NEP BDM-300X2 Instruction Manual

BDM-600

Installation User Manual

Northern Electric Power Co,. Ltd.

V2.0 rev.2023.2.10

DISCLAIMERS

The information in these documents is the property of Northern Electric Power Co., Ltd., hereafter referred to as NEP.

No part of this document may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means,

mechanical, electronic, photographic, magnetic or otherwise, without the prior written permission of NEP. Internal

reproduction used solely for the purpose of product evaluation or other proper use is allowed and does not require prior

approval.

NEP makes no representations or warranties, express or implied, with respect to this documentation or any of the

equipment and/or software it may describe, including without limiting the generality of the foregoing, to any implied

warranties of utility, merchantability, or fitness of any particular purpose. All such representations or warranties are

expressly disclaimed. Neither NEP nor its distributors or dealers shall be liable for any indirect, incidental, or

consequential damages under any circumstances.

The exclusion of implied warranties may not apply in all cases under some statutes, and thus the above exclusion may not

apply.

This document and the material furnished within is believed to be complete, accurate and up-to-date. Readers are

cautioned, however, that product improvements and field usage experience may cause NEP to make changes to

specifications and contents without prior notice, or per contract provisions in those cases where a supply agreement

requires advance notice. NEP assumes no responsibility for the use of this material, and no responsibility for any

damages, including indirect, incidental or consequential damages, caused by reliance on the material presented,

including, but not limited to, omissions, typographical errors, arithmetical errors or listing errors in the content material.

Specifications and contents in these documents are continually reviewed, and subject to change without prior notice

where necessary. However, discrepancies cannot be excluded. No guarantee is made for the completeness of these

documents.

NEP WARRANTY

You can download the latest warranty terms and conditions from website at northernep.com.

For technical problems concerning NEP products and requiring assistance, please refer to CONTACT.

Trademarks

All trademarks, including company, brand products and service names, are recognized, even if not explicitly identified as

such. Missing designations do not mean that a product or brand is not a registered trademark.

INFORMATION ON THIS DOCUMENT

Target Group

This document is intended for “Qualified Persons" and "End Users".

Tasks marked with a warning symbol and the caption “Qualified Persons” require associated skills to avoid and deal with

the dangers and risks in installing and using the product and tools described in this document.

Tasks not marked do not require particular qualifications and skill sets, and therefore can be performed by end users.

Qualified Persons

Qualified Persons required

Qualified persons are required to be familiar, understand and capable of following all applicable regulations, directives

and laws, and are aware of the potential risks to perform the activities marked in this document.

The following knowledge and skills are required for qualified persons:

Knowledge of how an inverter works and is operated

Knowledge of all applicable standards and directives, including country-specific grid conditions and regulatory

guidelines

Knowledge and training of how to minimize and deal with dangers and risks associated with using, installing, and

repairing electrical devices and installations

Knowledge and training in the installation and commissioning of electrical devices, especially those associated with

PV systems

Knowledge and training of and compliance with this document and all safety information

Knowledge of warranty terms and conditions associated with the product described in this document

"Qualified Person" means he/she is validly licensed from the local authority in:

Safely and properly installing electrical equipment and PV power systems

Safely and properly applying all applicable installation codes in practice

Properly analyzing and minimizing the hazards in performing electrical work and finished works for all persons

and properties involved

Properly selecting and using Personal Protective Equipment (PPE)

End Users

End users can be referred to any who intend to use the product described in these documents, and must avoid

performing tasks marked in this document with requirement for qualified persons.

End users should use this document for a comprehensive understanding of general features and functions involved in the

product, and as a guideline for performing tasks that do not require particular qualifications independently.

DO NOT put this product in use unless it has been successfully installed and commissioned by a qualified person

following described requirements and steps in the section of Installation and Commissioning as well as all applicable

laws and safety regulations.

