Neptune Systems AquaController II User manual

AquaControllerIIOwner's

Manual

Version 1.60

?Neptune Systems

6288 San Ignacio Ave. #B

San Jose, CA 95119

Phone (408) 578-3022 • Fax (408) 578-9383

AquaController II Owner’s Manual V1.60

Copyright 1999 -Neptune Systems

All rights reserved

AquaController II Owner’s Manual V1.60

Copyright 1999 -Neptune Systems

All rights reserved

Table of Contents

1. INTRODUCTION........................................................................................7

SCOPE OF THIS DOCUMENT ...............................................................................7

FEATURE LIST...................................................................................................7

2. GETTING STARTED.................................................................................9

BASE UNIT INSTALLATION................................................................................9

CONTROL INTERFACE INSTALLATION..............................................................10

SERIAL PORT INSTALLATION...........................................................................10

Macintosh Installation..........................................................................................10

PC Compatible Installation..................................................................................11

3. MENU OVERVIEW..................................................................................13

RUN DISPLAY .................................................................................................15

CONTROL AND STATUS ...................................................................................16

Feed Cycle...........................................................................................................16

Manual Control....................................................................................................17

Power Fail Log ....................................................................................................17

Power Log...................................................................................................................17

Reset Power Log..........................................................................................................18

DATA LOGGING ..............................................................................................18

Print Data Log.....................................................................................................18

Display Data Log.................................................................................................18

Reset Data Log.....................................................................................................18

Log Interval .........................................................................................................19

SETUP.............................................................................................................19

Timer Setup..........................................................................................................19

Clock Setup..........................................................................................................19

Setting the Tank Time or Clock Time...........................................................................19

Enabling/Disabling Advanced Clocking ........................................................................19

Leap Seconds...............................................................................................................20

Temperature Setup...............................................................................................20

pH Setup..............................................................................................................20

ORP Setup............................................................................................................20

Login Setup..........................................................................................................20

Login: On or Off..........................................................................................................21

Login Name.................................................................................................................21

Login Password ...........................................................................................................21

Pager Setup..........................................................................................................21

Pager Enable................................................................................................................21

Pager Number..............................................................................................................21

Alarm Name.................................................................................................................22

Dial Delay....................................................................................................................22

Re-page Delay..............................................................................................................22

Pager Test....................................................................................................................22

AquaController II Owner’s Manual V1.60

Copyright 1999 -Neptune Systems

All rights reserved

Init Memory

................................

................................

................................

.........

22

SELF TEST ......................................................................................................22

4. PROBE INSTALLATION AND CALIBRATION..................................25

PROBE INSTALLATION.....................................................................................25

Temperature Probe Installation...........................................................................25

pH Probe Installation...........................................................................................25

ORP Probe Installation........................................................................................26

PROBE CALIBRATION ......................................................................................27

Temperature Calibration .....................................................................................27

pH Calibration.....................................................................................................27

ORP Calibration..................................................................................................28

5. PROGRAMMING THE AQUACONTROLLER II................................31

PROGRAMMING BASICS...................................................................................31

Timer Names........................................................................................................31

Timer Program ....................................................................................................32

Repeat Interval ....................................................................................................32

Feed Interval........................................................................................................33

TEMPERATURE CONTROLLER SETUP ...............................................................33

Temperature Control Program.............................................................................34

Fixed Temperature.......................................................................................................34

Seasonal Temperature Variation...................................................................................35

PH CONTROLLER SETUP .................................................................................36

pH Control Program............................................................................................37

ORP CONTROLLER SETUP ..............................................................................38

ORP Control Program.........................................................................................38

TIMED EVENTS SETUP.....................................................................................39

Timed Lighting.....................................................................................................39

Timed Pumps.......................................................................................................40

Repetitive and Random Events.............................................................................41

Seasonal Lighting Variation.................................................................................42

Simulating the Moon Cycle..................................................................................43

Feed Cycle Timer Events .....................................................................................44

Externally Switched Events ..................................................................................45

Alarms.................................................................................................................46

Hysteresis ............................................................................................................47

ADVANCED PROGRAMMING ............................................................................49

Statement Evaluation Order.................................................................................49

6. SERIAL PORT INTERFACE................................................................51

SERIAL CONNECTOR PINOUT...........................................................................51

SERIAL PORT COMMANDS...............................................................................52

APPENDIX A -TROUBLE SHOOTING....................................................55

APPENDIX B -SAMPLE PROGRAMS......................................................57

AquaController II Owner’s Manual V1.60

Copyright 1999 -Neptune Systems

All rights reserved

D

EFAUL

T

T

IMER

N

AMES

................................

................................

.................

57

DEFAULT PROGRAM........................................................................................57

AquaController II Owner’s Manual V1.60

Copyright 1999 -Neptune Systems

All rights reserved

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

7

1. Introduction

Scope of this Document

Congratulations, you have just purchased the most advanced aquarium

controller on the market! It is recommended that you completely read the

Owner's Manual before proceeding to set up the AquaController II to

perform any task.

Feature List

The following features are fully supported in the AquaController II base

unit.

??Lighting Control

??Wave Maker

??Simulated Moon Cycle

??Seasonal Lighting Variation

??Seasonal Temperature Variation

??1 External Switch Input

??Temperature Monitor and Control

??pH Monitor and Control

??ORP Monitor and Control

??Flash Memory for Easy Firmware Upgrades

??Data Logging

??RS232 Computer Interface

Chapter

1

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

8

?

?

