NEP BDM-500 User manual

SAA

152167

l

USA

Address: 2570 N. First Street, Suite 200, San Jose, CA 95131

TEL: +1 888-598-9901

Japan

Address: 812-0011福岡市博多区博多駅前 3-10-24 藤井ビル 1F

TEL: +81 092-433-3252

FAX: +81 092-433-3171

China

Address: No.1 Anhe Rd Tsingtao Export Processing Zone, Tsingtao, China 266113

TEL: +86 532 87963900

FAX: +86 532 81100917

Email:info@northernep.com

Web: hp://www.northernep.com

hp://www.nep-japan.com

hp://www.micro-inverter.jp

Rev. 2017-01-12

Dual Module Macroinverter

BDM-500

Installation and Operation Manual

COMPANY PROFILE

01

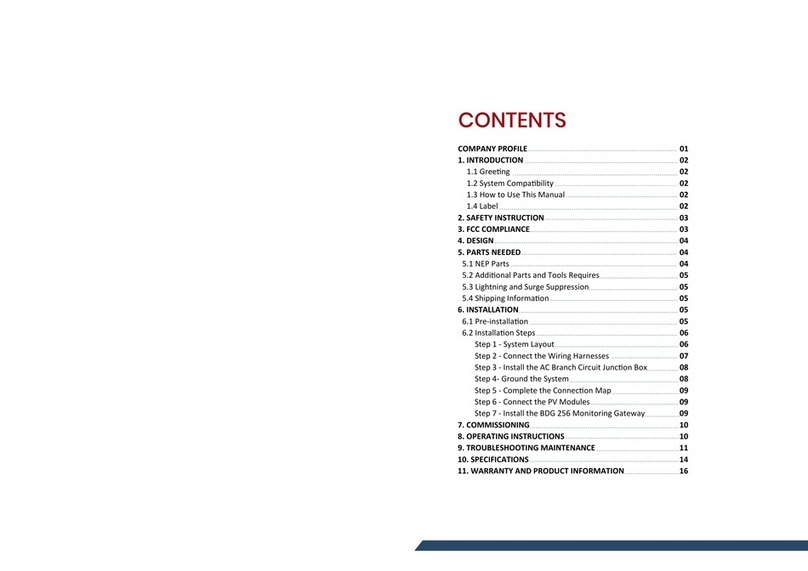

1. I NTRODUCTION

02

1.1 Greeting

02

1.2 System Compatibility

02

1.3 How to Use This Manual

02

1.4 Label

02

2. SAFETY INSTRUCTION

03

3. FCC COMPLIANCE

03

4. DESIGN

04

5. PARTS NEEDED

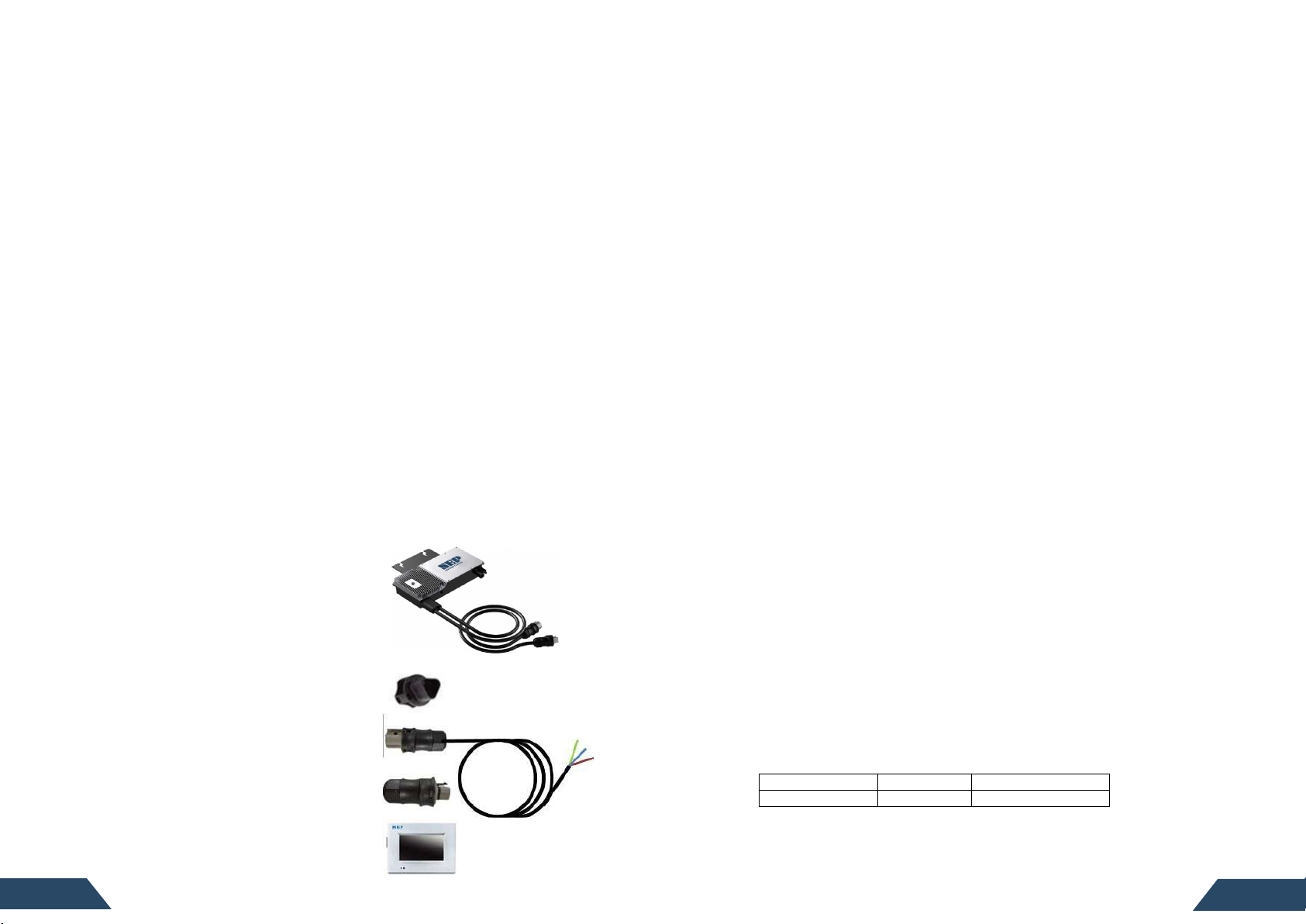

04

5.1 NEP Parts

04

5.2 Additional Parts and Tools Requires

05

5.3 Lightning and Surge Suppression

05

5.4 Shipping Information

05

6. INSTALLATION

05

6.1 Pre-installation

05

6.2 Installation Steps

06

Step 1 - System Layout

06

Step 2 - Connect theWiring Harnesses

07

Step 3 - Install the AC Branch Circuit Junction Box

08

Step 4- Ground the System 08

Step 5 - Complete the Connection Map

09

Step 6 - Connect the PV Modules

09

Step 7 - Install the BDG 256 Monitoring Gateway

09

7. COMMISSIONING 10

8. OPERATING INSTRUCTIONS 10

9. TROUBL ESHOOTING MAINTENANCE 11

10 . SPECIFICATIONS 14

11. WARRANTY AND PRODUCT INFORMATION 16

CONTENTS

0 1

COMPANY PROFILE

Northern Electric & Power Inc. (NEP) is an internaonal supplier of cung-edge clean

energy technologies headquartered in the United States.The company maintains facilies

both here and abroad, including a more than18 acre site in the Tsingtao Export Processing

Zone and has more than 650,000 square feet of building space.

The company’s founders are well-known experts in the elds of power electronics,

automa control, signal processing, and communicaons; each holding mulple U.S. and

world patents in their specialty areas.

NEP has a complete product line of grid-ed solar inverters, including 180W~600W micro

inverters, 1.5kW~5kW single phase solar inverters, 10kW~500kW three-phase solar

inverters, and rapid shutdown devices. Field deployment results demonstrated high system

eency and reliability of NEP solar inverters.

NEP is commied to develop Clean, Reliable, Affordable and Efficient (CARE) products for

worldwide customers to aid in the transion to a green economy.

03

1. INTRODUCTION

1.1 Greeting

Thank you for choosing the BDM-500 micro inverter from NEP. This product will

maximize your inversion benet with the minimal amount of design and

installaon complexity. This document should provide you with all of the

necessary steps to correctly install the NEP-500 dual module micro inverter in

