NEP BDM-250-240A User manual

USA

Address: 1781 Riverview Ave., Tracy, CA 95377

Australia

Address: 9 Meander Grove, Cameron Park, NSW2285

China

Address: No.1 Anhe Rd Tsingtao Export Processing Zone, Tsingtao, China 266113

TEL: +86 532 87963900

FAX: +86 532 81100917

SAA

122309

N

136

BDM-250-240A

BDM-250-AU

BDM-250-LV

BDM-250-208A

BDM-250-EU

Installan and Operan Manual

COMPANY PROFILE

1. INTRODUCTION

1.1 Prex

1.2 Grid-ed PV System

1.3 How to Use This Manual

1.4 Label

2. SAFETY INSTRUCTION

3. FCC COMPLIANCE

4. INSTALLATION

Parts Included

Other Parts and Tools Required

Lightning Surge Suppression

Installaon Procedure

Step 1 - Install the AC Branch Circuit Juncon Box

Step 2 - Aach the BDM-250 to the Racking

Step 3 - Connect the BDM-250 Wiring Harnesses

Step 4 – Ground the System

Step 5 – Complete the connecon map and

connect the PV Modules

5. COMMISSIONING

6. OPERATING INSTRUCTIONS

7. TROUBLRSHOOTING MAINTENANCE

8. SPECIFICATION

9. WARRANTY AND PRODUCTION INFORMATION

WARRANTY CARD

01

02

02

02

02

02

03

03

04

04

04

04

04

05

06

07

08

09

10

11

12

14

16

CONTENTS

COMPANY PROFILE

Northern Electric & Power Inc. (NEP) was founded in the United States and has

manufacturing and R&D facilies in China. The mission of the company is to

develop cung-edge clean energy technologies and provide state-of-the-art solar

inverter products to its customers. The rst round of investment to the company

was US$20 Million, with a planned total investment of US$50 Million. The

company is headquartered in the city of Tsingtao, a major industrial center and

trading port in the northeastern China. The company campus occupies more than

18 acres in the Tsingtao Export Processing Zone, and has more than 650,000

square feet building space. The campus is planned to be connected through a

micro smart grid demo community and powered by electricity from solar, wind

and micro turbines. Outside China, the company has operaon oces in Chicago,

U.S. and Vancouver, Canada.

The technology founders of the company are well-known experts in the elds of

power electronics, automac control, signal processing, and communicaons.

Each of the founders has mulple U.S. and world patents in their specialty areas.

They received Ph.D. degrees from top universies in North America, and each has

more than 10 years engineering and management experiences in leading U.S.

companies.

NEP has a complete product line of grid-ed solar inverters, including

250W~500W micro inverters, 1.5kW~5kW single phase solar inverters, and

10kW~500kW three-phase solar inverters. Field deployment results demonstrated

high system eciency and reliability of NEP solar inverters.

NEP is commied to develop Clean, Reliable, Affordable and Efficient (CARE)

products for worldwide customers.

0 1

1. INTRODUCTION

1.1 Prex

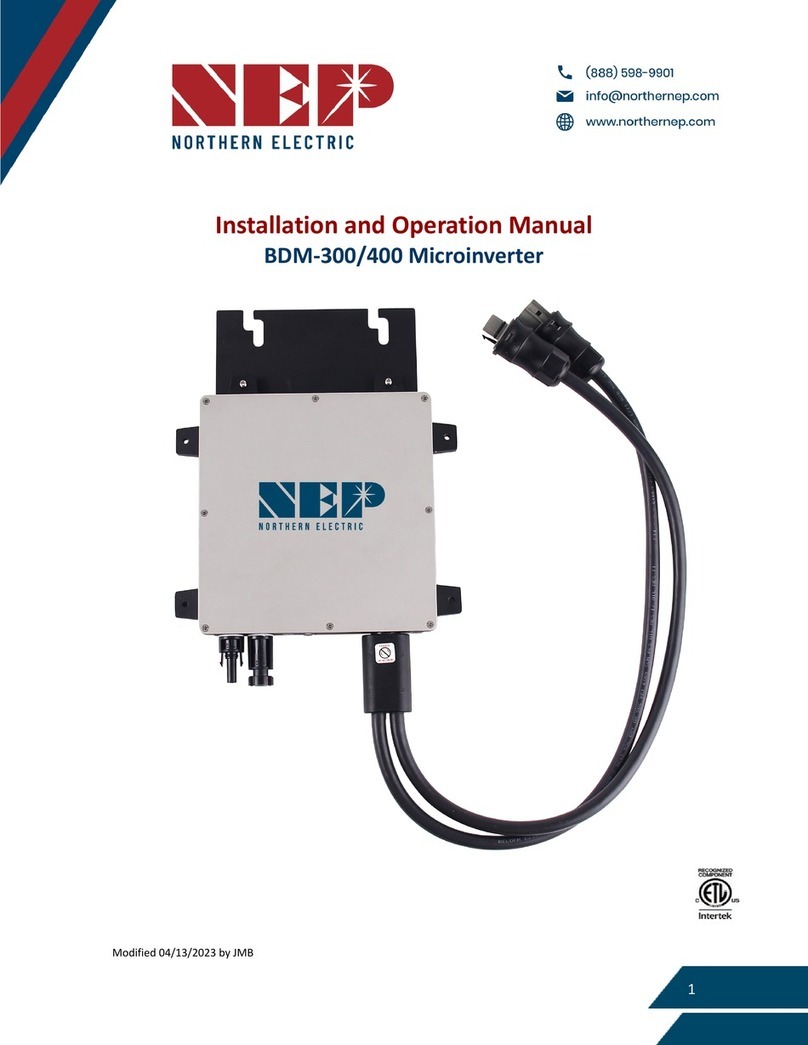

Dear customer, thank you for choosing the BDM-250 micro inverter from NEP.

We hope you will nd our products meet your need for renewable energy.

Meanme, we appreciate your feedback regarding our products.

