).

4. Replace any damaged parts.

5. Replace any fastener where the threads are damaged or have

been heated, stretched or corroded.

6. Replace any parts that have cracks, gouges or pits that will

aect sealing.

NOTE: When ordering spare parts, always include the following

information:

a. Valve type code as per technical bulletin and model

number from name plate,

b. If the valve is serialized - the serial number (stamped

on the valve body or name plate) or applicable

manufacturing order number,

c. Spare part set number as per Table 3.

4.5 VALVE ASSEMBLY

Numbers in ( ) refer to items shown in the exploded view.

It is advisable to replace seats and seals if complete disassembly

and reassembly become necessary.

1. Clean all valve components, if not previously done.

2. Inspect all components for damage before assembling the

valve. Look for damage to the sealing areas on the ball, stem,

and body.

3. With a brush, clean body studs (19) and gland stud (15)

of foreign material such as paint, thread locker, grime and

commodity. Inspect the threads for damage or defect with

appropriate ring or plug gage. Repair any out-of-tolerance

threads or replace in-kind.

4. Re-inspect all components for damage to the sealing areas, stem

(5), body (1), and end piece (2). Replace any damaged parts.

5. Carefully clean and polish the ball (3) sealing surface: It should

be free of all scratches and grooves.

6. If the ball is slightly damaged, it may be possible to smooth the

sealing surface with crocus cloth or equivalent. If deep scratches

are present, replace the ball.

7. With the body cavity facing up, insert one valve seat (4) into

the body (1) to below the stem bore. Tilt the seat into place and

position so the proper surface will be in contact with the ball.

8. Place stem washer (7) over stem (5) and gently press into

place against shoulder on stem (5).

9. Insert the stem (5) into the body (1), being careful not to

scratch the stem sealing surface; and press it gently up into

the stem bore until resistance is felt from the stem washer (7).

10. Holding stem (5) in place from the bottom, insert stem seal (6),

stem retainer 1 (8), v-ring stem seal (9), and stem retainer 2

(12) with both inner and outer o-rings (11) and (12).

11. Install disc springs (13) (see gure for proper orientation), gland

ange (14), and gland ange nuts (16).

