2

Specification Page 3

Electrical Page 3

Physical Page 3

Environment Page 3

Accreditation Page 3

Disposal Page 3

Input and Resolution Page 3

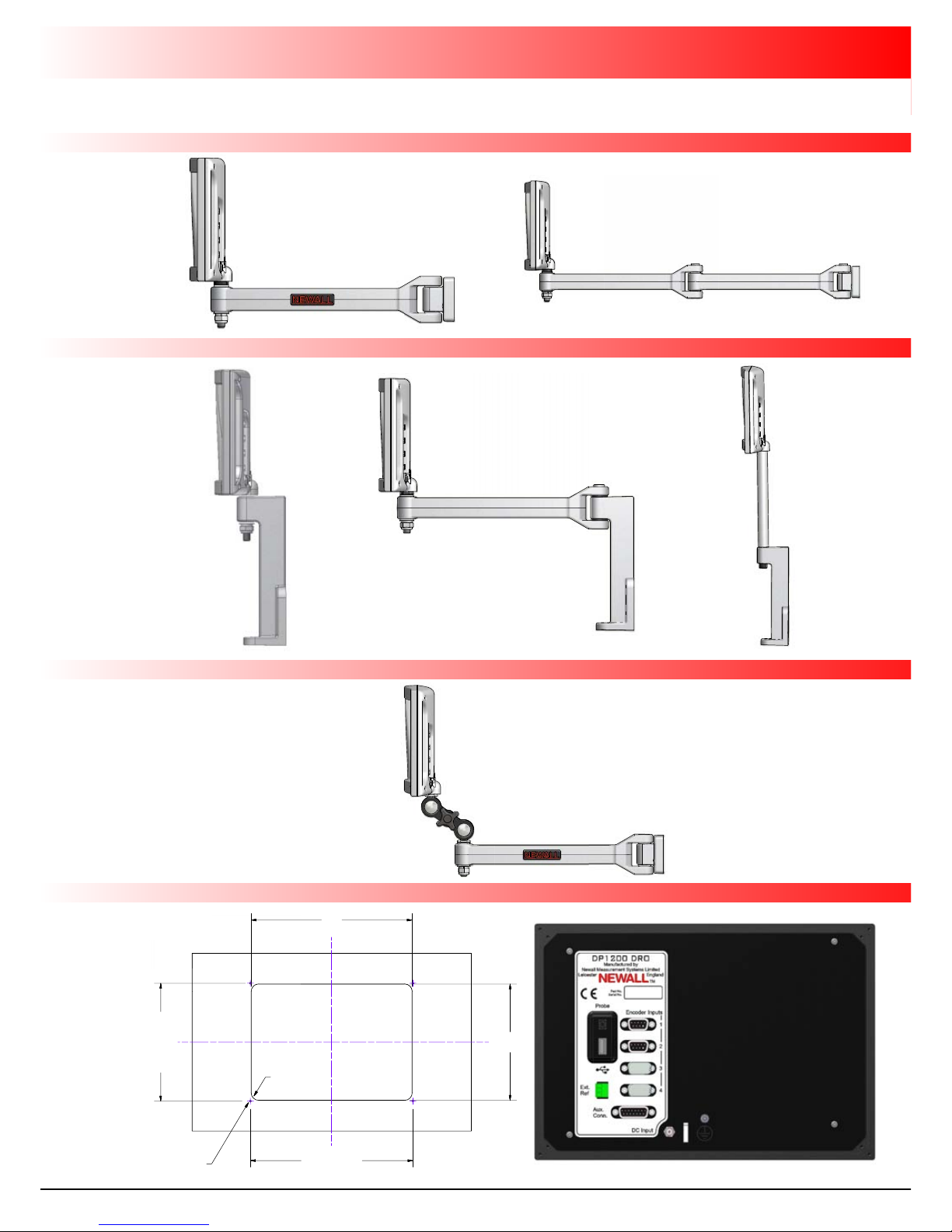

ounting Options Page 4

Mill Mount Page 4

Lathe Mount Page 4

Adjustable Mount Page 4

Panel Mount Page 4

Connection Details Page 5

Important Information Page 5

Connections Page 5

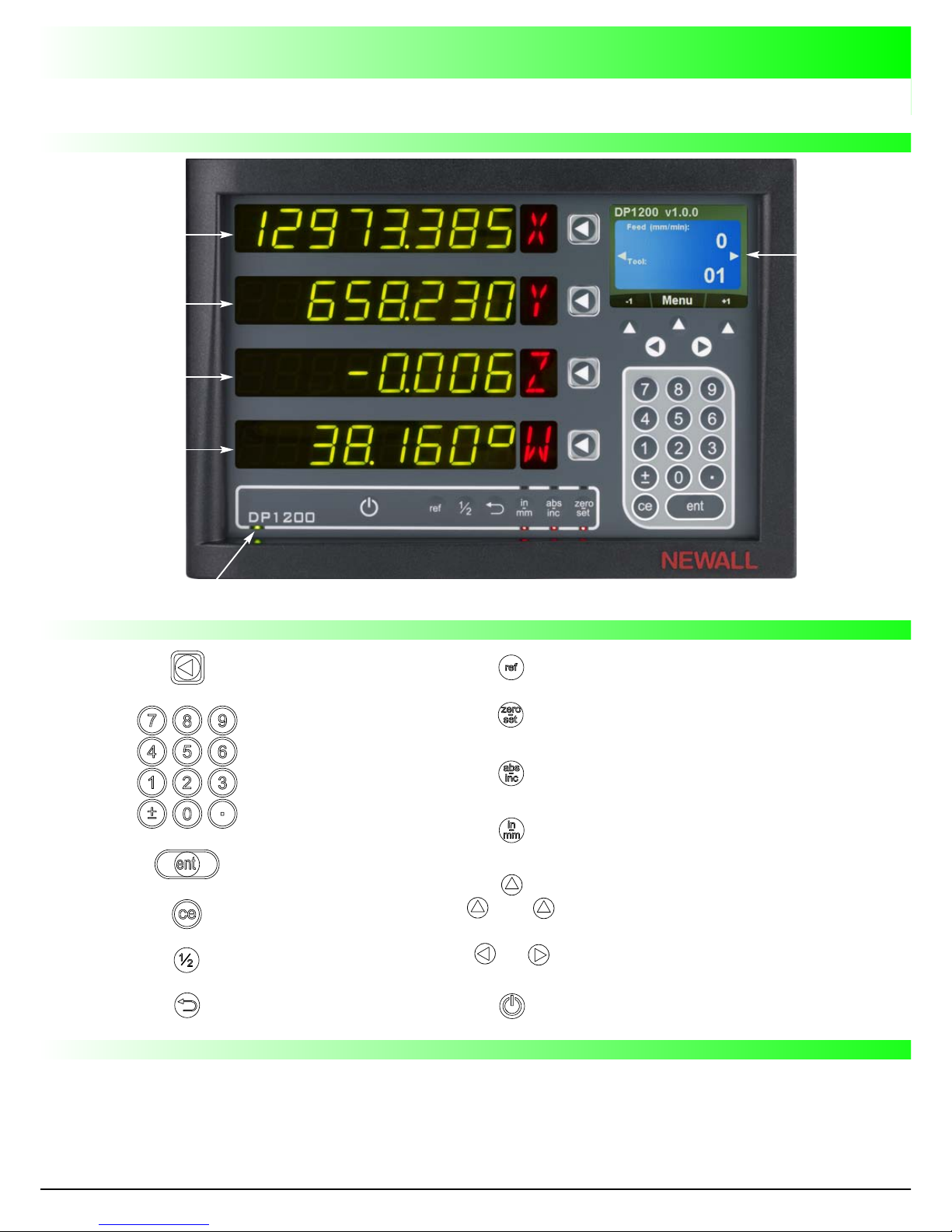

Display and Keypad Page 6

Understanding the Display Page 6

Understanding the Keypad Page 6

Invalid Key Warning Page 6

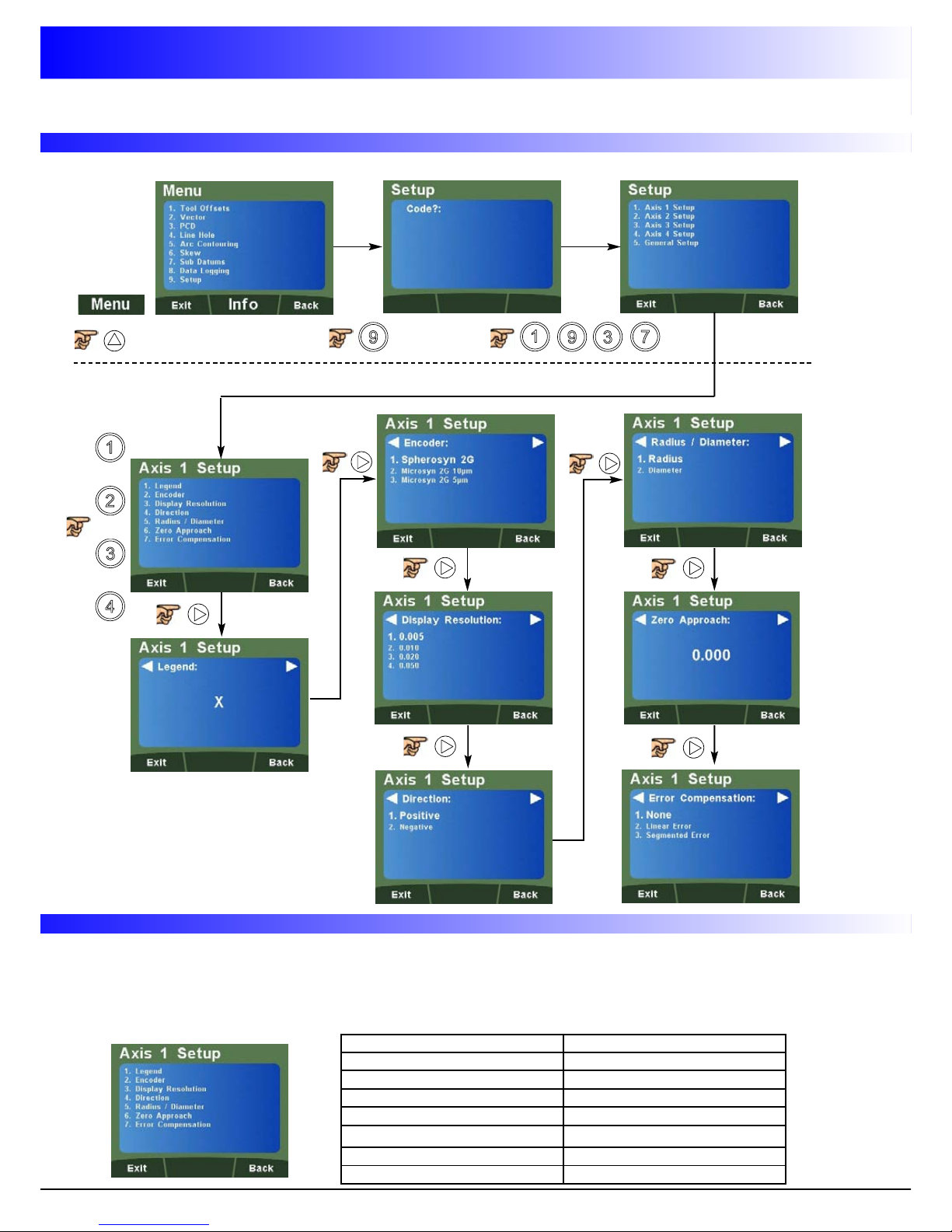

Setting up the Unit Page 7

Setup Menu Navigation Page 7

Navigating Axes 1, 2, 3, 4 (Analogue) Setup Page 7

Quick Navigation Axes 1, 2, 3, 4 (Analogue) Setup Page 7