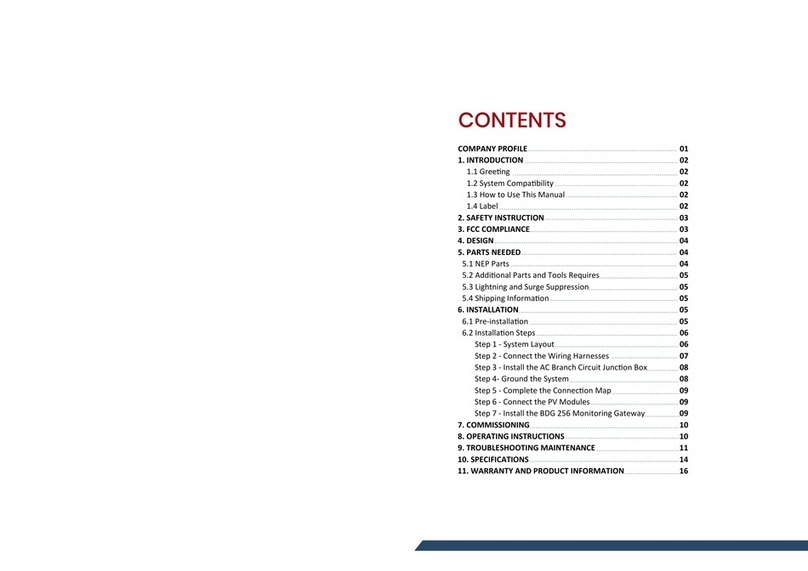

Content and Structure

This document describes the unpacking, mounting, installation, commissioning, startup, operation, troubleshooting,

maintenance, as well as the disconnection of the produc. Applicable inverter models are listed below:

BDM-600

BDM-600X

BDM-300X2

BDM-600WIFI

This document, as well as any data, images and illustrations included herein, are reduced to the essential information for

the user’s guidance, and therefore deviate from the real product. Update of this document may not be announced.

For the latest version of this document and further information on the described product, please visit website at

northernep.com.

For technical problems concerning the products in this document and requiring assistance, please refer to CONTACT.

Copyright © 2021 Northern Electric Power Co,. Ltd.. All rights reserved.

Warning Messages

The following warning messages are used in this document, and should be familiarized before installation or operation of

the product.

Failure to follow may result in injury, damage to properties, or a fatal event.

DANGER denotes a hazardous situation which, if not avoided, will result in death or severe injury.

WARNING denotes a hazardous situation which, if not avoided, can result in death or severe or moderate injury.

CAUTION denotes a hazardous situation which, if not avoided, can result in moderate or minor injury.

NOTICE denotes a situation which, if not avoided, that can result in property damage

FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential

installation. This equipment generates uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

● Reorient or relocate the receiving antenna.

● Increase the separation between the equipment and the receiver.

● Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

● Consult the dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for compliance may void the user’s authority

to operate the equipment.

SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

Users of these documents are cautioned to familiarize themselves with safety instructions contained in this section and

observe at all time when working.

Users are reminded that all electrical or electronic devices come with residual risks despite compliance with international

safety requirements and careful construction. To prevent injury and property damage, and to ensure long-term operation

of the product, please adhere to all applicable safety instructions in handling and usage of the product.

Danger to life due to electrical shock when live components are touched in opened product

High voltages and energies are present in live components and cables inside the product during operation, e.g.

capacitors, connectors. Touching live components and cables may result in death or severe injuries due to electric

shock.

DO NOT open the product.

DO NOT touch live components.

Danger to life due to electrical shock when live DC cables or components are touched

High DC voltages are present in the DC cables when PV modules are exposed to light. Touching live DC cables or

components may result in death or severe injuries due to electric shock.

DO NOT touch non-insulated parts or cables.

DO NOT touch live components when voltage sources are still connected or just disconnected.

DO NOT connect DC connectors to the product under load.

Personal protective equipment MUST be worn suitably and properly for all work on the product and the

system.

Voltage sources MUST be disconnected from the product before all work.

Danger to life due to electrical shock in case of over-voltages and missing surge protections

Over-voltages may conduct into other properties (e.g. electrical network of the building, connected devices via

network cables or data cables) in the event of a flash or lightning strike when there is no surge protection integrated

in the system. Touching live product, components and cables may result in death or severe injuries due to electric

shock.

Within the same electrical system and network, make sure all devices are integrated in the range of existing

over-voltage protection.

Integrate suitable surge protection to the transition from any cables, products or conductive component within

the system that are laid outdoor to the indoor system.

Danger to life due to electrical shock from touching ungrounded components or from touching live

components in case of a ground fault

Touching ungrounded PV modules, array frame, inverter or live system component, or parts of the system

components that are still live in the event of a ground fault, may result in death or severe injuries due to electric

shock.

PV modules and the array frames, including electrically conductive surfaces, MUST be connected and grounded

in compliance with all applicable regulations.