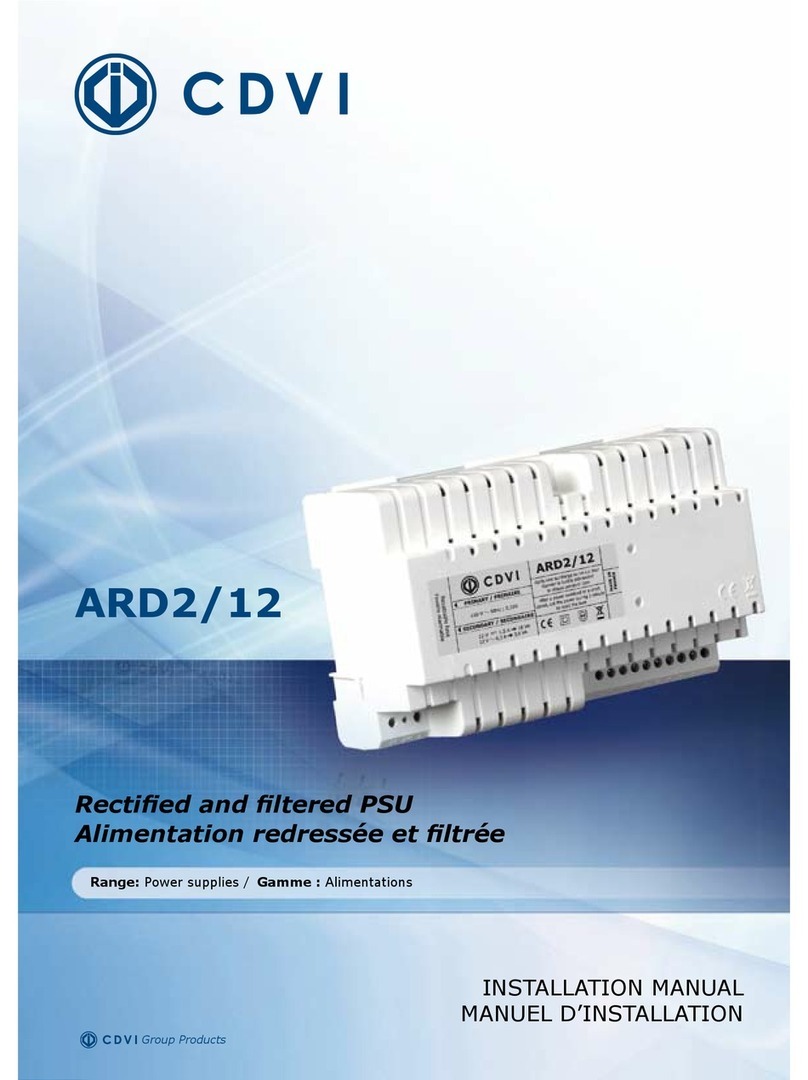

Figure 3. Proper Disc Spring Arrangement (uncompressed)

12. Tighten gland nuts (16) evenly until stem seal (9) is

compressed and then tighten an additional ¼ turn. Visually

inspect to ensure gland ange (14) is parallel with top of

actuator mounting ange.

13. Rotate the stem (5) so the ball drive is in the closed position.

Place the ball (3) into the body cavity by partially rotating and

sliding the ball onto the stem (5) and against the seat (4).

Make certain the stem is roughly in the middle of the ball slot.

14. Place the second seat (4) into the end piece (2) in the correct

orientation so the proper surface contacts the ball.

IMO-240 EN - Issue 7/20206

15. Install the body seal (17) and body gasket (18) onto the end

piece (2).

16. Carefully place the end piece (2) on top of the body (1) and

loosely install the body nuts (20). Lightly lubricate stud threads

and face of nut with anti-seize grease. Tighten the body nuts in

an alternating sequence across the body, gradually increasing

the tightening torque in multiple steps to applicable torque

from Table 1.

Table 1

Body Nut Tightening Torque, N.m

Stud size Carbon steel Grade B7 Stainless steel Grade B8M

1/4 - 20 UNC 15 12

5/16 - 18 UNC 30 25

3/8 – 16 UNC 50 40

7/16 – 14 UNC 75 65

1/2 - 13 UNC 120 100

9/16 – 12 UNC 160 150

5/8 – 11 UNC 230 200

3/4 - 10 UNC 400 370

7/8 – 9 UNC 650 500

17. After fully tightening the stem seal and body joint ange, operate

valve to verify smooth operation during opening and closing.

18. If the actuator was removed, reinstall and set the actuator

stops as described in the ACTUATOR MOUNTING

INSTRUCTIONS Section.

4.6 TESTING THE VALVE

WARNING:

WHEN PRESSURE TESTING, EXERCISE CAUTION

AND MAKE SURE ALL EQUIPMENT USED IS IN GOOD

WORKING CONDITION AND APPROPRIATE FOR THE

INTENDED PRESSURE.

If the valve is to be tested prior to returning to service, make sure

the test pressures are in accordance with an applicable standard.

When testing the valve for external tightness, keep the ball in the

half open position.

If testing for seat tightness, please contact Neles for advice.

WARNING:

WHEN PERFORMING ANY TESTS, NEVER EXCEED

THE MAXIMUM OPERATING PRESSURE OR MAXIMUM

SHUT-OFF PRESSURE LISTED ON THE IDENTIFICATION

PLATE.

5. ACTUATOR

WARNING:

BEFORE INSTALLING THE VALVE AND ACTUATOR, BE

SURE THAT THE INDICATOR POINTER ON TOP OF THE

ACTUATOR IS CORRECTLY INDICATING THE VALVE

POSITION. FAILURE TO ASSEMBLE THESE PRODUCTS

TO INDICATE CORRECT VALVE POSITION COULD

RESULT IN DAMAGE OR PERSONAL INJURY.

CAUTION:

When installing or servicing a valve/ actuator assembly, the best

practice is to remove the entire assembly from service.