Navigating Axis 4 Setup (Digital Linear) Page 8

Quick Navigation of Axis 4 Setup (Digital Linear) Page 8

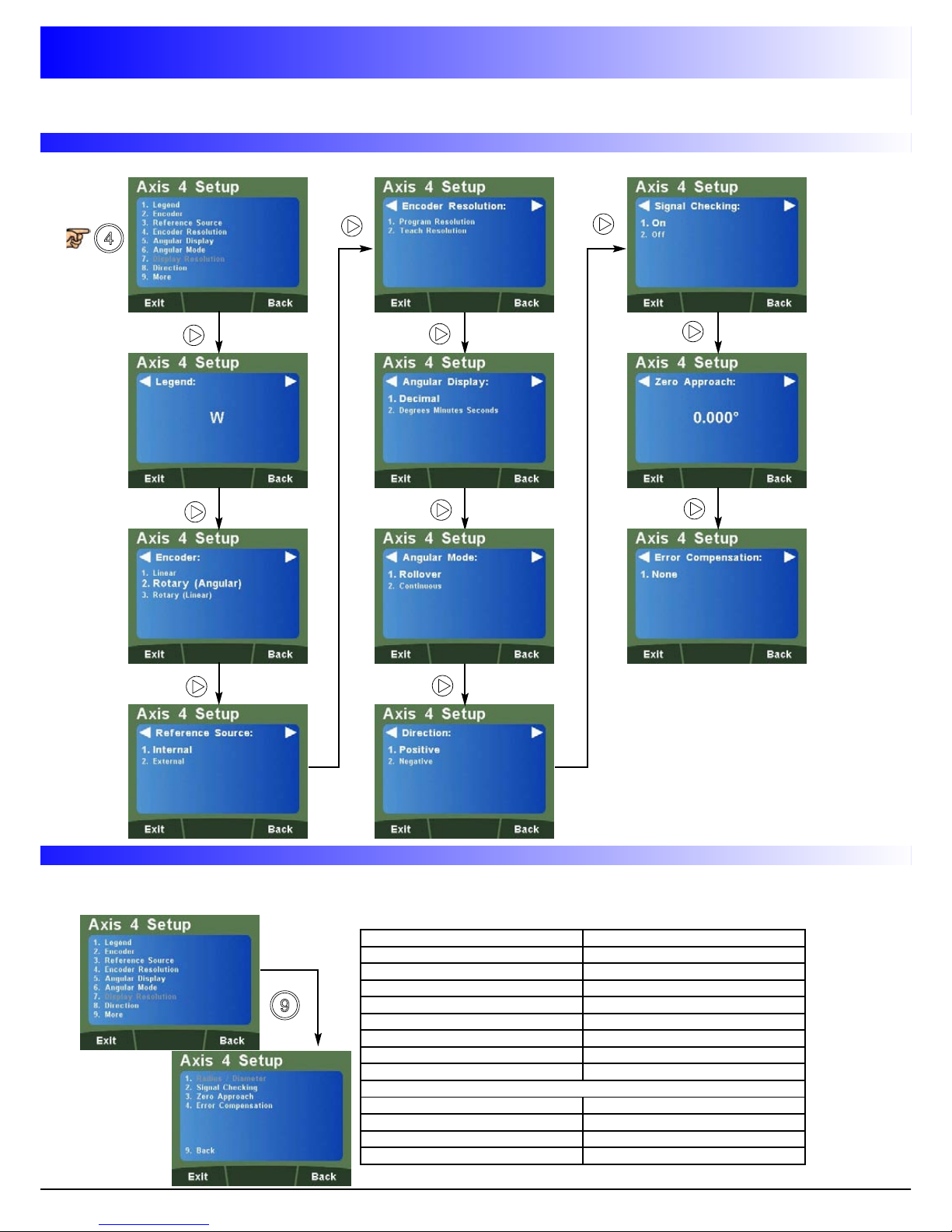

Navigating Axis 4 Setup (Digital Rotary Angular) Page 9

Quick Navigation of Axis 4 Setup (Digital Rot Ang) Page 9

Navigating Axis 4 Setup (Digital Rotary Linear) Page 10

Quick Navigation of Axis 4 Setup (Digital Rot Lin) Page 10

Navigating General Setup Page 11

Quick Navigation of General Setup Page 11

Setup Axis 1, 2, 3 & 4 (Analogue) Page 12

Legend Setup Page 12

Encoder Setup Page 12

Display Resolution Setup Page 12

Direction Setup Page 12

Radius / Diameter (Measure Setup) Page 12

Zero Approach Setup Page 13

Error Compensation Page 13

Types of Machine Error Page 14

