51PB270EN - 10/2020

Neles recommends inspecting valves at least every ve (5) years.

The inspection and maintenance frequency depend on the actual

application and process condition. Routine maintenance consists

of tightening the gland ange bolts (item 16 in exploded view)

periodically to compensate for stem seal wear.

Always loosen and tighten fasteners with the appropriate wrench to

avoid damaging the valve, handle, linkage, actuator, ttings or ats.

Overhaul maintenance consists of replacing seats and seals.

These parts may be obtained from Neles or an Authorized Neles

Distributor.

WARNING:

FOR YOUR SAFETY, IT IS IMPORTANT THE FOLLOWING

PRECAUTIONS BE TAKEN PRIOR TO REMOVAL OF

THE VALVE FROM THE PIPELINE OR BEFORE ANY

DISASSEMBLY:

1. BE SURE YOU KNOW WHAT FLUID IS IN THE

PIPELINE. IF THERE IS ANY DOUBT, DOUBLE-

CHECK WITH THE PROPER SUPERVISOR.

2. WEAR ANY PERSONAL PROTECTIVE EQUIPMENT

(PROTECTIVE CLOTHING OR EQUIPMENT)

REQUIRED WHEN WORKING WITH THE FLUID

INVOLVED.

3. DEPRESSURIZE THE PIPELINE AND CYCLE THE

VALVE AS FOLLOWS:

A. PLACE THE VALVE IN THE OPEN POSITION

AND DRAIN THE PIPELINE.

B. CYCLE THE VALVE TO RELIEVE RESIDUAL

PRESSURE IN THE BODY CAVITY BEFORE

REMOVAL FROM THE PIPELINE

C. AFTER REMOVAL AND BEFORE DISASSEMBLY,

CYCLE THE VALVE AGAIN SEVERAL TIMES.

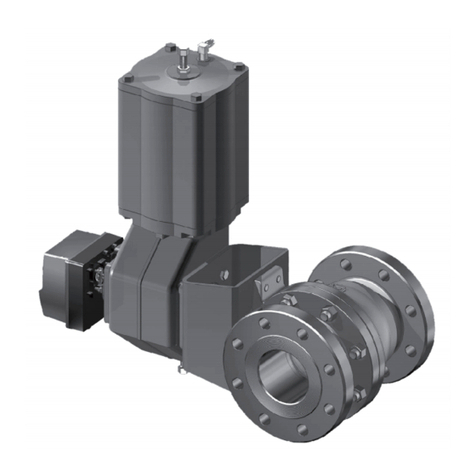

4.2 ACTUATED VALVE

It is generally most convenient to detach the actuator and its auxiliary

devices before removing the valve from the pipeline. If the valve

package is small or if it is dicult to access, it may be more practical

to remove the entire assembly.

NOTE: To ensure proper reassembly, observe the position of the

actuator and positioner/limit switch with respect to the valve before

detaching the actuator.

WARNING:

ALWAYS DISCONNECT THE ACTUATOR FROM ITS POWER

SOURCE, PNEUMATIC, HYDRAULIC OR ELECTRICAL,

BEFORE ATTEMPTING TO REMOVE IT FROM THE VALVE!

WARNING:

DO NOT REMOVE A SPRING-RETURN ACTUATOR UNLESS

A STOP-SCREW IS CARRYING THE SPRING FORCE!

1. Detach the air supply, electrical supply, hydraulic supply and

control signal cables or pipes from their connectors.

2. Remove the actuator mounting bracket screws.

3. Lift the actuator straight up in line with the valve stem until

the connection between actuator drive and valve stem is

completely disengaged.

4. Place actuator in a safe location to avoid damage

or personal injury.

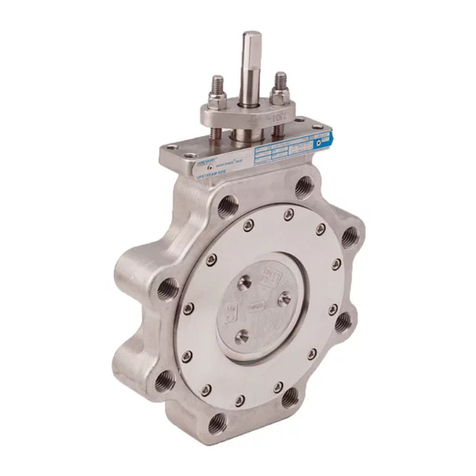

4.3 VALVE DISASSEMBLY

NOTE: It is good practice to replace all seats and seals any time a

valve is disassembled.

NOTE: Always use original OEM parts to make sure that the valve

functions properly.

Numbers in ( ) refer to items shown in the exploded view

1. Follow the steps in all the WARNING sections above before

performing any work on the valve.

2. Open and close the valve and leave in the closed position.

3. Remove the handle bolts (12), washers (10), handle (8).

4. Remove the C-ring (11), and then remove the stop plate (9).

5. Remove the gland bolts (14), washer (13), and then the gland (6).

6. Place the valve in the vertical position with the cap (2) end up.

7. Remove the body nuts (16) and remove the cap (2). Be careful

not to scratch the ball.

8. Remove the seat (5) from the body cap.

9. Close ball (3) by rotating stem (4) and lift ball (3) from body.

10. Remove the lower seat (4) from the valve body. Be careful not

to scratch the body sealing surface behind the seat.

11. Press the stem (4) from the top into valve body and carefully

remove it.

12. Remove the gland packing (7).

4.4 CHECKING PARTS

1. Clean all disassembled parts.

2. Check the stem (4) and ball (3) for damage. Pay particular

attention to the sealing areas.

3. Check all sealing and gasket surfaces on the body (1) and cap (2).

4. Replace any damaged parts.

5. Replace any fastener where the threads are damaged or have

been heated, stretched or corroded.

6. Replace any parts that have cracks, gouges or pits that will

aect sealing.

NOTE: When ordering spare parts, always include the following

information:

a. Valve type code as per technical bulletin and model

number from name plate,

b. If the valve is serialized - the serial number (stamped

on the valve body or name plate) or applicable

manufacturing order number,

4.5 VALVE ASSEMBLY

Numbers in ( ) refer to items shown in the exploded view.

It is advisable to replace seats and seals if complete disassembly

and reassembly become necessary.

1. Clean all valve components, if not previously done.

2. Inspect all components for damage before assembling the

valve. Look for damage to the sealing areas on the ball, stem,

and body.