Neles Metso T2 Series Operating and maintenance manual

1 T 70 en • 12/2008

TOP ENTRY BALL VALVE

Series T2

Installation, Maintenance and

Operating Instructions

21 T 70 en

READ THESE INSTRUCTIONS FIRST!

These instructions provide information about safe handling and operation of the valve.

If you require additional assistance, please contact the manufacturer or manufacturer's representative.

Addresses and phone numbers are printed on the back cover.

SAVE THESE INSTRUCTIONS!

Subject to change without notice.

All trademarks are property of their respective owners.

Table of Contents

1 GENERAL........................................................ 3

1.1 Scope of the manual..............................3

1.2 Valve description....................................3

1.3 Valve markings.......................................3

1.4 Technical specifications.........................3

1.5 Valve certifications.................................4

1.6 CE marking ............................................4

1.7 Recycling and disposal ..........................4

1.8 Safety precautions .................................4

2 TRANSPORTATION, RECEPTION AND

STORAGE........................................................ 4

3 INSTALLATION AND USE.............................. 5

3.1 General ..................................................5

3.2 Installing in the pipeline..........................5

3.3 Actuator..................................................5

3.4 Start-up ..................................................6

4 SERVICING...................................................... 6

4.1 General ..................................................6

4.2 Replacing the gland packing..................6

4.3 Repairing a jammed or stiff valve without

removing it from the pipeline..................7

4.4 Detaching the B series actuator.............7

4.5 Removing the valve from the pipeline....7

4.6 Dismantling the valve.............................8

4.7 Checking the parts of a dismantled valve . 8

4.8 Reassembling the valve.........................9

5 TESTING THE VALVE................................... 10

6 INSTALLING THE ACTUATOR .................... 11

6.1 General ................................................11

6.2 Installing the M-type manual gear operator11

6.3 Installing the B1C-series actuator........11

6.4 Installing the B1J-series actuator.........11

6.5 Installing other than Metso actuators.. 12

7 MALFUNCTIONS........................................... 12

8 TOOLS ........................................................... 12

9 ORDERING SPARE PARTS ......................... 12

10 EXPLODED VIEW AND PARTS LIST........... 13

11 DIMENSIONS AND WEIGHTS ...................... 14

12 TYPE CODING............................................... 15

1 T 70 en 3

1 GENERAL

1.1 Scope of the manual

This manual provides the essential information on the

T2 series ball valves. For further information on actua-

tors and other instruments, which are covered only

briefly, please refer to separate manuals on their instal-

lation, use and maintenance.

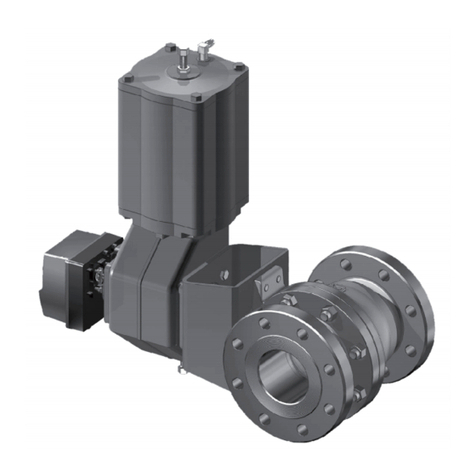

1.2 Valve description

The T2 series ball valve has flanges or welding ends,

Top entry body construction, one-piece body and one-

piece ball and stem (stem ball) supported by the bear-

ings.

The T2 valve series is intended for either control or

shut-off applications.

1.3 Valve markings

Body markings are cast or stamped on the body.

The identification plate (Fig. 2) is on the valve flange or in

the valve body.

Identification plates have the following markings:

1. Body material

2. Shaft material

3. Trim material

4. Seat material

5. Maximum and minimum operating temperatures

6. Maximum shut-off pressure differential/temperature

7. Pressure class

8. Type code

9. Serial manufacturing number

10. Valve ID code

1.4 Technical specifications

Face-to-face length: ASME B.16.10

Body rating: ASME Class 900, 1500

Max pressure differential:see Fig. 3

Temperature range for body:see Figs. 3 and 4

Flow direction: dependable on ball seat

configuration

Leakage rates:

Soft seated ISO 5208, leakage rate B

Dimensions: see Section 11

Weight: see Section 11

NOTE:

As the use of the valve is application-specific, a

number of factors should be taken into account when

selecting the application. Therefore, some of the situa-

tions in which the valves are used are outside the

scope of this manual. If you have any questions con-

cerning the use or application of the valve, contact

Metso’s Automation business for more information.

