1X72EN - 9/2020 19

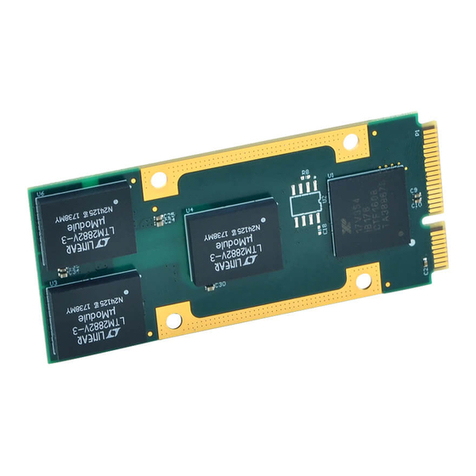

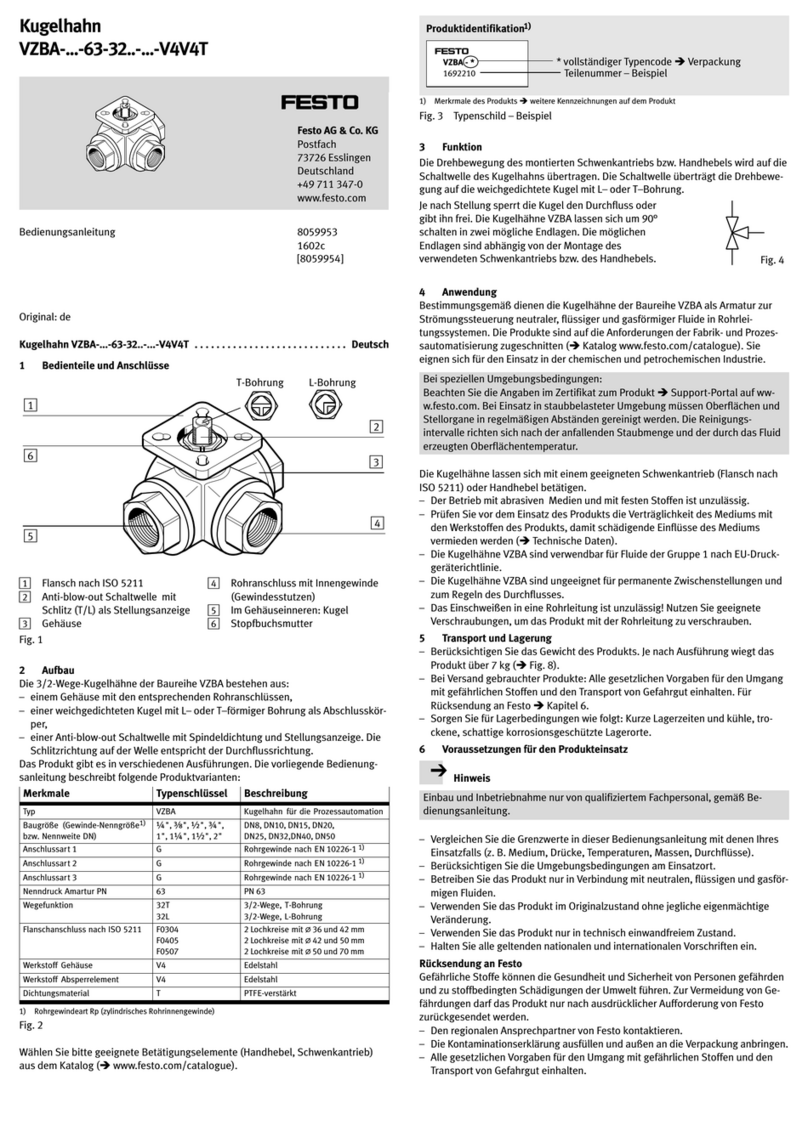

13 TYPE CODE

17-4PH stem material required to comply API 608 stem strength,

limitations may apply in XG size 8" & 12", see instructions after sign 11.

Balls with coating are used in metal seated valves.

Max temperatures for coatings:

- Hard Chrome (HCr): 450 °C

- Tungsten carbide (WC-Co): 450 °C

- Chrome carbide (CrC/CrC-LF): 600 °C

If seat coating is Chrome Carbide, CrC-LF, then use Chrome Carbide, CrC as

ball coating.