sites located in North America. However, should you have addional quesons

please contact NEP’s technical representave at support@northernep.com.

1.2 System Compatibility

The BDM-500 is designed to support either one or two 60 or 72 cell modules in

grid-ed PV system consists of PV panels, grid-ed inverter and juncon boxes.

The DC output from the PV panels is converted into AC energy and fedback to the

grid through the BDM-500. The BDM-500 also provides eecve an-islanding

isolaon between the PV module and AC grid output.

1.3 How to Use This Manual

This manual provides detailed product informaon and installaon instrucons

for the BDM-500micro solar inverter. Please read through this manual before

installaon and operaon.

WARNING:This indicates a situaon where failure to follow instrucons

may be a safety hazard or cause equipment malfuncon. Use extreme cauon

and follow instrucons carefully.

1.4 Label

A label is located on the side of the inverter which includes technical data as well

as type and serial number of the device. Safety instrucons are listed and

explained below:

Danger!

The term “danger” describes an issue which, if ignored can cause

personal injury.

Aenon!

With the term “aenon” a circumstance is listed which may

cause property damage if disregarded.

Instrucons for use!

Under “Instrucons for Use“, it is pointed out that installaon and

operang instrucons are to be read and understood before

installaon or repair.

Cauon, hot surface!

Under “Cauon, hot surface”, it should be noted that surfaces of

equipment may be hot and create a burn hazard.

Special disposal instrucons!

With “Note Separate Disposal”, it is pointed out that this product

may not be disposed of with normal garbage. An improperly

conducted disposal can lead to damage to the environment.

ETL Cercaon

This marks ceres that the product complies with all relevant

UL requirements for sale in North America.

2. SAFETY INSTRUCTION

WARNING:

PLEASE READ THIS MANUAL PRIOR TO INSTALLATION. PRODUCT DAMAGE RESULTING FROM FAILURE

TOFOLLOW THIS MANUAL IS NOT COVERED BY THE WARRANTEE.

INSTALLATIONS SHOULD BE DONE ONLY BY CERTIFIED ELECTRICIANS.

NOTHING INSIDE THE INVERTER SHOULD BE MODIFIED

ONLY NEP APPROVED CABLING SHOULD BE USED TO CONNECT MICROINVERTERS

ALL INSTALLATIONS SHOULD FOLLOW THE LOCAL ELECTRICAL CODES. ADDITIONAL PROTECTION FOR THE AC

WIRING FROM THE INVERTERS SHOULD BE PROVIDED AND MAY BE REQUIRED BY LOCAL AND NATIONAL WIRING

REGULATIONS. THIS PROTECTION IS LIKELY TO INCLUDE RESIDUAL CURRENT DEVICES, EARTH FAULT MONITORS

AND CIRCUIT BREAKERS. THIS PRODUCT MAY CAUSE AC CURRENT WITH A DC COMPONENT. IF A RESIDUAL

CURRENT-OPERATED PROTECTIVE DEVICE (RCD) OR A MONITORING DEVICE (RCM) IS USED FOR PROTECTION IN

CASE OF DIRECT OR INDIRECT CONTACT, ONLY AN RCD OR RCM OF TYPE B IS ALLOWED ON THE AC SIDE OF THIS

PRODUCT.