Direct Connection to External Modem

??Local and Remote Alarms

??Simple Yet Sophisticated Programming Language

??Built in Self Test

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

9

2. Getting Started

Base Unit Installation

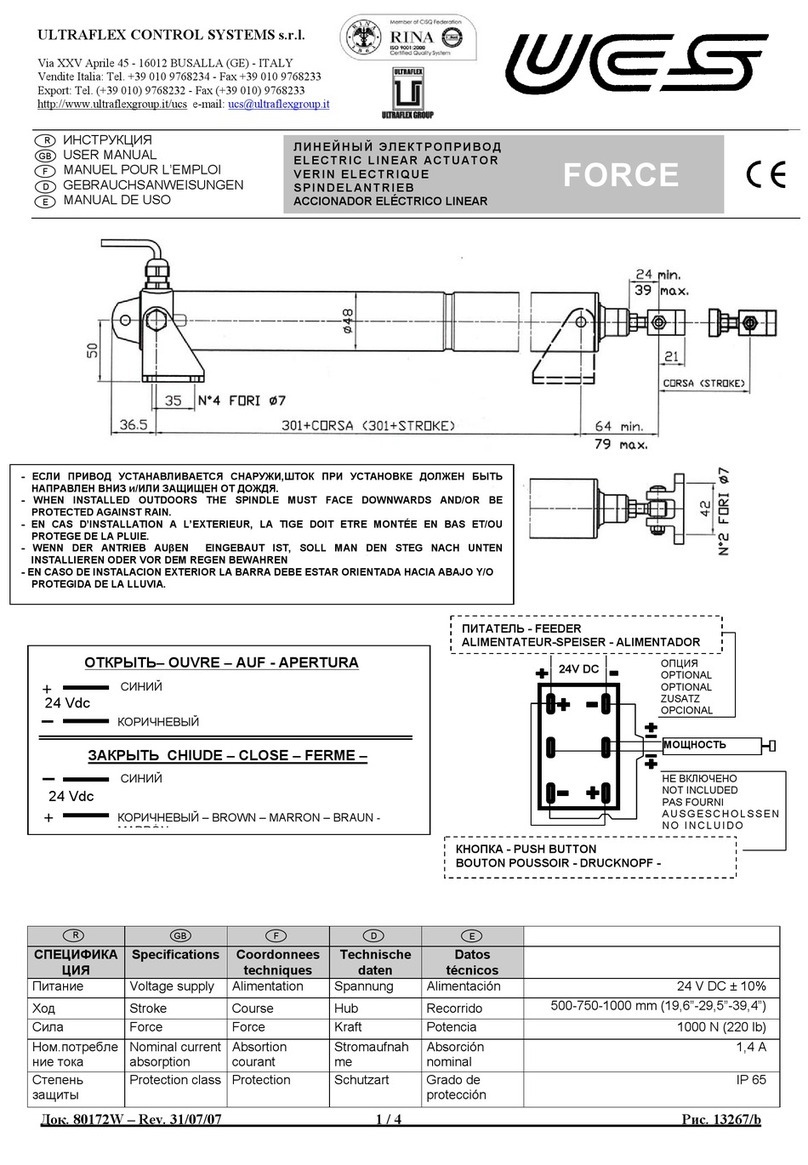

The following figure points out all the connectors located on the side of

the AquaController II. Please refer to it during installation.

Power

9V DC X10

RJ11 Serial

Mdin 8 Temp ORP

BNC pH

BNC

Figure 1: AquaController II Connectors

The AquaController II should be installed in a dry environment that has

little chance of getting wet. The AquaController II is a sensitive piece of

electronic equipment and is not waterproof. Ideally, it should be located

several feet from the aquarium. Velcro strips with adhesive backing can be

used to install the controller in its permanent location. Velcro strips work

well because the unit can be easily removed from its mounting point to

replace the 9V battery.

To prevent the loss of data logging and clock information, it is highly

recommended that a new 9V battery is installed. In the event of a power

outage the battery will maintain the internal state of the unit and allow for

the resumption of control of the aquarium as soon as power returns. A

high quality alkaline battery will keep the internal processor operational for

approximately 4 hours when an AC power failure occurs. When the

battery is low and should be replaced a ‘battery low’ display will flash on

the AquaController II’s Display. It should be noted that no state changes

will occur in the external control modules during a power outage. After

Chapter

2

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

10

power is

returned, all controlled devices will be in the correct state within

the Repeat Interval. The default interval is 5 minutes. See section ‘Repeat

Interval’ on page 32 for more details on modifying the Repeat Interval.

The 9V-DC power adapter should be plugged into a 120V wall socket and

the plug on the end of the cable should be connected to the power

connector on the AquaController II. Refer to the above figure for the

location of the connector.

Powerheads and pumps switching on and off generate power spikes that

can damage electronic equipment. The AquaController II has protection

circuitry in the base unit; however, it is recommended as an added safety

precaution to plug the controller in a 'clean' AC socket. Power strips with

transient suppression circuitry can be used to make a 'clean' socket and to

prevent power surges from damaging the AquaController II. Coil up all

power cords to reduce the amount of radiated electrical noise.

Control Interface Installation

Simply plug the control interface into the wall outlet located close to the

AquaController II and aquarium. It may be necessary to use one or more

power strips if multiple devices are to be controlled. Plug one end of the

cable with the RJ11 connectors (phone cable) into the Control Interface

and the other end into the AquaController II.

Serial Port Installation

Macintosh Installation

To connect the AquaController II to a Macintosh computer simply use an

Apple NULL modem (printer) cable. The cable necessary is exactly the

same as is used to connect two Apple Macintosh's together over an

AppleTalk network. Simply place one of the mini-DIN 8 connectors into

the AquaController II serial port (see figure 1) and the other end into the

modem or printer port of the Macintosh.

Any of the many serial port communications programs for the Macintosh

can be used. Kermit is one such public domain program. The

communications program on the Macintosh must be configured to run at

9600 baud, 8 bits/char, no parity, 1 stop bit and no flow control. Also

make sure that the correct serial port (printer or modem) on the Macintosh

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

11

is selected.