EN/ISO bolting materials are obsoleted. ASME bolting materials can be used in

EN rated valves.

* Bolting materials for stainless steel body

** Bolting materials for carbon and low alloy steel body

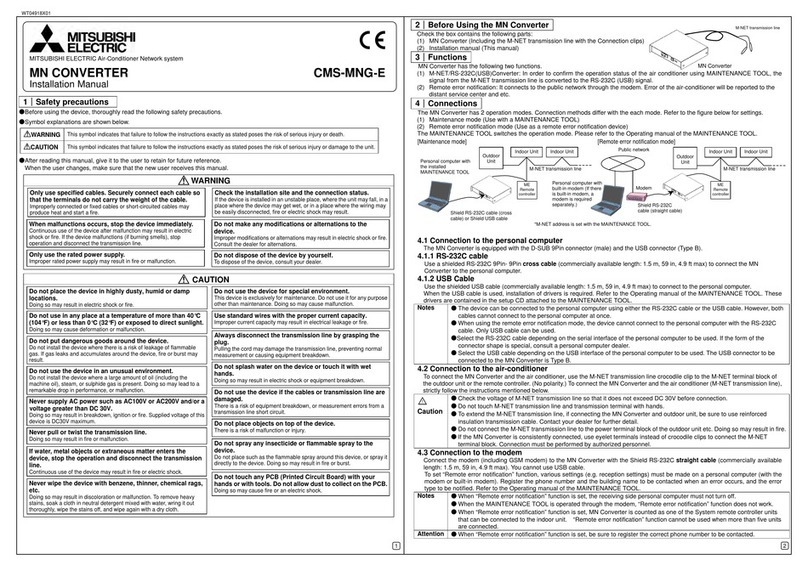

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11.

XG 06 D W TA J2 PJ S A B T

1. VALVE SERIES & STYLE & FACE-TO-FACE

XG Full bore, trunnions, f-to-f ASME B 16.10, Table 2, long pattern, ASME 300

XM Full bore, trunnions, f-to-f ASME B 16.10, Table 1, long pattern, ASME 150

2. SIZE

ASME valves with metric threads EN valves with metric threads

NPS DN / mm

02 2" 050 50

03 3" 080 80

04 4" 100 100

06 6" 150 150

08 8" 200 200

10 10" 250 250

12 12" 300 300

14 14" 350 350

16 16" 400 400

18 18" 450 450

20 20" 500 500

24 24" 600 600

3. PRESSURE CLASS

C ASME Class 150 (Use XM, size NPS 2"...24").

DASME Class 300 (Use XG, size NPS 2"...24").

J PN 10 (Use XM, sizes DN200 ... DN600).

KPN 16 ( Use XM, sizes DN100 ... DN600).

L PN 25 ( Use XG, size DN200 ... DN600).

MPN 40 ( Use XG, size DN50 ... DN600).

4. END CONNECTION STYLE

W raised face, ASME B 16.5 (Ra 3.2-6.3), standard with ASME rated flanges.

CEN 1092-1 Type B1, (Ra 3.2 – 12.5), standard with EN rated flanges.

5. CONSTRUCTION & APPLICATION

TA Standard construction. Double seated. Live loaded packing.

TE Single seated. Otherwise standard.

TQ Q-Trim construction. Otherwise standard.

EQ Single seated, Q-Trim construction.

2G Q2G-trim for gas application, single seated, otherwise standard.

2H Q2G-trim for gas application, HIGH CAPACITY version.

TZ BAM tested non-metallic materials, for oxygen service. Double seated. Metal

bearings. Live loaded graphite packing.

Temperature range -50...+200C. Max pressure based on body rating.

Oxygen cleaning acc. to Neles internal procedure FC-QC-0001included.