NEVER DISCONNECT THE PV MODULES FROM THE MICRO-INVERTER WITHOUT FIRST ISOLATING THE AC MAINS.

ALL PV AND AC CONNECTORS ARE NOT TO BE DISCONNECTED UNDER LOAD. THE AC BRANCH CIRCUIT BREAKERS

MUST BE FIRST SWITCHED OFF.

PLEASE CONTACT AUTHORIZED SERVICE AGENTS FOR ANY SERVICE WORK.

BDM-500 IS A GRID-TIED SOLAR INVERTER. IT MAY REQUIRE APPROVAL FROM THE LOCAL UTILITY COMPANY

PRIOR TO CONNECTION TO THE POWER GRID.

THE BDM-500 DOES NOT INCLUDE ANY USER SERVICABLE COMPONENTS.

WARNING: THE PV ARRAY SUPPLIES A DC VOLTAGE TO THE MICROINVERTER WHEN EXPOSED TO

LIGHT.

3. FCC COMPLIANCE

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable

protecon against harmful interference in a residenal installaon. This equipment generates

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instrucons, may cause harmful interference to radio communicaons. However, there is

no guarantee that interference will not occur in a parular installaon. If this equipment

does cause harmful interference to radio or television recepon, which can be determined by

turning the equipment oand on, the user is encouraged to try to correct the interference by

one or more of the following measures:

●Reorient or relocate the receiving antenna.

●Increase the separaon between the equipment and the receiver.

●Connect the equipment into an outlet on a circuit dierent from that to

which the receiver is connected.

●Consult the dealer or an experienced radio/TV technician for help.

Changes or modiaons not expressly approved by the party responsible for compliance may

void the user’s authority to operate the equipment.

0 2

05

0 4

11111111

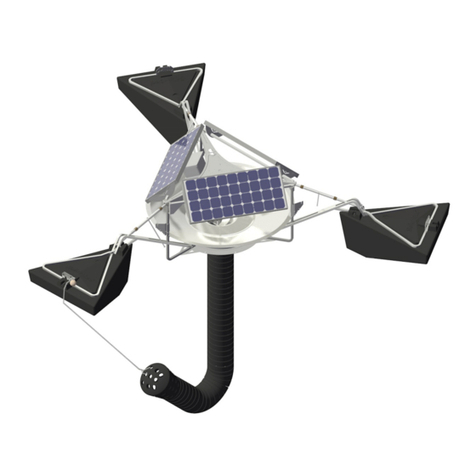

4. DESIGN

Microinverter technology greatly simplies the design process compared to

convenonal string inverter systems. The BD-500 allows for the PV modules to be

placed with dierent azimuths and orientaons to maximize site generaon. In

addion to the layout conguraon, a successful design needs to take into account

two other consideraons: branch circuit sizing and voltage rise calculaon.

Layout: Since the BD-500 is a single input device. A layout map showing the

locaon of each PV module and its corresponding microinverter should be rst

constructed. Care should be taken to review the DC lead length of the PV modules

to see if addional jumpers are required to reach the DC input of the BD-500. Each

microinverter comes with a number of peelable serial number skers. Remove a

sker and aach them to the corresponding modules on the site map.

Branch Circuit Sizing: Since the BD-500 uses #12 AWG cabling, NEC code species a

maximum breaker size of 20A. This limits the branch size to a maximum of seven

(7) devices for a 240V system and six (6) devices for a 208V system.

Voltage Rise Calcula�on: The addion of daisy chained, current producing

microinverters on the AC bus results in a sequenal rise in voltage along the bus,

with the highest at the furthest device. Care must be taken that the resulng

voltage doesn’t exceed the maximum permissible by code. For a 240 V system, this

is 264V and 229V for a 208V system. Please contact NEP technical support should

you need more informaon on this subject.

5. PARTS NEEDED

5.1 NEP Parts

You will need the following parts from NEP:

●Microinverters (one per every 2 modules)

●Protecve end cap (one per branch circuit)

●Tail cable (one per branch circuit- 16’ long)

●Male connector (oponal)

Used to make extension cables

●BDG-256 (or BDG-256P3)

5.2 Additional Parts and Tools Required

In addion to the PV modules, racking, and associated hardware, you’ll need the

following parts:

MLPE rail or frame aach clamps (2 per microinverter)

• AC juncon boxes (mulple opons possible)

• Cordgrip with locknut or strain relief ng (one per branch circuit)

• A subpanel may be required for systems with mulple branch circuits

• Cable clips

• Sockets, wrenches, torque wrench, mulmeter, small at head screwdriver,

and mirror with extension rod

• Lightning and surge suppressor (recommended)

5.3 Lightning and Surge Suppression

Since the NEP Limited Warranty does not cover “acts of God”, such as lightning

strikes or grid irregularies, NEP strongly recommends inclusion of a surge

protecon device in all systems. Lightning does not actually need to strike the

equipment or building where PV system is installedto cause damage. Oen, a

strike nearby will induce voltage spikes in the electrical grid that can damage

equipment. Addionally, many areas can experience irregularies in electrical

grid that can generate similar voltage spikes. While the BDM-500 includes

integrated surge protecon circuitry, if the surge has suent energy the

protecon circuitry can be exceeded and the equipment can be damaged.

Installaon of a suitable surge protector signicantly increases the protecon

against such events.

5.4 Shipping Information

The BDM-500 Ships six (6) to a box with each box measuring approximately 18” x

13.5” x 16”and weighing 57 lbs. A typical pallet contains 27 boxes.

6. INSTALLATION

6.1 Pre -installation

Prior to installaon, use the mulmeter to check the electrical panel to conrm

the correct service voltage per the below table. If this voltage is too high it can

prevent proper operaon of the microinverters. If this is the case, the uty

should be noed. However, an NEP technical representave may be able to

adjust microinverter operaonal parameters to accommodate the situaon.