1.2 Grid-ed PV System

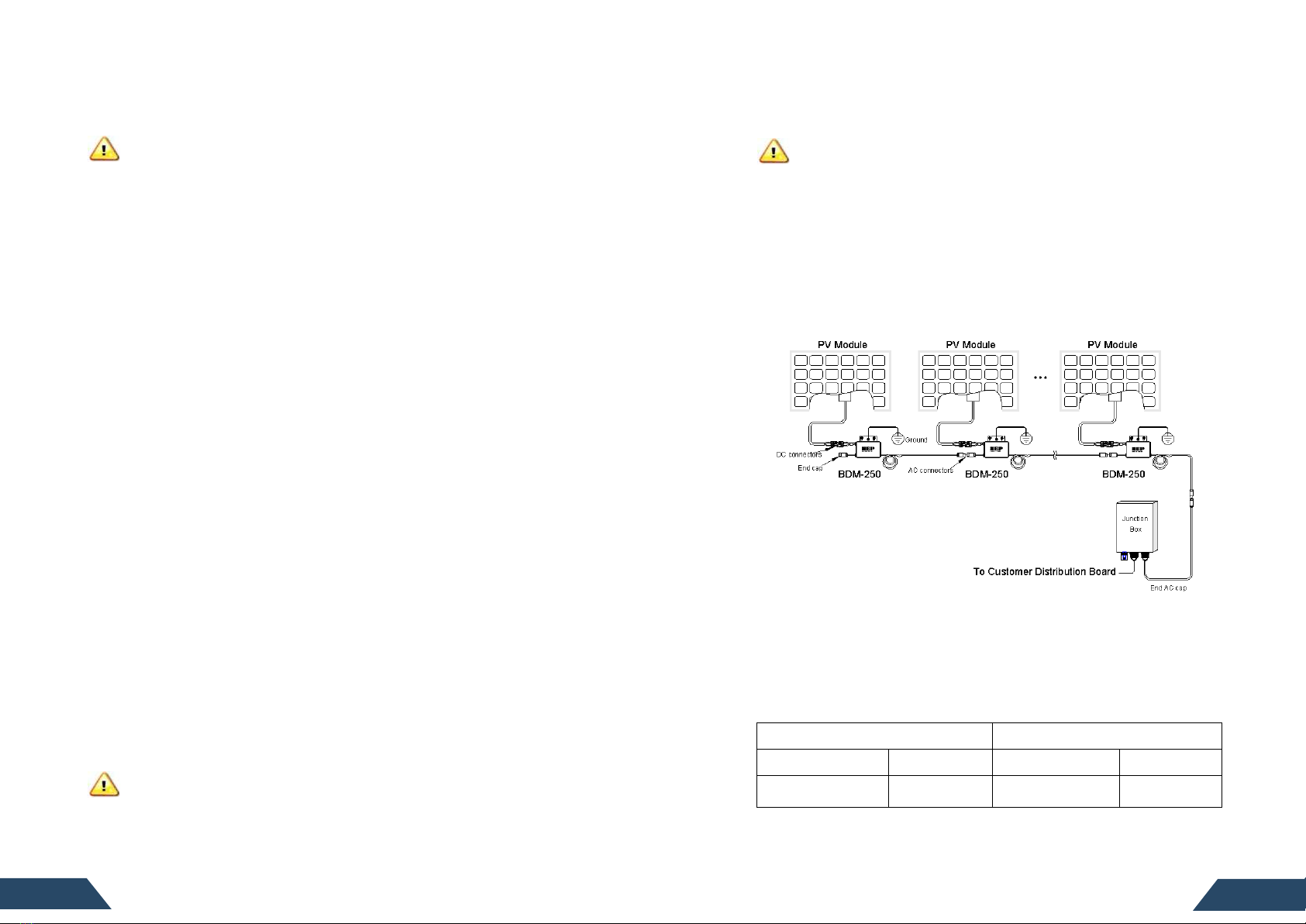

Grid-ed PV system consists of PV panels, grid-ed inverter and juncon boxes.

The DC output from the PV panels is converted into AC energy and feedback to

the grid through the BDM-250. BDM-250 series PV micro inverter contains

isolaon transformer with basic insulaon between PV input and AC grid output.

The PV panel terminals on BDM-250 shall not be earthed via external wiring, for

BDM-250 connects PV panel to earth via an internal earth fault interrupng 1A

fuse.

1.3 Hw tUse This Manual

This manual provides detailed product informaon and installaon instrucons

for the BDM-250 micro solar inverter. Please read through this manual before

installaon and operaon.

WARNING: This indicates a situaon where failure to follow instrucons

may be a safety hazard or cause equipment malfuncon. Use extreme

cauon and follow instrucons carefully.

1.4 Label

The label is located on the side of the inverter. The informaon on the label

includes technical data as well as type, rmware version and serial number of the

device. Safety instrucons on the label are listed and explained below:

Danger!

The term “danger” describes an issue which, if ignored can cause

personal injury.

Aenon!

With the term “aenon” a circumstance is listed which may

cause property damage if disregarded.

Instrucons for use!

Under “Instrucons for Use“, it is pointed out that installaon and

operang instrucons are to be read and understood before

installaon or repair.

Cauon, hot surface!

Under “Cauon, hot surface”, it should be noted that surfaces of

equipment may be hot and create a burn hazard.

Special disposal instrucons!

With “Note Separate Disposal”, it is pointed out that this product

may not be disposed of with normal garbage. An improperly

conducted disposal can lead to damage to the environment.

CE mark

The product complies with essenal requirements of relevant

direcves of EU

2. SAFETY INSTRUCTION

WARNING:

PLEASE READ THIS MANUAL BEFORE INSTALLATION. ANY DAMAGE TO THE PRODUCT DUE TO NOT

FOLLOWING THIS MANUAL IS NOT COVERED BY THE WARRANTEE.

ALL THE INSTALLATION SHOULD BE DONE BY CERTIFIED ELECTRICIAN.

BESIDES THE CABLE CONNECTORS, NOTHING INSIDE THE INVERTER SHOULD BE MODIFIED.

ALL INSTALLATION SHOULD FOLLOW THE LOCAL ELECTRIC CODES. FURTHER PROTECTION ON THE

AC WIRING FROM THE INVERTERS SHOULD BE PROVIDED AND MAY BE REQUIRED BY LOCAL AND

NATIONAL WIRING REGULATIONS. THIS PROTECTION IS LIKELY TO INCLUDE RESIDUAL CURRENT

DEVICES, EARTH FAULT MONITORS AND CIRCUIT BREAKERS. THIS PRODUCT MAY CAUSE AC

CURRENT WITH A DC COMPONENT. IF A RESIDUAL CURRENT-OPERATED PROTECTIVE DEVICE

(RCD) OR A MONITORING DEVICE (RCM) IS USED FOR PROTECTION IN CASE OF DIRECT OR

INDIRECT CONTACT, ONLY AN RCD OR RCM OF TYPE B IS ALLOWED ON THE AC SIDE OF THIS

PRODUCT.

NEVER DISCONNECT PV MODULE FROM THE MICRO-INVERTER WITHOUT FIRST ISOLATING THE AC

MAINS. ALL PV CONNECTORS AND AC CONNECTORS ARE FORBIDDEN TO BE DISCONNECTED

UNDER LOAD BEFORE SWITCHING OFF THE CIRCUIT BREAKER ON THE AC BRANCH.

PLEASE CONTACT AUTHORIZED SERVICE AGENTS FOR ANY SERVICE WORK.

BDM-250 IS A GRID-TIED SOLAR INVERTER. IT MAY REQUIRE APPROVAL FROM LOCAL UTILITY

COMPANY TO CONNECT IT TO THE POWER GRID.