6. BODY MATERIAL

J2 ASTM A216 gr WCB (Carbon Steel)

S6 ASTM A351 gr CF8M (Stainless Steel)

J5 ASTM A217 gr C5 (Low Alloy Steel)

7. BALL / COATING & STEM MATERIAL

PJ 316SS / Hard Chrome & 17-4PH

PP 316SS & 17-4PH (soft seats, ball without coating)

PV 316SS/Tungsten carbide, TC2

PL 316SS / NiBo & 17-4PH

PX 316SS / Chrome carbide & 17-4PH

SJ 316SS / Hard Chrome & XM-19 (Nitronic 50)

SP 316SS & XM-19 (Nitronic 50) (soft seats, ball without coating)

RX 316SS / CrC (Chrome carbide) & XM-19 (Nitronic 50), only with metal bearings.

RR 316SS / WC-Co (Tungsten carbide) & XM-19 (Nitronic 50)

SL 316SS / NiBo & XM-19 (Nitronic 50)

SW 410SS / Chrome carbide & XM-19 (Nitronic 50)

8. SEAT AND BACK SEAL TYPES / SPRING MATERIALS

Seat type Back seal Spring Back-up ring

S metal,

general service

O-ring Inconel 625 PTFE

Bmetal, solid proof,

firesafe

Graphite + O-ring Inconel 625 PTFE

K metal, solid proof, high

temp, firesafe

Graphite + Graphite Inconel 625 -

Gmetal, solid proof, high

temp, firesafe

Graphite + Graphite Inconel 625 -

L metal, polymer proof Graphite + O-ring - PTFE

Hmetal, bellows Graphite - -

T soft, general service O-ring Inconel 625 PTFE

Dsoft, firesafe service Graphite + O-ring Inconel 625 PTFE

9. SEAT MATERIAL

Metal seats

Seat material Coating

A Type 316 stainless steel (S, B, K, G, L seats),

AVESTA 248SV (H seats)

Cobalt based hard facing

BType 316 stainless steel (S, B, K, G, L seats),

AVESTA 248SV (H seat)

Chrome Carbide, CrC-LF

V Type 316 stainless steel with S, B, K

and L type seats

AVESTA 248SV with H type seat.

Tungsten Carbide, TC2

RType 316 stainless steel (S, B, K, G, L seats),

AVESTA 248SV (H seats)

Tungsten Carbide, WC-CO

Z Type 410 stainless steel (S, B, K, G, L seats) Tungsten Carbide, WC-Co

WType 410 stainless steel (S, B, K, G, Lseats) Chrome Carbide, CrC-LF

F F6NM (H seat for high temp. NACE service) Chrome Carbide, CrC-LF

DInconel 718 with H type seat Tungsten Carbide, WC-Co

Soft seats

Seat material Insert

T Type 316 stainless steel PTFE

MType 316 stainless steel Filled PTFE

P Type 316 stainless steel PEEK

NType 316 stainless steel Polyamid

L Monel Filled PTFE

10. BEARING AND SEAL MATERIALS

Trunnion bearing Packings Body

gaskets O-ring Thrust

bearing

A Reinforced PTFE V-rings PTFE PTFE Viton GF Metal

BReinforced PTFE Graphite Graphite Viton GF Metal

C Stellite V-rings PTFE PTFE Viton GF Metal

DStellite Graphite Graphite Viton GF Metal

H Reinforced PTFE V-rings PTFE PTFE EPDM Metal

SReinforced PTFE Graphite Graphite EPDM Metal

U SS + WC-CO Graphite Graphite Viton GF Metal

VSS + WC-CO Graphite gr.GTA Graphite Viton GF Metal

T SS + WC-CO Braided PTFE Graphite Viton GF Metal

*) Cobalt based alloy is NACE compatible

11. sign Bolting material with metric thread

Pressure retaining Packing gland bolting

Standard Studs Nuts Studs Nuts Temp range

E* B8M 8M gr. 660 gr. 660 -200 ... +538 °C

T** L7M 2HM B7 2H -40 ... +538°C

S** L7M 2HM gr. 660 gr. 660 -46 ... +538°C

D * B8M B8 B8M 8M -200 ... +800°C

F ** L7M 2HM L7M 2HM -46 ... +538°C

Non Standard Studs Studs Studs Nuts Temp range

A ** B7 2H B7 2H -40 ... +538°C

B * B8 8B8 8-200 ... +800°C

G ** B7M 2HM B7M 2HM -200 ... +260°C