Residenal

L1 to L2

240 Vac

Commercial

L1 to L2 to L3

208 Vac

Also, please check all microinverters and cabling for any potenal damage prior

to site deployment. Remember to rst create and bring a copy of the layout

map.This map should show the physical locaon of each BDM-500and their

associated PV modules in your installaon.

5

07

0 6

Step 2 – Connect the Wiring Harnesses

Each BDM-500 comes with an integrated trunk cable to simplify the AC

connecon process. The AC trunk cable includes a male connector on one end

and a female connector at the other end. Plug the male AC connector of the rst

BDM-500 into the connector on the tail cable. Plug the female AC connector of

the rst BDM-500 into the male connector of the next BDM-500(or jumper cable)

and connue this “daisy chain” process to form a connuous AC branch

circuit.Terminate the nal female connector on the last microinverter in the

branch circuit with the protecve cap. The connectors are keyed with a snap lock

pin. A “click” indicates proper mang. Secure the mated connector pairs and any

excess AC cable to the rail or racking using cable clips or wire es

WARNING: DO NOT EXCEED THE MAXIMUM NUMBER OF SEVEN (7) BDM-500s IN A

240V AC BRANCH CIRCUIT (SIX(6) FOR 208V) AND EACH BDM-500 AC BRANCH CIRCUIT

MUST BE SOURCED FROM A 20A MAXIMUM BREAKER.

Install a protecve end cap on the open female AC connector on the last

microinverter at the endof the truck cable.

WARNING: MAKE SURE PROTECTIVE END CAPS HAVE BEEN INSTALLED ON ALL UNUSED

AC CONNECTORS. UNUSED AC BDM-500 WIRE HARNESS CONNECTORSARE LIVE WHEN

THE SYSTEM IS ENERGIZED.

The AC branch circuit should look as pictured below:

7

6.2 Installation Steps

WARNING: CONNECT BDM-500S TO THE ELECTRICAL UTILITY GRID ONLY AFTER RECEIVING

PRIOR APPROVAL FROM THE UTILITY COMPANYAND LOCAL AHJ.

WARNING: BE AWARE THAT ONLY QUALIFIED PERSONNEL CAN CONNECT BDM-500 TO THE

ELECTRICAL UTILITY GRID.