BDM-250 DOES NOT INCLUDE COMPONENTS THAT CAN BE SERVED BY CUSTOMERS.

WARNING:

WHEN THE PHOTOVOLTAIC ARRAY IS EXPOSED TO LIGHT, IT SUPPLIES A DC

VOLTAGE TO THE MICRO-INVERTER.

3. FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to part 15 of the FCC Rules. These limits are designed to

provide reasonable protecon against harmful interference in a residenal

installaon. This equipment generates uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instrucons, may

cause harmful interference to radio communicaons. However, there is no

guarantee that interference will not occur in a parcular installaon. If this

equipment does cause harmful interference to radio or television recepon,

which can be determined by turning the equipment oand on, the user is

encouraged to try to correct the interference by one or more of the following

measures:

●Reorient or relocate the receiving antenna.

●Increase the separaon between the equipment and the receiver.

●Connect the equipment into an outlet on a circuit dierent from that to

which the receiver is connected.

●Consult the dealer or an experienced radio/TV technician for help.

Changes or modicaons not expressly approved by the party responsible for

compliance may void the user’s authority to operate the equipment.

03

0 2

03

4. INSTALLATION

WARNING: BE AWARE THAT INSTALLATION OF THIS EQUIPMENT INCLUDES RISK OF

ELECTRIC SHOCK. NORMALLY GROUNDED CONDUCTORS MAY BE UNGROUNDED AND

ENERGIZED WHEN A GROUND FAULT IS INDICATED.

Parts Included

In addion to the micro inverters, PV modules, racking, and associated hardware,

you’ll need the BDM-250 installaon kit. This kit includes the following items:

●Protece end cap

●Mounng Bracket (adapter plate)

●AC interconnect cable and protece end CAP

Other Parts and Tls Required

In addion to your PV array and its associated hardware, you will need the

following parts:

●Juncon box

●Connuous grounding conductor,grounding washers

●Number 2 Phillips screwdriver

●Sockets, wrenches for mounng hardware

●Torque wrench

●Mounng hardware suitable for module racking

Lightning Surge Suppressin

Lightning does not actually need to strike the equipment or building where PV

system is installed to cause damage. Oen, a strike nearby will induce voltage

spikes in the electrical grid that can damage equipment. BDM-250 has integrated

surge protecon, greater than most string inverters. However, if the surge has

sucient energy, the protecon built into the BDM-250 can be exceeded, and

the equipment can be damaged.

Since the NEP Limited Warranty does not cover “acts of God” such as lightning

strikes, and since lightning strikes can occur anywhere, it is best pracce to install

surge protecon as part of any solar installaon. Installaon of surge protecon

devices should follow vendor instrucons.

Installan Prcedure

WARNING: DO NOT CONNECT BDM-250 TO THE UTILITY GRID OR ENERGIZE THE AC

CIRCUIT(S) UNTIL YOU HAVE COMPLETED ALL OF THE INSTALLATION PROCEDURES AS

DESCRIBED IN THE FOLLOWING SECTIONS.

Installing the BDM-250 Micro inverter System involves several key steps:

1. Measuring service and installing the AC branch circuit juncon box.

WARNING: ONLY USE ELECTRICAL SYSTEM COMPONENTS APPROVED FOR WET

LOCATIONS.

2. Aaching the BDM-250 Micro inverter to the racking.

3. Connecng the BDM-250 Micro inverter wiring harnesses.

4. Grounding the system.

5. Compleng the BDM-250 Micro inverter installaon map and connecng the

PV modules.

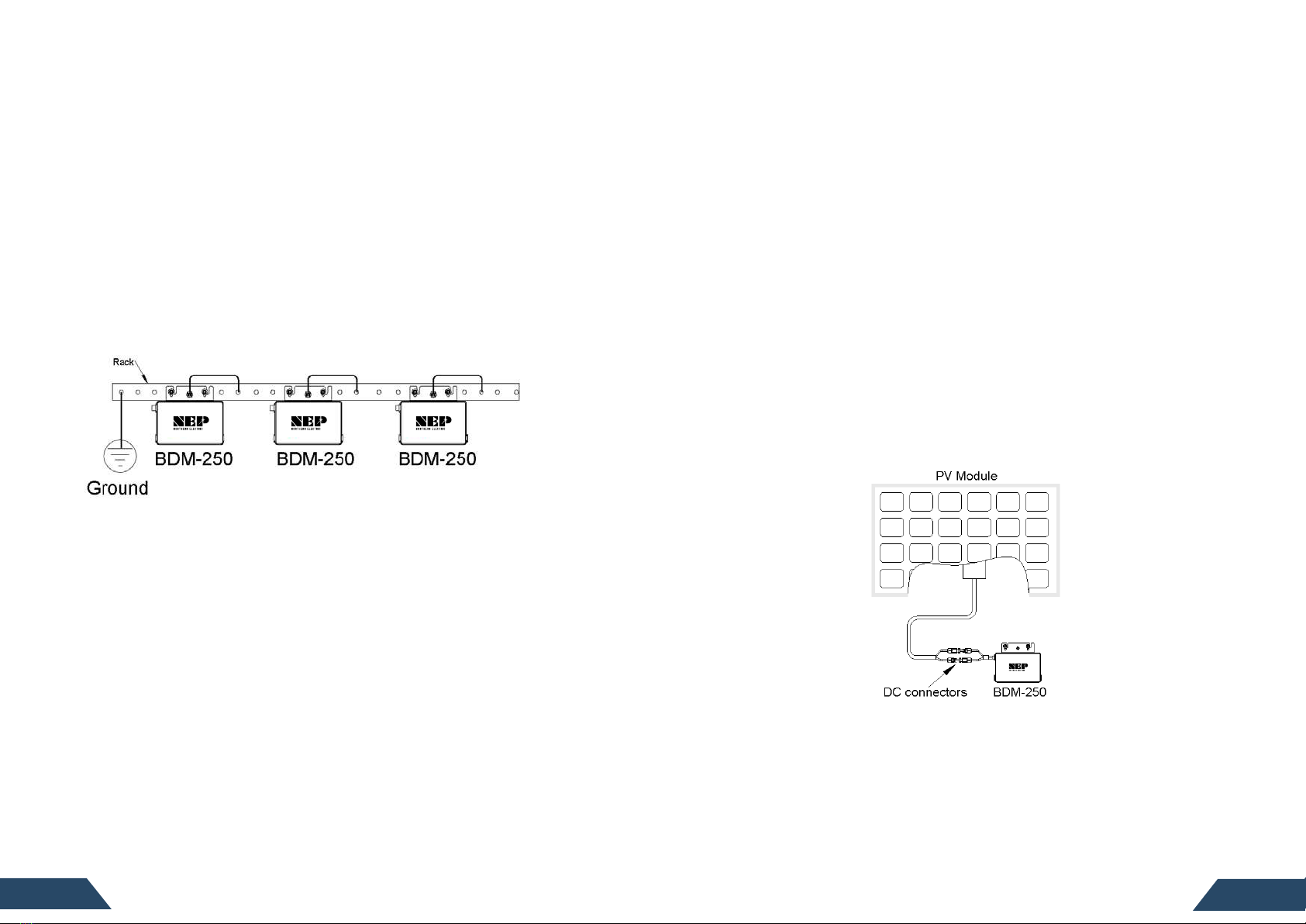

The nished system should be similar as in the diagram. Detailed installaon

steps are listed in the following secon.