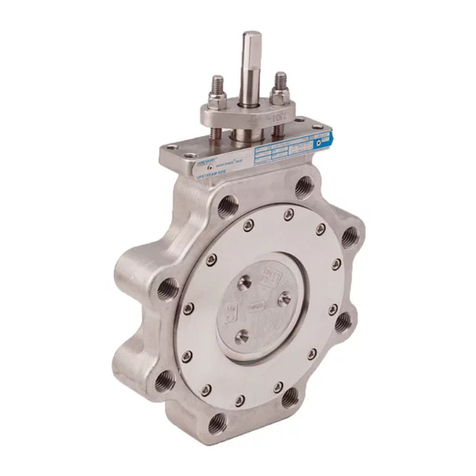

Fig. 1 Construction of T2 series valve

Fig. 2 Identification plate

Fig. 3 Pressure/temperature curves of valve body,

CF8M

Fig. 4 Pressure/temperature curves of valve body,

WCB

BODY

TRIM

SHAFT

SEAT

T max

T min

MAX. OPER. ps

at

RATING TYPE

No. MOD

ATTENTION : READ INSTRUCTIONS BEFORE INSTALLATION OR SERVICING. CONTACT METSOAUTOMATION FOR COPY. MADE BY METSO AUTOMATION

XXXX

(1) (2) (5) (7) (8)

(3)

(4) (6) (9) (10)

80

100

120

200

140

160

180

220

240

260

0 100 200 300 40050 150 250 350 450

100 200 300 400 500 600 700 800

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

Temperature (°F)

Temperature (°C)

Pressure (bar)

Pressure (psig)

0

500 550 600 650

60

40

20

00

200

400

600

800

1000

900 1000 1100 1200

ASME

1500

ASME

900

80

100

120

200

140

160

180

220

240

260

0 100 200 300 40050 150 250 350 450

100 200 300 400 500 600 700 800

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

3200

3400

3600

Temperature (°F)

Temperature (°C)

Pressure (bar)

Pressure (psig)

0

ASME

1500

ASME

900

41 T 70 en

1.5 Valve certifications

A tightness certificate and an EN/DIN 50049 3.1 B cer-

tificate for the valve body and bonnet can be supplied

on request.

1.6 CE marking

The valve meets the requirements of the European

Directive 97/23/EC relating to pressure equipment, and

has been marked according to the Directive.

1.7 Recycling and disposal

Most valve parts can be recycled if sorted according to

material. Most parts have material marking. A material

list is supplied with the valve. In addition, separate

recycling and disposal instructions are available from

the manufacturer. A valve can also be returned to the

manufacturer for recycling and disposal against a fee.

1.8 Safety precautions

2 TRANSPORTATION, RECEPTION

AND STORAGE

Check the valve and the accompanying device for any

damage that may have occurred during transport.

Store the valve carefully. We recommend storing

indoors in a dry place.

Do not remove the flow port protectors until installing

the valve. Move the valve to its intended location just

before installation. The valve is usually delivered in the

open position.

CAUTION:

Do not exceed the valve performance limitations!

Exceeding the limitations marked on the valve may

cause damage and lead to uncontrolled pressure

release. Damage or personal injury may result.

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

Dismantling or removing a pressurized valve will result in

uncontrolled pressure release. Always isolate the relevant

part of the pipeline, release the pressure from the valve

and remove the medium before dismantling the valve.

Be aware of the type of medium involved. Protect people

and the environment from any harmful or poisonous sub-

stances.

Make sure that no medium can enter the pipeline during

valve maintenance.

Failure to do this may result in damage or personal injury.

CAUTION:

Beware of the ball cutting movement!

Keep hands, other parts of the body, tools and other

objects out of the open flow port. Leave no foreign

objects inside the pipeline. When the valve is actu-

ated, the ball functions as a cutting device. Close and

detach the actuator pressure supply pipeline for valve

maintenance. Failure to do this may result in damage

or personal injury.