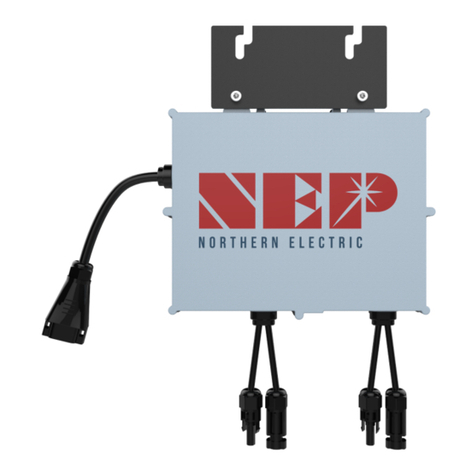

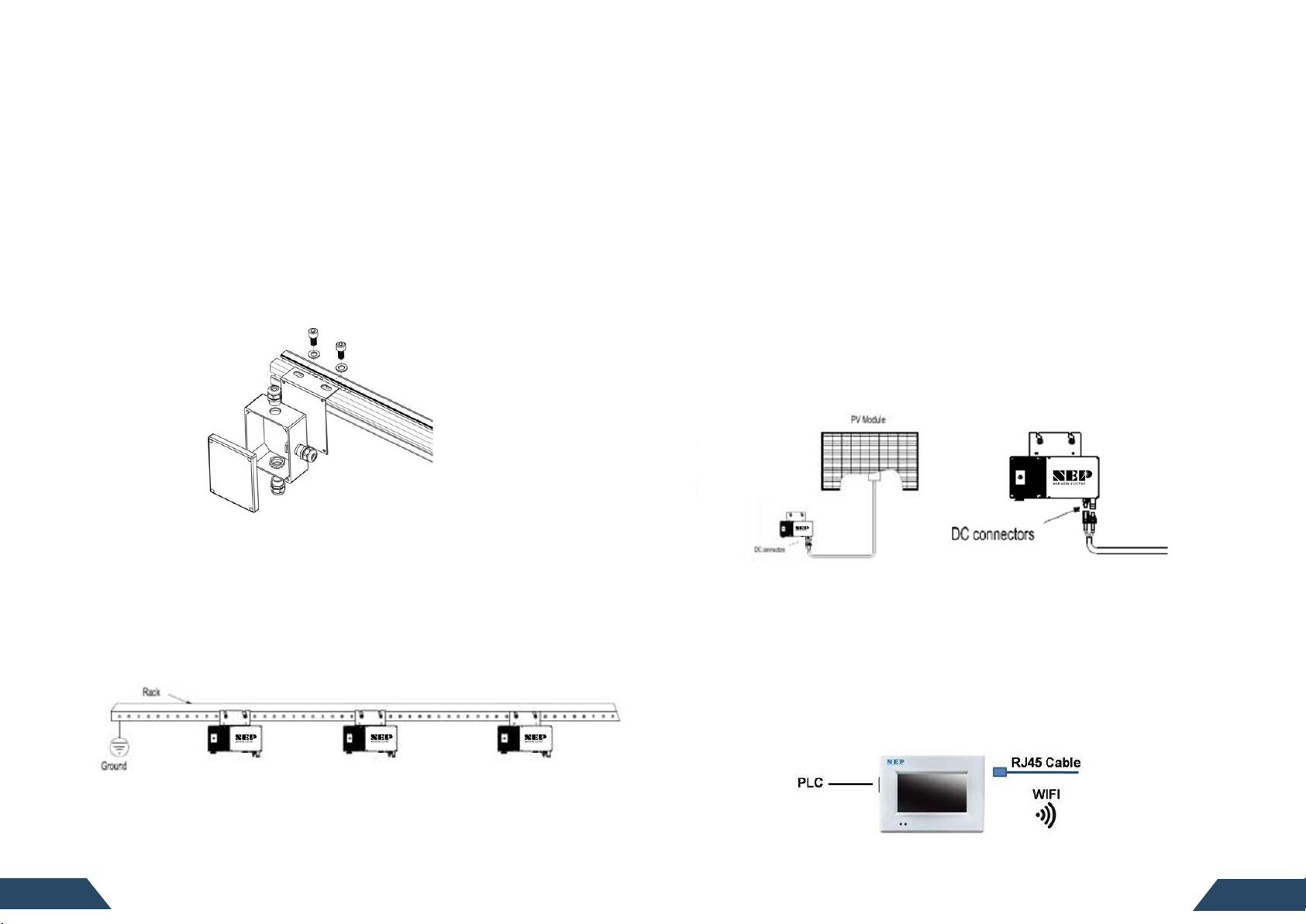

Step 1 – System Layout

Mark the approximate locaon of each pair of PV modules on the racking system.

Place the microinverters at the locaon called out in the layout map and loosely

aach to the rails using the MLPE clamps. Check the reach of all DC and AC

cabling. DC jumpers may be required for some modules. Reposion as needed.

WARNING: ALLOW A MINIMUM OF 2.75 INCHES BOTH BETWEEN THE TOP OF THE ROOF

AND THE BOTTOM OF THE BDM-500 AND BETWEEN THE BACK OF THE PV MODULE AND

THE TOP OF THE BDM-500. DO NOT PLACE THE BDM-500 IN A LOCATION SUBJECT TO

DIRECT SUNLIGHT.

For ground mount, ballasted, or at roof deployments it may be necessary to

aach the microinverters to the racking frame.

Once the nal posion is conrmed, secure the microinverters using the MLPE

clamps and torque per the manufacturer’s speciaons. Typical values are about

12 lbs (16.3 NM).

09

0 8

Step 3 – Install the AC Branch Circuit Junction Box

1. Install an appropriate juncon box on to the mounng plate.

2. Mount the adapter plate at a suitable locaon on the racking or frame. This

is typically near the end of a row of modules.

3. Feed the open wire end of the tail cable into the juncon box and secure with

an appropriate cord grip or strain relief ng. The AC tail cable requires a

strain relief connector with an opening of 3/8” in diameter.

4. Feed the connecng wires from either the main service panel or subpanel (if

mulple branch circuits are deployed) into the juncon box. This is most likely

via metal conduit.

5. Connect L1, L2 and Ground from the branch circuit to their corresponding

connecons from the electrical panel with wire nuts. NEP recommends the

applying sealant to the inside cavity of the wire nuts. Seal the juncon box.

Step 4– Ground the System

Each BDM-500 has an integrated ground protecon circuit.The grounding wire is

through the trunk cable, and should be securely connected to the ground

connector in the juncon box.

Ground the System Through Racking (Option)

BDM-500 may also be grounded through the racking as shown below.

Step 5– Complete the Connection Map

Each BDM-500 has a removable serial number label located on the mounng plate

as well as addional skers included in the microinverter’s protecve bag.

Remove one and ax it to the corresponding locaon on the layout map. Aer

entering this data, the BDM-256 will create a virtual array from the map you create.

Step6– Connect the PV Modules

Connect all AC all system inter-wiring connecons prior to installing the PV

modules.

1. Mount the PV modules in the posions corresponding to their associated

BDM-500 microinverter. Each BDM-500 comes with two sets of oppositely sexed

DC connectors.

2. Connect the posive DC wire from the rst PV module to the negavely marked

DC connector (male pin)on the BDM-500. Then connect the negave DC wire

from the PV module to thepositively marked DC connector (female socket) of the

BDM-500. Next, do the same for the second set of DC connectors from the

second module. Repeat for all remaining PV modules using one BDM-500 for

each set of modules. If the system contains an odd number of modules, it is

acceptable to connect only one PV module to the BDM-500.

Step 7– Install the Monitoring Gateway

The BDG-256 (or BDG-256P3) is a versae gateway that connects each of the

BDM-500 microinverter to the NEP server via the cloud, allowing for collecon of

producon and other data useful in system monitoring and trouble shoong. It is

easily installed either by plugging into an exisng 120V AC interior outlet or by

hardwiring into the 240V service in a suitable protecve enclosure. Connecng to

240V will maximize the strength of the PLC signal, thereby improving

communicaon. The BDG-256P3 is designed to support commercial three phase

systems and should only be located in a protecve enclosure. The gateway then

will connect to the server via either WiFi or direct Ethernet connecon.

Follow the instrucons in the NEP Gateway BDM-256/256P3 Installaon and

Operaons Manualfor speci details on registering the individual microinverters

11

10

7. COMMISSIONING

WARNING: ENSURE THAT ALL ACAND DC WIRING IS CORRECT. ENSURE THAT NONE OF THE

AC AND DC WIRES ARE PINCHED OR DAMAGED AND THAT ALL JUNCTION BOXES ARE

PROPERLY SEALED CLOSE.

Following these steps to commission the BDM-500 PV system:

1. Turn on the circuit breakers for each of the BDM-500 AC branch circuits.

2. Turn on the main service panel uity-grid AC circuit breaker. Your system will start

producing power aer no more than 5 minutes.

3. The BDM-500 will start to send performance data over the power lines using

power line communicaon (PLC) to the BDG-256. The me required for each

BDM-500 in the system to communicate to the BDG-256 will vary with the number

of microinverters in the system. For a typical residenal system data acquision

should take no more than 20-25 minutes.

8. OPERATING INSTRUCTIONS

The BDM-500 begins operaon only aer suent DC voltage from the PV module

is received. At this point the status LED will start ashing.

Status: standby

The LED light toggles on and oat two (2) second intervals

Red:error detected

Orange: no error, but not yet communicang to the BDG-256

Green: no error, and communicang to the BDG-256

Status: producing power

The LED light toggles on and oat one (1) second intervals

Orange: not communicang to the BDG-256

Green: communicang to the BDG-256

11

Status: grounding fault

The LED light is in solid red color.