To test the port type several carriage returns and an AquaController>

prompt should be returned. At this point data can be downloaded from

the AquaController II to the host Macintosh. Please refer to section ‘Serial

Port Commands’ on page 52 for a detailed description of the serial port

commands.

PC Compatible Installation

To connect the AquaController II to an IBM/PC compatible computer

use our serial cable (P/N SERPC). To install simply place the mini-DIN 8

connector into the AquaController II serial port (see figure 1) and the

DB25 connector into the PC's serial port. For PCs with DB9 connector a

DB25 to DB9 converter is required in addition to the serial cable.

Any of the many serial port communications programs for the PC can be

used. The terminal emulator in Windows (Hyperterminal) or a public

domain program such as Kermit will both work. The communications

program on the PC must be configured to run at 9600 baud, 8 bits/char,

no parity, 1 stop bit and no flow control. Also make sure that the correct

serial port is selected (COM1 or COM2).

To test the port type several carriage returns and an AquaController>

prompt should be returned. At this point data can be downloaded from

the AquaController II to the host PC. Please refer to section ‘Serial Port

Commands’ on page 52 for a detailed description of the serial port

commands.

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

12

This page intentionally left blank.

3. Menu Overview

The options and menus in the controller may seem overwhelming at first,

but after a little practice you will find that they are arranged in a logical and

consistent manner.

All menus and sub-menus follow the same user interface. The Up and

Down buttons move the arrow cursor up and down. When the cursor

reaches the bottom entry and the down button is pressed again, the menu

items scroll as expected. Similarly, if the cursor is at the top and the up

button is pressed, the menu items scroll. The Select button activates the

current menu entry pointed to by the cursor. The activation will execute a

command, bring up another menu, or exit the current menu.

The menu choices are in a circularly linked list, so repeated presses of the

Up (or Down) button will cycle through all the choices. Common to all

menus is the Exit entry. When Exit is selected, the current sub-menu pops

up and control is returned to the previous (next higher) level menu.

To make it easier to enter data into the AquaController II, all three of the

buttons have an auto repeat function. When any button is pressed for

greater than 3/4 of a second, the current action begins to repeat. If the

button is pressed an additional 1 second, the auto repeat rate increases.

For quick reference the following table lists all of the menus and

commands available to the AquaController II. On the left side of the table

are the root menu entries. Entries in the 2nd through 4th columns are sub-

menus of the column to the left of it.

Chapter

3

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

14

Root Level 2nd Level 3rd Level 4th Level

Run

Feed

Manual Cntl

Power Log

Control & Status Power Fail Log Reset Power Log

Exit

Display Lock

Exit

Print Data Log

Display Log (T, pH, ORP)

Data Log Display Log (Oxy, Cond)

Reset Data Log

Log Interval

Exit

Modify Name

Timer Names Add Name

Delete Name

Exit

Modify State

Timer Setup Timer Program Add State

Delete State

Exit

Repeat Interval

Feed Interval

Exit

Tank Time Set

Clock Time Set

Clock Setup Type: Adv/Normal

Setup Leap Second

Exit

pH Calibration

pH: On/Off

pH Setup pH Temp Comp:

Exit

Temp Calibration

Temp: On/Off

Temp Setup Temp Celsius

Temp Fahrenheit

Exit

ORP Calibrate

ORP Setup ORP: On/Off

ORP pH Comp:

Exit

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

15

Root Level 2nd Level 3rd Level 4th Level

Login: On/Off

Login Setup Login Name

Login Password

Pager: On/Off

Pager Number

Pager Setup Dial Delay

Repage Delay

Alarm Name:

Serial Setup Type: RS232/RS485

Exit

Init Memory

Exit

Run Display

The Run Display indicates the date, system time, temperature (temp), pH,

and ORP. During most of the AquaController II operation this will be the

active display. If no input occurs (button selection) the LCD screen will

automatically return to this display. It can be selected by pressing the Select

(left) button when the arrow cursor is pointing at RUN.

Jan 10 8:10:30

Figure 2: Clock Display

In Figure 2 Normal Clocking is enabled and the first line displays the date

(month day) followed by the tank time (hour:minute:second). The clock

Time can also displayed by setting Advanced Clocking to ON (see section

‘Enabling/Disabling Advanced Clocking’ on page 19).

The second line indicates the current status of the control modules; the

first character represents the status of the first timer name, the second

character represents the status of the second timer name and so on. If the

character displayed is either an "M" or "m" then that timer is in manual

mode (operation). The "M" indicates that the controlled device is

operating and the "m" indicates the device is idle. Manual Mode Operation

is described in section ‘Control and Status’ on page 16

The other special characters displayed on this line indicate that the timer is

in Automatic mode, and the controlled device(s) are either "on" or "off".

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

16

The character that is displayed for a particular timer is programmed in the

'Setup:Timer Setup:Timer Names' sub-menu. The following table shows

the special characters (the first column represents on and the second off):

Typically Lights

Typically Heater/Chiller

Typically Pumps/Powerheads

Other Controlled Devices

Figure 3: Run Display Special Characters

In the figure below the monitored probes are displayed. with temperature

(°F or °C), pH, and ORP (millivolts) enabled. The UP button is used to

toggle between the Clock Display and the Monitored Probes display.

Temp pH ORP

78.3 8.34 382mV

Figure 4: Monitored Probes Display

.

Pressing the Down button while the Run Display is active will initiate a

Feed Cycle. During the Feed Cycle the display will show a countdown of

the number of seconds remaining. The Run Display is resumed following

the completion of the Feed Cycle. The Select button can be used to end

the Feed Cycle early. See section ‘Feed Cycle’ on page 16 for more details.

To exit the Run Display and enter the root level menu press the Select

button.