CAUTION:

Beware of noise emission!

The valve may produce noise in the pipeline. The

noise level depends on the application. It can be

measured or calculated using the Metso Nelprof com-

puter program. Observe the relevant work environ-

ment regulations on noise emission.

CAUTION:

Beware of extreme temperatures!

The valve body may be very hot or very cold during

use. Protect people against cold injuries or burns.

CAUTION:

When handling the valve or the valve package,

bear in mind its weight!

Never lift the valve or valve package by the actuator,

positioner, limit switch or their piping.

Place the lifting belts securely around the valve body

(see Fig. 5). Damage or personal injury may result from

falling parts. The weights are shown in Section 11.

CAUTION:

Follow the proper procedures when handling and

servicing oxygen valves.

Fig. 5 Lifting the valve

1 T 70 en 5

3 INSTALLATION AND USE

3.1 General

Remove the flow bore protectors and check that the

valve is clean inside. Clean the valve if necessary.

3.2 Installing in the pipeline

Flush or blow the pipes clean before mounting the

valve. Impurities, sand and parts of welding electrodes

may damage the ball and seats surfaces.

There are three marks to indicate the open-closed posi-

tion of the valve.

❑an indicator on the actuator's drive centre

❑a groove at the end of the ball stem

❑the keyway of the ball stem

If you feel uncertain about the indicator, check by the

groove and the keyway.

The valve can be mounted in any position.If possible,

mount the valve in such a position that the actuator can,

if necessary, be detached without removing the valve

from the pipeline. The actuator must not touch the pipe-

line, as pipeline vibrations may damage it or cause dis-

turbance.

3.2.1 Assembly of welding end valve

The valves are mounted in the pipeline by using stand-

ard welding methods.

When welding or annealing the joints, assure that the

temperature of body in PTFE or the rubber sealings is

not higher than that allowed for this type of sealing

material, e.g. 120 °C. The increase of temperature can

be prevented by winding wet protection cloth around

the body during the welding. Fig. 7.

Valves with welding ends are, if necessary, supported

by flaky, arched supports on the machined part or pref-

erably (Fig. 8) on the part of pipeline next to the valve.

After welding, the piping should be carefully cleaned

and flushed before operating the valve.

After trial operation, the valve should be left in the

'Open' position until the process is started up.

If the valve is found to jam during test operation, open it

and flush again with a powerful flow.

3.3 Actuator

The valve open/closed position is indicated as follows:

❑by an indicator on the actuator

or

❑by a groove at the end of the ball shaft (parallel to

the ball flow opening).

If there is any uncertainty about the indicator, check the

ball position by the groove.

The actuator should be installed in a manner that allows

plenty of room for its removal.

CAUTION:

When handling the valve or the valve package as a

whole, bear in mind the weight of the valve or the

entire package!

NOTE:

Use screws, nuts, bolts and gaskets equivalent to the

fastenings used elsewhere in the pipeline. Center the

flange gaskets carefully when fitting the valve

between flanges.

NOTE:

Do not attempt to correct pipeline misalignment by

means of flange bolting or welding.

Fig. 6 Supporting the valve

Fig. 7 Valve body covered with wet protection cloth

during welding

Fig. 8 Supporting the welding end valve

NOTE:

When installing the actuator on the valve, make sure

that the valve package functions properly. Detailed

information on actuator installation is given in Section

6 or in the separate actuator instructions.

61 T 70 en

The upright position is recommended for the actuator

cylinder.

The actuator must not touch the pipeline, because

pipeline vibration may interfere with its operation.

In certain cases it may be considered advantageous to

provide additional support to the actuator. These cases

will normally be associated with large actuators,

extended shafts, or where severe vibration is present.

Please contact Metso’s Automation business for advice.

3.4 Start-up

3.4.1 Before start-up

❑If there is a long period between installation and

start-up during which piping installation or altera-

tions have been carried out, it is advisable to

check the valve operation again to ensure that it

is working perfectly.

❑At the start-up stage the valve should be kept in

the completely 'Open' or 'Closed' position. Any

pressure impact on a valve left in mid position

will damage the seat.

❑At the beginning of start-up it is advised to verify

the tightness of the gland packing and tighten if

necessary.