Step 1 - Install the AC Branch Circuit Juncn Bx

1. Measure service entrance conductors to conrm AC service at the site.

Acceptable ranges are shown in the table below:

●BDM-250-240A & BDM-250-208A (North America)

240 Volt AC Single Phase 208 Volt AC Single Phase

L1(red) to L2(black) 211 to 264 Vac L1(red) toL2(black) 183 to 229 Vac

L1(red), L2(black) to

neutral(blue)

106 to 132 Vac

L1(red), L2(black)

to neutral(blue)

106 to 132 Vac

05

0 4

●BDM-250-AU (Australia and New Zealand), BDM-250-EU (Europe)

L1(red)to L2(black)

200 to 270 Vac

●BDM-250-LV (U.S. and Mexico)

L1/L2(red) to N(black)

127 Vac

2. Mount the adapter plate at a suitable locaon on the PV racking system (typically

at the end of a row of modules).

3. Install an appropriate juncon box with the adapter plate.

4. Connect the open wire end of the AC interconnect cable into the juncon box using

an appropriate gland or strain relief ng. The AC interconnect cable requires a

strain relief connector with an opening of 3/8 inches in diameter.

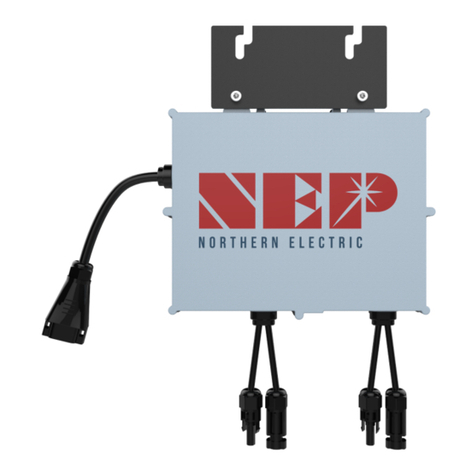

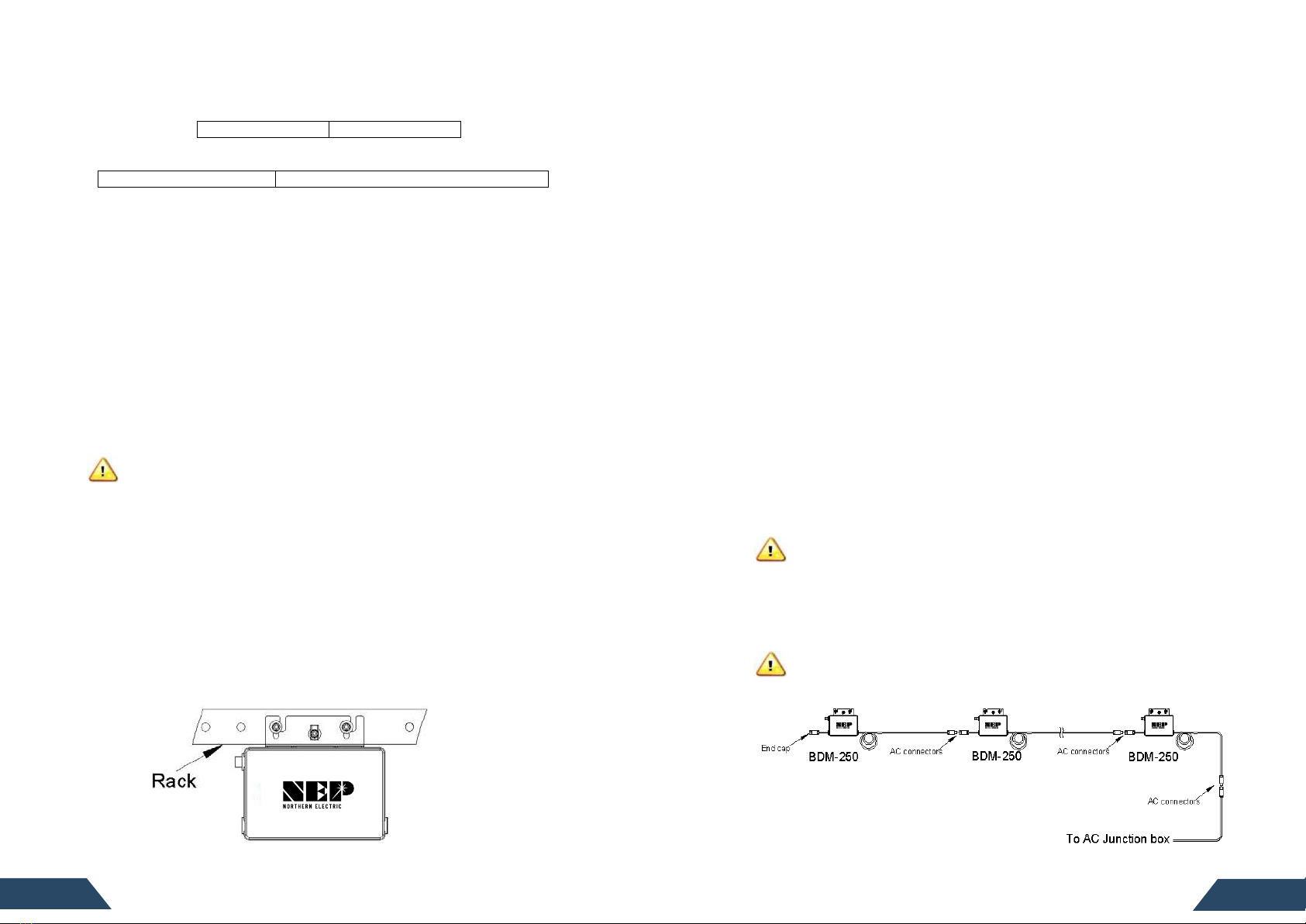

Step 2 - Aach the BDM-250 tthe Racking

1. Mark the approximate centers of each PV module on the racking system. Evaluate

the locaon of the micro inverter with respect to the PV module juncon box or any

other obstrucons.

WARNING: ALLOW A MINIMUM OF .75 INCHES BETWEEN THE TOP OF THE ROOF AND THE

BOTTOM OF BDM-250. WE ALSO RECOMMEND THAT YOU ALLOW .50 INCHES BETWEEN THE

BACK OF THE PV MODULE AND THE TOP OF BDM-250. DO NOT MOUNT BDM-250 IN A

LOCATION THAT ALLOWS LONG-TERM EXPOSURE TO DIRECT SUNLIGHT.