Control and Status

The control and status menu option allows the user to take any timer out

of the automatic mode of operation and force it to either an "on" or "off"

state as well as viewing other operational status.

Feed Cycle

A special case of manual mode of operation is the Feed Cycle. This option

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

17

allows the user to shut down certain pumps, powerheads, etc. for a fixed

period of time for the purpose of feeding the tank. To start a Feed Cycle

select the Feed Cycle entry in the Control and Status menu. When this

mode is entered, the Feed Cycle controlled modules are temporarily forced

into the programmed state. The display shows a countdown of the

number of seconds remaining. When the count reaches zero, the Feed

Cycle controlled modules return to normal operation. The Feed Cycle can

be interrupted early by pressing the Select button. See section ‘Feed Cycle

Timer Events’ on page 44 for instructions on how to program a timer to

use a Feed Cycle and section ‘Feed Interval’ on page 33 on how to change

the Feed Cycle duration.

To reduce the number of button presses required to initiate a Feed Cycle,

a shortcut has been added to the Run Display command. When the Run

Display is active (see section ‘Run Display’ on page 15), the Down button

can be used to initiate a Feed Cycle.

Manual Control

The manual timer menu allows you to place a control module out of

Automatic Mode and turn it continuously "on" or continuously "off". The

following procedure is used to modify the on, off or automatic status of a

timer:

1. Go to the Control & Status:Manual Control menu.

2. Use the Up and Down buttons to locate the desired timer. When

the cursor points to the desired timer press the Select button.

3. The underline cursor should now be under the ON, OFF, or

AUTO status of the timer. Use the Up and Down buttons to

scroll to the desired state. Press the Select button to complete the

operation.

Power Fail Log

The power fail menu allows you to display the last power failure and reset

the power failure log.

Power Log

Selecting the power log menu display the last power failure time/date and

the power restored time/date of the last power interruption. If ‘none’ is in

the power failed entry then no power failure has occurred.

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

18

Reset Power Log

Activating this menu entry will reset the power failure and power restored

time/date entries to ‘None’.

Data Logging

Data logging is a powerful feature that enables accurate tracking and

recording of the conditions in the aquarium. There are many possible uses

for the data, some of which include analysis to help find cause and effect

relationships, trends which may foreshadow potential problems, and

monitor the tank conditions necessary to induce fish or coral spawning.

The AquaController IIs internal memory can hold up to 744 data logs.

This size log buffer is enough to hold hourly data logs for four weeks.

When the data log exceeds 744 entries, the oldest log entry is replaced by

the newest log entry.

Print Data Log

The Print Data Log menu dumps the entire data log to the serial port. It

may take several seconds to dump the Data Log to the serial port, so be

patient. This operation cannot be interrupted. A terminal program on a PC

can capture the dumped data, and allows you to store it to disk. The data

can then be input into a spreadsheet, or similar program to generate graphs

or find trends. Refer to section ‘Serial Port Installation’ on page 10 for

instructions on how to attach the serial port to a computer. The 'd'

command input from the serial port performs the same function.

Display Data Log

The Display Data Log menu allows you to scroll through the contents of

the data log on the LCD screen. The first line displays the Month/Day

Hour:Minute of the datalog entry and the second line displays the

Temperature, pH, and ORP.

The initial display shows the earliest data entry and the Down button

scrolls to a later data entry. The Up button scrolls the display to an earlier

data entry. To exit the Display Data Log menu press the Select button.

Reset Data Log

The Reset Data Log menu option clears the log memory in the

AquaController II. NOTE: The data log is also cleared if the tank time is

changed or the log interval is modified. The 'r' reset command from the

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

19

serial port performs the same function.

Log Interval

The Log Interval menu allows you to set how often the AquaController II

logs a pH, ORP, or temperature measurement to the data log. To modify

the interval select Log Interval and use the Up and Down buttons to

advance to the desired setting. When the correct interval is displayed press

the Select button. Sixty minutes is the default setting for log interval.

NOTE: The data log is also cleared if the tank time is changed or the log

interval is modified.

Setup

Timer Setup

The timer setup and programming instructions are described in chapter 5

on page 31

Clock Setup

Setting the Tank Time or Clock Time.

The AquaController II has the capability to maintain two separate times on

two separate clocks. The tank clock keeps track of the time in the tank and

is the clock used by the timer program to turn off or on the desired

modules. The time clock is only included as a convenience to the user. It

can be set to display the actual time in case it is different than the time

used to control and monitor the tank. Following the directions listed below

can set either clock:

1. Go to the Setup:Clock Setup:

2. Select either Set Tank Time or Set Clock Time from the menu

depending on which clock needs to be set.

3. Use the Up and Down buttons to adjust the selected field to the

desired value. When the value is correct use the Select button to

advance to the next field. Repeat until all time values are entered.

Enabling/Disabling Advanced Clocking

Since some of the lighting control statements (SUN and MOON) occur at

fixed times, you may want to have the Tank Time and Clock Time set to

different times; Advanced clocking allows for this possibility. The

Advanced Clocking feature enables both the Tank Time and the Clock

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

20

Time to be visible in the Run Display simultan

eously. If Advanced

Clocking is disabled only the tank time is displayed in the Run Display.

The Tank Clock is always used in the timer program evaluation regardless

of the setting of Advanced Clocking. To enable or display Advanced

Clocking do the following:

1. Go to the Setup:Clock Setup:

2. Use the Up and Down buttons to move the cursor to either Adv

Clocking. When the cursor is positioned by the correct action

press the Select button; the clock mode will toggle.

3. To exit the clock setup menu, use the Up and Down buttons to

scroll through the options to the 'Exit' entry. Press the Select

button to exit the clock setup menu.