4 SERVICING

4.1 General

It is recommended that the gland packing is checked regu-

larly for tightness. If the valve requires maintenance, then

the following service measures should carried out. This

section outlines the service operations that can be carried

out by the end user.

The numbers in parentheses refer to the parts list and

the exploded view of the valve in Section 10, if not oth-

erwise stated.

4.2 Replacing the gland packing

If the gland packings leak even after being tightened,

they must be replaced. The packings are made of

graphite or PTFE.

❑To replace the packings, unscrew the bracket

nuts, see installation parts list, and remove the

actuator and key from the shaft.

❑Remove the gland.

❑Remove the graphite gland packings with a

sharp pointed tool, e.g. proper size screw driver.

❑Carefully clean the inside of the gland and the

shaft. The screws can be removed to make

cleaning easier.

❑Install the new gland packing taking care that the

edges of the key groove do not damage the inner

face on the packing.

❑Install the gland and tighten to the torque given

in the Table 1.

CAUTION:

Observe the safety precautions mentioned in Sec-

tion 1.8 before servicing!

CAUTION:

When handling the valve or the valve package as a

whole, bear in mind the weight of the valve or the

entire package.

NOTE:

Always use original spare parts to make sure that the

valve functions as intended.

NOTE:

If you send the valve to the manufacturer for servicing,

do not dismantle it. Instead, clean the valve carefully

of all medium and inform the manufacturer of any dan-

gerous medium involved.

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

1 T 70 en 7

❑Install the actuator.

4.3 Repairing a jammed or stiff valve

without removing it from the pipeline

Jamming or stiff function may be caused by a flow

medium clogging the seat (7) and the ball (3). The ball

and the seats can be cleaned without removing the

valve from the pipeline by turning the ball to a partly

open position and flushing the pipes. If this does not

help, follow the instructions below.

4.4 Detaching the B series actuator

It is usually easiest to detach the actuator and support

equipment before removing the valve from the pipeline.

If the valve/actuator unit is small or not easily accessi-

ble, it is adviced better to remove the whole unit at the

same time.

❑Close and detach the actuator pressure supply

and disconnect the control cables and pipes.

❑Loosen the bracket screws.

❑Detach the actuator from the valve with an

extractor that can be ordered from the manufac-

turer. See Section 8 Tools'.

❑Remove the bracket.

4.5 Removing the valve from the pipeline

❑Make sure that the pipeline is empty and unpres-

surized and that there is no medium flowing to

the pipeline while the valve is being serviced.

❑Carefully attach the lifting belts, loosen the pipe

flange screws and lift the valve using the ropes.

Make sure that you lift the valve correctly. See

also Fig. 5.

Fig. 9 Installing the gland packing

Table 1 Tightening torques for PTFE gland packing

(for information only)

Nut size Torque, Nm Torque lbf-ft

5/16 UNC 10 7

3/8 UNC 20 14

1/2 UNC 50 37

5/8 UNC 150 110

7/8 UNC 200 140

1 UNC 300 220

CAUTION:

When handling the valve or the valve package as a

whole, bear in mind the weight of the valve or the

entire package!

CAUTION:

Do not detach a spring-return actuator unless a

stop-screw is carrying the spring force!

NOTE:

Before dismantling, carefully observe the position of

the valve with respect to the actuator and positioner/

limit switch so as to make sure that the package can

be properly re-assembled.

Fig. 10 Detaching a B series actuator with an extractor

CAUTION:

Do not dismantle the valve or remove it from the

pipeline while the valve is pressurized!

81 T 70 en

4.6 Dismantling the valve

❑Remove the valve from the pipeline.

❑Remove the actuator as explained in 4.4.

❑Loosen the gland nuts. Do not remove the gland.

❑Remove the bonnet gland nuts and lift off the

bonnet. If necessary use an extractor to grip the

gland. See Fig. 11.

❑Install the locking tools (see Fig 12) to push sup-

port seat rings or bellows in to back position.

❑Pull out the ball and seats with the ball in the

'Open' position. See Fig. 13. Lower the ball on a

soft surface.

❑To check the bearings, remove the circlips if any

(27) and pull the bearing bushing (5) out off the

shaft.

❑Pull out the seat support rings or bellows.