In the event of a ground fault,

DO NOT touch any parts or frame of the PV array.

DO NOT touch any cables without reliable insulation.

DO NOT connect the product to any strings with ground faults.

Before working on the product, voltage resources MUST be disconnected.

Personal protective equipment MUST be worn suitably and properly for all work.

Risk of Injury from exposure to substances, gases and dusts

In rare cases, damaged electrical components can cause formation of toxic chemicals inside the inverter, in such

presence of substances, gases or dusts. Exposure or inhaling such chemical may result in poisoning, skin irritation

or burns, breathing difficulty and nausea.

Personal protective equipment MUST be worn suitably and properly for all work.

Danger to life due to fire or explosion

In rare cases, operating under fault conditions may generate gas mixture inside any electrical devices, that can be

explosive or inflammable while switching operational state (e.g. switching the product ON/OFF in a ground fault

event). Flying debris from the fire or explosion may result in death or severe injuries.

DO NOT work the DC Switch on the product in the event of ground fault.

Before working on the product, voltage resources MUST be disconnected and fully de-energized.

PV arrays MUST be disconnected using a disconnection device instead of bare hands.

AC circuit breaker (if any) MUST be disconnected.

Risk of injury and property damage due to inappropriate modifications or technical specifications

Modifications or alterations to the product and its connected system are not allowed unless with written permission

of NEP. Unauthorized modifications may cause incompliance with product's technical requirement (e.g. maximum

input voltage or current), that may result in moderate or minor injuries, and property damages.

Any guarantee and warranty claims in such cases will be voided.

Risk of injury due to hot enclosures

Touching parts of product enclosure that may get hot during operation (e.g. heatsink) and may result in burn

injuries.

DO NOT touch any parts other than the cover lid of the product.

Before working on the product, voltage resources MUST be disconnected, and leave the product to cool down

for 30 minutes.

Risk of injury due to weight of product

Lifting the product incorrectly or dropping in transportation or mounting may result in injuries like bruises or muscle

strains.

Make sure to take the weight of product into account in transportation and lifting, and proceed carefully.

To avoid muscle strain or injury, please use proper lifting techniques and any necessary aid/tools.

Personal protective equipment MUST be worn suitably and properly for all work.

Damage to product and property due to wrong output type

The product described in this document is designed to directly tie with and feed power into public utility power grid.

Connecting the product in any other forms of AC output source or equipment may result in product and property

damage.

DO NOT connect AC output of the product to any other sources than the utility grid, which will otherwise void

any guarantees and warranty claims.

Damage to product due to aggressive cleaning agents

For purpose of cleaning, using aggressive chemicals and cleaning agents may cause damage to the product and

components.

Use a wet cloth with clear water to clean the product.

The product must ONLY be connected and operated with PV arrays of protection class II, in accordance with IEC

61730, application class A. The PV modules must also be compatible with this product. Power sources other than

compatible PV arrays MUST not be connected and operate with the product.

The term “danger” describes an issue which, if ignored can cause personal injury.

With the term “attention” a circumstance is listed which may cause property damage if disregarded.

Under “Instructions for Use“, it is pointed out that installation and operating instructions are to be read and

understood before installation or repair.

Under “Caution, hot surface”, it should be noted that surfaces of equipment may be hot and create a burn

hazard.

With “Note Separate Disposal”, it is pointed out that this product may not be disposed of with normal

garbage. An improperly conducted disposal can lead to damage to the environment.

The product complies with essential requirements of relevant directives of EU

INFO denotes information that is important but non safety-relevant for a task or topic.

Label is located on the side of the inverter. The information on the label includes technical data as well as type and serial

number of the device. Safety instructions are listed and explained below:

Danger!

Attention!

Instructions for use!

Caution, hot surface!

Special disposal instructions!

CE mark

INSTALLING THE PRODUCT

Safety

Danger to life due to fire or explosion

All electrical devices can cause fires despite careful construction. Flying debris from the fire or explosion may result

in death or severe injuries.

DO NOT install the product in environment with any flammable materials or gases.

DO NOT install the product in environment with any potentially explosive items or gases.

Risk of injury due to weight of product

Lifting the product incorrectly or dropping in transportation or mounting may result in injuries like bruises or muscle

strains.

Make sure to take the weight of product into account in transportation and lifting, and proceed carefully.

To avoid muscle strain or injury, please use proper lifting techniques and any necessary aid/tools.