CAUTION:

An actuator should be remounted on the valve from which it was

removed. The actuator must be checked and readjusted for proper

open and close position each time it is remounted.

WARNING:

THE VALVE BODY AND MOUNTING INTERFACE

HAS BEEN DESIGNED TO SUPPORT THE WEIGHT

AND OPERATION OF NELES ACTUATORS AND

RECOMMENDED ACCESSORIES. USE OF THIS

INTERFACE TO SUPPORT ADDITIONAL EQUIPMENT

SUCH AS PEOPLE, LADDERS, ETC. MAY RESULT IN THE

FAILURE OF THE VALVE OR ACTUATOR AND MAY CAUSE

PERSONAL INJURY.

WARNING:

BEWARE OF BALL MOVEMENT!

KEEP HANDS, OTHER PARTS OF THE BODY, TOOLS

AND OTHER OBJECTS OUT OF THE OPEN FLOW PORT.

LEAVE NO FOREIGN OBJECTS INSIDE THE VALVE OR

PIPELINE. WHEN THE VALVE IS OPERATED, THE BALL

FUNCTIONS AS A CUTTING DEVICE.

5 .1 ACTUATOR MOUNTING

INSTRUCTIONS

1. When a spring-return actuator is being mounted, the valve should

be in the closed position for spring-to-close operation or in the

open position for the spring-to-open operation. When an electric

or double-acting pneumatic actuator is being mounted, the valve

position should correspond to the indicated actuator position.

2. Assemble actuator onto the valve, ensuring full engagement

between the stem and actuator drive, and the actuator fully

contacts the mounting face on the valve.

3. Tighten actuator mounting screws to the torque listed in Table 2.

CAUTION:

Do not exceed the tightening torque. Applying excessive tightening

torque can damage the aluminum threads in the actuator body.

7IMO-240 EN - Issue 7/2020

TABLE 2

Torque to Aluminum Body Actuators

Bolt Size No Lubrication to Screws

mm N.m

M6 6.8

M8 15

M10 30

M12 52

M16 122

M20 230

4. Cycle actuator and verify proper ball position in both open and

closed positions. Adjust the actuator travel stops as necessary.

6. SERVICE / SPARE PART

We recommend that valves be directed to Neles service centers for

maintenance. The service centers are equipped to provide rapid turn-

around at a reasonable cost and oer warranty for reconditioning

based on condition of each valve.

NOTE: When sending goods to the service center for repair, do not

disassemble them. Clean the valve carefully and ush the valve

internals. Include the material safety datasheet(s) (MSDS) for all

media owing through the valve. Valves sent to the service center

without MSDS datasheet(s) will not be accepted.

For further information on spare parts and service or assistance visit

our web-site at www.neles.com/products.

NOTE: When ordering spare parts, always include the following

information:

a. Valve type code as per technical bulletin and model

number from name plate,

b. If the valve is serialized - the serial number (stamped

on the valve body or name plate) or applicable

manufacturing order number,

c. Spare part set number as per Table 3.

*Sign.1 Sign.2 Sign.3 *Sign.4 #Sign.5 Spare part

sets

Valve

size

Series Seat

and seal

materials

O-Ring

material

Class rating Type codes

15 J7 ZG

(TFM™

1600 /

Graphite)

53

(FKM

Fluoroelastomer)

NA 15 J7ZG53

20 NA 20 J7ZG53

25 NA 25 J7ZG53

32 NA 32 J7ZG53

40 NA 40 J7ZG53

50 NA 50 J7ZG53

65 NA 65 J7ZG53

80 NA 80 J7ZG53

100 NA 100 J7ZG53

150 15 = Class 150 150 J7ZG53 15

30 = Class 300 150 J7ZG53 30

200 NA 200 J7ZG53

* leave space after Sign.1 and Sign.4

NA – Not applicable (both Class 150 and Class 300 have same spare part set)

# Sign.5 sufx 15 and 30 representing the valve class rating is applicable for DN150 valve size

e.g. 25 J7ZG53, 150 J7ZG53 15, 150 J7ZG53 30, etc.