2. If using grounding washers (e.g., WEEB) to ground the micro inverter chassis to the

PV module racking, choose a grounding washer that is approved for the racking

manufacturer. Install a minimum of one grounding washer per micro inverter.

Torque the micro inverter fasteners to the values listed below.

1/4” mounng hardware – 45 inlbs minimum

5/16” mounng hardware – 80 inlbs minimum

3. Mount one micro inverter at each of these locaons using hardware recommended

by your module racking vendor. Mounng slots on the micro inverter are 0.33

inches in diameter. Maximum bolt size is 5/16 inch. The two slots on the micro

inverter are 4 inches apart.

Step 3 - Cnnect the BDM-250 Wiring Harnesses

Each BDM-250 comes with one 3-pin bulkhead receptacle (or short pigtail) and

one 70-inch AC wire harness with mul-pin connectors. (The DC input wires are

approximately six inches long and are terminated with single pole connectors.)

The AC connectors are oppositely sexed, so that mulple inverters can be

connected to form one connuous AC branch circuit.

1. Orient the rst BDM-250 in each branch with its male connector facing the

juncon box. The juncon box AC interconnect cable has a female connector.

The BDM-250 can be mounted with either side facing up to accommodate

cable roung. Connect the rst BDM-250 to the AC interconnect cable.

2. Plug the AC connector of the rst BDM-250 into the connector of the next

BDM-250, and so forth, to form a connuous AC branch circuit. Please check the

BDM-250 rang label for the maximum allowable number of BDM-250 on one

AC branch circuit. For the chain of the BDM-250 micro inverters thus formed,

one end of the AC cable should be protected by a CAP (refer to the BDM-250

accessories). For the other end of the AC cable, it should be connected to an AC

juncon box through a tail cable (refer to the BDM-250 accessories). For

BDM-250-240A and BDM-250-208A, the L1 wire (red), L2 wire (black) and

neutral wire (blue) in the AC cable should be connected to the corresponding

phases of the main grid through the AC juncon box. For BDM-250-AU and

BDM-250-EU, the L1 wire (red) and L2 wire (black) should be connected to the L

and N phases of the main grid respecely at the AC juncon box. For

BDM-250-AU and BDM-250-EU, the neutral wire (blue) is unused and should be

terminated in the AC juncon box on an unused connector. It should NOT be

connected to L1 (red), or L2 (black), or earth, or any other wires.

WARNING: DO NOT EXCEED THE MAXIMUM NUMBER OF BDM-250 IN AN AC BRANCH

CIRCUIT, AS DISPLAYED ON THE UNIT-RATING LABEL. EACH BDM-250 AC BRANCH CIRCUIT

MUST BE SOURCED FROM A DEDICATED BRANCH CIRCUIT PROTECTED BY A 15A MAXIMUM

BREAKER.

3. Install a protece end cap on the open AC connector of the last BDM-250

in the AC branch circuit.

WARNING: MAKE SURE PROTECTIVE END CAPS HAVE BEEN INSTALLED ON ALL UNUSED

AC CONNECTORS. UNUSED AC BDM-250 WIRE HARNESS CONNECTORS ARE LIVE WHEN

THE SYSTEM IS ENERGIZED BY THE UTILITY SYSTEM.

07

0 6

Step 4 – Grund the System

Each BDM-250 comes with a ground clip that can accommodate a 6-8 AWG

conductor. If you are not using grounding washers to ground the BDM-250

chassis as described in step2, route a connuous GEC through each of the

BDM-250 to the NEC approved AC grounding electrode. The racking and module

could be grounded to this conductor using a crimp connecon. An alternae

method would be to connect the BDM-250 to the grounded racking using a

grounding washer approved for the racking.

NOTE: The neutral wire (blue) in the AC cable is NOT bonded to earth and

earth/ground connecon is not provided via the AC cable through the

micro-inverter. The earth/ground connector on the enclosure of micro-inverter

shall be reliably connected to the earth; otherwise there will be a risk of person

shock hazard or re hazard. The ground conductor size is recommended with at

least 4mm2and should be larger than live conductor cross secon area. Refer

to local regulaon for minimum size requirement for ground conductor size.

Step 5 – Cmplete the cnnecn map and cnnect the PV Mdules

BDM-250 connecon Map is a diagrammac representaon of the physical

locaon of each BDM-250 in your PV installaon. The virtual array in NEP micro

inverter gateway BDG-256 is created from the map you create.

Cmplete the cnnecn map

Each BDM-250 has a removable serial number located on the individual label.

Enter the unique address contained in part of the serial number into a

BDG-256, and correspond it to a number in the connecon map.

Cnnect the PV Mdules

Completely install all BDM-250 and all system inter-wiring connecons prior to

installing the PV modules.

1. Mount the PV modules above their corresponding BDM-250. Each BDM-250

comes with two oppositely sexed DC connectors.

2. First connect the posie DC wire from the PV module to the posiely marked

DC connector (male pin) of the BDM-250. Then connect the negae DC wire

from the PV module to the negaely marked DC connector (female socket) of

the BDM-250. Repeat for all remaining PV modules using one BDM-250 for each

module.

09

0 8

5. COMMISSIONING

WARNING: CONNECT BDM-250 TO THE ELECTRICAL UTILITY GRID ONLY AFTER RECEIVING

PRIOR APPROVAL FROM THE UTILITY COMPANY.

WARNING: BE AWARE THAT ONLY QUALIFIED PERSONNEL CAN CONNECT BDM-250 TO THE

ELECTRICAL UTILITY GRID.

WARNING: ENSURE THAT ALL AC AND DC WIRING IS CORRECT. ENSURE THAT NONE OF THE

AC AND DC WIRES IS PINCHED OR DAMAGED. ENSURE THAT ALL JUNCTION BOXES ARE

PROPERLY CLOSED.

Following these steps to commission the BDM-250 PV system:

1. Turn on the AC disconnects or circuit breakers on each BDM-250 AC branch circuit.

2. Turn on the main uty-grid AC circuit breaker. Your system will start producing

power aer a few minutes wait me.

3. The BDM-250 will start to send performance data over the power lines using

power line communicaon (PLC) to the BDG-256. The me required for each

BDM-250 in the system to communicate to the BDG-256 will vary with the number

of BDM-250 in the system.

10

6. OPERATING INSTRUCTIONS

The BDM-250 is powered on when sucient DC voltage from the module is applied.

The status LED will start ashing aer suicient DC power is applied as an indicaon

that the BDM-250 is live.

Status: standby

The LED light is on by 2 second, and oby 2 seconds.

Status: prducing pwer

The LED light is on by 1 second, and oby 1 second.