Leap Seconds

The Leap Seconds allows the user to fine tune the accuracy of the clocks

used in the AquaController II. The number programmed into the

AquaController II indicates how many seconds to adjust the internal clock

per day. For example if the clock is gaining 1.5 seconds per day, a value of

-1.5 would be entered to offset this inaccuracy. The AquaController II uses

this value to slow its time down by 1.5 seconds each day. To modify this

entry select Leap Seconds and use the Up and Down buttons to scroll to

the desired Leap Seconds value. When the correct value is displayed press

the Select button.

Temperature Setup

Temperature setup and probe installation are described in section

‘Temperature Probe Installation’ on page 25 and ‘Temperature Calibration’

on page 27.

pH Setup

pH setup and probe installation are described in section ‘pH Probe

Installation’ on page 25 and ‘pH Calibration’ on page 27.

ORP Setup

ORP setup and probe installation are described in section ‘ORP Probe

Installation’ on page 26 and ‘ORP Calibration’ on page 28.

Login Setup

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

21

This ROM version supports a modem so that a telephone connection is

possible without having a PC at the remote AquaController II site. For this

feature to work the AquaController II needs to be connected to the

modem with the modem serial cable. Our technical support department

supports only modems sold by Neptune Systems. Other Hayes command

set modem may work with the AquaController II, however, we make no

guarantees.

The following configuration must be set correctly for Login to function.

The login setup menu is found in Setup->Login Setup.

Login: On or Off

This menu turns login on or off. If On password login is enabled. Login

should be enabled only if the AquaController II is connected directly to a

modem, otherwise it should be left off.

Login Name

This menu allows for the setting of login name. The up and down keys

scroll through the letters of the alphabet and the select key moves to the

next letter. The space character is used to signal the end of the login name

if less than 8 characters are entered. This field is limited to 8 characters.

Login Password

Thismenu allows for the setting of login password. The up and down keys

scroll through the letters of the alphabet and the select key moves to the

next letter. The space character is used to signal the end of the login name

if less than 8 characters are entered. This field is limited to 8 characters.

Pager Setup

The following configuration must be set correctly for Alarm paging to

function. The pager setup menu is found in Setup->Pager Setup.

Pager Enable

This menu turns paging on or off. If On paging is enabled.

Pager Number

This field is self-explanatory; this number is called if an alarm condition is

on. The space character is used to signal the end of the pager number if

less than 16 numbers/characters are entered. Some special characters other

than numbers may be entered into the phone number. The following table

lists and describes these characters:

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

22

Character

Meaning

WWait unit dial tone

before dialing

,Pause 2 seconds

*Send the ‘*’ tone

#Send the ‘#’ tone

+

Alarm Name

This field is used by the AquaController II to determine which timer name

to monitor for an alarm condition. The default name is ALM. Repeatedly

pressing the select button scrolls through all the available timer names.

NOTE: The timer name does not necessarily have to control a physical alarm

module

Dial Delay

This field determines how long to delay after the pager number is dialed to

enter the AquaController II serial number, temperature, pH, and ORP

data. Most paging services work with a 5 second delay.

Re-page Delay

This field determines how long the AquaController II will wait before

repaging. The default is 60 minutes.

Pager Test

This entry will send a test page that contains the current AquaController II

conditions.

Init Memory

Executing the command will initialize the AquaController II’s memory

with the default program and calibration constants. A listing of the default

program can be found in Appendix B.

Self Test

The Self Test feature of the AquaController II performs a short diagnostic

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

23

on the major internal components in the base unit. If the Self Test is

selected and the unit is operating correctly, a "passed" message is displayed

on the screen. The other information displayed indicates the date and

revision of the AquaController II firmware as well as the controller's serial

number.

The ‘Aqua Serial’ tab on the Communications Settings window allows for

the configuration of the serial interface between each AquaController II

and the PC.

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

24

This page intentionally left blank.

4. Probe Installation and Calibration

Probe Installation

Temperature Probe Installation

Before installing the temperature probe in the aquarium, the probe should

be rinsed under tap water to make sure that it is clean. Route the cable

from the location of the AquaController II to the aquarium or the sump. It

should be installed in a vertical position where there is adequate water

flow.

The AquaController II must be informed that a temperature probe has

been installed. This is accomplished by following this procedure:

1. Go to the Setup:Temp Setup menu.

2. Select Temp On

3. Go to the Run menu at the top level. The Temp label and its

current reading should be on the display.

To remove Temperature from the AquaController II display follow the

above procedure and instead select Temp Off in step 2.

pH Probe Installation

The plastic cap on the end of the probe should be removed before it can

be used. Once the protective cap has been removed the probe must be

kept wet at all times. Failure to do so will result in damage to the probe. If

the probe is to be stored for some period of time, place pH=4.0

calibration solution into the protective cap before placing it on the end of

the probe.

Before installing the probe in the aquarium, it should be rinsed of any

white residue under warm tap water and then installed in a vertical position

in the aquarium or sump where there is adequate water flow. The pH

probe should be placed at least 6 inches away from the ORP probe to

prevent interference.

Chapter

4

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

26

Route the coax cable to the location of the AquaController II. Attach the

BNC connector on the cable to the pH BNC input of the AquaController

II. Refer to figure 1 for the position of the pH BNC input on the

AquaController II. Turn the BNC connector 1/4 turn clockwise to lock it

firmly into place.

The AquaController II must be informed that a pH probe has been

installed. This is accomplished by the following procedure:

1. Go to the Setup:pH Setup menu.

2. Select pH On

3. Go to the Run menu at the top level. The pH label and its current

reading should be on the display.

To remove pH from the AquaController II display follow the above

procedure and instead select pH Off in step 2.