Personal protective equipment MUST be worn suitably and properly for all work.

Risk of injury due to cables routed in wall

Drilling holes on a wall may damage power cables or pipes for gas or water routed inside.

Make sure to take cables or pipes into account before drilling.

Personal protective equipment MUST be worn suitably and properly for all work.

Risk of shortened product lifespan due to inappropriate installation environment

Installing the product in an inappropriate environment may risk shortening its lifespan. To ensure optimal

performance and operation, please:

DO NOT install the product in exposure to direct sunlight.

DO NOT install the product in exposure to rain and snow.

DO NOT install the product in exposure to splash of salt water.

Make sure the installation site meets ventilation requirement of the product.

The pollution degree of the external environment for NEP's inverters is PD3.

Pollution Degree 3 indicates:

Conductive pollution occurs, or dry, non-conductive pollution occurs which becomes conductive due to

condensation which is expected.

Lightning Surge Suppression

Lightning does not actually need to strike the equipment or building where PV system is installed to cause damage.

Often, a strike nearby will induce voltage spikes in the electrical grid that can damage equipment. BDM-600 has

integrated surge protection, greater than most string inverters. However, if the surge has sufficient energy, the

protection built into the BDM-600 can be exceeded, and the equipment can be damaged.

Since the NEP Limited Warranty does not cover “acts of God” such as lightning strikes, and since lightning strikes can

occur anywhere, it is best practice to install surge protection as part of any solar installation. Installation of surge

protection devices should follow vendor instructions.

Parts required

In addition to the micro inverters, PV modules, racking, and associated hardware, you’ll need the BDM-600 installation kit.

This kit includes the following items:

Protective end cap Male

Mounting Bracket (adapter plate)

Other Parts and Tools Required

In addition to your PV array and its associated hardware, you will need the following parts:

Junction box

Sockets, wrenches for mounting hardware

Procedure of Mounting

1. Measuring service and installing the AC branch circuit junction box.

ONLY USE ELECTRICAL SYSTEM COMPONENTS APPROVED FOR WET LOCATIONS.

2. Attaching the BDM-600 Micro inverter to the racking.

3. Connecting the BDM-600 Micro inverter wiring harnesses.

4. Grounding the system (optional).

DC circuits of BDM-600 are isolated and insulated from ground. An integrated ground protection circuit is included

in the micro inverter.

5. Completing the BDM-600 Micro inverter installation map and connecting the PV modules.

The finished system should be similar as in the diagram.

To only install one inverter or BALCONY SOLUTION

Please follow the sign

L1 to L2 230 Vac

L1 to L2 230 Vac

CONNECTING THE PRODUCT

Safety: Electrical Connections

Danger to life due to electric shock

DO NOT touch any live component.

TO prevent risk of electric shock during installation and maintenance, please make sure that the AC and DC inputs

are plugged out. DO NOT stay close to the instruments while there is severe weather conditions including storm,

lightening etc.

AC Connection

STEP 1 - Install the AC Branch Circuit Junction Box

Measure service entrance conductors to confirm AC service at the site. Acceptable ranges are differ according to local grid

parameter, specifics are shown in the table below:

L1 to L2 240 Vac

L1 to L2 208 Vac

North America

240 Volt AC Single Phase

208 Volt AC Three Phase

Australia and New Zealand

Europe

Mount the adapter plate at a suitable location on the PV racking system (typically at the end of a row of modules).

Install an appropriate junction box with the adapter plate.

Connect the open wire end of the AC interconnect cable into the junction box using an appropriate gland or strain relief

fitting. The AC interconnect cable requires a strain relief connector with an opening of 3/8 inches in diameter.

STEP 2 - Attach product to the Racking

Mark the approximate centers of each PV module on the racking system. Evaluate the location of the micro inverter with

respect to the PV module junction box or any other obstructions.

ALLOW A MINIMUM OF .75 INCHES BETWEEN THE TOP OF THE ROOF AND THE BOTTOM OF BDM-600. WE ALSO

RECOMMEND THAT YOU ALLOW .50 INCHES BETWEEN THE BACK OF THE PV MODULE AND THE TOP OF BDM-600.

DO NOT MOUNT BDM-600 IN A LOCATION THAT ALLOWS LONG-TERM EXPOSURE TO DIRECT SUNLIGHT.