In case of a fault, the BDM-500 enters a protecve mode and stops outputng

power. The fault message is usually sent to a connected BDG-256 gateway through

the power line communicaon. The error message is then displayed on the screen

of BDG-256 gateway by a 16-bit error code. The table below shows the codes:

Error code Error

Bit-0 DC over voltage

Bit-1 DC under voltage

Bit-2 hardware error

Bit-3 Inverter over voltage

Bit-4 Frequency over

Bit-5 Frequency under

Bit-6 AC voltage RMS over

Bit-7 AC voltage RMS under

Bit-8 Peak AC voltage over

Bit-9 AC current RMS over

Bit-10 Peak AC current over

Bit-11 Temperature over

Bit-12 ADC error

Bit-13 GFDI fault indicator

Bit-14 Relay fault (BDM-250-AU/BDM-250-EU only)

Bit-15 PLC Communicaon Error

9. TROUBLESHOOTING AND MAINTENANCE

WARNING: DO NOT ATTEMPT TO REPAIR THE BDM-500; IT CONTAINS NO

USER-SERVICEABLE PARTS. IF TROUBLESHOOTING METHODS FAIL, PLEASE CONTACT NEP FOR

FURTHER ASSISTANCE.

WARNING: NEVER DISCONNECT THE DC WIRE CONNECTORS UNDER LOAD. ENSURE THAT

NO CURRENT IS FLOWING IN THE DC WIRES PRIOR TO DISCONNECTING. AN OPAQUE

COVERING MAY BE USED TO COVER THE MODULE PRIOR TO DISCONNECTING.

WARNING: BDM-500 IS POWERED BY DC POWER FROM PV MODULES. MAKE SURE YOU

DISCONNECT THE DC CONNECTIONS AND RECONNECT DC POWER TO WATCH FOR THE TWO

SECONDS LED ON/OFF TOGGLE AFTER DC IS APPLIED.

13

12

2

1

WARNING:

ALWAYS DISCONNECT AC POWER BEFORE DISCONNECTING PV MODULE WIRES

FROM THE BDM-500. THE AC CONNECTOR OF THE FIRST BDM-500 IN A BRANCH CIRCUIT IS

SUITABLE AS A DISCONNECTING MEANS ONCE THE AC BRANCH CIRCUIT BREAKER IN THE

LOADCENTER HAS BEEN OPENED.

LED indication of error

•error mode (except for grounding error)

The LED light ashes in red color.

•NOT communicating with BDG-256, and with no error

The LED light ashes in orangecolor.

•grounding fault

The LED light is in solid red color.

Troubleshooting an inoperable BDM -500

To troubleshoot an inoperable BDM-500, follow the steps in the order shown:

1. Check the connecon to the uty grid. Verify that the uty voltage and

frequency are within allowable ranges shown in the label of BDM-500.

2. Verify uty power is present at the inverter in queson by removing AC, then DC

power. Never disconnect the DC wires while the BDM-500 is producing power.

Re-connect the DC module connectors, and then watch for the LED blinks.

3. Check the AC branch circuit interconnecon harness between all the BDM-500.

Verify that each inverter is energized by the uity grid as described in the

previous step.

4. Make sure that any AC disconnects are funconing properly and are closed.

5. Verify the PV module DC voltage is within the allowable range shown in the label

of BDM-500.

6. Check the DC connecons between the BDM-500 and the PV module.

7. PLC signal quality may be checked through the interface on the BDG-256 gateway.

If the PLC signal is weak, it might be due to the distance between the micro

inverters and the gateway. It may also be caused by the interference from other

electronic devices.In most cases, signal quality may be signiantly improved by

moving the BDG-256 to closer to the micro inverter arrays, and/or farther away

from other interferers. In some cases, a signal ter (LCF) may be installed to

reduce the interference to PLC communicaon. If there are two or more

separate BDM systems close by, it is highly recommended to install LCF for each

micro inverter system to block interference from adjacent other systems.

7. If the problem persists, please call customer support at NEP.

WARNING: DO NOT ATTEMPT TO REPAIR THE BDM-500; IT CONTAINS NO

USER-SERVICEABLE PARTS. IF TROUBLESHOOTING METHODS FAIL, PLEASE RETURN THE

BDM-500 TO YOUR DISTRIBUTOR FOR MAINTENANCE.

Disconnecting a BDM-500 from the PV Module

To ensure the BDM-500 is not disconnected from the PV modules under load,

adhere to the following disconnecon steps in the order shown:

1. Disconnect the AC by opening the branch circuit breaker.

2. Disconnect the rst AC connector in the branch circuit.

3. Cover the module with an opaque cover.

4. Using a DC current probe, verify there is no current owing in the DC wires

between the PV module and the BDM-500.

5. Care should be taken when measuring DC currents, most clamp-on meters

must be zeroed rst and tend to driwith me.

6. Disconnect the PV module DC wire connectors from the BDM-500.

7. Remove the BDM-500 from the PV array racking.

Installing a replacement BDM -500

1. Aach the replacement BDM-500 to the PV module racking using hardware

recommended by your module racking vendor in the same locaon as the one

previously removed.

2. Connect the AC cable of the replacement BDM-500 and the neighboring

BDM-500s to complete the branch circuit connecons.

3. Obtain serial number of the replacement BDM-500

Each BDM-500 has a removable serial number located on the mounng

plate and addional skers in the shipping bag.

4. Reconnect the PV Modules.

First connect the posive DC wire from the PV module to the negavely marked

DC connector (male pin) of the BDM-500. Then connect the negave DC wire

from the PV module to theposively marked DC connector (female socket) of the

BDM-500. Repeat for the remaining PV modules.

5. Replace the old PLC ID in the BDG-256 gateway with the new PLC ID of the

newly installed micro inverter.