ORP Probe Installation

The plastic cap on the end of the probe should be removed before it can

be used. Once the protective cap has been removed the probe must be

kept wet at all times. Failure to do so will result in damage to the probe. If

the probe is to be stored for some period of time, place pH=4.0

calibration solution into the protective cap before placing it on the end of

the probe.

Before installing in the aquarium the probe should be rinsed of any white

residue under warm tap water and then installed in a vertical position in the

aquarium or sump where there is adequate water flow. The ORP probe

should be placed at least 6 inches away from the pH probe to prevent

interference.

Route the coax cable to the location of the AquaController II. Attach the

BNC connector on the cable to the ORP BNC input of the

AquaController II. Refer to figure 1 for the position of the ORP BNC

input on the AquaController II. Turn the BNC connector 1/4 turn

clockwise to lock it firmly into place.

The AquaController II must be informed that an ORP probe has been

installed. This is accomplished by following this procedure:

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

27

1.

Go to the Setup:ORP Setup menu.

2. Select ORP On

3. Go to the Run menu at the top level. The ORP label and its

current reading should be on the display.

To remove ORP from the AquaController II display follow the above

procedure and instead select ORP Off in step 2.

Probe Calibration

Calibration of the AquaController II is quite simple, and should be

checked at regular maintenance intervals to insure accurate operation.

Temperature Calibration

It is not necessary to calibrate the temperature probe of the

AquaController II. It has been properly calibrated at the factory to

maintain accurate temperature readings for the lifetime of the probe.

However, it is possible to make small adjustments to the displayed

temperature so that it is more closely correlated with another temperature

monitor. The following procedure should be used:

1. Note the amount that the temperature needs to be adjusted either

up or down. For example, if the AquaController II temperature

reads 77.4 °F and the reference thermometer reads 77.0 °F, an

offset of -0.4 °F should be added to the AquaController II

temperature.

2. Go to the Setup:Temp Setup:Temp Calibration menu.

3. Use the Up/Down buttons to enter the desired offset, which is -

0.4°F in the above example. When finished push the Select

button.

4. Go to the Run menu and now the temperature should match the

reference. If not, go back to step 1 and try again.

pH Calibration

Because of the variability in pH probes and the fact that they change over

time, it is best to calibrate the AquaController II’s pH circuitry. A two-

point calibration scheme is used to obtain good results. For the most

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

28

accurate results it is best to use pH 7.00 and 10.00 solutions for salt water

and pH 4.00 and 7.00 for fresh water.

The following procedure outlines the steps necessary:

1. Go to the Setup:pH Setup menu. Enable or disable temperature

compensation depending upon your requirements.

2. Select the pH Calibrate menu.

3. Use the Up and Down buttons to select the lowest valued

calibration solution. In order for the calibration procedure to

work correctly the lowest valued calibration solution must be used

first.

4. Place the pH probe into lowest valued calibration solution. Wait

for the numbers on the bottom of the LCD screen to stop

changing. It does not matter what value is displayed only that it is

not changing. When the display stops changing press the select

button.

5. Rinse the probe in room temperature tap water.

6. Use the Up and Down buttons to select the high valued

calibration solution. Press the select button when the correct

value is displayed.

7. Place the pH probe into high valued calibration solution. Wait for

the numbers on the bottom of the LCD screen to stop changing.

When the display stops changing press the select button.

8. The pH probe should now be properly calibrated.

ORP Calibration

It is not necessary to calibrate the ORP probe of the AquaController II. It

has been properly calibrated at the factory to maintain accurate ORP

readings for the lifetime of the controller. However, it is possible to

calibrate the probe if so desired. Quinhydrone, pH 4.00 and pH 7.00

calibration solutions are required for the calibration. The following

procedure should be used to calibrate the ORP:

1. Create a saturated solution of Quinhydrone and pH 7.00

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

29

calibration solution.

2. Select Setup:ORP Setup:ORP Calibrate from the AquaController

II’s menus.

3. Place the ORP probe into the Quin-7.00 solution. Wait for the

numbers on the bottom of the LCD screen to stop changing. It

does not matter what value is displayed only that it is not

changing. When the display stops changing press the select

button.

4. Create a saturated solution of Quinhydrone and pH 4.00

calibration solution.

5. Place the ORP probe into the Quin-4.00 solution. Wait for the

numbers on the bottom of the LCD screen to stop changing. It

does not matter what value is displayed only that it is not

changing. When the display stops changing press the select

button.

6. The ORP probe is now calibrated.

5. Programming the

AquaController II

The AquaController II comes equipped with a simple yet powerful

programming language which enables it to perform the normal

aquarium control tasks as well as many tasks which are impossible to

perform on a conventional controller. All program statements are

entered through the three button user interface of the base controller

unit and follow the same user interface as the menu navigation

commands. The Up and Down buttons navigate through the various

options of the fields. The Select button advances to the next field or

completes the command entry.

The program and configuration information input are stored in the

AquaController II's non-volatile memory. Power failures do not affect

the contents of this memory even if the 9V backup battery is not

installed.

The default program installed in the AquaController II is listed in

Appendix A. Most users will only have to make minor modifications to

this program to control and monitor their aquatic system.

Programming Basics

Timer Names

The first step in setting up the AquaController II for any type of

control is deciding which communication channel is to be used for a

controlled device. It does not matter which channel is used, only that it

is unique for each device in the household. For example, one control

module is to be used to control the heater in the aquarium. The

description name HET^ is chosen for the timer name, and it is assigned

the communication ID of A1. Make sure that the control modules

Chapter

5

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

32

communications ID matches the ID that is associated with the Timer

Name.

To program the AquaController II with this communication ID and

Timer Name, the following procedure is used:

1. Go to the Setup:Timer Setup:Timer Names menu.

2. Select Add Name from the menu.

3. Input a 4 character descriptive name for this timer channel

(HET^ in the above example). Use the Up and Down buttons

to scroll through the alphabet and the Select button to advance

to the next character. The fourth character entered is special in

that it is displayed on the Run screen to indicate that status of

the controlled device.