4.7 Checking the parts of a dismantled

valve

4.7.1 Seats

Seat T

❑Check the sealing and back surfaces of the seat

ring (7), the support ring (35) and the o-ring (63).

Sealing surfaces may require lapping.

❑If damage is extensive, the parts should be

replaced. Check the spring groove for any impu-

rities which may jam the support ring (35).

Seat S

❑Check the sealing and back surfaces of the seat

ring (7), the support ring (35) and the o-ring (63).

Sealing surfaces may require lapping. The seal-

ing surface of the seat (7) is lapped against ball

surface.

❑If damage is extensive, the parts should be

replaced. Check the spring groove for any impu-

rities which may jam the support ring (35).

Fig. 11 Lifting the bonnet

Fig. 12 Spreading and locking tool

Fig. 13 Pulling out the ball

Fig. 14 Seat T

Fig. 15 Seat S

62 63 35 7

64

7

35

64

63

62

1 T 70 en 9

Seat H

❑Check the sealing surfaces of seat (7) and bel-

lows (62). The sealing surfaces may require lap-

ping. Parts with extensive damage must be

replaced.

❑Check the bellows for any impurities which may

effect operation.

❑If necessary, the sealing surface of the seat (7)

may be lapped against ball surface. The back

surface of the seat (7) and straight edges of the

bellows (62) may be lapped on. Also the body

may be lapped if the sealing surface is dam-

aged.

4.7.2 Ball

❑Lift the ball with ball seats from the body onto a

soft surface for cleaning. Check the sealing and

bearing surfaces of the ball stem. Remove

smaller scratches and impurities with emery

cloth. The ball may require lapping. See also

Section 4.6. File off any burrs from the stem key-

way.

❑If there are deep scratches on the ball it shall be

replaced.

4.7.3 Bearings

Standard construction

Bearings are of PTFE with stainless steel net.

❑Check that the bearing strips and replace if nec-

essary.

Hi-temp construction

❑Bearings are of stainless steel with hard coating

or solid cobalt based alloy.

❑Replace if necessary.

4.8 Reassembling the valve

❑Clean all the inside parts. If there is any rust

inside, the surfaces can be sprayed with an anti-

rust agent after cleaning. Check the reactions of

the agent to flowing medium.

❑Install first the spring, into the support ring.

❑Lubricate the O-rings, for example with silicone.

Locate them into their grooves.

❑Place the support ring, made of two rounds of

PTFE strip, into the O-ring groove. The strip must

be one-piece with the ends cutted as shown in

Figure .

❑Install the support rings or bellows (C and H con-

structions) in both flow ports and press them into

the back position by using extractor tool.

❑Hold the tool in place until the locking tools are

installed.

Fig. 16 Seat H

7

62

Fig. 17 Mounting the spring

Fig. 18 O-ring as backseal

Fig. 19 Using extractor tool

10 1 T 70 en

❑Place the locking tools in position and tighten as

shown in Fig. 19. Remove the extractor tool.

❑Lower the ball with bearings and seats into the

body, in the 'Open position'. Check that the back

face of the seat does not damage the support

ring seat when lowering the ball into the ball

body. See Fig. 20.

❑Remove the locking tools.

❑Install the bonnet gasket. This graphite gasket

should always be replaced.

❑Place the bonnet in position. If the gland pack-

ings are in place and in good condition, lower

the bonnet carefully, ensuring that the shaft key

groove does not damage them. If necessary

replace the gland packings as explained in

2.6.12.

❑Tighten the bonnet nuts by using the torques

given in Table 2. Tighten in the order shown in

Fig. 22.

❑Assemble the gland packing as described in 4.2.

5 TESTING THE VALVE

The hydraulic body test shall be carried out after the

reassembly.

Test pressure shall be in accordance with an applica-

ble standard. Use the pressure required by the pres-

sure class or the flange bore. Keep the valve in the half

open position during the test.

If the tightness of the closure member is also to be

tested, please contact the manufacturer.

Fig. 20 Lowering the ball into the body

Fig. 21 Bonnet gasket

Table 2 Recommended tightening torques of the

body stud nuts (for information only)

Recommended tightening torques

T h r ea d To r q ue , N m To r q u e, l b f. f t .