Status: prducing pwer and cmmunicang with BDG-256

The LED light is on by 0.5 second, and oby 0.5 second.

In case of fault, BDM-250 has mulple protece funcons and stops output power.

The fault message may be sent to a connected BDG-256 gateway through power

line communicaon. The error message is displayed on the screen of BDG-256

gateway by a 16-bit error code.

Errr cde Errr

Bit-0 DC over voltage

Bit-1 DC under voltage

Bit-2 hardware error

Bit-3 Inverter over voltage

Bit-4 Frequency over

Bit-5 Frequency under

Bit-6 AC voltage RMS over

Bit-7 AC voltage RMS under

Bit-8 Peak AC voltage over

Bit-9 AC current RMS over

Bit-10 Peak AC current over

Bit-11 Temperature over

Bit-12 ADC error

Bit-13 GFDI fault indicator

Bit-14 Relay fault (BDM-250-AU/BDM-250-EU only)

Bit-15 PLC Communicaon Error

11

10

12

7. TROUBLESHOOTING AND MAINTENANCE

WARNING: DO NOT ATTEMPT TO REPAIR THE BDM-250; IT CONTAINS NO

USER-SERVICEABLE PARTS. IF TROUBLESHOOTING METHODS FAIL, PLEASE RETURN THE

BDM-250 TO YOUR DISTRIBUTOR FOR MAINTENANCE.

WARNING: NEVER DISCONNECT THE DC WIRE CONNECTORS UNDER LOAD. ENSURE THAT

NO CURRENT IS FLOWING IN THE DC WIRES PRIOR TO DISCONNECTING. AN OPAQUE

COVERING MAY BE USED TO COVER THE MODULE PRIOR TO DISCONNECTING

WARNING: ALWAYS DISCONNECT AC POWER BEFORE DISCONNECTING PV MODULE WIRES

FROM BDM-250. THE AC CONNECTOR OF THE FIRST BDM-250 IN A BRANCH CIRCUIT IS

SUITABLE AS A DISCONNECTING MEANS ONCE THE AC BRANCH CIRCUIT BREAKER IN THE LOAD

CENTER HAS BEEN OPENED.

WARNING: BDM-250 IS POWERED BY DC POWER FROM PV MODULES. MAKE SURE YOU

DISCONNECT THE DC CONNECTIONS AND RECONNECT DC POWER TO WATCH FOR THE TWO

SECONDS LED ON AND TWO SECONDS LED OFF AFTER DC IS APPLIED.

LED indican f errr

●Errr reprt: ACr DC fault

The LED light is on by 4 second, and oby 4 seconds.

●Errr reprt: GFDI fault

The LED light stays on.

Trubleshng an inperable BDM-250

To troubleshoot an inoperable BDM-250, follow the steps in the order shown:

1. Check the connecon to the ulity grid. Verify that the uty voltage and

frequency are within allowable ranges shown in the label of BDM-250.

2. Verify uty power is present at the inverter in queson by removing AC, then DC

power. Never disconnect the DC wires while the BDM-250 is producing power.

Re-connect the DC module connectors, and then watch for the LED blinks.

3. Check the AC branch circuit interconnecon harness between all the BDM-250.

Verify that each inverter is energized by the ulity grid as described in the

previous step.

4. Make sure that any AC disconnects are funconing properly and are closed.

5. Verify the PV module DC voltage is within the allowable range shown in the label

of BDM-250.

6. Check the DC connecons between the BDM-250 and the PV module.

7. If the problem persists, please call customer support at NEP.

WARNING: DO NOT ATTEMPT TO REPAIR THE BDM-250; IT CONTAINS NO

USER-SERVICEABLE PARTS. IF TROUBLESHOOTING METHODS FAIL, PLEASE RETURN THE

BDM-250 TO YOUR DISTRIBUTOR FOR MAINTENANCE.

Discnnecng a BDM-250 frm the PV Mdule

To ensure the BDM-250 is not disconnected from the PV modules under load, adhere

to the following disconnecon steps in the order shown:

1. Disconnect the AC by opening the branch circuit breaker.

2. Disconnect the rst AC connector in the branch circuit.

3. Cover the module with an opaque cover.

4. Using a DC current probe, verify there is no current owing in the DC wires between

the PV module and the BDM-250.

5. Care should be taken when measuring DC currents, most clamp-on meters must be

zeroed rst and tend to driwith me.

6. Disconnect the PV module DC wire connectors from the BDM-250.

7. Remove the BDM-250 from the PV array racking.

Installing a replacement BDM-250

1. Aach the replacement BDM-250 to the PV module racking using hardware

recommended by your module racking vendor. If you are using grounding washers

(e.g., WEEB) to ground the chassis of the BDM-250, the old grounding washer should

be discarded, and a new grounding washer must be used when installing the

replacement BDM-250. Torque the BDM-250 fasteners to the values listed below:

1/4” mounng hardware – 45 in-lbs minimum

5/16” mounng hardware – 80 in-lbs minimum.

2. If you are using agrounding electrode conductor to ground the BDM-250 chassis,

aach the grounding electrode conductor to the BDM-250 ground clamp.

3. Connect the AC cable of the replacement BDM-250 and the neighboring BDM-250

to complete the branch circuit connecons.

4. Complete the connecon map and connect the PV Modules.

1) Complete the connecon map

2) Each BDM-250 has a removable serial number located on the individual label.

Enter the unique address contained in part of this serial number into a BDG-256,

and correspond it to a number in the connecon map.

3) Connect the PV Modules

4) Completely install all BDM-250 and all system inter-wiring connecons prior to

installing the PV modules.

a) Mount the PV modules above their corresponding BDM-250. Each

BDM-250 comes with two oppositely sexed DC connectors.

b) First connect the posie DC wire from the PV module to the posiely

marked DC connector (male pin) of the BDM-250. Then connect the negae

DC wire from the PV module to the negaely marked DC connector (female

socket) of the BDM-250. Repeat for all remaining PV modules using one

BDM-250 for each module.