4. Input the communications ID letter and number next. These

letters and numbers should match channel IDs set on the

control module earlier.

Timer Program

The AquaController II uses a simple programming language to control

the external modules. The program statements are input through the

three button interface. The procedure below illustrates how to input a

typical program statement:

1. Go to the Setup:Timer Setup:Timer Program menu.

2. Select ‘Add State’ from the menu.

3. Use the Up and Down buttons to locate the desired token

(word). When it is displayed use the Select button to advance

to the next input field.

4. Continue to input the control statements until finished by

jumping back to step 2. If a mistake is made entering a

statement, the Modify State command from the Setup:Timer

Setup:Timer Program can be used to correct it.

Repeat Interval

The Repeat Interval defines how often the AquaController II

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

33

retransmits commands to the remote control modules. The commands

are repeated on a periodic basis to ensure that all of the control modules

are in the correct state. The default setting for Repeat Interval is 5

minutes and should not have to be changed by you. The following

procedure is used if you chose to modify this parameter:

1. Go to the Setup:Timer Setup:Repeat Interval menu.

2. Use the Up/Down buttons to enter the desired Repeat

Interval (minutes). When finished push the Select button.

Feed Interval

The Feed Interval menu allows you to change the length of time for a

Feed Cycle. The procedure for modifying it is described below:

1. Go to the Setup:Timer Setup:Feed Interval menu.

2. Use the Up/Down buttons to enter the desired feed interval

(minutes). When finished push the Select button.

Temperature Controller Setup

For the successful aquarium, it is very important to maintain an accurate

and stable temperature throughout the day. Large fluctuations in

temperature can result in the loss of aquatic life. The AquaController II

is capable of controlling the temperature very accurately (+-.3 °F),

since it continuously monitors the environment.

Depending on the external conditions both a heater and chiller may be

necessary to maintain a stable temperature for the aquarium inhabitants.

The AquaController II is capable of controlling a heater, a chiller, or

both.

Desired

Temperature

Turn Chiller

On

Turn Heater

On

Cold Hot

Heater and

Chiller Off

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

34

Figure 5: Temperature Scale

The above figure illustrates the mechanism that is used to maintain the

temperature. When the temperature drops below a preset value, the

heater is turned on and when the temperature rises to the desired

temperature, the heater is shut off. Likewise when the temperature

exceeds the preset high value, the chiller is turned on and when the

temperature falls to the desired temperature, the chiller is shut off.

Temperature Control Program

Fixed Temperature

Suppose that the desired temperature of the aquarium is 77 °F. The

heater should be enabled if the temperature falls below 76.7 °F, and

disabled when the aquarium reaches the desired 77 °F. Likewise the

chiller should be enabled if the temperature rises above 77.3 °F, and

disabled when the temperature reaches the desired 77 °F. It is

recommended that the high and low set points be at least 0.3°F from

the desired temperature.

For the heater control described above the following code produces the

desired result assuming that the heater timer name is 'HET^':

If Temp < 76.7

Then HET^ ON

If Temp > 77.0

Then HET^ OFF

For the chiller control described above the following code produces the

desired result assuming that the chiller timer name is 'COL^':

If Temp > 77.3

Then COL^ ON

If Temp < 77.0

Then COL^ OFF

If the aquarium only has a heater, it is necessary to only enter the heater

portion of the control program shown above. Conversely, if only a

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

35

chiller is to be used, then the chiller portion of the control is all that is

necessary to enter into the AquaController II.

NOTE: The default factory setting comes with the HET^ and COL^

timer names already installed to ease the initial setup. Choose the

‘Modify Name’ command from the Setup:Timer Setup:Timer Name

menu to modify the names and channel IDs. Also the ‘Delete Name’

can be used to remove unwanted names.

NOTE: The default factory setting comes with generic heater and

chiller programs already installed to ease the initial setup. Choose the

‘Modify State’ command from the Setup:Timer Setup:Timer Program

menu to modify the temperatures. Also the ‘Delete State’ can be used

to remove unwanted statements.

Seasonal Temperature Variation

One of the AquaController II’s more advanced features is its ability to

simulate the varying temperatures during the seasons of the year. The

following table lists the default temperatures for the first of each

month. On days other than the first the temperatures are interpolated

with the current and next month values.

Month Temp (°F)

January 76.0

February 75.0

March 76.0

April 76.0

May 76.5

June 77.5

July 78.5

August 80.5

September

78.5

October 77.5

November

76.5

December

76.0

To illustrate how to use this advanced feature for heater control, refer

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

36

to the following program:

If Temp < RT+-0.4

Then HET^ ON

If Temp > RT+0.0

Then HET^ OFF

The above statements turn the heater (HET) on if the tank temperature

falls below the season temperature (RT) of the day by more than 0.4 °F

and shuts the heater off when the tank temperature exceeds the season

temperature (RT). For chiller control a similar program is used and is

illustrated below:

If Temp > RT+0.4

Then COL^ ON

If Temp < RT+0.0

Then COL^ OFF

The first program statement turns on the chiller (COL) when the tank

temperature exceeds the seasonal temperature (RT) by 0.4 °F and shuts

the heater off when the tank temperature is below the seasonal

temperature (RT).

pH Controller Setup

pH is perhaps one of the most critical parameters to maintaining

successful aquariums. Many reef aquariums that are heavily stocked

with stony corals require large additions of kalkwasser on a continuous

basis. The large additions of kalkwasser can result in the pH rising too

high. To counter the high pH, CO2 is injected into the aquarium.