Linear Error Compensation Page 14

Error Compensation Setup Page 15

Linear Error Compensation Setup Page 15

Segmented Error Compensation Page 16

Segmented Error Compensation Setup Page 16/17

Setup Axis 4 (Digital Linear) Page 18

Legend Setup Page 18

Encoder Setup Page 18

Reference Source Setup Page 18

Encoder Resolution Setup Page 18

Display Resolution Setup Page 18

Direction Setup Page 19

Radius / Diameter (Measure Setup) Page 19

Signal Checking Setup Page 19

Zero Approach Setup Page 19

Error Compensation Setup Page 19

Setup Axis 4 (Digital Rotary Angular) Page 20

Legend Setup Page 20

Encoder Setup Page 20

Reference Source Setup Page 20

Encoder Resolution Setup Page 20

Setup Axis 4 (Digital Rotary Angular) continued

Angular Display Setup Page 21

Angle Mode Setup Page 21

Direction Setup Page 21

Signal Checking Setup Page 21

Zero Approach Setup Page 21

Setup Axis 4 (Digital Rotary Linear) Page 22

Legend Setup Page 22

Encoder Setup Page 22

Reference Source Setup Page 22

Encoder Resolution Setup Page 22

Display Resolution Setup Page 23

Direction Setup Page 23

Radius / Diameter (Measure Setup) Page 23

Signal Checking Setup Page 23

Zero Approach Setup Page 23

Error Compensation Setup Page 23

General Setup Page 24

Language Setup Page 24

Application Setup Page 24

Plane Setup Page 24

Axis Coupling Setup Page 24

unctions Setup Page 25

Probe Diameter Setup Page 25

Beep Setup Page 25

LCD Brightness Setup Page 25

Sleep Setup Page 26

Unlock Axis Page 26

Reset Setup Page 26

Standard Functions Page 27

Absolute / Incremental Page 27

Inch / mm Page 27

Zero and Preset an Axis Page 28

Undo unction Page 28

Half unction / Centre ind Page 29

Digifind / Reference Page 29

Sub Datums / Memory (SDM) Page 30/31

Sleep Mode Page 31

RS232 (Data Logging) / Data Acquisition Page 32

RS232 Connections Page 32

RS232 Setup Page 32/33

RS232 Output Data ormat Page 34

ill Functions Page 35

PCD / Bolt Hole Circle Page 35/36

Line Hole Page 37/38

Arc Contouring Page 39/40

Polar Coordinates Page 41

Skew Page 42/43

Lathe Functions Page 44

Tool Offsets Page 44/45

Vector Page 46

Taper Angle Page 47

Axis Summing Page 48

Troubleshooting Guide Page 49

Contents