13

12

8. SPECIFICATION

MODEL BDM-250-240A BDM-250-208A

INPUT(DC)

Max Recommended PV Power (Wp) 285

Max DC Open Circuit Voltage (Vdc) 60

Max DC Input Current (Adc) 12

MPPT Tracking Accuracy >99.5%

MPPT Tracking Range (Vdc) 22-55

OUTPUT(AC)

Rated AC Output Power (Wp) 220

Nominal Power Grid Voltage (Vdc) 240 / 220 208/220

Allowable Power Grid Voltage (Vdc) 211-264/198-253 186-228/198-253

Allowable Power Grid Frequency (Hz) 59.3-60.5/45.5-52.5

THD <3% (at rated power)

Power Factor (cos phi, xed) >0.99%

SYSTEM

EFFICIENCY

Peak Eciency 96.3% 95.70%

CEC Eciency 95%

Night Time Tare Loss (Wp) 0.17

PROTECTION

FUNCTIONS

Over/Under Voltage Protecon Yes

Over/Under Frequency Protecon Yes

An-Islanding Protecon Yes

Over Current Protecon Yes

Reverse DC Polarity Protecon Yes

GFDI Integrated

Overload Protecon Yes

Protecon Degree NEMA-6

Environment Temperature -40℃——+65℃

OTHER

PARAMETERS

Environment Humidity 100%, condensaon

Display LED LIGHT

Communicaons Power Line

Dimension (D-W-H mm) 230*138*35

Weight (Kg) 2

MODEL

BDM-250-EU

BDM-250-AU

INPUT(DC)

Max Recommended PV Power (Wp)

285

Vmax PV (absolute maximum) (Vdc)

60

PV Input Operang Voltage Range (Vdc)

22-55

Maximum Operang PV Input Current (Adc)

12

MPPT Tracking Accuracy

>99.5%

Isc PV (absolute maximum) (Adc)

14

Maximum Inverter Backfeed Current to the Array (Adc)

0

OUTPUT(AC)

Rated AC Output Power (W)

220

Nominal Power Grid Voltage (Vac)

230

Current (maximum connuous) (Aac)

1.0

Current (inrush) (Peak and Duraon)

12A, 15us

Nominal Frequency (Hz)

50

Power Factor (cos phi, xed)

>0.99

Maximum Output Fault Current (Aac)

2.2A peak

Maximum Output Overcurrent Protecon (Aac)

6.3

Maximum Number of Units Per Branch

15

SYSTEM

EFFICIENCY

Peak Eciency

96.30%

CEC Eciency

95.0%

Night Time Tare Loss (Wp)

0.17

PROTECTION

FUNCTIONS

Over/Under Voltage Protection

Yes

Over/Under Frequency Protecon

Yes

An-Islanding Protecon

Yes

Over Current Protecon

Yes

Reverse DC Polarity Protecon

Yes

Overload Protecon

Yes

GFDI

Integrated

Protecve Class

I

IP Rang per Part 1

IP67

OTHER

PARAMETERS

Environment Temperature

-40℃~ +65℃

Environment Category

Indoor and outdoor

Wet Locaon

SUITABLE

Polluon Degree

PD 3

Environment Humidity

100%, condensaon

Maximum Altude

2000 M

Overvoltage Category

II(PV), III (AC MAINS)

Display

LED LIGHT

Communicaons

POWERLINE

Dimension (D-W-H mm)

230*138*35

Weight(Kg)

2

Product Safety Compliance

IEC/EN 62109-1

Grid Code Compliance* (Refer to the label for the

detailed grid code compliance)

VDE-AR-N 4105*

VDE V 0126-1-1/A1

G83/2

AS 4777.2 & AS

Note: For grid code VDE-AR-N 4105, maximum 3.68kVA PV plant is limited. The

grid protecon report and seng are readable from the gateway.

For grid code G83/2, maximum 16A per phase is limited. The grid protecon

report and seng are readable from the gateway.

15

14

9. WARRANTY AND PRODUCTION INFORMATION

What des this warranty cver and hw lng des it last?

This Limited Warranty is provided by Northern Electric & Power Co. Ltd (NEP) and

covers defects in workmanship and materials in your BDM-250 Grid-Tied Inverter. This

Warranty Period lasts for 10 years from the date of purchase at the point of sale to

you, the original end user customer, unless otherwise agreed in wring. You will be

required to demonstrate proof of purchase to make warranty claims.

This Limited Warranty is transferable to subsequent owners but only for the

unexpired poron of the Warranty Period. Subsequent owners also require original

proof of purchase as described in "What proof of purchase is required?"

What will NEP d?

During the Warranty Period, NEP will, at its opon, repair the product (if economically

feasible) or replace the defece product free of charge, provided that you nofy NEP

of the product defect within the Warranty Period, and provided that NEP through

inspecon establishes the existence of such a defect and that it is covered by this

Limited Warranty.

NEP will, at its opon, use new and/or recondioned parts in performing warranty repai

r

and building replacement products. NEP reserves the right to use parts or products of

original or improved design in the repair or replacement. NEP repairs or replaces a

product, its warranty connues for the remaining poron of the original Warranty

Period or 90 days from the date of the return shipment to the customer, whichever is

greater. All replaced products and all parts removed from repaired products become the

property of NEP.

Hw dyu get service?

If your product requires troubleshoong or warranty service, contact your merchant. If

you are unable to contact your merchant, or the merchant is unable to provide service,

contact NEP directly at:

Nrthern Electric & Pwer C. Ltd

Address:NO.1 Anhe Rd Tsingtao Export Processing Zone, Tsingtao, China 266113

Phne:+86 532 87963900

Fax:+86 532 81100917

What des this warranty nt cver?

Claims are limited to repair and replacement or if in NEP's discreon that is not

possible, reimbursement up to the purchase price paid for the product. NEP will be

liable to you only for direct damages suered by you and only up to a maximum

amount equal to the purchase price of the product.

This Limited Warranty does not warrant uninterrupted or error-free operaon of the

product or cover normal wear and tear of the product or costs related to the removal,

installaon, or troubleshoong of the customer's electrical systems. This warranty

MODEL BDM-250-LV

INPUT(DC)

Max Recommended PV Power (Wp)

285

Vmax PV (absolute maximum) (Vdc)

60

PV Input Operang Voltage Range (Vdc)

22-55

Maximum Operang PV Input Current (Adc)

12

MPPT Tracking Accuracy

>99.5%

Isc PV (absolute maximum) (Adc)

14

Maximum Inverter Backfeed Current to the Array (Adc)

0

OUTPUT(AC)

Rated AC Output Power (W)

220

Nominal Power Grid Voltage (Vac)

127

Current (maximum connuous) (Aac)

1.73

Current (inrush) (Peak and Duraon)

12A, 15us

Nominal Frequency (Hz)

60

Power Factor (cos phi, xed)

>0.99

Maximum Output Fault Current (Aac)

4.2A peak

Maximum Output Overcurrent Protecon (Aac)

10

Maximum Number of Units Per Branch

8

SYSTEM

EFFICIENCY

Peak Eciency

96.30%

CEC Eciency

95.0%

Night Time Tare Loss (Wp)

0.17

PROTECTION

FUNCTIONS

Over/Under Voltage Protecon

Yes

Over/Under Frequency Protecon

Yes

An-Islanding Protecon

Yes

Over Current Protecon

Yes

Reverse DC Polarity Protecon

Yes

Overload Protecon

Yes

GFDI

Integrated

Protecve Class

I

IP Rang per Part 1

IP67

OTHER

PARAMETERS

Environment Temperature

-40℃~ +65℃

Environment Category

Indoor and outdoor

Wet Locaon

SUITABLE

Polluon Degree

PD 3

Environment Humidity

100%, condensaon

Maximum Altude

2000 M

Overvoltage Category

II(PV), III (AC MAINS)