5/16 UNC 24 18

3/8 UNC 45 35

1/2 UNC 100 75

5/8 UNC 200 150

3/4 UNC 350 250

7/8 UNC 500 350

1 UNC 700 500

1 1/4 8UN 1300 950

1 1/2 8UN 1600 1200

1 3/4 8UN 1600 1200

2 8UN 2500 1800

2 1/4 8UN 3500 2600

2 1/2 8UN 5000 3700

2 3/4 8UN 6300 4600

3 8UN 8400 6200

Note: Threads must be well lubricated

Fig. 22 Nut tightening order

CAUTION:

Pressure testing should be carried out using equip-

ment conforming to the correct pressure class!

1 T 70 en 11

6 INSTALLING THE ACTUATOR

6.1 General

Use suitable mounting parts and couplings when you

install the actuators.

6.2 Installing the M-type manual gear

operator

❑The mark at the end of the shaft indicates the

direction of the ball flow bore. Turn the valve to

the closed position.

❑Lubricate the key groove of the actuator and the

couplings. Install the coupling on the shaft and

lock it. Install the bracket(s) on the valve. A plate

should be installed between the valve flange

mounting face or bracket and the actuator

mounting face, see actuator's instructions for

details.

❑Lubricate the actuator screws. Install and tighten

all screws.

❑Adjust the ball fully open and fully closed posi-

tions with the hexagon screws located on both

sides of the housing (see Fig. 23). The stop-

screw for the open position is nearest to the

handwheel on the side of the housing and the

screw for the closed position is at the opposite

end. The turning directions for the handwheel

are marked on the wheel.

❑Check the valve by turning the handwheel to the

extreme positions. The indicator on the top of

actuator shows the direction of the ball flow bore.

6.3 Installing the B1C-series actuator

❑Operate the actuator to the same position as the

valve (fully open or fully closed).

❑File off any burrs and clean the shaft bore .

❑The line at the end of the shaft indicates the

direction of the ball flow bore.

❑Lubricate the actuator shaft bore. Fasten the

bracket loosely to the valve.

❑Slip the actuator carefully onto the valve shaft.

Avoid forcing it since this may damage the ball

and seats. We recommend mounting the actua-

tor so that the cylinder is pointing upwards.

❑Position the actuator parallel or vertical to the

pipeline as accurately as possible. Lubricate the

actuator mounting screws and then fasten all

screws.

❑Adjust the ball open and closed positions by

means of the actuator stop screws located at

both ends (see Fig. 24). An accurate open posi-

tion can be seen in the body flow bore.

Check that the yellow arrow on the actuator indi-

cates the ball flow opening position. Keep fin-

gers out of the flow bore!

There is no need for stop screw adjustment if the

actuator is re-installed in the same valve. Drive

actuator piston to the housing end (open posi-

tion). Turn the actuator by hand until the valve is

in the open position. Fasten the actuator in this

position as explained above.

❑Check the stop screw thread tightness. An O-

ring is used for sealing.

❑Check that the actuator is functioning correctly.

Drive the actuator piston to both cylinder ends and

check the ball position and its movement with

respect to the actuator (close: clockwise; open:

counterclockwise). The valve should be closed

when the piston is in the extreme outward position.

❑If necessary, change the position of the actuator

pointing cover to correctly indicate the valve

open/closed position.

6.4 Installing the B1J-series actuator

Spring-return actuators are used in applications where

valve opening or closing movement is needed in case

the air supply is interrupted. The B1J type is used for

spring-to-close operation; the spring pushes the piston

towards the cylinder end, the extreme outward position.

In turn, the B1JA type is used for spring-to-open opera-

tion; the spring pushes the piston towards the housing.

Spring-return actuators are installed in a manner similar to

B1 C-series actuators, taking into account the following.

6.4.1 B1J-type

❑Install the actuator so that the piston is in the

extreme outward position. The cylinder must not

be pressurized and air supply connections must

be open. The valve must be in the closed posi-

tion.

CAUTION:

Beware of ball cutting movement!

Fig. 23 Open and closed positions of the M actuator

Stop screw for Stop screw for

OPEN position

CLOSED position

Fig. 24 Open and closed positions of the B1C/B1J

actuator

Stop screw for CLOSED position

Stop screw for OPEN position

12 1 T 70 en

6.4.2 B1JA-type

❑Install the actuator so that the piston is in the cyl-

inder end position at housing side. The cylinder

must not be pressurized and air supply connec-

tions must be open. The valve must be in the

open position.