Mount one micro inverter at each of these locations using hardware recommended by your module racking vendor

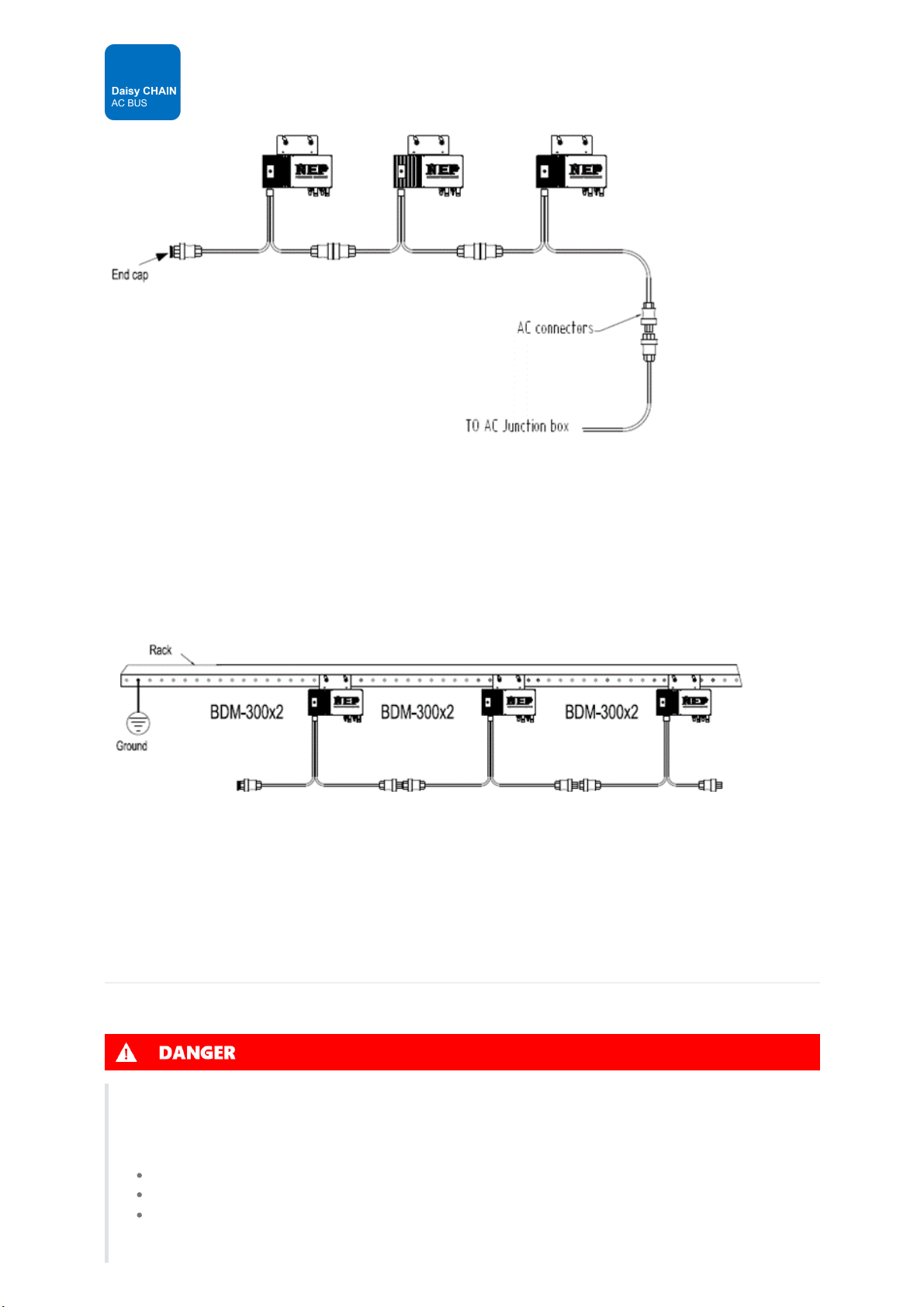

STEP 3 - Inter-connect Micro inverters into branch

Each BDM-600 comes with two AC output cable with oppositely sexed connectors at the end. Plug the AC connector of the

each BDM-600 into the connector of neighbored micro inverter to form a continuous AC branch circuit. Please check the

rating label of the trunk cable for the maximum allowable number of BDM-600 on one AC branch circuit.