IMO-240 EN - Issue 7/20208

7. EXPLODED VIEW

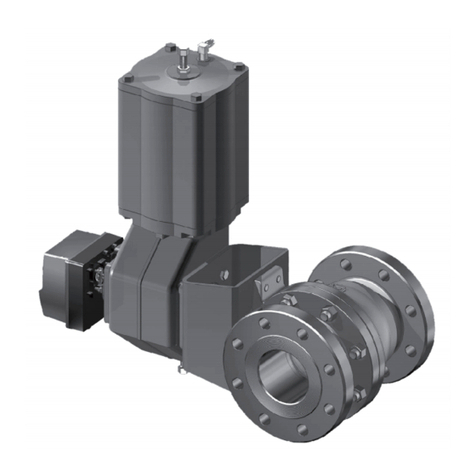

Figure 4.

Part list

Part no. Part name

1 Body

2 End piece

3 Ball

4* Seat

5 Stem

6* Stem seal

7* Stem washer

8* Stem retainer 1

9* V-ring stem seal

10* Stem retainer 2

11* Outer stem O-ring

12* Inner stem O-ring

13* Disc spring

14 Gland ange

15 Gland stud

16 Gland nut

17* Body seal

18* Body gasket

19 Body stud

20 Body nut

* These items form the spare part

set. Refer Table 3 for spare part

set details for each valve.

EXPLODED VIEW DN15 TO DN200

9IMO-240 EN - Issue 7/2020

8. TYPE CODE

EASYFLOW BY NELES J7 REDUCED BORE FLANGE FLOATING

BALL VALVE

1. 2. 3. 4. 5. 6. 7. 8. 9.

50 J7 15 22 36 36 ZG 53 -

1. Size, DN (NPS ref.)

15 15 (1/2) Note 2

20 20 (3/4)

25 25 (1)

32 32 (1 1/4)

40 40 (1 1/2)

50 50 (2)

65 65 (2 1/2)

80 80 (3)

100 100 (4)

150 150 (6)

200 200 (8) Note 1

Note 1: Class 150 only

Note 2: With full bore trim

2. Series

J7

3. Flange / rating

15 ASME Class 150

30 ASME Class 300

4. BODY MATERIAL

22 Carbon Steel (WCB)

36 Stainless Steel (CF8M)

5. Ball Material

36 316 Stainless Steel

6. Stem Material

36 316 Stainless Steel

43 17-4PH Stainless Steel

7. Seat and Seal Materials

ZG TFM™ 1600 / Graphite

8. O-Ring Material

53 Fluoroelastomer (FKM)

9. OPTIONS

- Blank, standard option

QCavity ller seat

TFM™ is a trademark of Dyneon, a 3M Company

NOTE:

As the use of the valve is application specific, a number of factors should be taken into account when selecting a valve for a given application.

Therefore, some of the applications in which the valves are used are outside the scope of this document. If you have any questions concerning

the use, application or compatibility of the valve with the intended service, contact nearest Neles sales office for more information.

IMO-240 EN - Issue 7/202010

11IMO-240 EN - Issue 7/2020

IMO-240 EN - 7/2020

Neles

Vanha Porvoontie 229, P.O. Box 304, FI-01301 Vantaa, Finland.

Tel. +358 10 417 5000. Fax +358 20 483 151

neles.com

Subject to change without prior notice. Neles, Jamesbury and Easyow by Neles, and certain other

trademarks, are either registered trademarks or trademarks of Neles Corporation or its subsidiaries or

aliates in the United States and/or in other countries. For more information www.neles.com/trademarks

This manual suits for next models

2

Table of contents

Other Neles Control Unit manuals

Neles

Neles PB2 Series Operating and maintenance manual

Neles

Neles XG Series Operating and maintenance manual

Neles

Neles R1L Titanium Series Operating and maintenance manual

Neles

Neles Metso T2 Series Operating and maintenance manual

Neles

Neles Jamesbury Series Operating and maintenance manual

Neles

Neles JAMESBURY CLINCHER 2000 Series Operating and maintenance manual