The rest of the installation procedure is the same as in

Section 6.3.

6.5 Installing other than Metso

actuators

Other actuators can be installed only if they have an

ISO 5211 actuator connection and taking account the

stem and keyway dimensions.

7 MALFUNCTIONS

The following Table 4 lists malfunctions that might occur

after prolonged use.

8TOOLS

In addition to standard tools, the following special tools

might be needed.

❑For removal of the actuator:

- extractor

9 ORDERING SPARE PARTS

When ordering spare parts, always include the follow-

ing information:

❑type code, sales order number, serial number

(stamped on a valve body)

❑number of the parts list, part number, name of

the part and quantity required

This information can be found from the identification

plate or documents.

NOTE:

Metso accepts no responsibility for compatibility of actu-

ators not installed by Metso.

Table 3 Malfunctions

Malfunction Possible cause Action

Leakage through a

closed valve

Wrong stop screw adjustment of the

actuator

Adjust the stop screw for closed position

Damaged ball surface Replace the ball

Damaged seat(s) Replace seat(s)

Ball cannot move freely Clean the inside of the valve

Stick valve movement Impurities between the ball and seats Flush the valve from the inside

Clean the sealing surfaces and seats

mechanically

Damaged bearings Replace bearings

Damaged seat Replace seat(s)

Over-tightened gland packing Untighten the nuts

Leakage through gland

packing

Loose packing Tighten the nuts

Worn-out or damaged packing Replace the gland packing

Leakage through

bonnet sealing

Loose bonnet nuts Re-tighten the bonnet nuts

Damaged body gasket Replace the body gasket

1 T 70 en 13

10 EXPLODED VIEW AND PARTS LIST

9

18

14

69

16

12

65

10

3

119

89

60

4

94

61

5

5

4

7

62

7

64

63

35

62

H

S, T

8

7

64

63

35

62

G

129130

Item Qty Description Recommended spare

11Body

31Ball

4 1 Trunnion bearing

5 1 Trunnion bearing

7 1 Ball seat

8 1 Bonnet

91Gland

10 1 Key

12 Stud

14 Stud

16 Hexagon nut

18 Hexagon nut

19 1 ID plate

35 2 Secondary seat (S, T, G)

60 1 Bearing strip

61 1 Bearing strip

62 2 Bellows spring (H)

2 Spring (S, T, G)

63 2 O-ring (S, T, G)

64 4 Back-up ring (S, T, G)

65 1 Seal strip

69 5 Packing ring

77 1 Plug

89 1 Thrust bearing

94 1 Thrust bearing

129 2 Support ring (G)

130 2 Back seal (G)

14 1 T 70 en

11 DIMENSIONS AND WEIGHTS

Valve T2H, ASME 1500

G1

G2

V

UL

R

˚

øU

DN

øD

P

øO

M

N

E

C

A

J1

J2øB

TYPE DIMENSIONS IN mm α° V

8 UN KG

DN A øB C øD E M N øO P R UL G1 G2 øU J1 J2

T2H 02 50 368 215.9 89 50.8 348 9.52 58 35 39.1 163 60 - - 167 ø224 22.5 1 1/8 95

T2H 03 80 470 266.7 125 76.2 447 12.7 80 45 50.4 201 70 - - 225 ø300 22.5 1 1/2 205

T2H 04 100 546 311.1 150 507 12.7 90 55 60.6 218 80 - - 280 348 348 16.6 1 1/2 335

T2H 06 150 705 393.7 240 730 22.22 146 85 94.6 328 80 415.2 216.2 - 440 575 - 2 800

T2H 08 200 832 482.6 305 850 25.4 180 105 116.1 358 95 480 128 - 545 625 - 2 1500

1 T 70 en 15

12 TYPE CODING

TOP ENTRY BALL VALVE, Series T2

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

Q- T2 G H 20 D H H 03 01 Y

Q-CODE PRODUCT DESIGN

Q- Standard low noise trim for gas and liquid application,

single seat construction

Q-CODE SPECIAL PRODUCT OPTIONS

QLF- Feedwater trim, single set construction

QX- Multichannel Q-ball for gas and liquid applications

QXA- *) Multichannel Q-ball + attenuator plate in downstream

flow port of body for gas applications

*) For liquid applications customized baffle plates are used.