DO NOT EXCEED THE MAXIMUM NUMBER OF BDM-600 IN AN AC BRANCH CIRCUIT, AS DISPLAYED ON THE UNIT-

RATING LABEL. For 12AWG trunk cable, EACH BDM-600 AC BRANCH CIRCUIT MUST BE SOURCED FROM A

DEDICATED BRANCH CIRCUIT PROTECTED BY A 20A MAXIMUM BREAKER.

Install a protective end cap on the open AC connector at the end of the branch.

NEP micro inverters are designed to be able to inter-connect with other NEP models.

MAKE SURE PROTECTIVE END CAPS HAVE BEEN INSTALLED ON ALL UNUSED AC CONNECTORS. UNUSED AC BDM-

600 WIRE HARNESS CONNECTORS ARE LIVE WHEN THE SYSTEM IS ENERGIZED BY THE UTILITY SYSTEM.

Typical Balcony Solution Topology

For balcony solution, there is only one inverter in the system. The monitoring is realized by WIFI connection between

WiFi dongle on the inverter and home router.

Typical Daisy Chain AC BUS Topology

STEP 4 – Ground the system

Each BDM-600 has an integrated ground protection circuit. The grounding wire is through the trunk cable, and should be

securely connected to the ground connector in the junction box.

STEP 5 - Ground the system through racking (option)

BDM-600 may also be grounded through the racking as shown below.

STEP 6 - Complete the connection map and connect the PV Modules

BDM-600 connection Map is a diagrammatic representation of the physical location of each BDM-600 in your PV

installation. The virtual array in NEP micro inverter gateway BDG-256 is created from the map you create.

Each BDM-600 has a removable serial number label located on the mounting plate. Enter this serial number into the BDG-

256, and correspond it to a number in the connection map.

DC Connection

Safety: Connecting DC

Danger to life due to electrical shock when live DC cables or components are touched

High DC voltages are present in the DC cables when PV modules are exposed to light. Touching live DC cables or

components may result in death or severe injuries due to electric shock.

DO NOT touch non-insulated parts or cables.

DO NOT touch live components when voltage sources are still connected or just disconnected.

DO NOT connect DC connectors to the product under load.

### DC Connection Procedure

Personal protective equipment MUST be worn suitably and properly for all work on the product and the

system.

Voltage sources MUST be disconnected from the product before all work.

Danger to life due to electrical shock from touching ungrounded components or from touching live

components in case of a ground fault

Touching ungrounded PV modules, array frame, inverter or live system component, or parts of the system

components that are still live in the event of a ground fault, may result in death or severe injuries due to electric

shock.

PV modules and the array frames, including electrically conductive surfaces, MUST be connected and grounded

in compliance with all applicable regulations.

In the event of a ground fault,

DO NOT touch any parts or frame of the PV array.

DO NOT touch any cables without reliable insulation.

DO NOT connect the product to any strings with ground faults.

Before working on the product, voltage resources MUST be disconnected.

Personal protective equipment MUST be worn suitably and properly for all work.

Risk of injury and property damage

In connection of DC cables to the inverter, maximum input current and voltage MUST not exceed permitted range

as stated in Product Parameters.

Any guarantee and warranty claims in such cases will be voided.

Requirements for PV Modules

All PV modules of connected arrays should be of the same type.

All PV modules of connected arrays should be aligned properly and tilted identically.

DO NOT parallel modules in one string of DC input.

In connection of each independent MPPT, PV arrays in parallel connection should have the same number of

modules.

Max. input voltage and current per string

For connection of PV modules to the inverter, all PV modules MUST be fitted with the supplied DC connectors.

When assembling the DC connectors, cables MUST be equipped with DC connectors of the correct polarity.

e.g. [positive] connection cable to [positive] DC connectors, [negative] connection cable to [negative] DC

connectors.

Before connecting the PV modules to the inverter, the inverter's DC switch MUST be switched OFF.

The DC input voltage AND DC input current of the PV array MUST never exceed the maximum input voltage and

current of the inverter.

Completely install all BDM-600 and all system inter-wiring connections prior to installing the PV modules.

1. Mount the PV modules above their corresponding BDM-600. Each BDM-600 comes with two oppositely sexed DC

connectors.

2. First connect the positive DC wire from the PV module to the negatively marked DC connector (male pin) of the BDM-

600. Then connect the negative DC wire from the PV module to the positively marked DC connector (female socket)

of the BDM-600. Repeat for all remaining PV modules using one BDM-600 for each module.