However, the pH must be monitored closely when CO2 is injected so

that the pH does not dip too low. The injection is difficult if not

impossible to do adequately by hand. This task is ideally suited for the

AquaController II, since it continuously monitors the pH and can

enable /disable CO2 injection at the appropriate times.

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

37

Turn CO2

Injection On

Lower

pH Higher

pH

Desired pH

Turn CO2

Injection Off

Figure 6:pH Scale

The above figure illustrates the mechanism that is used to maintain the

pH. When the pH rises above a preset level the CO2 injection is turned

on, and when the pH falls to the desired value, the injection is shut off.

pH Control Program

Suppose that the desired pH of the aquarium is 8.35, and the CO2

injector should be enabled if the pH rises above 8.40. It is

recommended that the high set point be at least 0.05 from the desired

pH.

For the pH control described above the following code produces the

desired result. The code assumes that the CO2 injector timer name is

'CO2$':

If pH > 8.40

Then CO2$ ON

If pH < 8.35

Then CO2$ OFF

NOTE: The default factory setting comes with the CO2$ timer name

already installed to ease the initial setup. Choose the Modify Name

command from the Setup:Timer Setup:Timer Name menu to modify

the name and channel IDs. Also the Delete Name can be used to

remove unwanted names.

NOTE: The default factory setting comes with a generic pH control

program already installed to ease the initial setup. Choose the Modify

State command from the Setup:Timer Setup:Timer Program menu to

modify the pH set points. Also the Delete State can be used to remove

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

38

unwanted statements.

ORP Controller Setup

Oxidation Reduction Potential (ORP) is a good indicator of the water

quality of the aquarium. ORP is a measurement of the potential for

chemical reactions in the aquarium. If it is too low the aquarium water

contains many organic carbons and the water can be toxic. Ozone is a

highly reactive form of oxygen that can be injected into the aquarium to

reduce the amount dissolved organic carbons in the aquarium. It must

be injected carefully as too much can be lethal to the aquarium

inhabitants. The AquaController II can do this task easily since it

continuously monitors the ORP and can enable and disable ozone

injection at the appropriate times.

Turn ozone

Injection On

Lower

ORP

Higher

ORP

Desired ORP

Turn ozone

Injection Off

Figure 7: ORP Scale

The above figure illustrates the mechanism that is used to maintain the

ORP. When the ORP falls below a preset level the ozone injection is

turned on, and when the ORP rises to the desired value, the injection is

shut off.

ORP Control Program

Suppose that the desired ORP of the aquarium is 375 mV, and the

ozone injector should be enabled if the ORP falls below 365 mV. It is

recommended that the low set point be at least 10 mV from the desired

ORP.

For the ORP control described above the following code produces the

desired result assuming that the ozone injector timer name is 'OZN$':

IF ORP < 365

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

39

Then OZN$ ON

If ORP > 375

Then OZN$ OFF

NOTE: The default factory setting comes with the ozone timer name

already installed to ease the initial setup. Choose the Modify Name

command from the Setup:Timer Setup:Timer Name menu to modify

the name and channel IDs. Also the Delete Name can be used to

remove unwanted names.

NOTE: The default factory setting comes with a generic ORP control

program already installed to ease the initial setup. Choose the Modify

State command from the Setup:Timer Setup:Timer Program menu to

modify the ORP set points. Also the Delete State can be used to

remove unwanted statements.

Timed Events Setup

The AquaController II can control such devices as lights, pumps,

power-heads, and chemical dosing. The AquaController II has an

internal real time clock which can be used to enable/disable many

control modules throughout the day. The times programmed into the

AquaController II are compared with the Tank Time clock not the

Normal Time Clock. The timed events capability is best illustrated

through several examples.

Timed Lighting

Suppose that a reef aquarium has two independent lights which need to

be turn on and off at appropriate times. The first lighting system should

come on at 8:30 AM and be turned off at 9:30 PM. The second lighting

system should come on at 9:30 AM and be turned off at 8:30 PM.

For the lighting control described above the following code produces

the desired result. It assumes that the light timer names are LT1* and

LT2*. NOTE: The AquaController II time display is in 24 hour military

format.

IF Time > 08:29

AquaController II Owner’s Manual V1.00b

Copyright 1998/1999 -Neptune Systems

All rights reserved

40

Then LT1* ON

If Time > 21:29

Then LT1* OFF

IF Time > 09:29

Then LT2* ON

If Time > 20:29

Then LT2* OFF

NOTE: The default factory setting comes with the LT1* and LT2*

timer names already installed to ease the initial setup. Choose the

Modify Name command from the Setup:Timer Setup:Timer Name

menu to modify the names and channel IDs. Also the Delete Name can

be used to remove unwanted names.

NOTE: The default factory setting comes with generic lighting

programs already installed to ease the initial setup. Choose the Modify

State command from the Setup:Timer Setup:Timer Program menu to

modify the enabled and disabled times. Also the Delete State can be

used to remove unwanted statements.

Timed Pumps

The AquaController II can be used to simulate the tide in an aquarium.

This can be accomplished by having two power heads at opposite ends

of the aquarium that are alternately turned on and off.

The following AquaController II code will produce this effect:

If Time > 00:00

Then PM1% OFF

IF Time > 06:00

Then PM1% ON

If Time > 12:00

Then PM1% OFF

IF Time > 18:00

Then PM1% ON

Table of contents

Other Neptune Systems Controllers manuals

Popular Controllers manuals by other brands

Danfoss

Danfoss AVPL 1.0 instructions

MQ Multiquip

MQ Multiquip WHISPERWATT Series Operation and parts manual

Aventics

Aventics Marex 3D Assembly instructions

Siemens

Siemens SINUMERIK 840D sl Configuration manual

BFT

BFT VISTA SEL SW Installation and user manual

Lynxspring

Lynxspring JENEsysONE JO-PC1 Mounting guide