Code "A" replaced with "Y".

1. sign SERIES / DESIGN

TTop entry body, trunnion mounted, gland packing

(except subsea)

STANDARD

T2 Full bore, flanged

NON-STANDARD

T3 Full bore, weld ends

T4 Reduced bore, weld ends

2. sign PRESSURE RATING

GASME Class 900

HASME Class 1500

3. sign CONSTRUCTION

AGeneral, PTFE bearings, double-seated

BSingle-seated, metal bearings, one-way tight

ESingle-seated, PTFE bearings, one-way tight

HHigh temperature, metal bearings, double-seated

SSubsea-construction

YSpecial

4. sign SIZE (in)

02, 03, 04, 06, 08, 10, 12, 14, 16, 18, 20, 24, 28, 30

5. sign BODY BOLTING

STANDARD MATERIALS

ACF8M B8M

DWCB L7M

NON-STANDARD MATERIALS

FLCC L7M

GWCC L7M

JLC2 L7M

YSpecial

6. sign BALL

STANDARD MATERIALS

ACF8M / AISI 316 + Chrome *)

DCF8M / AISI 316 + NiBo

NON-STANDARD MATERIALS

BCF8M / AISI 316 + Cobalt based hard facing

GType AISI 329 (SS 2324) + Chrome *)

HCA-6NM (or F6NM) + Chrome *)

YSpecial

*) Ball without Chrome with soft seats

7. sign SEAT

H, S Standard metal seat

TStandard soft seat

GMetal seat

8. sign Seat seal Bonnet

gasket

Gland

packing

Back seal

of support

ring

Spring /

Bellows

STANDARD MATERIALS

02 (Polyamide) Graphite Graphite Viton GF Inconel

X-750

03

(Polyamide) Graphite Graphite Wno.

1.4418

(Avesta

248SV)

18 Graphite Graphite GR660 /

F6NM

NON-STANDARD MATERIALS

05* Viton GF V-rings,

PTFE

Viton GF AISI 329

(SS 2324)

* subsea

9. sign Construction code

10. sign

YSpecial flanges

Metso Automation Inc.

Europe, Levytie 6, P.O. Box 310, 00811 Helsinki, Finland. Tel. +358 20 483 150. Fax +358 20 483 151

North America, 44 Bowditch Drive, P.O. Box 8044, Shrewsbury, MA 01545, USA. Tel. +1 508 852 0200. Fax +1 508 852 8172

Latin America, Av. Independéncia, 2500-Iporanga, 18087-101, Sorocaba-São Paulo, Brazil. Tel. +55 15 3235 9700. Fax +55 15 3235 9748/49

Asia Pacific, 238A Thomson Road, #25-09 Novena Square Tower A, 307684 Singapore. Tel. +65 6511 1011. Fax +65 6250 0830

China, 19/F, the Exchange Beijing, No. 118, Jianguo Lu Yi, Chaoyang Dist, 100022 Beijing, China. Tel. +86-10-6566-6600. Fax +86-10-6566-2575

Middle East, Roundabout 8, Unit AB-07, P.O. Box 17175, Jebel Ali Freezone, Dubai, United Arab Emirates.

Tel. +971 4 883 6974. Fax +971 4 883 6836

www.metso.com/automation

16 1 T 70 en

Table of contents

Other Neles Control Unit manuals

Neles

Neles XG Series Operating and maintenance manual

Neles

Neles Easyflow J7 Series Operating and maintenance manual

Neles

Neles JAMESBURY CLINCHER 2000 Series Operating and maintenance manual

Neles

Neles Jamesbury Series Operating and maintenance manual

Neles

Neles PB2 Series Operating and maintenance manual

Neles

Neles R1L Titanium Series Operating and maintenance manual

Popular Control Unit manuals by other brands

Deif

Deif Multi-line 2 Description of Options

Johnson Controls

Johnson Controls A19 Series Installation Sheets Manual

Savant

Savant ITP-E8000 Series Quick reference guide

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS 6110 How to perform

Flotrol

Flotrol F60 Service manual

Omron

Omron SYSMAC C500-NC113 Operation manual