Removing DC

Safety: Disconnection

Danger to life due to electrical shock when live components are touched in opened product

High voltages and energies are present in live components and cables inside the product during operation, e.g.

capacitors, connectors. Touching live components and cables may result in death or severe injuries due to electric

shock.

DO NOT open the product.

DO NOT touch live components.

The product MUST ONLY be opened for maintenance reasons by a qualified person, after

both DC and AC switches or isolators, if any, externally connected or integrated, are switched to OFF

both DC and AC connections are plugged out

voltages inside the product are fully discharged

Danger to life due to electrical shock when live DC cables or components are touched

High DC voltages are present in the DC cables when PV modules are exposed to light. Touching live DC cables or

components may result in death or severe injuries due to electric shock.

DO NOT touch non-insulated parts or cables.

DO NOT touch live components when voltage sources are still connected or just disconnected.

DO NOT connect DC connectors to the product under load.

Personal protective equipment MUST be worn suitably and properly for all work on the product and the

system.

Voltage sources MUST be disconnected from the product before all work.

Risk of injury due to weight of product

Lifting the product incorrectly or dropping in transportation or mounting may result in injuries like bruises or muscle

strains.

Make sure to take the weight of product into account in transportation and lifting, and proceed carefully.

To avoid muscle strain or injury, please use proper lifting techniques and any necessary aid/tools.

Personal protective equipment MUST be worn suitably and properly for all work.

Procedure of Disconnecting

Before any work on the disconnection of the inverter, ALWAYS disconnect it from all voltage sources in the described

sequence as following.

1. Disconnect the AC by opening the branch circuit breaker.

2. Disconnect the first AC connector in the branch circuit.

3. Cover the module with an opaque cover.

4. Using a DC current probe, verify there is no current flowing in the DC wires between the PV module and the BDM-

600.

5. Care should be taken when measuring DC currents, most clamp-on meters must be zeroed first and tend to drift

with time.

Do not pull on the cable.

Instead, use the disassembly tool for PV connectors at the point of interconnection of female and male

connectors.

Pull out the connectors in a downward direction.

6. Use a suitable measuring device to ensure that no voltage is left at the DC inputs of the inverter.

7. Disconnect the PV module DC wire connectors from the BDM-600.

8. Remove the BDM-600 from the PV array racking.

9. Use a suitable measuring device to ensure that no voltage is left at the AC inputs.

Measure the voltage by inserting the probe to the opening of each terminal.

Check the voltages between L and N, and between L and PE.

10. If necessary, remove the M5 screw securing the inverter to mounting bracket. Lift the inverter from the mounting

bracket.

Dispose of the inverter should be in accordance with disposal regulations for electronic waste. Refer to Recycling and

Disposal.

Re-install micro inverter

1. Attach the replacement BDM-600 to the PV module racking using hardware recommended by your module racking

vendor

2. Connect the AC cable of the replacement BDM-600 and the neighboring BDM-600 to complete the branch circuit

connections.

3. Complete the connection map and connect the PV Modules.

1. Complete the connection map

2. Each BDM-600 has a removable serial number located on the mounting plate. Enter this serial number into a

BDG-256, and correspond it to a number in the connection map.

3. Connect the PV Modules

4. Completely install all BDM-600 and all system inter-wiring connections prior to installing the PV modules.

1. Mount the PV modules above their corresponding BDM-600. Each BDM-600 comes with two oppositely

sexed DC connectors.

2. First connect the positive DC wire from the PV module to the negatively marked DC connector (male pin) of

the BDM-600. Then connect the negative DC wire from the PV module to the positively marked DC

connector (female socket) of the BDM-600. Repeat for all remaining PV modules using one BDM-600 for

each module.

4. Replace the old PLC_ID in the BDG-256 gateway with the new PLC_ID of the replacement micro inverter.

This manual suits for next models

3

Table of contents

Other NEP Inverter manuals

Popular Inverter manuals by other brands

Westerbeke

Westerbeke 8 BCDT-614 Specifications

Lenze

Lenze EVS 9300 series System manual

Generac Power Systems

Generac Power Systems 7 kW NG Repair manual

Tektronix

Tektronix TLA715 Series instructions

Champion Power Equipment

Champion Power Equipment 100319 owner's manual

ECTIVE

ECTIVE MI Series Installation and operating instructions