15

14

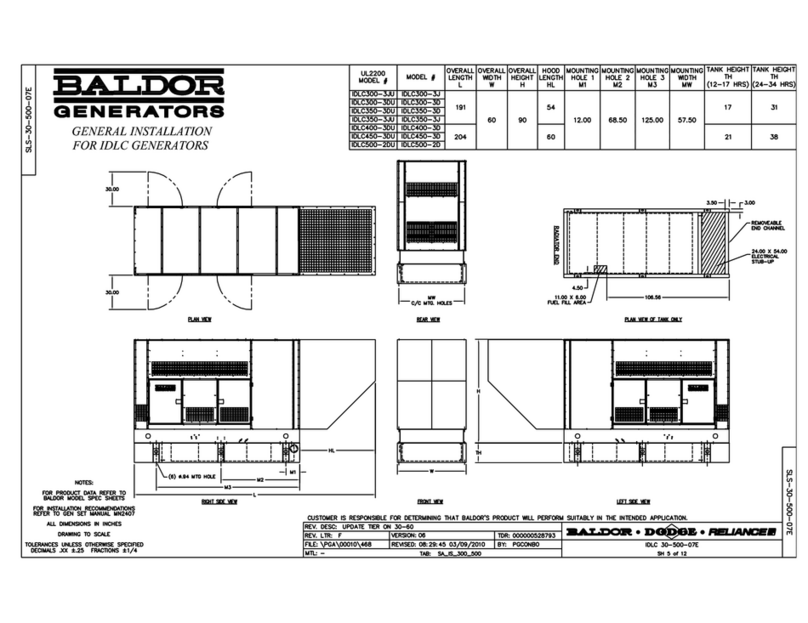

10. SPECIFICATIONS *per IEEE1547A

MODEL BDM-500-240A BDM-500-208A BDM-500

INPUT(DC)

Max Recommended PV Power(Wp) 750 750 750

Max DC Open Circuit Voltage(Vdc) 60 60 60

Max DC Input Current (Adc) 25 25 25

MPPT Tracking Accuracy >99.5% >99.5% >99.5%

MPPT Tracking Range(Vdc) 22-55 22-55 22-55

OUTPUT(AC)

Peak AC Output Power(Wac) 550 550 550

Rated AC Output Power(Wac) 500 500 500

Nominal Power Grid Voltage(Vac) 208 240 230

Allowable Power Grid Voltage(Vac)

183-228 (Adjustable

*

)

211-264 (Adjustable

*

)

180-264 (Adjustable)

Allowable Power Grid Frequency(Hz)

59.3-60.5(Adjustable

*

)

59.3-60.5(Adjustable

*

)

45.5-54.5 (Adjustable)

THD

<3% (at rated power)

<3% (at rated power)

<3% (at rated power)

Power Factor

>0.99 (at rated power)

>0.99 (at rated power)

>0.99 (at rated power)

SYSTEM

EFFICIENCY

CEC Eciency 95.5% 95.5% 95.5%

Night Time Tire Loss(W) 0.11 0.11 0.11

PROTECTION

FUNCTIONS

Over/Under Voltage Protecon Yes Yes Yes

Over/Under Frequency Protecon Yes Yes Yes

An-Islanding Protecon Yes Yes Yes

Over Current Protecon Yes Yes Yes

ReverseDC Polarity Protecon Yes Yes Yes

Overload Protecon Yes Yes Yes

GroundFault Detecon Integrated Integrated Integrated

Protecon Degree NEMA-6 NEMA-6 NEMA-6

Environment Temperature -40

℃

~+65

℃

-40

℃

~+65

℃

-40

℃

~+65

℃

Operang Temperature -40

℃

~ +85

℃

-40

℃

~ +85

℃

-40

℃

~ +85

℃

OTHER

PARAMETERS

Display

LED LIGHT

LED LIGHT

LED LIGHT

Communicaons POWERLINE POWERLINE POWERLINE

Dimension (D-W-H mm) 277*132*50 277*132*50 277*132*50

Weight(Kg) 2.9 2.9 2.9

17

16

7

11 .WARRANTY AND PRODUCT INFOR MATION

What does this warranty cover and how long does it last?

This Limited Warranty is provided by Northern Electric & Power Co. Ltd (NEP) and covers

defects in workmanship and materials in your BDM-500 Grid-Tied Inverter. This Warranty

Period lasts for 10 years from the date of purchase at the point of sale to you, the original

end user customer, unless otherwise agreed in wring. You will be required to demonstrate

proof of purchase to make warranty claims.

This Limited Warranty is transferable to subsequent owners but only for the unexpired

poron of the Warranty Period. Subsequent owners also require original proof of purchase

as described in "What proof of purchase is required?"

What will NEP do?

During the Warranty Period, NEP will, at its opon, repair the product (if economically

feasible) or replace the defecve product free of charge, provided that you nofy NEP of the

product defect within the Warranty Period, and provided that NEP through inspecon

establishes the existence of such a defect and that it is covered by this Limited Warranty.

NEP will, at its opon, use new and/or recondioned parts in performing warranty repair and

building replacement products. NEP reserves the right to use parts or products of original or

improved design in the repair or replacement. NEP repairs or replaces a product, its warranty

connues for the remaining poron of the original Warranty Period or 90 days from the date

of the return shipment to the customer, whichever is greater. All replaced products and all

parts removed from repaired products become the property of NEP.

How do you get service?

If your product requires troubleshoong or warranty service, contact your merchant. If you are

unable to contact your merchant, or the merchant is unable to provide service, contact NEP

directly at:

Northern Electric & Power Inc

Email:supp[email protected]

What does this warranty not cover?

Claims are limited to repair and replacement or if in NEP's discreon that is not possible,

reimbursement up to the purchase price paid for the product. NEP will be liable to you only

for direct damages suered by you and only up to a maximum amount equal to the

purchase price of the product.