Display

LED LIGHT

Communicaons

POWERLINE

Dimension (D-W-H mm)

230*138*35

Weight(Kg)

2

Product Safety Compliance UL 1741

CSA C22.2 No. 107.1

Grid Code Compliance* (Refer to the label for the

detailed grid code compliance)

IEEE 1547

17

16

Warranty Card

Custmer Infrman

Name:

Address:

City: State: Zip Code:

Tel: Fax: E-mail:

System Infrman

Fault Product(s) Serial Numbers:

System Commissioning Date: Product Models:

No. of Products Used: Bill of Lading Date:

Fault Product(s) Quanes: Fault Time/Date:

Fault Message(s) or Code(s):

Brief Fault Descripon and Photos:

Installan Infrman

Modules Used:

Modules Quanty: Inverters quanty per string:

Installaon Company Name:

Installer Name:

For the informaon on our warranty terms and condions,

please see our website: www.northernep.com/en

All elds must be completed in order to process claim.

Custmer Signature: Date:

*All rights reserved by NEP. This informaon is subject to changes without noce.

does not apply to and NEP will not be responsible for any defect in or damage to:

a) the product if it has been misused, neglected, improperly installed, physically

damaged or altered, either internally or externally, or damaged from improper

use or use in an unsuitable environment; b) the product if it has been subjected

to re, water, generalized corrosion, biological infestaons, or input voltage that

creates operang condions beyond the maximum or minimum limits listed in

the NEP product specicaons including high input voltage fromgenerators and

lightning strikes; c) the product if repairs have been done to it other than by NEP

or its authorized service centers (hereaer "ASCs"); d) the product if it is used as

a component part of a product expressly warranted by another manufacturer; e)

the product if its original idencaon (trade-mark, serial number) markings

have been defaced, altered, or removed; f) the product if it is located outside of

the country where it was purchased; and g) any consequenal losses that are

aributable to the product losing power whether by product malfuncon,

installaon error or misuse.

Disclaimer Prduct

THIS LIMITED WARRANTY IS THE SOLE AND EXCLUSIVE WARRANTY PROVIDED BY NEPIN

CONNECTION WITH YOUR NEP PRODUCT AND IS, WHERE PERMITTED BY LAW, IN LIEU OF ALL

OTHER WARRANTIES, CONDITIONS, GUARANTEES, REPRESENTATIONS, OBLIGATIONS AND

LIABILITIES, EXPRESS OR IMPLIED, STATUTORY OR OTHERWISE IN CONNECTION WITH THE

PRODUCT, HOWEVER ARISING (WHETHER BY CONTRACT, TORT, NEGLIGENCE, PRINCIPLES OF

MANUFACTURER'S LIABILITY, OPERATION OF LAW, CONDUCT, STATEMENT OR OTHERWISE),

INCLUDING WITHOUT RESTRICTION ANY IMPLIED WARRANTY OR CONDITION OF QUALITY,

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE TO THE EXTENT REQUIRED

UNDER APPLICABLE LAW TO APPLY TO THE PRODUCT SHALL BE LIMITED IN DURATION TO THE

PERIOD STIPULATED UNDER THIS LIMITED WARRANTY.

IN NO EVENT WILL NEP BE LIABLE FOR: (a) ANY SPECIAL, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING LOST PROFITS, LOST REVENUES, FAILURE TO REALIZE

EXPECTED SAVINGS, OR OTHER COMMERCIAL OR ECONOMIC LOSSES OF ANY KIND, EVEN IF

NEP HAS BEEN ADVISED, OR HAD REASON TO KNOW, OF THE POSSIBILITY OF SUCH DAMAGE,

(b) ANY LIABILITY ARISING IN TORT, WHETHER OR NOT ARISING OUT OF NEP'S NEGLIGENCE,

AND ALL LOSSES OR DAMAGES TO ANY PROPERTY OR FOR ANY PERSONAL INJURY OR

ECONOMIC LOSS OR DAMAGE CAUSED BY THE CONNECTION OF A PRODUCT TO ANY OTHER

DEVICE OR SYSTEM, AND (c) ANY DAMAGE OR INJURY ARISING FROM OR AS A RESULT OF

MISUSE OR ABUSE, OR THE INCORRECT INSTALLATION, INTEGRATION OR OPERATION OF THE

PRODUCT.

IF YOU ARE A CONSUMER (RATHER THAN A PURCHASER OF THE PRODUCT IN THE COURSE OF A

BUSINESS) AND PURCHASED THE PRODUCT IN A MEMBER STATE OF THE EUROPEAN UNION, THIS

LIMITED WARRANTY SHALL BE SUBJECT TO YOUR STATUTORY RIGHTS AS A CONSUMER UNDER

THE EUROPEAN UNION PRODUCT WARRANTY DIRECTIVE 1999/44/EC AND AS SUCH DIRECTIVE

HAS BEEN IMPLEMENTED IN THE EUROPEAN UNION MEMBER STATE WHERE YOU PURCHASED

THE PRODUCT. FURTHER, WHILE THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS,

YOU MAY HAVE OTHER RIGHTS WHICH MAY VARY FROM EU MEMBER STATE TO EU MEMBER

STATE OR, IF YOU DID NOT PURCHASE THE PRODUCT IN AN EU MEMBER STATE, IN THE COUNTRY

YOU PURCHASED THE PRODUCT WHICH MAY VARY FROM COUNTRY TO COUNTRY AND

JURISDICTION TO JURISDICTION.

19

18

USA

Add:1781 Riverview Ave., Tracy, CA 95377

Australia

Address: 9 Meander Grove, Cameron Park, NSW2285

China

Add: No.1 Anhe Rd Tsingtao Export Processing Zone, Tsingtao, China 266113

TEL: +86 532 87963900

FAX: +86 532 81100917

This manual suits for next models

4

Table of contents

Other NEP Inverter manuals

Popular Inverter manuals by other brands

Heat Controller

Heat Controller VMH 09 SD Installation, operation & maintenance manual

Sourcetronic

Sourcetronic ST130 Series user manual

Projoy Electric

Projoy Electric PEFS-PL Series user manual

Allmand

Allmand Maxi-Power MP25 T4F Operator's manual

EZIHEAT

EZIHEAT MSC90 user manual

Redback

Redback ST10000 owner's guide

Hitachi

Hitachi L300P Series instruction manual

Inverter

Inverter WVC Series user manual

OWT Industries

OWT Industries Black Max BM10700 manual

THOR

THOR PW Series instruction manual

Generac Power Systems

Generac Power Systems PRIMEPACT 50 04164-3 owner's manual

Wagan

Wagan PURE SINE WAVE INVERTER 9754 user manual