This Limited Warranty does not warrant uninterrupted or error-free operaon of the

product or cover normal wear and tear of the product or costs related to the removal,

installaon, or troubleshoong of the customer's electrical systems. This warranty

does not apply to and NEP will not be responsible for any defect in ordamage to: a) the

product if it has been misused, neglected, improperlyinstalled,physically damaged or

altered, either internally or externally, or damaged from improper use or use in an

unsuitable environment; b) the product if it has been subjected to re, water,

generalized corrosion, biological infestaons, or input voltage that creates operang

condions beyond the maximum or minimum limits listed in the NEP product

speciaons including high input voltage from generators and lightning strikes; c) the

product if repairs have been done to it other than by NEP or its authorized service

centers (hereaer "ASCs"); d) the product if it is used as a component part of a product

expressly warranted by another manufacturer; e) the product if its original idenaon

(trade-mark, serial number) markings have been defaced, altered, or removed; f) the

product if it is located outside of the country where it was purchased; and g) any

consequenal losses that are aributable to the product losing power whether by

product malfuncon, installaon error or misuse.

Disclaimer Product

THIS LIMITED WARRANTY IS THE SOLE AND EXCLUSIVE WARRANTY PROVIDED BY NEP IN CONNECTION

WITH YOUR NEP PRODUCT AND IS, WHERE PERMITTED BY LAW, IN LIEU OF ALL OTHER WARRANTIES,

CONDITIONS, GUARANTEES, REPRESENTATIONS, OBLIGATIONS AND LIABILITIES, EXPRESS OR IMPLIED,

STATUTORY OR OTHERWISE IN CONNECTION WITH THE PRODUCT, HOWEVER ARISING (WHETHER BY

CONTRACT, TORT, NEGLIGENCE, PRINCIPLES OF MANUFACTURER'S LIABILITY, OPERATION OF LAW,

CONDUCT, STATEMENT OR OTHERWISE), INCLUDING WITHOUT RESTRICTION ANY IMPLIED

WARRANTY OR CONDITION OF QUALITY, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE TO THE

EXTENT REQUIRED UNDER APPLICABLE LAW TO APPLY TO THE PRODUCT SHALL BE LIMITED IN

DURATION TO THE PERIOD STIPULATED UNDER THIS LIMITED WARRANTY.

IN NO EVENT WILL NEP BE LIABLE FOR: (a) ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, INCLUDING LOST PROFITS, LOST REVENUES, FAILURE TO REALIZE EXPECTED SAVINGS, OR

OTHER COMMERCIAL OR ECONOMIC LOSSES OF ANY KIND, EVEN IF NEP HAS BEEN ADVISED, OR HAD

REASON TO KNOW, OF THE POSSIBILITY OF SUCH DAMAGE, (b) ANY LIABILITY ARISING IN TORT,

WHETHER OR NOT ARISING OUT OF NEP'S NEGLIGENCE, AND ALL LOSSES OR DAMAGES TO ANY

PROPERTY OR FOR ANY PERSONAL INJURY OR ECONOMIC LOSS OR DAMAGE CAUSED BY THE

CONNECTION OF A PRODUCT TO ANY OTHER DEVICE OR SYSTEM, AND (c) ANY DAMAGE OR INJURY

ARISING FROM OR AS A RESULT OF MISUSE OR ABUSE, OR THE INCORRECT INSTALLATION,

INTEGRATION OR OPERATION OF THE PRODUCT.

IF YOU ARE A CONSUMER (RATHER THAN A PURCHASER OF THE PRODUCT IN THE COURSE OF A BUSINESS)

AND PURCHASED THE PRODUCT IN A MEMBER STATE OF THE EUROPEAN UNION, THIS LIMITED

WARRANTY SHALL BE SUBJECT TO YOUR STATUTORY RIGHTS ASA CONSUMER UNDER THE EUROPEAN

UNION PRODUCT WARRANTY DIRECTIVE 1999/44/EC AND AS SUCH DIRECTIVE HAS BEEN IMPLEMENTED

IN THE EUROPEAN UNION MEMBER STATE WHERE YOU PURCHASED THE PRODUCT. FURTHER, WHILE

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, YOU MAY HAVE OTHER RIGHTS WHICH MAY

VARY FROM EU MEMBERSTATE TO EU MEMBERSTATE OR, IF YOU DID NOT PURCHASE THE PRODUCT IN

AN EU MEMBER STATE, IN THE COUNTRY YOU PURCHASED THE PRODUCT WHICH MAY VARY FROM

COUNTRY TO COUNTRY AND JURISDICTION TO JURISDICTION.

19

Warranty Card

Customer Informa�on

Name:

Address:

City: State: Zip Code:

Tel: Fax: E-mail:

System Informa�on

Fault Product(s) Serial Numbers:

System Commissioning Date: Product Models:

No. of Products Used: Bill of Lading Date:

Fault Product(s) Quanes: Fault Time/Date:

Fault Message(s) or Code(s):

Brief Fault Descripon and Photos (monitoring gateway is required for vercaon):

Installa�on Informa�on

Modules Used:

Modules Quany: Inverters quany per string:

Installaon Company Name:

Installer Name:

For the informaon on our warranty terms and condons,

please see our website: www.northernep.com/en

All elds must be completed in order to process claim.

Customer Signature: Date:

*All rights reserved by NEP. This informaon is subject to changes without noce.

USA

Address: 2570 N. First Street, Suite 200, San Jose, CA 95131

TEL: +1 888-598-9901

Japan

Address: 812-0011 福岡市博多区博多駅前 3-10-24 藤井ビル 1F

TEL: +81 092-433-3252

FAX: +81 092-433-3171

China

Address: No.1 Anhe Rd Tsingtao Export Processing Zone, Tsingtao, China 266113

TEL: +86 532 87963900

FAX: +86 532 81100917

Email: [email protected]

Web: hp://www.northernep.com

hp://www.nep-japan.com

hp://www.micro-inverter.jp

Table of contents

Other NEP Inverter manuals